Beruflich Dokumente

Kultur Dokumente

Case Study: A Lean Six Sigma Deployment Success: Bank of America

Hochgeladen von

Sakshi KhuranaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Case Study: A Lean Six Sigma Deployment Success: Bank of America

Hochgeladen von

Sakshi KhuranaCopyright:

Verfügbare Formate

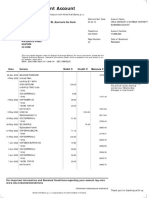

Scott Lasater, President 619 E. Dupont Rd., Suite 222 Fort Wayne, Indiana 46825 scott@lasaterinstitute.com 260.602.

5457

Case Study: Bank of America A Lean Six Sigma Deployment Success

Bank of America began its Continuous Improvement journey several years prior to its Six Sigma deployment, a journey undertaken simply because senior leaders realized that inefficient, errorprone processes were costing the company money through non-value-added rework. Unfortunately, according to quality leader Milton Jones, these efforts had minimal lasting effect because they lacked systematic implementation and often lacked executive support. This led to a perception by some in the company that quality approaches were nothing more than another "Flavor of the Month." This situation changed radically when Ken Lewis became CEO in 2001. Lewis announced a major strategic shift in the company from growth through acquisitions to organic growth. Realizing many of its customer satisfaction metrics were still at poor levels, and realizing that organic growth would require significantly enhanced customer loyalty, Lewis decided to get serious about quality improvement. In particular, he felt the need for a disciplined, rigorous, and comprehensive approach to process improvement. Based on the results he had seen others achieve, he chose Six Sigma as his approach. Then he hired Chuck Goslee as the first Bank of America quality executive, reporting to Lewis. It is particularly noteworthy that as CEO, Lewis took on the first Green Belt project in the company, setting the expectation for others. This project involved resolution of customer complaints that had been elevated to the executive level. In a talk given at the American Society for Quality (ASQ) annual Six Sigma conference on February 2, 2004, Lewis described his experiences on this project:

Some of you may wonder why the CEO would get involved in a Green Belt project. The answer is three-fold: (1) First, I wanted to send a clear message to the entire company that Six Sigma had the support of the company's most senior leadership. (2) Second, I wanted to have a useful command of the terms, tools, and techniques that we would be adopting throughout the company. (3) And third, this was a problem that really needed to be solved. Let me elaborate. I felt it was critical to our success that everyone in the company get on board with this effort. When we began our quality journey back in 2001, there were skeptics some of them inside the company who wondered whether we could use disciplines, methods, and tools from the factory floor and apply them at a large financial services company. I knew we had to get the message out, loud and clear, that we were very serious about quality and that Six Sigma would be our methodology. We hired a seasoned quality executive, Chuck Goslee, and I made him a member of my executive leadership team. That sent a message. Then I took my Green Belt training, and I asked each executive on my leadership team to complete Green Belt training as well. That sent a message, too. Today, I'm proud to say that every member of my leadership team has Green Belt certification, and about 95% of leaders in the next two levels have completed their Green Belts, as well.

Scott Lasater, President 619 E. Dupont Rd., Suite 222 Fort Wayne, Indiana 46825 scott@lasaterinstitute.com 260.602.5457

I knew that in many companies, Six Sigma professionals were frustrated with the "bottom-up" implementation of quality, and the absence of executive sponsor ship. At Bank of America, our leaders have made the effort to understand the language of Six Sigma its tools and techniques. They support its implementation across our company, and everyone in the company knows it. My other reason for wanting to look at this particular Green Belt project, as I said, was that this was a problem that simply needed to be solved. We were getting 20,000 of these complaints per year, and the actual and potential losses were in the millions of dollars. A lot of those letters were on my desk. So I took it personally.

Other executives would do well to take customer complaints as personally as Lewis did! Lewis stated later in his talk that the ultimate result of this project, which included efforts of many others beyond his own, was a doubling of Bank of America's customer delight metric and a financial impact of more than $2 million.

Deployment Strategy

It is often difficult to find the appropriate technical resources for Master Black Belt (MBB) and Black Belt (BB) roles when launching a deployment beyond the factory floor. Bank of America decided to address this by using internal Green Belts (GBs), but aggressively recruiting MBBs and BBs externally, especially from Six Sigma successes such as Motorola and GE. In addition to providing needed technical skills right away, this also helped to "seed a culture of quality throughout the company". Another important aspect of deployment was to have all Lewis's direct reports conduct their own GB projects. This approach not only ensured that leadership was driving the initiative personally, but also that critical, strategic issues were being addressed. The list of executive projects included the following: Increased customer delight with problem resolution More precise control over payments to suppliers Increased productivity of new hires via training Elimination of significant travel expenses Enhancement of enterprise e-mail governance to improve productivity Reduction of credit-risk assessment that was considered biased Elimination of significant numbers of electronic information subscriptions Increased associate retention in key areas Increased collections by reducing abandoned inbound calls Improved ability to detect and prevent fraud at banking centers Further, new quality executive Goslee established an enterprise-wide customer delight metric, replacing product- specific and channel-specific measures. Bank of America benchmarked externally to identify world-class performance in several areas, including a 90% goal for customer delight. They also obtained extensive voice-of-the-customer data to identify the key processes that needed to be improved to enhance customer delight, which included deposits and payments. Crossfunctional teams began working on projects to improve these critical processes.

Scott Lasater, President 619 E. Dupont Rd., Suite 222 Fort Wayne, Indiana 46825 scott@lasaterinstitute.com 260.602.5457

Results

The results that Bank of America was achieving through Six Sigma were impressive. For example: Missing items on customer statements were reduced by 70% Through a series of focused projects, defects in electronic channels (ATMs, online banking, etc.) decreased by 88% One project on mortgage applications reduced average cycle time by 15 days Non-credit losses, including fraud, were driven down by 28% on a per-account basis, whereas the number of accounts increased by more than a million in 2003 alone Same-day payments have been improved by 22% Deposit processing has been improved by 35% The cumulative financial benefits exceeded $2 billion by the end of 2003 The customer delight metric had increased 25% across the company in 2003 Six Sigma was generating the same magnitude of benefits at a bank that have been seen in manufacturing organizations.

Next Steps

When Chuck Goslee retired in April 2003, Lewis asked Milton Jones to lead the Bank of America Six Sigma effort and take it to a new level. In particular, Jones was asked to focus the effort on driving revenue growth. As in other application areas, including manufacturing, initial efforts often produce more bottom-line cost savings than top-line revenue growth. In the next phase of Six Sigma, Lewis wanted to have the same impact on top-line growth. In addition, the application of Six Sigma was expanded along the entire value chain, including suppliers and the sales force. Many of the sales projects focused on new revenue generation. Lewis and Jones now require key vendors to apply Six Sigma and to participate in Bank of America's training. In his talk at the ASQ annual Six Sigma conference, Lewis noted the beneficial impact Six Sigma had on the merger with Fleet Bank and how it would continue to drive improvement in this part of the business. He stated:

And when we agreed last Fall to our pending merger with FleetBoston, we did so expecting that Six Sigma would be a key to unlocking the full value of the merger. We plan to accelerate the existing Six Sigma effort underway at Fleet, including a training center there. We are also using Six Sigma in the very process of organizing the transition itself the first time, to my knowledge, Six Sigma has been used to execute the merger of major financial institutions.

According to Jones, Bank of America has trained more than 10,000 Champions, Master Black Belts (MBBs), Black Belts (BBs), and Green Belts (GBs) in DMAIC Detective-Work Methodology for existing

3

Scott Lasater, President 619 E. Dupont Rd., Suite 222 Fort Wayne, Indiana 46825 scott@lasaterinstitute.com 260.602.5457

processes, as well as Design For Six Sigma (DFSS) for designing new processes, and other quality methods. He also pointed out that there are currently more than 100 open senior leadership positions that require BB certification as a prerequisite. In summarizing the keys to success, Jones stated:

Quality and Six Sigma have become part of the culture at Bank of America, thanks to senior commitment, a robust internal training program, aggressive and ongoing external recruiting, and results that excite everyone in our company.

This statement captures the keys to success that we have seen here and elsewhere, both in manufacturing and beyond. Some key lessons learned from this case study are as follows: The critical importance of strong leadership The huge potential benefits available in many financial services How obtaining top technical resources externally can help obtain momentum early in the deployment, when such resources are not readily available within the organization The ability to drive top-line growth as well as bottom-line savings with Six Sigma ________________________________________________________________________________

Das könnte Ihnen auch gefallen

- Instructions for Building Credit with Retail Credit CardsDokument51 SeitenInstructions for Building Credit with Retail Credit CardsOnline ShopperNoch keine Bewertungen

- Etf Gold VS E-GoldDokument22 SeitenEtf Gold VS E-GoldRia ShayNoch keine Bewertungen

- Northwestern Mutual v2Dokument9 SeitenNorthwestern Mutual v2Shekhar PawarNoch keine Bewertungen

- Types of SwapsDokument25 SeitenTypes of SwapsBinal JasaniNoch keine Bewertungen

- Metrics That Matter For A Successful Treasury Transformation Session 22Dokument5 SeitenMetrics That Matter For A Successful Treasury Transformation Session 22vino06cse57Noch keine Bewertungen

- 29th July 2022Dokument2 Seiten29th July 2022Morena hartnettNoch keine Bewertungen

- UniCredit Euro Credit Pilot JULYDokument92 SeitenUniCredit Euro Credit Pilot JULYMiir ViirNoch keine Bewertungen

- CDS Bond BasisDokument41 SeitenCDS Bond BasisSharad DuttaNoch keine Bewertungen

- Market Risk: Strategy Tree and Scorecard DetailsDokument4 SeitenMarket Risk: Strategy Tree and Scorecard DetailsmariosalNoch keine Bewertungen

- Amplify University TrainingDokument11 SeitenAmplify University Trainingshariz500100% (1)

- Beyond Traditional Beta 032015Dokument24 SeitenBeyond Traditional Beta 032015Ton ChockNoch keine Bewertungen

- Citi Bank StrategiesDokument44 SeitenCiti Bank Strategiesgabriel gabuyaNoch keine Bewertungen

- Bond Price Volatility: Chapter SummaryDokument41 SeitenBond Price Volatility: Chapter SummaryHicham NassitNoch keine Bewertungen

- Structured Products in The Swiss MarketDokument51 SeitenStructured Products in The Swiss Marketbenjamin100% (1)

- Emerging Market Debt and The Three CsDokument44 SeitenEmerging Market Debt and The Three CsAnonymous Ht0MIJNoch keine Bewertungen

- Joy Pathak - Credit SpreadsDokument21 SeitenJoy Pathak - Credit Spreadspathak5100% (1)

- CDS PricingDokument28 SeitenCDS Pricingexet2695Noch keine Bewertungen

- GIOA Book Return and Total Return Good Bad UglyDokument55 SeitenGIOA Book Return and Total Return Good Bad UglyrpcampbellNoch keine Bewertungen

- (Hoff) Novel Ways of Implementing Carry Alpha in CommoditiesDokument13 Seiten(Hoff) Novel Ways of Implementing Carry Alpha in CommoditiesrlindseyNoch keine Bewertungen

- Callable BrochureDokument37 SeitenCallable BrochurePratik MhatreNoch keine Bewertungen

- R User Guide V13Dokument89 SeitenR User Guide V13pharssNoch keine Bewertungen

- How To Think Like A Strategy Consultant A Primer For General Managers1Dokument3 SeitenHow To Think Like A Strategy Consultant A Primer For General Managers1jexxicuhNoch keine Bewertungen

- Running and Operating A Successful BusinessDokument16 SeitenRunning and Operating A Successful BusinessObert SanyambeNoch keine Bewertungen

- Cva HedgingDokument16 SeitenCva HedgingjeanturqNoch keine Bewertungen

- Wire MoldDokument29 SeitenWire MoldSakshi KhuranaNoch keine Bewertungen

- Measuring Carry Trade ActivityDokument26 SeitenMeasuring Carry Trade ActivityOkay KiygiNoch keine Bewertungen

- 8.sources of Short-Term FinancingDokument26 Seiten8.sources of Short-Term FinancingJohann BonillaNoch keine Bewertungen

- S&OP Finance InvolDokument112 SeitenS&OP Finance InvolPhantrungsonNoch keine Bewertungen

- VRL Marketing Project ReportDokument85 SeitenVRL Marketing Project Reportkaustubh383Noch keine Bewertungen

- What trustees need to know about swapsDokument19 SeitenWhat trustees need to know about swapsPrabhakar SharmaNoch keine Bewertungen

- Kaizen Management for Continuous ImprovementDokument39 SeitenKaizen Management for Continuous ImprovementSakshi Khurana100% (4)

- Foundational Theories and Techniques for Risk Management, A Guide for Professional Risk Managers in Financial Services - Part II - Financial InstrumentsVon EverandFoundational Theories and Techniques for Risk Management, A Guide for Professional Risk Managers in Financial Services - Part II - Financial InstrumentsNoch keine Bewertungen

- Balanced Scorecard, Operations Management, CompetitivenessDokument48 SeitenBalanced Scorecard, Operations Management, CompetitivenessAkhil SoniNoch keine Bewertungen

- Risk Management Lesson 2Dokument2 SeitenRisk Management Lesson 2Ken TuazonNoch keine Bewertungen

- Structured Products OverviewDokument7 SeitenStructured Products OverviewAnkit GoelNoch keine Bewertungen

- Stitch GuideDokument8 SeitenStitch GuideFlorin NiteNoch keine Bewertungen

- Our Team Agenda Securitization CDS CDO LiquidityDokument81 SeitenOur Team Agenda Securitization CDS CDO Liquidityshwetata986Noch keine Bewertungen

- Operation Breakdown of A JacketDokument16 SeitenOperation Breakdown of A JacketSakshi Khurana25% (4)

- Corporate Banking Summer Internship ProgramDokument2 SeitenCorporate Banking Summer Internship ProgramPrince JainNoch keine Bewertungen

- UBS Business Plan - Stategic Planning and Financing Basis - Model For Generating A Business Plan - (UBS AG) PDFDokument26 SeitenUBS Business Plan - Stategic Planning and Financing Basis - Model For Generating A Business Plan - (UBS AG) PDFQuantDev-MNoch keine Bewertungen

- Capital Market AssumptionsDokument19 SeitenCapital Market AssumptionsKerim GokayNoch keine Bewertungen

- FS Consulting Capital Markets - Case Study 1 (Regulatory Change)Dokument1 SeiteFS Consulting Capital Markets - Case Study 1 (Regulatory Change)FabrizioNoch keine Bewertungen

- Icap Global Macro MonitorDokument14 SeitenIcap Global Macro MonitorZerohedgeNoch keine Bewertungen

- Introducing Overnight Indexed SwapsDokument6 SeitenIntroducing Overnight Indexed SwapsShi PengyongNoch keine Bewertungen

- Measuring Bank PerformanceDokument8 SeitenMeasuring Bank PerformanceNoor SalmanNoch keine Bewertungen

- Oracle Hyperion Users Group Presentation - Bank of AmericaDokument34 SeitenOracle Hyperion Users Group Presentation - Bank of AmericaRose HoangNoch keine Bewertungen

- Trade Surveillance QADokument2 SeitenTrade Surveillance QAManoj GuptaNoch keine Bewertungen

- DCM For LSEDokument14 SeitenDCM For LSEAlbert TsouNoch keine Bewertungen

- ABCP State StreetDokument28 SeitenABCP State StreetAngshujit MajumderNoch keine Bewertungen

- CargoTalk-warehousing Report PDFDokument64 SeitenCargoTalk-warehousing Report PDFShubham PriyadarshiNoch keine Bewertungen

- Conjoint AnalysisDokument51 SeitenConjoint AnalysisAarij TanveerNoch keine Bewertungen

- Steen Stress IndicatorsDokument13 SeitenSteen Stress IndicatorsZerohedgeNoch keine Bewertungen

- Managing The Apparel Omnichannel Cost-To-ServeDokument19 SeitenManaging The Apparel Omnichannel Cost-To-ServeShweta TomarNoch keine Bewertungen

- Merrill Lynch Case Study - PrajDokument19 SeitenMerrill Lynch Case Study - PrajAmit Shrivastava100% (3)

- CdosDokument53 SeitenCdosapi-3742111Noch keine Bewertungen

- The GIC Weekly Update November 2015Dokument12 SeitenThe GIC Weekly Update November 2015John MathiasNoch keine Bewertungen

- Scorecard Valuation Methodology Jan111Dokument7 SeitenScorecard Valuation Methodology Jan111Franch Maverick Arellano LorillaNoch keine Bewertungen

- Login to careerclap.com and build your profileDokument9 SeitenLogin to careerclap.com and build your profileAnonymous 1aCZDEbMMNoch keine Bewertungen

- Technical LineDokument27 SeitenTechnical LinemalisevicNoch keine Bewertungen

- Glossary of PerformanceDokument31 SeitenGlossary of PerformanceAteeq Ur RehmanNoch keine Bewertungen

- Lehman Brothers ABS Credit Default Swaps - A Primer - December 9, 2005Dokument21 SeitenLehman Brothers ABS Credit Default Swaps - A Primer - December 9, 2005AC123123Noch keine Bewertungen

- OTC Derivatives Collateral ManagementDokument2 SeitenOTC Derivatives Collateral ManagementNeeal ParikhNoch keine Bewertungen

- Barclays POINT BrochureDokument6 SeitenBarclays POINT BrochureQilong ZhangNoch keine Bewertungen

- 8 Japan Structured Products Forum 2007Dokument10 Seiten8 Japan Structured Products Forum 2007Marius AngaraNoch keine Bewertungen

- Operational Readiness Review A Complete Guide - 2020 EditionVon EverandOperational Readiness Review A Complete Guide - 2020 EditionNoch keine Bewertungen

- Indian Wound Care Market Overview Morulaa HealthTechDokument1 SeiteIndian Wound Care Market Overview Morulaa HealthTechSakshi KhuranaNoch keine Bewertungen

- Value Added Tax. and Vat CalculationsDokument17 SeitenValue Added Tax. and Vat CalculationsMikezCimafrancaDiputadoNoch keine Bewertungen

- Mattelfinal19nov2010 110121202423 Phpapp01Dokument60 SeitenMattelfinal19nov2010 110121202423 Phpapp01Sakshi Khurana100% (2)

- Tacobellbrandrepositioing 140516175412 Phpapp01Dokument15 SeitenTacobellbrandrepositioing 140516175412 Phpapp01Sakshi KhuranaNoch keine Bewertungen

- Globalization: International BusinessDokument7 SeitenGlobalization: International BusinessSakshi KhuranaNoch keine Bewertungen

- DivC 223 Sakshi KhuranaDokument8 SeitenDivC 223 Sakshi KhuranaSakshi KhuranaNoch keine Bewertungen

- Group Assignment QuestionsDokument3 SeitenGroup Assignment QuestionsSakshi KhuranaNoch keine Bewertungen

- DivC Group5 GreeceDokument18 SeitenDivC Group5 GreeceSakshi KhuranaNoch keine Bewertungen

- Ethics & CSR in Business DecisionsDokument50 SeitenEthics & CSR in Business DecisionsSakshi Khurana100% (2)

- 2005-10!12!234424 Copy of Logical Fallacies and The Art of DebateDokument12 Seiten2005-10!12!234424 Copy of Logical Fallacies and The Art of DebateSakshi KhuranaNoch keine Bewertungen

- Retail Store Automation PresentationDokument15 SeitenRetail Store Automation PresentationSakshi Khurana0% (2)

- DivC Group5 GreeceDokument18 SeitenDivC Group5 GreeceSakshi KhuranaNoch keine Bewertungen

- Quantitative Ability SyllabusDokument3 SeitenQuantitative Ability SyllabusSakshi KhuranaNoch keine Bewertungen

- Terms of DeliveryDokument4 SeitenTerms of DeliveryctrleNoch keine Bewertungen

- Healthcare and Distributed Systems Technology: Ansaworks 95Dokument8 SeitenHealthcare and Distributed Systems Technology: Ansaworks 95fahdbabaNoch keine Bewertungen

- © Year 2010 National Institute of Fashion Technology (NIFT)Dokument8 Seiten© Year 2010 National Institute of Fashion Technology (NIFT)Sakshi KhuranaNoch keine Bewertungen

- Ergonomics and CamerasDokument25 SeitenErgonomics and CamerasSakshi KhuranaNoch keine Bewertungen

- WordsDokument1 SeiteWordsSakshi KhuranaNoch keine Bewertungen

- Aqm 2Dokument69 SeitenAqm 2Sakshi KhuranaNoch keine Bewertungen

- BonDokument17 SeitenBonSakshi KhuranaNoch keine Bewertungen

- Aqm 2Dokument69 SeitenAqm 2Sakshi KhuranaNoch keine Bewertungen

- Western Chemical Uses IS for E-Commerce, Operations, Decision-MakingDokument3 SeitenWestern Chemical Uses IS for E-Commerce, Operations, Decision-MakingSakshi Khurana100% (2)

- Uganda Management Institute Cash Deposit SlipDokument3 SeitenUganda Management Institute Cash Deposit SlipNyeko Francis100% (3)

- Current Affairs Study PDF - December 2016 by AffairsCloud PDFDokument168 SeitenCurrent Affairs Study PDF - December 2016 by AffairsCloud PDFdinesh kumarNoch keine Bewertungen

- Bank Copy: Position Code For Assistant Is 301 Position Code For Stenotypist Is 302Dokument1 SeiteBank Copy: Position Code For Assistant Is 301 Position Code For Stenotypist Is 302i am lateNoch keine Bewertungen

- Road Transport Act SummaryDokument9 SeitenRoad Transport Act SummaryFarah Najeehah ZolkalpliNoch keine Bewertungen

- Auditing Gray 2015 CH 12 Final Work General Principles Analitical Review of Fs Non Current Assets Trade Receivables PDFDokument38 SeitenAuditing Gray 2015 CH 12 Final Work General Principles Analitical Review of Fs Non Current Assets Trade Receivables PDFChairani MaulinaNoch keine Bewertungen

- Introduction to Banking Types and HistoryDokument164 SeitenIntroduction to Banking Types and HistoryAiny Rajpoot RajpootNoch keine Bewertungen

- Brazilian Sovereign Bonds in DollarsDokument6 SeitenBrazilian Sovereign Bonds in DollarsquiquemoNoch keine Bewertungen

- Microfinance Provision in Ethiopia: September 2020Dokument11 SeitenMicrofinance Provision in Ethiopia: September 2020yeshitilaNoch keine Bewertungen

- Intact Iq Feature ListDokument10 SeitenIntact Iq Feature ListPaul MarryNoch keine Bewertungen

- 10000017306Dokument180 Seiten10000017306Chapter 11 DocketsNoch keine Bewertungen

- Functions of RBIDokument8 SeitenFunctions of RBIdchauhan21Noch keine Bewertungen

- Reinsurance DefinitionDokument16 SeitenReinsurance DefinitionAnju RajNoch keine Bewertungen

- Chapter 10 SolutionsDokument14 SeitenChapter 10 SolutionsEdmond ZNoch keine Bewertungen

- Marketing Plan Report ItradeDokument8 SeitenMarketing Plan Report ItradeVkNoch keine Bewertungen

- NMP March12Dokument52 SeitenNMP March12Andrew T. BermanNoch keine Bewertungen

- Reconcile bank balancesDokument7 SeitenReconcile bank balancesLEEN hashemNoch keine Bewertungen

- Gonzaga - Sec1 - Exercises On Internal Control FrameworkDokument2 SeitenGonzaga - Sec1 - Exercises On Internal Control FrameworkSteph GonzagaNoch keine Bewertungen

- List of Cases Part V - MortgageDokument2 SeitenList of Cases Part V - MortgageJ Heje EstarNoch keine Bewertungen

- The United Republic of Tanzania: Annual Report For The Year Ended 30 JUNE 2018Dokument130 SeitenThe United Republic of Tanzania: Annual Report For The Year Ended 30 JUNE 2018Hussein BoffuNoch keine Bewertungen

- ComlawDokument60 SeitenComlawBrave NeventuraNoch keine Bewertungen

- Advantages of Auditing Accounts for BusinessesDokument3 SeitenAdvantages of Auditing Accounts for BusinessesNikita ChavanNoch keine Bewertungen

- Statement of account transactionsDokument1 SeiteStatement of account transactionsSagar GuptaNoch keine Bewertungen

- Adrian Douglas: Gold Market Isn't 'Fixed' It's RiggedDokument12 SeitenAdrian Douglas: Gold Market Isn't 'Fixed' It's RiggedChrys AureusNoch keine Bewertungen

- SMEFinancingDokument60 SeitenSMEFinancingKhan Jewel100% (4)

- Account StatementDokument12 SeitenAccount StatementDavidRiyazMithraNoch keine Bewertungen

- Kay Breeze Balance SheetDokument9 SeitenKay Breeze Balance Sheetdaniel whitelyNoch keine Bewertungen