Beruflich Dokumente

Kultur Dokumente

Testing of Thermocouples For Inhomogeneity

Hochgeladen von

liam15111981Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Testing of Thermocouples For Inhomogeneity

Hochgeladen von

liam15111981Copyright:

Verfügbare Formate

XVIII IMEKO WORLD CONGRESS Metrology for a Sustainable Development September, 17 22, 2006, Rio de Janeiro, Brazil

TESTING OF THERMOCOUPLES FOR INHOMOGENEITY

Davor Zvizdic , Tomislav Veliki

1

Laboratory for Process Measurement, University of Zagreb, Zagreb, Croatia, tomislav.veliki@fsb.hr

Abstract: It is good calibration practice to test thermocouples for homogeneity of the Seebacks coefficient during calibration process. If change in homogeneity the coefficient, commonly known as inhomogeneity is not detected, thermometer although calibrated might not be able to measure temperature correctly. Several different testing techniques are developed, depending on type of the thermocouple and the equipment available. In order to automate process of thermocouple inhomogeneity testing for all applicable testing methods a Thermocouple Inhomogeneity Testing Device was developed in Laboratory for Process Measurement (LPM), University of Zagreb. The device is mostly used for the testing of thermocouple inhomogeneity in conjunction with heater moving along the thermocouple. The sled for mounting of the heater or the thermometer is translated by a threaded shaft and a step motor in horizontal axis, vertical axis or its sliding direction can be tilted in six steps between those two positions. Sled is mounted on shafts guides with precision linear ball bearing, which allow for smooth translation. The frame of the device is designed with adjustable height and distance between legs, which allows testing in most available metrological baths or furnaces. System is controlled by custom made program on LabView platform, with ability to automatically acquire, store and analyze data test data. Variation of the thermovoltage recorded during measurement is used in calculation of the uncertainty of the calibration. This paper describes the techniques for inhomogeneity testing and design of the testing device. Interpretation of the measurement results and calculation of inhomogeneity related component of the uncertainty budget is presented. Keywords: inhomogeneity testing, thermocouple. 1. INTRODUCTION

Seebecks coefficient of thermocouple wire is changing during prolonged use of thermocouple in elevated temperature, which may be main source of error in thermocouple temperature measurement [1]. Shock, mechanical deformation, radiation and other variables can also cause change in Seebacks coefficient of thermocouple wire. Thermoelectric emf is generated at zones with temperature gradients along thermocouple wire, i.e. along whole length of wire except segments which are in the isothermal zones. Level of generated emf is proportional to applied temperature gradient between cold and hot junction and to relative Seebecks coefficient in segment which

passes through temperature gradient. Thus change in the local Seebecks coefficient in one segment of thermocouple wire may give wrong information about temperature level between cold and hot junction. Magnitude of error will depend on temperature profile along the thermocouple wire: only if segment of wire with degraded thermoelectric properties is in the isothermal zone, emf reading may be correct. Usually, this is not a case. Thermocouples are often used in different insertion depths, and there is little chance that non-degraded part of wire will be in isothermal zone which makes correct measurement with such thermometer impossible. Further, during routine calibration thermometers are inserted into calibration furnace at certain insertion depth. Temperature profile at calibration temperature could be very different from profile that occurs during regular use. If calibration furnace with large insertion depth is used significant variation of relative Seebecks coefficient may not be detected, because degraded area is kept isothermal. In such case, calibration certificate for degraded thermocouple may be issued in bona fide, with uncertainties which do not reflect physical state of the thermometer. In order to avoid inhomogeneity-related mistakes, a device was developed, which is used for testing of thermocouple inhomogeneity, as a part of their calibration procedure at LPM. Measured deviation of the generated thermovoltage is used for calculation of the inhomogeneity related uncertainty component for the calibration of the thermocouple. Device is designed on such manner that it allows testing of the thermocouple along most of its working length, while temperature gradient zone in which thermovoltage is generated can be of required length. Functionality of the device is further extended to all thermometric errands in LPM which require measurement of temperature distribution along some axis, such as thermometer immersion profiles and gradients in calibration baths and furnaces. The device is capable to running fully automated precision measurement at prescribed linear translation rates and sampling intervals. Tests can be done with displacement in vertical and horizontal direction. 2. METHODS FOR INHOMOGENEITY TESTING

Thermocouples are always tested for inhomogeneity defects on same basic principle regardless of the type of the thermocouple and the selected method. Temperature gradient is applied on part of the thermocouple wire and the thermovoltage is measured at the ends of the wires [2]. If difference between measured thermovoltage and expected

level of thermovoltage is not within tolerable margin for the type of the thermocouple and the testing method, thermocouple is considered to have became inhomogeneous. In calibration practice, tests of the single wire are seldom performed. Two methods are most commonly used for testing of inhomogeneity of thermocouples: moving temperature ramp and immersion test. Temperature ramp testing method consists of moving two temperature gradients of opposite direction along the wire, while temperature at both ends is kept constant. Terminal emf measured at the end of the thermocouple is actually deference between emfs generated at both temperature gradients. In homogenous thermocouple those two emfs should cancel regardless of the shape of the temperature ramp. If temperature ramp is covering only small segment of thermocouple wire, like in the traveling flame test, generated emfs can also cancel since they were generated in adjacent regions where the Seebecks coefficient may be degraded by same amount. In such case thermocouple with a large segment of inhomogeneity may pass the test (properly nicked fools test [2], [3]. Immersion test is actually process during which thermocouple is gradually or in small steps immersed into temperature zone of high stability. Reading on the digital multimeter to which thermocouple is connected in that method is measure of relative Seebecks coefficient at the segment of the thermocouple which is subjected to temperature gradient. If transition zone between ambient temperature and temperature zone is very narrow, relative Seebecks coefficient of the small segment of the wire is examined. This is usually case when water, oil, salt baths or liquid nitrogen are used as temperature zones for inhomogeneity testing. On the other hand, when thermometer is being immersed in fixed point or calibration furnace, larger segment of the wire is subjected to temperature gradient. The temperature zone has to have temperature stability over test period at the level which would not produce significant effect on measured emf, since this could be reckoned as local inhomogeneity. When inhomogeneity is tested by insertion in fixed point stability is not a problem, otherwise monitoring thermometer must be used to estimate possible corrections. Inhomogeneity testing by immersion method at high temperature can add significant exposure time to high temperature (because inhomogeneity testing could last much longer than calibration), and in turn may impose risk of developing further inhomogeneity. Design of the Testing device allows execution of the both methods of testing and selection of the method is based on following parameters: type of thermocouple, accumulated working hours, working depth of immersion, foreseen type of calibration and overall acceptable calibration costs. Most of the thermocouples are routinely tested with moving ramp method, for which the practice has shown is most economical in costs and time for everyday practice in the lab. Heaters of different lengths can be used for ramp method according to length of the segment which is suspected to be inhomogeneous, all in order to avoid test turning to fools test [2], [3]. Length may vary from 10 cm as default value to 20 cm for long industrial thermocouples.

Tests are performed in vertical and tilted position, with cold and hot junction submerged in ice/water mixture, with rubber waterproof protection for ceramic insulated hot junction. Temperature of the heater is controlled in the range from 250 to 300C. During test part of the thermocouple above the heater becomes hot because of the convection transfer from the heater, which makes second temperature ramp very broad. If exact location of inhomogeneity zone is needed, fan blowing across the heater is used to make two short ramps at the ends of the heater. Thin metal sheathed mineral insulated (MIMS) thermocouples are tested by ramp method when used for regular (>250 mm) immersion measurements. In case where customer specify they are used in conjunction with popular small immersion dry block calibrators where only tip of the thermocouple is inserted into the thermal zone and there is sharp transition zone between working temperature and the environment, they are tested with gradual immersion into stabilized oil bath. This method allows accurate inhomogeneity evaluation of the short segment of wire in proximity of the hot junction of the thermocouple. Abovementioned methods are used for the themocouples which are to be calibrated by comparison method. Thermocouples calibrated in fixed points are tested for inhomogeneity on traditional method by slow insertion into the fixed point. 3. TESTING DEVICE Both methods require uniform motion of the thermocouple or a heater at predefined motion rate which may significantly vary, depending on thermocouple thermal capacity and type of the thermal source used. Furthermore, dependable and precision displacement control is required if testing of the thermocouple is to be left unattended. In order to meet those requirements the device was designed and manufactured at LPM. It can be used for immersion as well as for moving temperature ramp tests. System is designed around sturdy rectangular frame which allows motion of the sled with support for the heater or for the thermocouple. The sled is mounted on two large linear ballbearings sliding on two shafts, and moved by spindle and stepper motor. The dedicated LabView program controls movements of the sled, as well as the acquisition and storage of the data from DMM to which thermocouple under test is connected. The frame consists of two legs and inner frame on which the guide-shafts for the sled are mounted. Both legs and the inner frame are manufactured from stainless steel in order to sustain proximity of baths and furnaces. Two additional spacers can extend distance between the legs so that the frame can be positioned above thermometric baths or furnaces of different widths. Mounts for wheels are welded on the legs so that the device can be wheeled around the lab. Inner frame is mounted on the legs with four stainless steel screws, there are 26 holes along the legs height in 5 cm steps, and depending on the holes chosen to mount the inner frame, the distance between inner frames lowest point and a floor can vary between 0 and 130 cm. Furthermore the inner frame can be tilted in 15 steps from perpendicular to horizontal position by means of the perforated tilting plate

with positioning holes distributed along its outer diameter.

Figure 1: Drawing of the frame of the Thermocouple Inhomogeneity Testing Device. On the left default configuration for immersion testing is shown. Frame can be tilted in six steps from vertical to horizontal, and adjustable space between legs allows to position device above baths and furnaces of different width.

The inner frame carries the stepper motor, the threaded shaft, and the holders for the shaft on which sled is guided. Distance between shaft holders allows for about 100 cm of working distance for the sled. The commercially obtained linear translation system consists of two shafts of 20 mm diameter, holders for the shafts, and large linear ballbearings to which the box-shaped aluminum sled is attached. The linear system components assure low friction and stiffness and smooth running at desired rate at any position and in the translation range. Movement of the sled is implemented with threaded shaft connected to the stepper motor. Thermocouples and heaters are mounted on interchangeable supports, which are designed with adjustable clamp capable of receiving various types of thermometers. The design allows for two ways of fixing of the thermometer to the sled: rigidly (when used in a stirred baths or with moving heater), or flexibly, when thermometer is pushed or pulled by a sled but can displace in two lateral planes, as required for self aligning in, for example narrow bore of a furnace or a fixed point. Control over stepper motor is achieved through custom-built control circuit. It is contained in separate box, which also contains transformer and rectifier for the circuit, switch for the step down transformer for the heater, potentiometer for the heater and stepper motorss cooling fan and all the connectors and fuses to ensure tidy connection between PC and the device. Circuit itself is built with an Atmel AT89C2051 8-bit microcontroller and L297 stepper motor controller in combination with L298N bridge driver. Microcontroller has 2Kb of In-System Programmable Flash Memory, 15 programmable I/O lines, two 16-bit timer/counter, built-in serial peripheral interface for communication with PC and on-chip analog comparator. Microcontroller feeds step clock and direction signal to L297 stepper motor controller.

Figure 2: Connection scheme of the Thermocouple inhomogeneity testing device when used in moving heater configuration.

Controller integrates all control circuitry required to control bipolar and unipolar stepper motor, and generates signal for power driving circuitry. This combination was chosen because it has small number of components increases reliability and simplifies software development. Unipolar permanent magnet type stepper motor was chosen for drivetrain. It has nominal voltage 12.7 V, 12.5 W power rating, 48 steps per revolution which makes 7.5 step angle, holding torque of 240 mNm and maximum detent torque of 16 mNm. When used in conjunction with 10 mm threaded shaft with 1.5 mm pitch per revolution, the resulting resolution of the sled movement is less than 0.04 mm. In default configuration, control circuit is connected to the PC via second serial RS 232 communication port. Digital multimeter (Keithley 2001, resolution 7 digits) is used for data acquisition, and is connected via IEEE 484 port. First channel on DMM multiplexer is used for reading of the emf generated in DUT, while second is used in conjunction with the heater for temperature monitoring. First serial port (COM1) is reserved for resistance bridge when PRTs are used, either for monitoring stability of the bath, or for independent measurements which do not include inhomogeneity testing. Dedicated PC program based on LabView platform was written to perform simultaneous control over the stepper motor, acquisition of values of DUT from DMM, on-line analysis and storage of the readings for documentation as well as the temperature of the heater when used.

Figure 3: User interface to the program for control of the hardware, data acquisition, analysis and storage.

lower, ascending temperature gradient, which is closer to the degraded tip of the thermometer, is very short, and as the heater moves along, it becomes wider and embraces segments with smaller degradation of local Seebecks coefficient. This explains the local maximum at 5 cm scanned length. As the heater progresses further, first ascending ramp is still in degraded zone, while descending ramp due to heat convection becomes wider and embraces zones closer to the cold junction where degradation of the local Seebecks coefficient is small, which causes decrease of measured emf.

0 -10 0

Detected thermovoltage, microV

It allows in burst mode manual positioning of the sled to specified height, then selection of the final position and the rate at which sled should be translated during test. Rate of translation is selectable in the range from 0.1 mm/min to 50 cm/min, reading of the current position, DUTs emf at that position and the temperature of the heater (when used) are provided. Also selection of the thermocouple used for heater control is enabled. Selectable diagram allows on line analysis of the DUTs output or heater temperature, and those data together with appropriate position of the sled can be stored. When used for applications other than inhomogeneity testing, program is used to select length and the rate of displacement of the sled. 4. TEST RESULTS The purpose of the inhomogeneity testing is to detect possible inhomogeneity of the Seebacks coefficient of the thermocouple, and if detected quantitatively incorporate it into the uncertainty budget. Depending on the test results three scenarios are possible. When the thermovoltage deviation is found to be within uncertainty of the testing itself, the thermocouple is considered to have homogenous Seebacks coefficient. Uncertainty of the testing comprising mostly of the DMM uncertainty components is then used for inhomogeneity related component of the uncertainty budget. In case when measured deviation of the thermovoltage is by its magnitude intolerable for this type of thermocouple, issue of the calibration certificate is denied. Customer is advised to discard this thermometer. En example of such testing is presented on Figure 4. Thermocouple has outer diameter of 6 mm and the length of 700 mm and was not dismantled prior to the test. Heater with length of 100 mm and inner diameter 15 mm was used. Temperature of the heater during test was controlled to 270C. Top 10 centimeters of the hot junction of the thermocouple were inserted in thin rubber protection sheath and immersed in ice/water mixture, as well as cold junction. Thermocouple was tested in vertical position with continuous rate of heater movement of 2 mm/min, from the hot junction of the thermometer toward cold junction. From results can be concluded that thermocouple is severely degraded through its length. At the start of the measurement

100

200

300

400

-20 -30 -40 -50 -60 -70 -80 -90 -100

Scanned length, mm

Fig. 2. Measured emf during inhomogeneity test.

In most cases outcome of the test will be between those two extremes. Deviation will be detected, its magnitude can be measured, and it inhomogeneity related component of the calibration uncertainty budget has to be calculated. When thermometers are calibrated at fixed points, calculation of uncertainty components emanating from inhomogeneity is straightforward. Since thermovoltage deviation is measured at the temperature of calibration by withdrawing thermometer from the thermometer well, difference of the thermovoltages at the bottom of the well and at 5 cm from the bottom is taken to be span of the rectangular distribution. Standard deviation is calculated simply by dividing value by square root of three. When the moving ramp method is used, thermocouples are tested at the single temperature. For short MIMS thermocouples temperature of the stabilized oil bath is 100, while temperature of the heater is in the range 250 - 300, which is upper limit before any additional harmfull efect on thermocouple will take effect. The errors that would be induced due to inhomogeneity are both proportional on Seeback's coefficient degradation and temperature gradient, meaning that for the same thermocouple on lower temperature error would be proportionally smaller than on higher temperature.

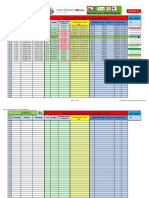

Table 1: Uncertainty budget of the calibrated type K thermocouple at 660. Component of the standard deviation due to inhomogeneity is printed bold. It was calculated by multiplying measurement results obtained with the ramp method for inhomogeneity testing which was carried out at 270 by factor of 2.4.

DUT emf uncertainty budget Type A Quantity DUT emf DMM calibration DMM resolution Parasitic voltages B Inhomogeneity Comp\Ext cables Ice/water bath Temp. deviation AB C DUT emf Interpolation Symbol ViX ViX1 ViX2 VR VH VLX t0S t VX Vint VX

tcal: Estimation 27.4350 0.00 V 0.00 V 0.00 V 0.00 V 0.00 V 0.005 C 0.00 C 27.43517 mV 0.00 V 27.4352 mV

658.6716 C Uncertainty 0.00002 mV 2.19 V 0.01 V 1.20 V 50.00 V 0.00 V 0.004 C 0.578 C Probability normal (1) normal (2) rectangular rectangular rectangular rectangular rectangular normal (1) Sensitivity coeff. 1.0 [ - ] 1.0 [ - ] 1.0 [ - ] 1.0 [ - ] 1.0 [ - ] 1.0 [ - ] 39.5 V/ C@0 C C@t cal 42.19 V/ Uncertainty (1) 12.088 V rectangular 1.00 [ ] Uncertainty (1) Contribution 0.02 V 1.09 V 0.01 V 0.69 V 28.87 V 0.00 V 0.09 V 24.41 V 37.824 V 0.897 C 6.98 V 38.462 V 0.912 C

ABC DUT emf

As the authors were not aware of any written recommendations for calculation of the standard deviation in moving ramp method, simple proportional method is used. For the part of temperature related errors, as rule of the thumb is accepted that probable thermovoltage deviation on higher temperatures would be proportionally higher, i.e. deviation on the 900C would be three times higher than that measured on 300. Thermovoltage deviation calculated on this way is taken as range of rectangular distribution, and standard deviation is calculated by dividing that value by square root of three. Method is considered to be a bit conservative, and is used until more accurate investigations are carried out. An example is of uncertainty budget is presented in the table 1. Ceramic sheated Type K thermocouple was tested for the inhomogeneity and deviation was found to be in the range 20 microK. Temperature of the heater was at 270C. In order to assess inhomogeneity at the calibration point of 660C, the value of measured deviation at 270 was multiplied by factor 2.4. Calculated value is than taken as range of the rectangular distribution and standard deviation is calculated by dividing with square root of three. CONCLUSION Testing of the thermocouples for inhomogeneity is important part of good calibration practice. Tests are mostly conducted with the heater installed on the sled. The results obtained from the inhomogeneity tests are used for quantification of the inhomogeneity uncertainty component to the overall calibration uncertainty. In some cases the testing can prevent the unnecessary calibration effort when the severe inhomogeneity is detected. The Thermocouple Inhomogeneity Testing Devicedesigned for this purpose has proved to be useful and time saving tool in thermocouple testing. The device is also used in profiling axial temperature gradients in equalizing blocks for comparison calibration of the thermocouples and

PRTs. Further application in which the device will be used is investigation of hydrostatic head effect profile in fixed points. Also further investigation in calculation of the standard deviation for the ramp method is planned.

ACKNOWLEDGMENTS Authors would like to thank Mr. Damir Serfezi, BSc ME, for the great effort he has invested in design and prototyping of the Testing device, and especially for development of custom program for control, data acquisition, analysis and storage. REFERENCES [1] R. P. Reed, Thermoelectric inhomogeneity testing: Part I-Principles, Proceedings of International Symposium on Temperature Measurement and Control in Science and Industry, Volume 6, edited by James F. Schooley, American Institute of Physics, New York, 1992, pp. 519-524 [2] R. P. Reed, Thermoelectric inhomogeneity testing: Part II-advanced methods, Proceedings of International Symposium on Temperature Measurement and Control in Science and Industry, Volume 6, edited by James F. Schooley, American Institute of Physics, New York, 1992, pp. 525530 [3] R. P. Reed, Thermocouples: Calibration, traceability, instability and inhomogeneity, Isotech journal of technology, Volume 7 No. 2, edited by Henry E. Sostmann, Isothermal Technology Ltd, 1996, pp. 91-114

Das könnte Ihnen auch gefallen

- Rotor Hot Spot Treatment PDFDokument10 SeitenRotor Hot Spot Treatment PDFramnadh803181Noch keine Bewertungen

- Thermocouple InhomogeneityDokument6 SeitenThermocouple InhomogeneityArmando_84Noch keine Bewertungen

- Thermocouples Definition PDFDokument4 SeitenThermocouples Definition PDFmouNoch keine Bewertungen

- Fiber Optic Photonic Thesis PDFDokument2 SeitenFiber Optic Photonic Thesis PDFKim0% (1)

- Reactor, Its Components, TypesDokument32 SeitenReactor, Its Components, TypesAzhar AliNoch keine Bewertungen

- Review of Analog Sensors/Transducers: Muhammad Zaigham Abbas ShahDokument16 SeitenReview of Analog Sensors/Transducers: Muhammad Zaigham Abbas ShahAbdul Razaque MagsiNoch keine Bewertungen

- 3512C Marine Engine TTC00001-UP (SEBP4534 - 23) - Bearing Clearance - CheckDokument4 Seiten3512C Marine Engine TTC00001-UP (SEBP4534 - 23) - Bearing Clearance - CheckMYO MINNoch keine Bewertungen

- Iso Standards, Brainstorming 11Dokument24 SeitenIso Standards, Brainstorming 11Siddharth ShahNoch keine Bewertungen

- Risk Assessment 1Dokument1 SeiteRisk Assessment 1AfiaNoch keine Bewertungen

- Obe Learner App Guide PDFDokument9 SeitenObe Learner App Guide PDFAsmaael adnanNoch keine Bewertungen

- Nuclear (Atomic) Power Plant: Mr.B.RameshDokument31 SeitenNuclear (Atomic) Power Plant: Mr.B.RameshDr. B. Ramesh0% (1)

- Thread Connector IdentificationDokument11 SeitenThread Connector IdentificationbearNoch keine Bewertungen

- Testing of Thermocouples PDFDokument6 SeitenTesting of Thermocouples PDFbasdownloadNoch keine Bewertungen

- Feasibility of Nuclear Power Plant For JordanDokument25 SeitenFeasibility of Nuclear Power Plant For JordanDr Ned Xoubi100% (3)

- Smoke in Cars SuvDokument9 SeitenSmoke in Cars Suvgreg gabrielNoch keine Bewertungen

- Hmi GxuDokument14 SeitenHmi GxuGameR VanrenheitNoch keine Bewertungen

- Coe Electrical EngineeringDokument13 SeitenCoe Electrical EngineeringManuelNoch keine Bewertungen

- GTG 1383om Piel Sul 48mchpDokument18 SeitenGTG 1383om Piel Sul 48mchpjohn smithyNoch keine Bewertungen

- Thermocouples Experiment: To Determine The Time Constant of A Typical Iron-Constantan Thermocouple.Dokument8 SeitenThermocouples Experiment: To Determine The Time Constant of A Typical Iron-Constantan Thermocouple.Hafiz Tanveer50% (2)

- Mitsubishi SU KUDokument2 SeitenMitsubishi SU KUMd ShNoch keine Bewertungen

- EPA Exp RegistrationDokument22 SeitenEPA Exp RegistrationFuaad DodooNoch keine Bewertungen

- Ruppur Nuclear Power PlantDokument4 SeitenRuppur Nuclear Power PlantShafi Muhammad IstiakNoch keine Bewertungen

- Diesel Engine ValvesDokument2 SeitenDiesel Engine ValvesLaxman Singh SankhlaNoch keine Bewertungen

- ThermocouplesDokument8 SeitenThermocouplesRakesh NayakNoch keine Bewertungen

- Diesel Engine TestDokument9 SeitenDiesel Engine TestSamuel Blandes RwegasiraNoch keine Bewertungen

- SIMATIC S5 Communication CableDokument8 SeitenSIMATIC S5 Communication CableAlex GonzalezNoch keine Bewertungen

- Schneider HMI GXODokument76 SeitenSchneider HMI GXORohit DashrathiNoch keine Bewertungen

- Thermocouple NotesDokument5 SeitenThermocouple NotesJane Marek100% (1)

- Fully Automated Three Phase Transformer Turns Ratio Meter: Features and BenefitsDokument4 SeitenFully Automated Three Phase Transformer Turns Ratio Meter: Features and BenefitsAnonymous HFIQgANMQNoch keine Bewertungen

- Heat Transfer in Nuclear ReactorDokument25 SeitenHeat Transfer in Nuclear ReactorPrashantNoch keine Bewertungen

- Dielectric OilDokument2 SeitenDielectric OilMohammed Imran100% (1)

- Experiment 1: Response Characteristics of Thermocouples: ObjectiveDokument4 SeitenExperiment 1: Response Characteristics of Thermocouples: ObjectiveSarfaras Ali KNoch keine Bewertungen

- Input: This Excelsheet Expired! Download Again!Dokument54 SeitenInput: This Excelsheet Expired! Download Again!romanz_657710156Noch keine Bewertungen

- 11 Metal Clad ThermocouplesDokument2 Seiten11 Metal Clad ThermocouplesMduduzi Magiva MahlanguNoch keine Bewertungen

- Cam ShaftDokument9 SeitenCam ShaftashokkumarNoch keine Bewertungen

- Adsorption Refrigeration System For Cabin Cooling of Trucks 1Dokument20 SeitenAdsorption Refrigeration System For Cabin Cooling of Trucks 1Jithin JoseNoch keine Bewertungen

- The Effect of Lean Methods and Tools On The Environmental Performance of Manufacturing OrganizationsDokument11 SeitenThe Effect of Lean Methods and Tools On The Environmental Performance of Manufacturing OrganizationsNuriaNoch keine Bewertungen

- Lab Report ThermocoupleDokument8 SeitenLab Report ThermocoupleKhalidIqbal100% (2)

- Ch24 DynModelsDokument155 SeitenCh24 DynModelselectrical_1012000Noch keine Bewertungen

- Scada BasicsDokument41 SeitenScada Basicskarkey82Noch keine Bewertungen

- PRDDokument30 SeitenPRDMostafa MohmmedNoch keine Bewertungen

- E R P System Assignment-3Dokument12 SeitenE R P System Assignment-3SWATI MISHRANoch keine Bewertungen

- Magnetic Pick UpsDokument4 SeitenMagnetic Pick UpslunikmirNoch keine Bewertungen

- UNIT-1 ManagementDokument128 SeitenUNIT-1 ManagementDeepa Shree100% (1)

- CL NabllabDokument71 SeitenCL NabllabBhart AutomationNoch keine Bewertungen

- CMVP ResumeDokument3 SeitenCMVP ResumeAjit ImperiumNoch keine Bewertungen

- Fiber Optic Equipment Spec PDFDokument12 SeitenFiber Optic Equipment Spec PDFAkashNoch keine Bewertungen

- Design and Construction of Arc Welding MDokument4 SeitenDesign and Construction of Arc Welding MSarthak sainiNoch keine Bewertungen

- Generator End-Winding Vibration AnalysisDokument8 SeitenGenerator End-Winding Vibration AnalysisMohsen Vafaei Zadeh100% (1)

- MST For Below Ground UPVC Drainage PipesDokument17 SeitenMST For Below Ground UPVC Drainage Pipesمقاول تكييف كهرباء وصحيNoch keine Bewertungen

- Important Topics For GATE 2017Dokument6 SeitenImportant Topics For GATE 2017Suraj SerigarNoch keine Bewertungen

- Torque Ripple Reduction in Reluctance Synchronous Machines Using Magnetic WedgesDokument32 SeitenTorque Ripple Reduction in Reluctance Synchronous Machines Using Magnetic WedgesRobert Smith100% (1)

- Chapter 9 Hydro GeneratorDokument32 SeitenChapter 9 Hydro GeneratorDivyansh Singh ChauhanNoch keine Bewertungen

- Thermocouple CalibirationDokument18 SeitenThermocouple CalibirationAnonymous w6v7JWfr5100% (2)

- A Alternator DesignDokument6 SeitenA Alternator DesignKathir RkpNoch keine Bewertungen

- Testing of Thermocouples For InhomogeneityDokument6 SeitenTesting of Thermocouples For InhomogeneitySunil DeshmukhNoch keine Bewertungen

- Calibration of ThermocoupleDokument22 SeitenCalibration of ThermocoupleMuhammad Fahad100% (1)

- Validation Da LoggersDokument5 SeitenValidation Da LoggersApoloTrevinoNoch keine Bewertungen

- Homogeneidade Sirilanca PDFDokument6 SeitenHomogeneidade Sirilanca PDFjerrybsNoch keine Bewertungen

- Factors Affecting Temperature Measurement AccuracyDokument2 SeitenFactors Affecting Temperature Measurement AccuracyMarvZz VillasisNoch keine Bewertungen

- Douglas 2011Dokument446 SeitenDouglas 2011Ibnu FajarNoch keine Bewertungen

- Neutron Fluence Calculation Methodology For Reactor Vessel: Non-ProprietaryDokument36 SeitenNeutron Fluence Calculation Methodology For Reactor Vessel: Non-ProprietaryelsayedNoch keine Bewertungen

- Nondimensionalization of NS EquationDokument2 SeitenNondimensionalization of NS EquationusamaNoch keine Bewertungen

- Mohr - Structural Geology of Impact CratersDokument27 SeitenMohr - Structural Geology of Impact CratersJorgeTrabajoNoch keine Bewertungen

- Optimization of Cobb-Douglas Production Functions: IOP Conference Series: Materials Science and EngineeringDokument7 SeitenOptimization of Cobb-Douglas Production Functions: IOP Conference Series: Materials Science and Engineeringsenthil6872Noch keine Bewertungen

- Maintenance AmckoDokument10 SeitenMaintenance AmckoAli Akbar0% (1)

- Prover Meter CalibrationDokument11 SeitenProver Meter CalibrationwisujNoch keine Bewertungen

- Experiment 1 Measure Water PressureDokument7 SeitenExperiment 1 Measure Water PressureAbhijit KuchbhilikhtaNoch keine Bewertungen

- Ws06 - Normal Mode AnalysisDokument17 SeitenWs06 - Normal Mode AnalysisIamzura AbdullahNoch keine Bewertungen

- Astronomical HarmonicsDokument73 SeitenAstronomical HarmonicsRalph WuNoch keine Bewertungen

- Comparison of Spectrophotometric and HPLC Methods For DeterminationDokument8 SeitenComparison of Spectrophotometric and HPLC Methods For DeterminationChung KuNoch keine Bewertungen

- Maxwell 2D - Setup Solution Options PDFDokument382 SeitenMaxwell 2D - Setup Solution Options PDFAnonymous d23gWCRQNoch keine Bewertungen

- Coal RejectDokument15 SeitenCoal RejectRupasree PandaNoch keine Bewertungen

- Below The Hook PDFDokument1 SeiteBelow The Hook PDFmaomontesNoch keine Bewertungen

- Conservation Between Art and ScienceDokument18 SeitenConservation Between Art and ScienceMichael Nabil100% (1)

- Vray Physical Camera GuideDokument4 SeitenVray Physical Camera GuideeoghanobrienNoch keine Bewertungen

- 02 - Forming Factors of Blowhole Defect in Continuously-Cast Beam Blank at Dragon SteelDokument7 Seiten02 - Forming Factors of Blowhole Defect in Continuously-Cast Beam Blank at Dragon SteelJitendra UmaraliyaNoch keine Bewertungen

- 1Dokument5 Seiten1api-236119409Noch keine Bewertungen

- Quench Tower PerhitunganDokument7 SeitenQuench Tower PerhitunganRizqia Putri ZakkaNoch keine Bewertungen

- ECE Final Upto 4th Year Syllabus 6 June, 2013Dokument58 SeitenECE Final Upto 4th Year Syllabus 6 June, 2013menilanjan89nLNoch keine Bewertungen

- Lab ManualDokument80 SeitenLab ManualRavindra KumarNoch keine Bewertungen

- Test Schedule & Syllabus of Online Test Series Class XII/XII+Dokument1 SeiteTest Schedule & Syllabus of Online Test Series Class XII/XII+Romelu MartialNoch keine Bewertungen

- HBM PlatformsDokument43 SeitenHBM PlatformsAlexandru IonescuNoch keine Bewertungen

- A Compact Dual-Band Dual-Polarized Patch AntennaDokument7 SeitenA Compact Dual-Band Dual-Polarized Patch Antennaagmnm19620% (1)

- Linde Hydraulics - HPV-02Dokument0 SeitenLinde Hydraulics - HPV-021antonio100% (1)

- Bright Field vs. Dark Field in Vision: Released 4/20/2016Dokument4 SeitenBright Field vs. Dark Field in Vision: Released 4/20/2016Ahmad DanielNoch keine Bewertungen

- The New Joint Australian and New Zealand Bridge Design Standard AS/NZS 5100 - Part 6: Steel and Composite ConstructionDokument12 SeitenThe New Joint Australian and New Zealand Bridge Design Standard AS/NZS 5100 - Part 6: Steel and Composite ConstructionStephen HicksNoch keine Bewertungen

- Skyscraper & Intelligent BuildingsDokument21 SeitenSkyscraper & Intelligent BuildingsMariel Paz MartinoNoch keine Bewertungen

- ISA Transactions: Rames C. Panda, V. Vijayan, V. Sujatha, P. Deepa, D. Manamali, A.B. MandalDokument9 SeitenISA Transactions: Rames C. Panda, V. Vijayan, V. Sujatha, P. Deepa, D. Manamali, A.B. MandalAnonymous WkbmWCa8MNoch keine Bewertungen

- Design of Combined-Footings by Is-456Dokument48 SeitenDesign of Combined-Footings by Is-456jkedar_7860% (5)