Beruflich Dokumente

Kultur Dokumente

Development of Timing Belt Drives

Hochgeladen von

Blaza StojanovicOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Development of Timing Belt Drives

Hochgeladen von

Blaza StojanovicCopyright:

Verfügbare Formate

Blaa Stojanovi, Nenad Miloradovi

DEVELOPMENT OF TIMING BELT DRIVES

UDC: 621.83/.85 INTRODUCTION Timing belt drive is relatively new conception of power transfer, accepted in all areas of industry today. Actually, they represent a combination of chain and gear transmission. They are flat belts with series of equal spatial teeth inside addendum diameter.Timing belt transfers the torque by means of its shape. The teeth, equally spaced at inner side of timing belts, contact the belt pulleys teeth with their hollows between teeth and, thus, by conjugate gear action, achieve the coupling between the belt and the belt pulley and transfer the torque. Power transmission through timing belts has a series of good features [1]: small amount of slip, constant speed; cheap maintenance, because, due to absence of contact between metal parts, there is no need for lubrication; possibility for power transfer in a broad range, over 400 kW; small load of construction bearings; broad range of speeds, from 0.5 m/s to over 33 m/s; compact construction, conditioned by small centre distance, small belt width and possibility to transfer large power; possibility to simultaneously transfer power to a large number of shafts; small heating; smoother running in a period of run in; small mass of construction, which is sometimes a critical factor (in design of airplanes, hand devices and similar); precise kinematic ratio (i=const); relatively low level of noise; very high efficiency (=0.99). Timing belt drives have broad application in industry. They are applied starting from calculation machines, computers and instruments, through machine tools, pumps and compressors, to heavy industrial plants. Shortcomings of the timing belt drives are: expensive manufacture, sensitivity to irruption of foreign bodies (possibility of damage during coupling), possibility of teeth skipping . In spite of advantages in operation, timing belt drives have only recently achieved great application. It was yet after their application as IC engines camshaft drive, that their purposefulness of application had become obvious. Popularity of timing belts in automotive

Volume 35, Number 2, June 2009

32

Blaa Stojanovi, Nenad Miloradovi

industry has accelerated their use in other branches of industry. Today, timing belts are applied more and more, especially since technology of manufacture of polyurethane belts has emerged and developed. Market suggests the use of belts of unlimited length and with unlimited number of teeth. HISTORICAL DEVELOPMENT OF TIMING BELTS Timing belt is a relatively young drive, firstly designed as a drive for a sewing machine by engineer Richard Y. Case in 1946. It was a rubber belt with trapezoidal teeth profile. After twenty years, in 1962, the timing belt was for the first time built in an automobile, Glas 1004. Engine of Glas 1004 was the first engine where the timing belt was utilized as the camshaft drive (Synchroflex). Valve train was very simple and the timing belt drive had no belt tensioner, Figure 1. Massive use of the timing belts started at the end of 1960s on Fiat 125 and Fiat 128 automobile and, at the beginning of 1970s, on the first Golf automobile.

Figure 1: Engine of Glas 1004 automobile (1962) After initial doubt, almost all producers of Otto and Diesel engines for passenger cars have utilized the timing belts. The timing belt is today the most frequently used camshaft drive. Application of the timing belts is mostly linked to automobiles, though just 2% of timing belt production is intended for application in automotive industry. SUBDIVISION OF TIMING BELTS There are different types of timing belts in exploitation, differing by construction application, manufacturing technology, materials, teeth profile, etc. There are some attempts to standardize the timing belts. Nevertheless, until today, theses attempts were unsuccessful, because the belts are relatively new, their constructions are special and belt dimensions are determined in different systems, which aggravate their comparison. The timing belts may be divided according to several criteria:

Volume 35, Number 2, June 2009

Development of timing belt drives

33

According to purpose:

1. Timing belts for energy machines. These are the endless belts with spiral tractive elements. They are used as power transmission between the shafts. Also, they are applied in lathes, sawmills, mills and bakeries, then as drives of pistons, compressors and polygraph devices. The timing belts are used in high-speed gears for driving the grinding wheels, web machines, centrifugal machines and textile and wood-processing machines. Maximal belt length is 22 m. 2. Timing belts for geared transmission and position systems. Their tractive elements are positions parallel to side edges. They are used for realization of linear motion. The timing belts for small transmissions, geared transmissions and position systems are applied in devices for regulation and control of metal rolling machines, power devices and chemical plants. The belts length is unlimited. 3. Special timing belts. Specially built belts are used for special working conditions. Double-sided timing belts are recommended for reversible transmissions. Belts with modified back surface may be used as transporters for carrying raw materials and final products. Besides, timing belts resistive to high temperatures and lubricants and electricresistive belts are manufactured. According to manufacturing technology:

1. Die casted timing belts. Timing belts manufactured by this method consist from two components a belt with teeth and a strained tractive element that receives the workload. The belt is manufactured from plastic masses or special texture rubber, therewith the both materials must be highly resistive to wear. The tractive element is manufactured from thin steel wire or from polyetheric ply and it is situated in belts body. In very small belts, the dilatation is controlled by the tractive element. Mould for belt casting should provide standard dimensions and minimal tolerances of teeth shape for uniform power transmission. Belts teeth should have a precise shape and should be precisely positioned in order to provide and guarantee quality coupling with belt pulleys teeth. 2. Timing belts obtained by vulcanization. The timing belts are manufactured with the tractive element housed in belts body, having fibrous film teeth. The belts body (teeth and back surface) is made of synthetic rubber compound, resistive to wear, which protects the tractive element. This compound should be firm and should poses dimensional stability, so the teeth should reliably receive cross-sectional forces. Protective teeth film is made of wear resistive nylon that has small friction coefficient and protects the teeth and the belt from wear. The film also reduces the noise during operation of belt drive. The belts body, the tractive element and the belt film join into a set in the mould, during the process of vulcanization. 3. Timing belts obtained by extrusion. Some timing belts are made by method of extrusion. In that case, sections of the belt are obtained which ends may be joined together and, thus, the belt of arbitrary length is obtained. Belts sections have parallel tractive elements in the shape of steel wire or polyetheric fibre. They also have nylon teeth coatings or back surfaces (or both elements). Timing belts with continuous rolled metal tractive elements, without joints, are manufactured in any length up to 25.5 m. Similar belts made by PLASMATIC company (USA), are

Volume 35, Number 2, June 2009

34

Blaa Stojanovi, Nenad Miloradovi

applied, first of all, in high torque and high speed drives. Belts body and teeth are made of polyurethane by extrusion method. According to measuring units:

1. Timing belts with dimensions given in mm metric system. The basic parameter of these belts is a modulus or a pitch given in mm. 2. Timing belts with dimensions given in inches ". These belts are mostly made of neoprene and the basic parameter is a pitch in ". Both types of belts are not compatible to each other. According to material:

The following materials are used for manufacture of timing belts [2]: Natural caoutchouc (rubber) Neoprene Polyurethane (urethane) Basic characteristics of these materials are: Natural rubber: large elasticity, easy design, large friction coefficient, high bursting stress limit, small wear, wide temperature range (especially low temperatures), small resistance to oils and solvents, especially to acetone and alcohol and natural rubber is susceptible to oxidation. Neoprene: large elasticity, wide temperature range (especially high temperatures), good resistance to external influences (convenient for opened transmissions) and small resistance to oils and solvents. Polyurethane: high wear resistance, small friction coefficient, good resistance to oils and oxidation, wide temperature range (especially low temperatures), small resistance to high temperatures. According to teeth profile shape [3]: trapezoidal, semicircular (curvilinear),

Volume 35, Number 2, June 2009

Development of timing belt drives

35

semicircular with flat top, triangular (saw-timing), belt with optimized rounded profile, etc.

Most of the timing belts are made as double-sided constructions, with teeth at both sides of the belt. TIMING BELT PULLEYS Belt pulleys are very important and responsible parts of belt transmissions. Synchronicity of transmission and the level of exploitation characteristics largely depend on proper selection, construction and quality of manufacture of belt pulleys [1]. Like timing belts, the timing belt pulleys defer by their construction characteristics. They consist of a certain number of equal hollows between teeth that enable correct coupling with the belt. Belt pulleys are design in such a way that belt teeth enter and leave the hollow between teeth with negligible friction. Hollows between teeth are manufactured with clearance. The clearance makes the entering and exiting of belt teeth from coupling easier, compensates for cumulative errors of addendum diameter, profile errors of hollows between teeth and belt teeth and for tilting of transmission shaft axles. According to their construction shapes, timing belt pulleys are made in several different forms. They consist of: a rim, a hub and a plate or a spoke that connect the rim with the hub. They are made with or without rim rings, with symmetrical or asymmetrical hub. The rim is connected with the hub with the plate that may be of equal thickness in smaller belt pulleys (up to 100 mm). In larger belt pulleys, the plate is thinner than the rim and it is made with symmetrically drilled holes for weight reduction and for easier capture of the belt pulley during machining. Linking the rim and the hub with spokes is recommended for larger sizes (over 300 mm). The belt pulleys are made of different materials, resistant to wear, like: steel, cast iron, aluminium alloys, plastic masses depending on the belt pulleys dimensions and the terms of use. In order to reduce weight, it is recommended to produce the vehicle parts out of new, advanced materials [4,5]. Lately, plastic masses are more frequently used: LEXAN 500, FIBERGLASS (reinfoirced) and DELRIN 500. The belt pulleys form MULCO company for newer belt profiles are made of aluminium alloys (AlCuMgPb, AlZnMgCu0.5-F48) [6]. Flanges are mostly made of carbon steel or aluminium and its alloys. The timing belt pulleys made from plastic masses and easy alloys are usually manufactured by die-casting. The belt pulleys teeth are threaded with form-growned cutter. The rectilinear part of belt pulleys teeth profile is gained using corresponding form-growned cutter teeth. To facilitate the entrance of the belt teeth into the coupling with the belt pulley,

Volume 35, Number 2, June 2009

36

Blaa Stojanovi, Nenad Miloradovi

the teeth head of the belt pulley id rounded. Belt pulleys teeth for belts up to 12.7 mm, due to small height, may be threaded with the gear hobs with rectilinear profile. Precision of the belt pulleys pitch, small surface roughness and proper shape of teeth guarantee noiseless operation of transmission and a long life time of the belt. CONCLUSIONS The timing belt drives are relatively new transmissions, designed in 1950s. Their shape (teeth profile) and materials that they are made of are still changing. Considering that the motion of the belt along the envelope angle of the belt pulley is performed on polygonal profile, by finding the optimal teeth profile, the so called polygon effect is reduced and the load is more evenly distributed on all teeth in coupling. At trapezoidal teeth profiles, the first tooth in the coupling, considering that the contact is firstly obtained in a contact point, carries the greatest load. In production of timing belt pulleys, rubber and steel or tractive elements made of fibreglass were used at first. Today, polyurethane (urethane) and neoprene find bigger and bigger use. New materials have increased wear resistance and wide temperature range. Trends in development of timing belts are to obtain, by convenient combination of teeth profile shape and the belt materials: larger carrying capacity, longer life-time and smoother load distribution. REFERENCES [1] Tanasijevi, S.: Mechanical transmissions: chain transmissions, timing belt drives, cardanic transmissions (in Serbian), Yugoslav tribology society, Faculty of Mechanical Engineering Kragujevac, 1994 [2] World of Timing Belts, Stock drive products, New York, 1998 [3] Stojanovi, B.: New designs of timing belts (in Serbian), Proceedings, Sever prenosnici, Subotica, October, 2003 [4] Belingardi G., Avalle M.: Advanced materials for automotive applications, Mobility and Vehicle Mechanics, vol. 30, No. 2-3, p.p. 51-65, 2004 [5] Pei R.: Automobile SI engines with minimal fuel consumption (in Serbian), Monograph, Special edition of Mobility and Vehicle Mechanics, Faculty of Mechanical Engineering, Kragujevac, 1994 [6] Catalogues of the companies: Mulco, Bando, Gates, Dayco, Goodyear, Breco, Flender, Contitech [7] Mitrovic S., Babic M., Bobic.: ZA-27 Alloy Composites Reinforced with Al2O3Particles, Tribology in Industry, vol. 29, No. 3&4, pp. 35-42, 2007

Volume 35, Number 2, June 2009

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Nove Konstrukcije Zupčastih KaiševaDokument6 SeitenNove Konstrukcije Zupčastih KaiševaBlaza StojanovicNoch keine Bewertungen

- Experimental Determination of Timing Belt Height at Inter-TeethDokument6 SeitenExperimental Determination of Timing Belt Height at Inter-TeethBlaza StojanovicNoch keine Bewertungen

- Failure Analysis of The Timing Belt DrivesDokument6 SeitenFailure Analysis of The Timing Belt DrivesBlaza StojanovicNoch keine Bewertungen

- Analytical Model of The Pressure Variation in The Gerotor Pump ChambersDokument9 SeitenAnalytical Model of The Pressure Variation in The Gerotor Pump ChambersBlaza StojanovicNoch keine Bewertungen

- Determination of Gerotor Pump Theoretical FlowDokument8 SeitenDetermination of Gerotor Pump Theoretical FlowBlaza StojanovicNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

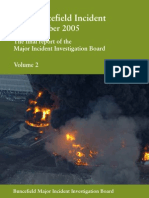

- Buncefield Volume 2Dokument208 SeitenBuncefield Volume 2Hammy223Noch keine Bewertungen

- Legal Aspects of Construction Ethics PaperDokument11 SeitenLegal Aspects of Construction Ethics PaperbikaresNoch keine Bewertungen

- 1349122940100212diggerDokument24 Seiten1349122940100212diggerCoolerAdsNoch keine Bewertungen

- Modal Verbs EjercicioDokument2 SeitenModal Verbs EjercicioAngel sosaNoch keine Bewertungen

- Mindset For IELTS Level 1 Student's Book PDF English As A Second or Foreign Language International English Language TestinDokument1 SeiteMindset For IELTS Level 1 Student's Book PDF English As A Second or Foreign Language International English Language TestinhiNoch keine Bewertungen

- Department of Education: Republic of The PhilippinesDokument6 SeitenDepartment of Education: Republic of The PhilippinesLalaine QuitoNoch keine Bewertungen

- EmbOS GenericDokument324 SeitenEmbOS Genericbogd33Noch keine Bewertungen

- A Hack For The Yoga PoseDokument3 SeitenA Hack For The Yoga PoseAlex NNoch keine Bewertungen

- Sow and Learning ObjectivesDokument14 SeitenSow and Learning ObjectivesEhsan AzmanNoch keine Bewertungen

- Manual G Ingles - V6Dokument68 SeitenManual G Ingles - V6Phùng Thế Kiên50% (2)

- BAFINAR - Quiz 2 ColarDokument3 SeitenBAFINAR - Quiz 2 ColarRonalyn ColarNoch keine Bewertungen

- Imamsha Maharaj Na Parcha NewDokument16 SeitenImamsha Maharaj Na Parcha NewNARESH R.PATELNoch keine Bewertungen

- EASA CS-22 Certification of SailplanesDokument120 SeitenEASA CS-22 Certification of SailplanessnorrigNoch keine Bewertungen

- NPN Silicon: Semiconductor Technical DataDokument8 SeitenNPN Silicon: Semiconductor Technical DataMinh Hà QuangNoch keine Bewertungen

- Irregular Verbs Lesson PlanDokument13 SeitenIrregular Verbs Lesson Planapi-311868026Noch keine Bewertungen

- Booklet The 8th JAKINUDokument20 SeitenBooklet The 8th JAKINUsamuelionardiNoch keine Bewertungen

- Lesson 5 Flight of Projectile, Air Resistance Neglected: OverviewDokument7 SeitenLesson 5 Flight of Projectile, Air Resistance Neglected: OverviewNadjer C. AdamNoch keine Bewertungen

- Cultures of The West A History, Volume 1 To 1750 3rd PDFDokument720 SeitenCultures of The West A History, Volume 1 To 1750 3rd PDFtonnyNoch keine Bewertungen

- Nonlinear Robust Control of High-Speed Supercavitating Vehicle in The Vertical PlaneDokument10 SeitenNonlinear Robust Control of High-Speed Supercavitating Vehicle in The Vertical Planesamsaptak ghoshNoch keine Bewertungen

- Dinengdeng RecipeDokument1 SeiteDinengdeng RecipeFuNoch keine Bewertungen

- Serie10 ElecDokument75 SeitenSerie10 Elecmealier severineNoch keine Bewertungen

- Lab5.ipynb - ColaboratoryDokument8 SeitenLab5.ipynb - ColaboratoryMin YNoch keine Bewertungen

- Assignment 1 SolutionDokument11 SeitenAssignment 1 SolutionKash TorabiNoch keine Bewertungen

- Engineering Data: Wireway SelectionDokument3 SeitenEngineering Data: Wireway SelectionFidel Castrzzo BaeNoch keine Bewertungen

- Performance Task 1st Quarter Poetry Writing WorkshopDokument3 SeitenPerformance Task 1st Quarter Poetry Writing WorkshopNicole john ZuluetaNoch keine Bewertungen

- Amended August 8 2016Dokument31 SeitenAmended August 8 2016lux186Noch keine Bewertungen

- Ism Practical File NothingDokument84 SeitenIsm Practical File NothingADITYA GUPTANoch keine Bewertungen

- The Complete Guide To Installing The 44 Split Defense PDFDokument171 SeitenThe Complete Guide To Installing The 44 Split Defense PDFsaid100% (1)

- Lazard Levelized Cost of Storage v20Dokument46 SeitenLazard Levelized Cost of Storage v20macNoch keine Bewertungen

- Subject-Verb AgreementDokument10 SeitenSubject-Verb AgreementLouie Jay Cañada AbarquezNoch keine Bewertungen