Beruflich Dokumente

Kultur Dokumente

CSCC6201104V04S01A0010

Hochgeladen von

CHOFOR VITALISCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CSCC6201104V04S01A0010

Hochgeladen von

CHOFOR VITALISCopyright:

Verfügbare Formate

Studii i Cercetri tiinifice Chimie i Inginerie Chimic, Biotehnologii, Industrie Alimentar Scientific Study & Research Chemistry &

Chemical Engineering, Biotechnology, Food Industry

2011, 12 (4), pp. 387 399

ISSN 1582-540X ORIGINAL RESEARCH PAPER

RHEOLOGY OF CHICKPEA PROTEIN CONCENTRATE DISPERSIONS

Aurelia Ionescu1, Iuliana Aprodu1*, Gabriela Gurau2, Iuliana Banu1

Department of Biochemistry, Faculty of Food Science and Engineering, Dunrea de Jos University, 111 Domneasc Street, 800201, Galai, Romania 2 Department of Functional Sciences, Faculty of Medicine and Pharmacy, Dunrea de Jos University of Galai, Romania

*Corresponding author: iuliana.aprodu@ugal.ro Received: July 01, 2010 Accepted: June 30, 2011 Abstract: Chickpea proteins are used as ingredients in comminuted sausage products and many oriental textured foods. Rheological behaviour of chickpea protein concentrate was studied using a controlled stress rheometer. The protein dispersion prepared with phosphate buffer at pH 7.0 presented non-Newtonian shear thinning behaviour and rheological data well fitted to the Sisko, Carreau and Cross models. The viscoelastic properties of the chickpea protein suspensions were estimated by measuring the storage and loss moduli in oscillatory frequency conditions (0.1-10 Hz) at 20C. Moreover, thermally induced gelation of the chickpea proteins (16, 24 and 36%) was studied at pH 7.0 and 4.5 in the temperature range 50 to 100oC and salt concentration ranging from 0 to 1 M. Gelling behaviour was quantified by means of dynamic rheological measurements. Gels formation was preceded by the decrease of storage modulus and loss moduli, coupled with the increase of the phase angle (delta). The beginning of thermal gelation was influenced by protein concentration, pH and salt level. In all studied cases, storage modulus increased rapidly in the temperature range 70-90C. All rheological parameters measured at 90C were significantly higher at pH 4.5 compared to pH 7.0. Keywords:

chickpea proteins, dynamic tests, flow tests, rheological behaviour, thermal gelation

Paper presented at the 6th edition of Colloque Franco-Roumain de Chimie Applique, COFrRoCA 2010, 7-10 July 2010, Orlans, France

2011 ALMA MATER Publishing House, VASILE ALECSANDRI University of Bacu. All rights reserved.

387

IONESCU, APRODU, GURAU and BANU

INTRODUCTION Chickpea (Cicer arientum L.) is an annual legume cultivated mainly for human consumption. Chickpea is grown mostly in West Asia and Mediterranean region [1 - 6], India (65%), Turkey (6.7%), Pakistan (7.5%) and Mexico being the most important producers and exporters in the world [7]. Chickpea is rich in proteins (18-25%) [8], with high biological value due to the equilibrated amino-acids composition, to their high biological availability and relatively reduced content of antinutritional factors [9 - 10]. Several papers [2, 5, 11, 12] report chemical composition and functional properties (emulsifying capability, solubility and deionised water adsorption properties at pH 7.0) of chickpea protein isolates and recommend their use at industrial scale as functional ingredients in different foodstuff (cheese, bakery, meat products, creams, etc). Functional properties and rheological behaviour of chickpea protein isolates and concentrates, generally, give indications about composition, structure, denaturation and aggregation degree of their major component legumin and vicilin. Protein gelling is an important functional property that recommend protein ingredients to be used in comminuted sausage products and many oriental textured foods, e.g. tofu [13]. Gels properties can be characterised by monitoring rheological properties such as viscosity, plasticity, and elasticity. The aim of the present paper was to study the rheological behaviour of the dispersions based on chickpea protein concentrate. Different protein concentrations were investigated as well as the influence of pH and salt concentration when running temperature sweep tests. MATERIALS AND METHODS Materials The chickpea was purchased in a local vegetable market, Galati, Romania. All chemicals used were of analytical grade Preparation of protein concentrate Chickpea protein concentrate was obtained starting from defatted chickpea flour. Since most of the chickpea proteins are soluble at pH > 9.0, the pH of the defatted flour was fixed to 10.5 with NaOH 2N. Starch and fiber fractions were separated from the alkaline dispersion by centrifugation at 3000 rpm for 20 min at 4C. The supernatant containing all soluble proteins was collected and used for recovering the protein fraction by means of isoelectric precipitation method. After adjusting the pH to 4.5 with HCl 2N, the precipitated proteins were separated by centrifugation at 3000 rpm for 20 min at 4C. The precipitate was washed three times with distilled water with pH 7.0 to remove any potential contaminants and was dried on an Alpha 1-4 LD plus lyophilizator from Christ. Before drying, the samples were first frozen at -48C for 42 hours in an ultrafreezer Platinum 500. 388

St. Cerc. St. CICBIA 2011 12 (4)

RHEOLOGY OF CHICKPEA PROTEIN CONCENTRATE DISPERSIONS

Proximate composition and pH The moisture, protein and ash contents of the chickpea protein concentrate were determined according to standard AOAC methods [14]. The crude fat content was determined by AOAC method 991.36 [15], while the fiber and polysaccharide content was estimated as difference by knowing the other components. All determinations were made in triplicate. pH measurements were made according to AOAC [16]. The pH values were measured at 22 1C on 10% (w/v) protein solution by means of a Hanna digital pH-meter. Determination of least gelation concentration Gelation property of the chickpea protein concentrate was investigated using the method described in [17], which was slightly modified. Sample suspensions of 8-24% were prepared in test tubes by mixing for 20 min the chickpea protein concentrate with phosphate buffer (pH 7.0). The test tubes were then heated in water bath at 90C for 30 min, followed by rapid cooling in an ice bath. The test tubes were further stored overnight at 4C. The least gelation concentration was determined as the concentration when the sample from the inverted test tube did not slip or fall. Preparation of chickpea protein suspension for rheological measurements Rheological measurements were carried out on protein suspensions (16, 24 and 32%) prepared in phosphate buffer using a magnetic stirrer for 20 min at room temperature. The protein concentrations were chosen taking into account the least gelation concentration and the hydration ratios of the protein derivates usually used in meat industry (1 kg of protein concentrate to 2.5-3 kg water). The chickpea protein behaviour was investigated at pH 7.0 and 4.5; the pH was adjusted using HCl 0.1N. The salt effect on the rheological properties of chickpea protein suspensions was studied by replacing distilled water with various salt concentrations (0.2, 0.5 and 1.0 M). Before rheological tests, all protein suspensions were stored overnight at 4C to allow a better hydration and avoid endogenous enzyme activity. Rheological measurements Rheological measurements were carried out in triplicate using a controlled-stress rheometer (AR 2000, TA Instruments, New Castle, DE) attached with computer control software (Rheology Advantage Data Analysis Program, TA, New Castle, DE). The temperature was maintained at 4C using the Peltier temperature control system. All dynamic oscillatory and steady-shear rheological measurements were done using a 40 mm 2 steel cone plate geometry and a gap of 1000 m was used. For each test, approximately 2 g of protein suspension was poured on the bottom plate of the rheometer. The controlled shear-rate measurement technique was employed by progressively increasing the shear-rate from 0.1 up to 100 s-1 and decreasing it to obtain shear-rate vs.

St. Cerc. St. CICBIA 2011 12 (4)

389

IONESCU, APRODU, GURAU and BANU

viscosity data. All rheological measurements were carried out in triplicates at constant temperature of 4C. The shear rate vs. viscosity data were fitted to rheological models such as power law, Herschel-Bulkley, Casson, Bingham, Sisko, Carreau, and Cross equation. The best fit model was selected on the basis of standard error. Frequency sweeps are oscillatory tests performed at variable frequencies, keeping the amplitude (and also temperature) at a constant value. This test was conducted by applying a constant sinusoidal strain of 0.05% within the linear region, over a frequency range between 0.1 - 10 Hz. This range of frequencies is suitable for determining the viscoelastic behaviour of cross-linked polymers [18 - 20], and also of proteins gels [21 24]. The storage modulus (G), loss modulus (G) and delta were recorded as function of frequency. Temperature sweep tests were performed by heating at 1C/min the 16, 24 and 36% chickpea protein suspensions from 50 to 100C. In order to test the influence of pH (4.5 and 7.0) and NaCl concentration (0; 0.2; 0.5; and 1M) the rheological measurements were done in the temperature range 5 to 80C. The frequency was 0.05 Hz while the angular frequency was 0.3142 rad/s. Both temperature and frequency sweep tests were done at oscillatory stress of 0.5964 Pa within the linear viscoelastic region as assessed by stress sweep experiments. Statistical analysis Statistical analysis was carried out using Sigma Plot 2001/Statistiques Data Software. Each experiment was carried out in triplicate and the results are reported as mean values. RESULTS AND DISCUSSION Proximate chemical analysis of the chickpea protein concentrate The results of chemical analysis showed that the chickpea protein concentrate had 81.26 3.17% protein, 1.55 0.05% fat, 4.15 0.18% water and 2.75 0.08% ash. The ash content of the chickpea protein concentrate was very high compared to the lupin protein concentrate (0.71%) as reported in [17]. Due to the chickpea protein concentrate refinement, the level of total polysaccharides, represented by starch and fibers, was about 10.29%, comparable to other protein concentrates [25]. Rheological behaviour of the chickpea protein concentrates The capacity of vegetal proteins to form three-dimensional networks sequestering water and other ingredients (polysaccharides and aromas) is one of the most important functional properties that justify protein derivates applications in food industry [13]. Protein gels are characterized by rather high viscosity, plasticity and elasticity. 390

St. Cerc. St. CICBIA 2011 12 (4)

RHEOLOGY OF CHICKPEA PROTEIN CONCENTRATE DISPERSIONS

Rheological measurements are frequently employed to evaluate some functional properties (gelling, thickening) of the food-grade proteins and to predict mouth feel. In order to study the viscosity, shear thinning behaviour and the capacity of the chickpea protein concentrate to form gels or viscous paste, dynamic tests were carried out. Different chickpea protein concentrations, pH and ionic strength were tested. Shear thinning rheology The least gelation concentration tests showed that 16% is the lowest protein concentration that allows gel forming and all rheological tests were carried out on protein suspensions with higher concentrations (16, 24, 32%) prepared in phosphate pH 7.0. The measurements were done at 4C to resemble the processing temperature of the meat products supplemented with proteins derivates, by varying the shear rate from 0.1 to 100 s-1. The viscosity shear rate rheogram presented in Figure 1 shows that, chickpea protein suspension exhibits shear thinning behavior characterized by viscosity decrease when shear rate increases.

7000 6000 Viscosity, Pa.s 5000 4000 3000 2000 1000 0 0 Cross Carreau Sisko

10

20 30 Shear rate, s-1

40

50

Figure 1. Viscosity-shear rate rheogram of the 32% chickpea protein suspension The flow curves were evaluated using the rheological models Herschel-Bulkley, power law, Bingham, Casson, Sisko, Cross and the quality of the fits was established based on standard error values. The Sisko, Cross and Carreau models proved to give the best fits to the flow curves of the chickpea protein suspensions. As shown in Figure 1, Cross and Carreau models are nearly overlapping; the values of the rheological parameters of the two models are very similar (Table 1). The other rheological models gave poor fits depending on protein concentration.

St. Cerc. St. CICBIA 2011 12 (4)

391

IONESCU, APRODU, GURAU and BANU

Cross and Carreau models allow to estimate the maximum viscosity corresponding to zero shear rate [26] and in all cases the results obtained (Table 1) are in agreement with the viscosity measured at a shear rate of 0.1 s-1 (4544, 1372 and 49.93 Pas for chickpea protein concentrations of 32, 24 and 16%, respectively). The infinite-rate viscosity was estimated in all cases and the results were influenced by the applied rheological model and the concentration of the chickpea protein suspension (Table 1). The consistency estimated through Sisko model was significantly higher with respect to Cross and Carreau models; the consistency values from the latter models were similar and decreased when increasing the protein concentration from 16 to 32%. Table 1. Rheological parameters of the chickpea protein suspension

Rheological parameters Protein concentrate suspension 16% Zero-rate viscosity, Pas Infinite-rate viscosity, Pas Consistency, s Rate-index Standard error Area under the curve, s-1Pas Protein concentrate suspension 24% Zero-rate viscosity, Pa.s Infinite-rate viscosity, Pa.s Consistency, s Rate-index Standard error Area under the curve, s-1Pas Protein concentrate suspension 32% Zero-rate viscosity, Pas Infinite-rate viscosity, Pas Consistency, s Rate-index Standard error Area under the curve, s-1Pas Sisko 7.73410-9 12.61 0.2821 27.02 3.00210-7 223.5 0.1146 20.64 6.19910-7 647.6 2.17110-4 67.65 Rheological models Cross 60.51 0.1201 2.077 0.9852 1.559 240.5 1843 0.8516 3.750 1.096 10.87 4680.0 4835 6.45510-5 1.504 1.380 56.65 14800.0 Carreau 50.96 0.0959 2.122 0.9371 2.060 1447 0.7847 3.223 1.079 10.68 4599 3.76110-6 1.509 1.368 56.69

In Figure 2 is presented the viscosity-shear rate relationship for different chickpea protein concentrations. For shear rates ranging from 10.09 to 95.10 s-1 the viscosity was significantly higher for more concentrated protein suspensions (32%), when higher particles density caused a more accentuated internal friction. The differences between protein suspensions in terms of viscosity are very obvious for lower shear rates (10.09 25.05 s-1) and less important when the viscosity moderately decreases with the shear rate increase from 25.0 to 75.09 s-1. In all studied cases a plateau of minimum viscosities was reached for shear rates of 75.09 99.76 s-1, varying with the protein concentration. Molecular aggregates destruction and proteins tendency to align their backbone with the flowing direction due to the shearing forces are responsible for the thinning behaviour of the analyzed protein suspensions. The shear thinning behaviour is

392

St. Cerc. St. CICBIA 2011 12 (4)

RHEOLOGY OF CHICKPEA PROTEIN CONCENTRATE DISPERSIONS

very important in the industrial processing during the mixing step, transport through tubes and for choosing the appropriate design of the transport pumps. The viscosity of the chickpea protein suspensions was recorded at increasing and decreasing shear rates (upward and downward flow curve) allowing to identify the hysteresis loop. The upward-downward flow curves do not overlap due to the partial reconstruction of the protein structure when decreasing the shear rate.

140 120 Vviscosity, Pa.s 100 80 60 40 20 0 5 15

32% 24% 16%

25

35

45

55

65

75

85

95

Shear rate, 1/s

Figure 2. Viscosity vs. shear rate rheogram for different concentrations of the protein concentrate suspension (frequency 1 Hz, temperature 4C) Oscillatory frequency sweep tests Viscoelastic properties of the chickpea protein suspensions with pH 7.0 were estimated by measuring the storage modulus (G is a measure of stored energy) and loss modulus (G is a measure of dissipated energy) in oscillatory frequency conditions (0.1-10 Hz) at 20C. The oscillatory frequency sweep tests in the linear viscoelatic domain indicate that storage and loss moduli are influenced by the protein concentration. G and G had an increasing trend for the entire frequency domain (Figure 3). Moreover, G and G increased with the protein concentration. In case of all chickpea protein suspensions (16%, 24% and 32%) with pH 7.0, G values were significantly higher compared to G. The more accentuate increase of the G suggests an improvement of the elastic component of the protein suspensions, coupled with the flexibility loss, when the structure became more rigid. The plots presented in Figure 3 indicate that, for low protein concentrations, G and G, respectively exhibit plateaus in the range 3-10 Hz. The increase of both G and G with the frequency suggests continuum modifications of viscoelastic properties of the chickpea protein suspensions, coupled with the energy storage into the system.

St. Cerc. St. CICBIA 2011 12 (4)

393

IONESCU, APRODU, GURAU and BANU

Temperature sweep tests Most of the common food products are based on protein gels formed through thermal treatment that involves partial denaturation of the native polypeptide chains [27] followed by their gradual association into the gel network in appropriate thermodynamic conditions. The transformation of colloidal suspensions into threedimensional network comes together with physico-chemical modifications that can be tracked using different techniques. We used the dynamic tests to examine rheological behaviour of the chickpea protein suspensions as a function of temperature. Molecular transformations and chemical forces involved in structure formation and destruction during heating were estimated through the evolution of G, G and phase angle (delta). The tests were carried out on 16, 24 and 32% chickpea protein suspensions with pH 7.0 at a frequency of 0.05 Hz; the temperature was increased from 50 to 100C. The lower limit of the temperature range was chosen based on preliminary tests that showed no significant modifications of the rheological parameters at lower temperatures.

600 Storage molulus, Pa a 500 400 300 200 100 0 0 2 32% 24% Loss modulus, Pa a 16%

250 200 150 100 50

32% 24% 16%

a)

4 6 Frequency, Hz

10

b)

4 6 Frequency, Hz

10

Figure 3. Evolution of storage (a) and loss (b) moduli with frequency for different protein concentrations As depicted in Figure 4a, the 16% protein suspension is characterized by insignificant increase of G and G moduli in the temperature range 50-73.7C, followed by moderate increase in 75-91.4C and a sudden increase at temperatures higher than 91.4C. This behaviour agrees with previous experimental works indicating the 90C as the denaturation temperature of most vegetable proteins. For the whole studied temperature range the G modulus had rather high values compared to G modulus indicating a slight prevalence of the viscous component on the elastic one. The phase angle decreased for the whole studied temperature range. Delta values lower than 45 indicate the fluid nature of the analyzed protein suspensions. A similar behavior was noticed in case of the 24% chickpea protein suspensions, when G and G moduli were substantially higher (results not shown). In the 71-100C temperature range the chickpea proteins were progressively denaturated, most of the energy being stored and only a small part dissipated (G > G). In case of the 32% chickpea protein suspensions, important differences between G and G values were found mostly for the temperatures over 51C (Figure 4b). The very

394

St. Cerc. St. CICBIA 2011 12 (4)

RHEOLOGY OF CHICKPEA PROTEIN CONCENTRATE DISPERSIONS

high values of G compared to G indicate that the protein suspensions behave like solids, when deformations are essentially elastic or recoverable.

Storage (G') and moduli, loss (G") Pa Storage and loss

Storage (G') and loss (G") moduli, Pa

9,00E+00 8,00E+00 8 7,00E+00 6,00E+00 6 5,00E+00 4,00E+00 4 3,00E+00 2,00E+00 2 1,00E+00 0,00E+00 0

Storage and loss moduli, Pa

1,00E+01 10

G' G" Delta

85 85 75 65 65 55 45 45 35 25 25 15 5 5 Delta, gradeo Delta,

1600 1600 1400 1200 1200 1000 800 800 600 400 400 200 0 0 45 45

G', Pa G", Pa Delta, grade

50 50 45 40 40 35 30 30 25 20 20 15 10 10 5 0 0

45 45

55 55

(a)

65 75 85 75 85 65 Temperature,o oC Temperature, C

95 95

55 55

(b)

65 75 85 65 75 85 Temperature, oCoC Temperature,

95 95

Figure 4. Evolution of storage modulus, loss modulus and delta angle with temperature for protein suspensions of 16% (a) and 32% (b) Influence of NaCl Salt is frequently used as food ingredient for its multiple roles. Salt helps myofibrillar proteins solubilisation in case of the minced meat-based products, has a plasticizing effect on the wheat dough and reduces glass transition temperature. In order to study the influence of the pH and ionic strength on the chickpea protein gel formation and gel properties, the rheological parameters of the samples with pH 7.0 and 4.5 and salt concentrations of 0.2, 0.5 and 1 M were evaluated in the temperature range 6-80C. The evolution of the rheological parameters G, G, and delta corresponding to the chickpea protein suspensions with pH 7.0 are presented in Figure 5. In case of the chickpea protein suspensions with NaCl, the G vs. temperature curves presented three different domains. The first one is between 6 and 58.7C and is characterized by a continuum decrease of G values, indicating proteins denaturation and energy storage. In the 58.7-65.2C range, a slight increase of G was noticed, indicating the beginning of sol-gel transition. The temperature domain over 65.2C was characterized by a sudden increase of the storage modulus until 80C and protein suspension conversion to high viscous gels. The loss modulus (G) had a similar patter but lower values compared to G. Since in the given experimental conditions the G and G do not crossover, was not possible to establish the gelling temperature [28]. A different behaviour of delta was noticed, compared to storage and loss moduli. A plateau of maximum delta values was obtained for 53.4 60.9C followed by a sudden decrease. Maximum gelling occurs when tan remains constant or decreases [29]. The quaternary structure of the protein seems to be stabilized by 0.2M salt, and the lack of molecular expansion results in a less viscous protein system [30]. In case of the high ionic strength continuum phase, the globulins that represent 62.7% of the chickpea proteins [31] were better solubilised and determined a slight decrease of G and G moduli (Figure 5). Concerning the sample with 0.2M NaCl, for extreme temperatures, the G and G moduli were lower compared to the blank sample: at 5C the G and G were 188.4 and 55.26 Pa for the sample with 0.2M NaCl compared to 210.2 and 81.47 Pa for the blank sample, while at 80C the G and G were 96.5 and 20.61 Pa, for the

St. Cerc. St. CICBIA 2011 12 (4)

Delta, Delta, grade

moduli, Pa

395

IONESCU, APRODU, GURAU and BANU

sample with 0.2M NaCl, compared to 177.8 and 39.67 Pa for the blank sample; the delta values at 80C were 12.05 for the sample with NaCl and 12.35 for the blank sample. G decreases in the temperature range 6-53.4C, remains constant until 63C and afterwards increases (the increase is smaller than the blank sample). In the protein systems with 0.2M NaCl, the G values are smaller compared to G. The difference between the two moduli in the gelling temperature range was significantly higher compared to the blank sample. The high solubility of the protein reduces the protein aggregation and gels rigidity [32]. The increase of NaCl concentration up to 0.5 and 1 M influences the rheological properties of the chickpea protein dispersions. The trend of the curves indicating the rheological parameters as function of temperature is significantly different compared to the sample with 0.2M NaCl and blank sample (Figure 5). The G modulus decreases first to 99.8 Pa at 45.8C in case of the sample with 0.5M NaCl and to 47.9 Pa at 44.7C in case of the sample with 1.0 M NaCl, and afterwards increases. The salt concentration increase causes the decrease of the gelling temperature plateau to 41.5 47.9C (sample with 0.5M NaCl) and 41.5 49C (sample with 1M NaCl), compared to 54.4-63oC (sample with 0.2M NaCl) and 55.5-58.7oC (blank sample). A similar evolution was noticed in case of G witch had lower values compared to G. The delta values decreased for all samples with NaCl indicating the tendency to form gel networks similar to the solid state structures.

Storage and loss moduli, Pa P 400 Storage and loss moduli, Pa P 300 200 100 0 5 400 300 200 100 0 5 15 25 35 45 55 o Temperature, C 65 75 15 25

G' G" Delta

G' G" Delta

a)

40 30

o

400 300 200 100 0 5 15

G' G" Delta

b)

40 30 20 10 0 Delta, Delta,

o

20 10 0 35 45 55

o

65

75

Delta,

25

Temperature, C Storage and loss moduli, Pa P Storage and loss moduli, Pa P

35 45 55 o Temperature, C

65

75

c)

40 30

o

400 300 200 100 0 5 15

G', Pa G", Pa Delta

d)

40 30 20 10 0

o

20 10 0

Delta,

25

35 45 55 o Temperatura, C

65

75

Figure 5. Evolution of storage modulus, loss modulus and delta angle with temperature for protein suspensions of 24 %, pH 7.0 (a), supplemented with 0.2 M NaCl (b), 0.5 M NaCl (c) and 1.0 M NaCl (d)

396

St. Cerc. St. CICBIA 2011 12 (4)

RHEOLOGY OF CHICKPEA PROTEIN CONCENTRATE DISPERSIONS

Salt concentrations higher than 0.2M improve rheological properties of the samples with pH 7.0 at thermal treatment, when behave like gels with prevalent elastic modulus. When the salt concentration is high (higher than 0.2M) the water molecules are attracted by the salt ions causing protein dehydration and solubility decrease due to the interprotein hydrophobic interactions. Similar effects of NaCl addition was noticed in case of the samples with pH 4.5 when the G and G moduli increased with the salt concentration (Figures 6). The blank sample (pH 4.5) behaved like protein solutions with extremely low elastic and viscous components [18 - 19]; the G was lower than G until 55.5C which is cross-over point, also considered as gelling temperature (Figure 6). In case of the samples with 0.2 and 0.5 M NaCl (pH 4.5), the G and G moduli increased for the whole temperature range compared to the blank sample. This behaviour is due to the salting-in effect when the protein solubility increases as a consequence of pH 4.5 combined with the ionic strength up to 0.5M NaCl. For higher salt concentration (1M) the G and G moduli are smaller as a consequence of the salting-out effect when the protein solubility is decreased.

Storage and loss moduli, Pa P 700 Storage and loss moduli, Pa P 600 500 400 300 200 100 0 5 20 35 50 65 o Temperature, C 80

a)

G' G" Delta

100 80 Delta, 60 40 20 0

o

700 600 500

b)

G' G'' Delta

100 80 Delta, Delta,

o

400 300 200 100

60 40 20 0 5 20 35 50 65 o Temperature, C 80 100 80 60 40 20 0 5 20 35 50 65 o Temperature, C 80

Storage and loss moduli, Pa P

600 500

Storage and loss moduli, P Pa

700

c)

G' G" Delta

100 80 Delta, 60 40 20 0

o

700 600 500 400 300 200 100 0

d)

G' G" Delta

400 300 200 100

0 5 20 35 50 65 o Temperature, C

80

Figure 6. Evolution of storage modulus, loss modulus and delta angle with temperature for protein suspensions of 24 %, pH 4.5 (a), supplemented with 0.2M NaCl (b), 0.5M NaCl (c) and 1.0M NaCl (d) The stiffness of the gels was influenced by pH and salt concentration, being higher at 90C for pH 4.5 compared to pH 7.0 (Figures 5, 6). Proteins association and dissociation during heating depend on pH and salt concentration. At pH 4.5, close to isoelectric point, the proteins precipitate and are highly networked, while at pH 7.0 the

St. Cerc. St. CICBIA 2011 12 (4)

397

IONESCU, APRODU, GURAU and BANU

protein gel is less rigid since the proteins are better soluble. Our results are in agreement with the observations of Puppo et al. [21], who showed that pH and ionic strength influence the gelling properties of soy globular proteins. CONCLUSIONS Rheological properties of chickpea protein concentrate were investigated by conducting two types of tests: flow tests and dynamic tests. The chickpea protein concentrate presented non-newtonian shear thinning behavior and the rheology during upward shearing can be well described by Sisko, Carreau and Cross models. The oscillatory frequency sweep tests in the linear viscoelatic domain indicated increasing G and G moduli for the entire frequency domain (0.1-10 Hz) at 20C. Concerning thermal rheological studies of the chickpea proteins (16, 24 and 36%), our results indicate that gels formation was highly influenced by protein concentration, pH and NaCl concentration. REFERENCES

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. Singh, U., Subrahmanyam, N.: Cooking quality and nutritional attributes of some newly developed cultivars of chickpea (Cicer arietinum L.), Journal of the Science of Food and Agriculture, 1991, 55, 3746; Gil, J., Nadal, S., Luna, D., Moreno, M.T., De Haro, A.: Variability of some physico-chemical characters in Desi and Kabuli chickpea types, Journal of the Science of Food Agriculture, 1996, 71, 179-184; Poltronieri, F., Aras, J.A.G., Colli, C.: Extrusion and iron bioavailability in chickpea (Cicer arietinum L.), Food Chemistry, 2000, 70, 175-178; Singh, K.B.: Chickpea (Cicer arietinum L.), Field Crops Research, 1997, 161- 170. Clemente, A., Vioque, J., R. Snchez-Vioque, R.: Effect of processing on water adsorption and softening kinetics in chickpea (Cicer arietinum L.) seeds, Journal of the Science of Food and Agriculture, 1998, 78, 169-174; Kaur, M., Singh, N., Sodhi, N.S.: Physicochemical, cooking, textural and roasting characteristics of Chickpea (Cicer arietinum L.) cultivars, Journal of Food Engineering, 2005, 69, 511-517; Grelda, A.Y.F., Moreno-Valencia, J.G., Del Refugio, F.V., Barron-Hoyos, J.M.: Isolation and partial characterization of starches from dry beans (Phaseolus vulgaris) and chickpeas (Cicer arietinum) grown in Sonora, Mexico, Starch, 1997, 49, 341-345; Singh, D.G., Abas, A.W., Kaur, D., Sogi Singh, D.S.: Characterisation and functional properties of proteins of some Indian chickpea (Cicer arietinum) cultivars, Journal of the Science of Food and Agriculture, 2008, 88 (5), 778-786; Friedman, M.: Nutritional value of proteins from different food sources: A review, Journal of Agricultural and Food Chemistry, 1996, 44, 6-29; Santiago Cardoso, R.A., Moreira-Arajo, R.S.R., Pinto de Silva, M.E.M., Aras, J.A.G.: The potential of extruded chickpea, corn and bovine lung for malnutrition programs, Innovative Food Science & Emerging Technologies, 2001, 2-3, 203-209; Paredes-Lopez, O., Ordorica-Falomir, C., Olivares-Vazquez, M.R.: Chickpea protein isolates: physicochemical, functional and nutritional characterization, Journal of Food Science, 1991, 56 (3), 726-729; Snchez-Vioque, R., Clemente, A., Vioque, J., Bautista, J., Milln, F.: Protein isolates from chickpea (Cicer arietinum L.): chemical composition, functional properties and protein characterization, Food Chemistry, 1999, 64, 237-243;

398

St. Cerc. St. CICBIA 2011 12 (4)

RHEOLOGY OF CHICKPEA PROTEIN CONCENTRATE DISPERSIONS 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. Kinsella, J.E.: Functional properties of soy proteins, Journal of the American Oil Chemists' Society, 1979, 56, 940 958; AOAC (1995). Official methods of analysis (16th ed.), Washington, DC, Association of Official Analytical Chemists; AOAC (1991). Official methods of analysis (15th ed.), Washington, DC, Association of Official Analytical Chemists; AOAC (1984). Official methods of analysis (11th ed.), Washington, DC, Association of Official Analytical Chemists; Sathe, S.K., Deshpande, S.S., Salunkhe, D.K.: Functional properties of lupin seeds (Lupinus mutabilis) proteins and protein concentrates, Journal of Food Science, 1982, 47, 491-497; Giboreau, A., Cuvelier, G., Launay, B.: Rheological behaviour of three biopolymer/water systems, with emphasis on yield stress and viscoelastic properties, Journal of Texture Study, 1994, 25, 119137; Ross-Murphy, S.B.: Rheological characterization of gels, Journal of Texture Study, 1995, 26, 391400; Lazaridou, A., Duta, D., Papageorgiou, M., Belc, N., Biliaderis, C.G.: Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations, Journal of Food Engineering, 2007, 79, 10331047; Puppo, M.C., An, M.C.: Rheological properties of acidic soybean protein gels: Salt addition effect, Food Hydrocolloids, 1999, 13,167 176; Gabriele, D., De Cindio, B., DAntona, P.: A weak gel model for foods, Rheologica Acta, 2001, 40, 120-127; Tovar, C.A., Franco, I., Carballo, E.M.J., Cmara, M.J., Carballo, J., Cerdeiria, C.: Influence of the ripening time on the viscoelastic behaviour of Tetilla cheese, Food Science and Technology International, 2004, 10, 297-304; Mleko, S., Kristinsson, H.G., Liang, Z., Gustaw, W.: Rheological properties of foams generated from egg albumin after pH treatment, Lebensmittel Wissenschaft Und Technologie Food Science and Technology, 2007, 40, 908-914; Ulloa, J.A., Garcia-Quinterro, Z.H., Valencia, M.E.: Obtention of a protein concentrate of chickpea (Cicer arietinum) by ultrafitration, Archivos latinoamericanos de nutricin, 1991, 41 (4), 595-608; Yao, B., Figueiredo, A.A., Rao, M.A.: Rheological properties of mesquite seed gum in steady and dynamic shear, Lebensmittel Wissenschaft und Technologie, 1994, 27, 151-157; Coffman, C.W., Garcia, V.V.: Functional properties and amino acid content of a protein isolate from mung bean flour, Journal of Food Technology, 1977, 12, 473-484; Clark, A.H., Ross-Murphy, S.B.: Structural and mechanical properties of biopolymer gels, Advances in Polymer Science, 1987, 83, 57-192; Lai, M.F., Lii, C.: Rheological and thermal characteristics of gel structures from various agar fractions, International Journal of Biological Macromolecules, 1997, 21 (1-2), 123-130; Urbanski, G.E., Wei, L.S., Nelson, A.I., Steinberg, M.P.: Effect of solutes on soy flour and its components, Journal of Food Science, 1982, 47, 792795; Chavan, J.K., Kadam, S.S., Salunkhe, D.K.: Biochemistry and technology of chickpea (Cicer arietinum L.) seeds, CRC Critical Reviews in Food Science and Nutrition, 1987, 25 (2), 107-158; Verheul, M., Roefs, S.P.F.M.: Structure of particulate whey protein gels: Effect of NaCl concentration, pH, heating temperature, and protein composition, Journal of Agricultural and Food Chemistry, 1998, 46, 49094916.

St. Cerc. St. CICBIA 2011 12 (4)

399

Das könnte Ihnen auch gefallen

- Team Work: Team Work Poems - Others Poems - Html#Ixzz2SkojeaesDokument1 SeiteTeam Work: Team Work Poems - Others Poems - Html#Ixzz2SkojeaesCHOFOR VITALISNoch keine Bewertungen

- DocumentDokument4 SeitenDocumentCHOFOR VITALISNoch keine Bewertungen

- Suggestions For Article CorrectionsDokument2 SeitenSuggestions For Article CorrectionsCHOFOR VITALISNoch keine Bewertungen

- HomeDokument21 SeitenHomeCHOFOR VITALISNoch keine Bewertungen

- Skills Attrib Qual PDFDokument2 SeitenSkills Attrib Qual PDFEvans MumiasNoch keine Bewertungen

- UNAOC-EF Summer School Application GuidelinesDokument3 SeitenUNAOC-EF Summer School Application GuidelinesCHOFOR VITALISNoch keine Bewertungen

- A Study of Various Factors Determining The Stability of MoleculesDokument5 SeitenA Study of Various Factors Determining The Stability of MoleculesCHOFOR VITALISNoch keine Bewertungen

- This Day New Light Will Shine Upon The EarthDokument1 SeiteThis Day New Light Will Shine Upon The EarthCHOFOR VITALISNoch keine Bewertungen

- FermentedDokument108 SeitenFermentedCHOFOR VITALIS100% (2)

- SPM Add Maths Formula List Form5Dokument44 SeitenSPM Add Maths Formula List Form5Norman de Kattun100% (1)

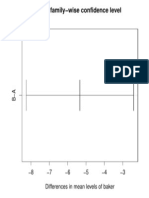

- 8 7 6 5 4 3 Differences in Mean Levels of BakerDokument1 Seite8 7 6 5 4 3 Differences in Mean Levels of BakerCHOFOR VITALISNoch keine Bewertungen

- Plot Nuages.1pdfDokument1 SeitePlot Nuages.1pdfCHOFOR VITALISNoch keine Bewertungen

- Form 5 Additional Maths NoteDokument10 SeitenForm 5 Additional Maths NoteEric WongNoch keine Bewertungen

- EMULSIFIED MEAT PRODUCTS ReviewDokument7 SeitenEMULSIFIED MEAT PRODUCTS ReviewCHOFOR VITALISNoch keine Bewertungen

- Animal FatsDokument8 SeitenAnimal FatsCHOFOR VITALISNoch keine Bewertungen

- Cover Page CADokument1 SeiteCover Page CACHOFOR VITALISNoch keine Bewertungen

- Presentation1 2Dokument16 SeitenPresentation1 2CHOFOR VITALIS100% (1)

- 50 Ways of Promoting PeaceDokument8 Seiten50 Ways of Promoting PeaceCHOFOR VITALISNoch keine Bewertungen

- Fluidized BedsDokument26 SeitenFluidized BedsCHOFOR VITALISNoch keine Bewertungen

- Your Word Is Your Wand PDFDokument46 SeitenYour Word Is Your Wand PDFCHOFOR VITALISNoch keine Bewertungen

- Assignment Group 6Dokument4 SeitenAssignment Group 6CHOFOR VITALISNoch keine Bewertungen

- Pilot-Scale Lactic Acid Production Via Batch Culturing of Lactobacillus Sp. RKY2 Using Corn Steep Liquor As A Nitrogen SourceDokument6 SeitenPilot-Scale Lactic Acid Production Via Batch Culturing of Lactobacillus Sp. RKY2 Using Corn Steep Liquor As A Nitrogen SourcekopisusumantapNoch keine Bewertungen

- Eng Grade 1Dokument4 SeitenEng Grade 1CHOFOR VITALISNoch keine Bewertungen

- Singapore: Singa PHD Awards For International Students in Singapore, 2014/15Dokument1 SeiteSingapore: Singa PHD Awards For International Students in Singapore, 2014/15CHOFOR VITALISNoch keine Bewertungen

- I So StandardsDokument1 SeiteI So StandardsCHOFOR VITALISNoch keine Bewertungen

- Article To AssignmentDokument1 SeiteArticle To AssignmentCHOFOR VITALISNoch keine Bewertungen

- Prospectus Scholarships 2013Dokument4 SeitenProspectus Scholarships 2013tamilarasansrtNoch keine Bewertungen

- 511 Project Partner Roles and ResponsibilitiesDokument2 Seiten511 Project Partner Roles and ResponsibilitiesCHOFOR VITALISNoch keine Bewertungen

- Can Christianity Be CoolDokument3 SeitenCan Christianity Be CoolCHOFOR VITALISNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Spreadsheet Practice Exercises-2016FDokument40 SeitenSpreadsheet Practice Exercises-2016FDharneeshkarDandy92% (12)

- Early Thermal CrackingDokument2 SeitenEarly Thermal Crackingsudhir12345Noch keine Bewertungen

- Mikrotik Traffic Control With HTBDokument63 SeitenMikrotik Traffic Control With HTBSigit PrabowoNoch keine Bewertungen

- DB Irradiance Sensor Si-Series en 20171016Dokument3 SeitenDB Irradiance Sensor Si-Series en 20171016Solar ProjectsNoch keine Bewertungen

- Lucifer's Mirror and The Emancipation of OnenessDokument23 SeitenLucifer's Mirror and The Emancipation of OnenessTony BermansederNoch keine Bewertungen

- Emulsions: - Part 1 Preparation Methods (Some) PropertiesDokument52 SeitenEmulsions: - Part 1 Preparation Methods (Some) PropertieschandramohanNoch keine Bewertungen

- FTKM 0419 B L (Leaflet)Dokument2 SeitenFTKM 0419 B L (Leaflet)Wan SyahlanNoch keine Bewertungen

- Question Paper Code:: (10×2 20 Marks)Dokument3 SeitenQuestion Paper Code:: (10×2 20 Marks)PradeepNoch keine Bewertungen

- (Pakget - PK) Maths MCQS Book (Pakget - PK)Dokument42 Seiten(Pakget - PK) Maths MCQS Book (Pakget - PK)Mohammad AshfaqNoch keine Bewertungen

- Scania SOPS ParametersDokument32 SeitenScania SOPS Parametersjose breno vieira silva89% (19)

- Design of Machine Elements - IDokument69 SeitenDesign of Machine Elements - IAnonymous utfuIcnNoch keine Bewertungen

- Chapter 4 Solutions To Exercises PDFDokument70 SeitenChapter 4 Solutions To Exercises PDFWilly Rodríguez GuerreroNoch keine Bewertungen

- Excel Sales Report TemplateDokument3 SeitenExcel Sales Report TemplateMark11311100% (1)

- Precept 9Dokument24 SeitenPrecept 9Julia HinesNoch keine Bewertungen

- ELTE 307 - DR Mohamed Sobh-Lec - 5-1-11-2022Dokument28 SeitenELTE 307 - DR Mohamed Sobh-Lec - 5-1-11-2022Lina ElsayedNoch keine Bewertungen

- KHDtrack Standard 7Dokument30 SeitenKHDtrack Standard 7Aziz AzizNoch keine Bewertungen

- Learning Activity Sheet In: Computer Systems ServicingDokument12 SeitenLearning Activity Sheet In: Computer Systems ServicingCarvalds 0315100% (1)

- Recent Advances in Biophoton Research and Its Applications - Quantum Theory of Biophoton EmissionDokument54 SeitenRecent Advances in Biophoton Research and Its Applications - Quantum Theory of Biophoton Emissionfrederic dugenouxNoch keine Bewertungen

- HMT16 MarksDokument12 SeitenHMT16 MarkstagoreboopathyNoch keine Bewertungen

- Introduction To The Visual Basic Programming LanguageDokument24 SeitenIntroduction To The Visual Basic Programming Languageapi-3749038100% (1)

- Strategik Sains THN 4Dokument9 SeitenStrategik Sains THN 4fletchertchrNoch keine Bewertungen

- Irhlf77214 250V Radhard N MosfetDokument9 SeitenIrhlf77214 250V Radhard N MosfetarsebiscuitsNoch keine Bewertungen

- Icc Esr-1385 Kb3 MasonryDokument4 SeitenIcc Esr-1385 Kb3 MasonryxpertsteelNoch keine Bewertungen

- A Study of Martensitic Stainless Steel AISI 420 Modified Using Plasma NitridingDokument6 SeitenA Study of Martensitic Stainless Steel AISI 420 Modified Using Plasma NitridingmanishtubNoch keine Bewertungen

- Programa A4Q Selenium Tester FoundationDokument3 SeitenPrograma A4Q Selenium Tester FoundationAdrian MazgaNoch keine Bewertungen

- 05 Traps PDFDokument17 Seiten05 Traps PDFDevinaacsNoch keine Bewertungen

- Basic of Statistical DataDokument15 SeitenBasic of Statistical DatacataiceNoch keine Bewertungen

- Je Tire 006084Dokument7 SeitenJe Tire 006084AmerNoch keine Bewertungen

- Robotics 1 - Coordinate SystemDokument102 SeitenRobotics 1 - Coordinate System15.Rushikesh IrabattinNoch keine Bewertungen

- About Ramfs Rootfs InitramfsDokument7 SeitenAbout Ramfs Rootfs InitramfsNavaneethNoch keine Bewertungen