Beruflich Dokumente

Kultur Dokumente

Purga

Hochgeladen von

capitaotaylorOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Purga

Hochgeladen von

capitaotaylorCopyright:

Verfügbare Formate

Purging compounds for use when molding thermoplastics

Injection molding

Material and color changes

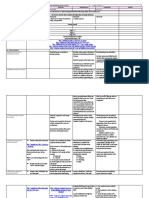

Frequent material and color changes are a cost-intensive factor in plastics processing. They are often associated with significant time and effort, large quantities of granules, long start-up times and production downtime. Purging processes can sometimes take hours to complete, it often being necessary to disassemble the plasticating unit and then mechanically clean it. The market offers emulsions, powders, granules and liquids for purging. These products are intended to minimize the time required for purging. The purging compounds listed in the table were used at Bayer MaterialScience AG (Polycarbonates Business Unit) to test their efficiency. Analysis focused on the change in color (from black to

natural) of a specific molded part made of Bayer MaterialScience thermoplastics. Purging compounds with a chemical, chemical/mechanical and exclusively mechanical effect were tested. In addition to the purging effect, the potential wear on the plasticizing unit was tested by ENGEL AUSTRIA GmbH. The granular products were investigated to determine their abrasive or corrosive effect. Problems encountered in practice vary greatly. The user must therefore choose a purging compound that best meets his needs. The criteria listed in the table can facilitate this decision-making process.

page 1 of 4 File No. PCS 1102 e, replaces ATI 1102 e dated 08.04.2008 Edition 2011-10-10

Technical Information

Trade name (delivery form, mode of action) Purgex 527 plus (concentrate in granular form; chemical effect)

Manufacturer, distributor Neutrex, Inc., www.neutrex.com/ Kunststoff-technik Ulrike Lapacz, www.kunststofftechnik-lapacz.de

Mixing ratio

Processing temperature range; [ C] 150 320 (up to 350, but without soak)

Suitable for hot runner molds*1

Abrasive and corrosive effect *2

special notes

Environmental concerns

Add 8% of the concentrate

yes

Abrasive Purge intermittently, see effect minor gas formation, appears to apply several times and manufacturer briefly allow to soak be possible Abrasive Gas odor, apply several effect see times and briefly allow appears to manufacturer to soak be possible Can have a very abrasive and, under Set screw speed as certain high as possible, see conditions, increasing temperature manufacturer also a improves purging effect corrosive effect Abrasive Purge intermittently, effect faint odor formation, see appears to solids can stuck in the manufacturer be possible nozzle Purge intermittently, no see streaking with the manufacturer subsequent material*1

Rapid Purge IG Rapid Purge, www.rapidpurge.com/ 3000 (concentrate in granular form; Schlicht Handelsgesell-schaft oHG, www.schlicht-gmbh.com chemical effect) Sun Plastech Inc. Asaclean New www.asahi-kasei.co.jp/asaclean/en/ Ex (granules; mechanicalVelox GmbH, chemical effect) www.velox.com

30% to 50% of Rapid up to 300 (up to Purge with 70% to 320 possible, 50% of the same or but flows out) subsequent material

yes

used straight

200 to 360

no, but special material is available in this case

Romatin AG/ 30% to 50% of Rozylit Rozylit T with 70% to 50% of the (granules, Kunststofftechnik Mittelhuser, same or subsequent mechanical kunststofftechnik@mittelhaeuser.de material effect) Lusin Clean 25% of Lusin Clean 1500 Chem-Trend with (concentrate in www.chemtrend.com 75% Polycarbonat granular form; chemical effect)

*1

200 to 300

no

180 to 320

yes

No

According to manufacturer, *2According to ENGEL AUSTRIA Gmbh

It is recommended for all purging compounds and processes to extract the resulting vapors. Wear a face mask and gloves. (See also the respective Instructions for use.)

All of the information, documents and illustrations published on this website are the exclusive property of BAYER. Permission for their use is given on the proviso that the copyright note appears on all copies, that only personal and not commercial use is made of the information, that the information is not altered in any way and that all illustrations on the website are used only in conjunction with the associated texts. BAYER assumes no liability or warranties with respect to the information, documents and illustrations on the website. BAYER is not responsible for any damage of whatever nature that might arise from the use or existence of the website and the information, documents and illustrations it contains. The user bears full responsibility for all risks to him that might arise from the use of this website. BAYER reserves the right to amend or supplement the documents and information provided on the website at any time and without prior notice. The user of this website is fully responsible for the content and correctness of details he or she sends to BAYER, as well as for non-violation of any third-party rights that may be involved in such details. We have carefully checked this Internet presentation and make every effort to continually expand and update it. However, we cannot accept responsibility for errors, omissions, or possible obsolescence. This information and our technical advice - whether verbal, in writing or by way of trials - are given in good faith but without warranty, and this also applies where proprietary rights of third parties are involved. Our advice does not release you from the obligation to check its validity and to test our products as to their suitability for the intended processes and uses. The application, use and processing of our products and the products manufactured by you on the basis of our technical advice are beyond our control and, therefore, entirely your own responsibility. Our products are sold in accordance with the current version of our General Conditions of Sale and Delivery. Editor: Global Innovations - Polycarbonates Bayer MaterialScience AG D-51368 Leverkusen, Germany www.bayermaterialscience.de pcs-info@bayermaterialscience.com page 4 of 4 File No. PCS 1102 e, replaces ATI 1102 e dated 08.04.2008 Edition 2011-10-10

Technical Information

Das könnte Ihnen auch gefallen

- Access The Facilitator Product Catalog - Franklin Covey (PDFDrive)Dokument108 SeitenAccess The Facilitator Product Catalog - Franklin Covey (PDFDrive)DJENNANENoch keine Bewertungen

- Busselton Water Operational Audit and Asset Management ReviewDokument42 SeitenBusselton Water Operational Audit and Asset Management Reviewpipoy555222Noch keine Bewertungen

- Purchasing Dictionairy PDFDokument90 SeitenPurchasing Dictionairy PDFEmba MadrasNoch keine Bewertungen

- Presentacion Diego Sales Plan Assa Abloy 2023Dokument12 SeitenPresentacion Diego Sales Plan Assa Abloy 2023damaNoch keine Bewertungen

- Supply Chain Management - A Learning Perspective - CourseraDokument3 SeitenSupply Chain Management - A Learning Perspective - CourseraSana Bhittani0% (1)

- Stocking Strategy For Service Parts - A Case StudyDokument18 SeitenStocking Strategy For Service Parts - A Case StudyTammy GyaNoch keine Bewertungen

- Facility Management Reporting: The Value of Metrics & KpisDokument46 SeitenFacility Management Reporting: The Value of Metrics & KpisRajeshwari MgNoch keine Bewertungen

- Motoman AR1440: Arc Welding With The AR-seriesDokument2 SeitenMotoman AR1440: Arc Welding With The AR-seriesMayank JainNoch keine Bewertungen

- Gestion de AlmacenDokument11 SeitenGestion de Almacenjuan carlosNoch keine Bewertungen

- Project Manufacturing A Complete Guide - 2020 EditionVon EverandProject Manufacturing A Complete Guide - 2020 EditionNoch keine Bewertungen

- Plan de Vuelo Nacional 2015Dokument66 SeitenPlan de Vuelo Nacional 2015Eduardo RamirezNoch keine Bewertungen

- White Belt Certification A Complete Guide - 2020 EditionVon EverandWhite Belt Certification A Complete Guide - 2020 EditionNoch keine Bewertungen

- CBEX Elite 100-1200 Operation and Maintenance ManualDokument146 SeitenCBEX Elite 100-1200 Operation and Maintenance Manualfauzi endra100% (1)

- Maintenance Spare Parts Logistics PDFDokument9 SeitenMaintenance Spare Parts Logistics PDFAnonymous ABPUPbKNoch keine Bewertungen

- Assessment Guidelines 2020 - CombinedDokument48 SeitenAssessment Guidelines 2020 - CombinedAlfonsoNoch keine Bewertungen

- LO 5 Handout Maintenace Store and CMMS ManagmentDokument14 SeitenLO 5 Handout Maintenace Store and CMMS Managmentsushil.vgiNoch keine Bewertungen

- Filling Your Pipeline SlipsheetDokument2 SeitenFilling Your Pipeline SlipsheetCoco MaciNoch keine Bewertungen

- Stocking Strategy For Service Parts A Case StudyDokument19 SeitenStocking Strategy For Service Parts A Case StudyFernando GómezNoch keine Bewertungen

- Service Value Chain Models in Higher EducationDokument6 SeitenService Value Chain Models in Higher EducationGeorge MarchanNoch keine Bewertungen

- Spare Parts Inventory Management: A Literature Review: SustainabilityDokument23 SeitenSpare Parts Inventory Management: A Literature Review: SustainabilitySana MusroorNoch keine Bewertungen

- 17 CSCMP Processes Satndard 2009 PDFDokument64 Seiten17 CSCMP Processes Satndard 2009 PDFMarcel C.Noch keine Bewertungen

- Chase Consulting - The Business Case Guide PDFDokument26 SeitenChase Consulting - The Business Case Guide PDFmanuel estradaNoch keine Bewertungen

- Maintenance, Repair and Operation (MRO) : Market Challenges and Cost Saving OpportunitiesDokument12 SeitenMaintenance, Repair and Operation (MRO) : Market Challenges and Cost Saving Opportunitiesfercba1Noch keine Bewertungen

- 66112438X 2Dokument12 Seiten66112438X 2Zayd AhmedNoch keine Bewertungen

- CSCP MaintenanceDokument11 SeitenCSCP MaintenanceSaurabh ShindeNoch keine Bewertungen

- PlantPAx EXTERNAL PresentationDokument17 SeitenPlantPAx EXTERNAL PresentationAnonymous qiAIfBHnNoch keine Bewertungen

- 1A Basics of Methods EngineeringDokument7 Seiten1A Basics of Methods EngineeringLesterNoch keine Bewertungen

- Roto-Flo Instruc Manual-ORIGINAL Adobe 5 8 08Dokument73 SeitenRoto-Flo Instruc Manual-ORIGINAL Adobe 5 8 08nestor100% (1)

- Cpim Modules ReferencesDokument5 SeitenCpim Modules ReferencesZayd AhmedNoch keine Bewertungen

- Mexico, Your Ally For Innovation (Book) PDFDokument124 SeitenMexico, Your Ally For Innovation (Book) PDFCarlos M. TalaveraNoch keine Bewertungen

- Training Within IndustryDokument5 SeitenTraining Within Industryapi-313899066Noch keine Bewertungen

- The Supply Chain Management Article4Dokument24 SeitenThe Supply Chain Management Article4Elzein Amir ElzeinNoch keine Bewertungen

- Enticing Fashions LTD Designs and Manufactures Upscale Women S Clothing TheDokument1 SeiteEnticing Fashions LTD Designs and Manufactures Upscale Women S Clothing Thehassan taimourNoch keine Bewertungen

- 2.3. ASCM ProcurementDokument10 Seiten2.3. ASCM ProcurementRasel AhmedNoch keine Bewertungen

- NSSMC en Ar 2013 All V Nippon SteelDokument56 SeitenNSSMC en Ar 2013 All V Nippon SteelJatin KaushikNoch keine Bewertungen

- CMRP, Pillar4Dokument89 SeitenCMRP, Pillar4mmblakoshaNoch keine Bewertungen

- Managing Spare PartsDokument3 SeitenManaging Spare PartsPrasad PnNoch keine Bewertungen

- 02 Oliver Wight Effective-Demand-planningDokument12 Seiten02 Oliver Wight Effective-Demand-planningRicardo MontecéNoch keine Bewertungen

- Lean Playbook Series - The TPM Playbook - A Step-By-step Guideline For The Lean PractitionerDokument37 SeitenLean Playbook Series - The TPM Playbook - A Step-By-step Guideline For The Lean PractitionerMatheus NascimentoNoch keine Bewertungen

- Fish BoneDokument2 SeitenFish BoneRia FitriyanaNoch keine Bewertungen

- A Framework For Lean Manufacturing ImplementationDokument22 SeitenA Framework For Lean Manufacturing Implementationbramwill.bbNoch keine Bewertungen

- Acad98 004R1Dokument66 SeitenAcad98 004R1michael1971Noch keine Bewertungen

- Asset Management Day 01Dokument50 SeitenAsset Management Day 01Ra Nu100% (1)

- The Role of Operations Maintenance in Asset Management PDFDokument30 SeitenThe Role of Operations Maintenance in Asset Management PDFsayyed ali sayyedy poorNoch keine Bewertungen

- Theory of ConstraintsDokument12 SeitenTheory of ConstraintsVikas NandanwarNoch keine Bewertungen

- Certified Application Developer ProgramDokument6 SeitenCertified Application Developer ProgramJayModiNoch keine Bewertungen

- Knowledge Management in Manufacturing SectorDokument22 SeitenKnowledge Management in Manufacturing SectorVaishnavi PreranaNoch keine Bewertungen

- FlippedClassroom PDFDokument18 SeitenFlippedClassroom PDFspleen1976Noch keine Bewertungen

- Chase - Shankar - JacobsDokument44 SeitenChase - Shankar - JacobsAleena IdreesNoch keine Bewertungen

- Supply Chain Management and The Value ChainDokument5 SeitenSupply Chain Management and The Value ChainAwanish PandeyNoch keine Bewertungen

- Vda 5733 JB 2022 en Web RZ PDFDokument131 SeitenVda 5733 JB 2022 en Web RZ PDFSoufian BirjaliNoch keine Bewertungen

- Question 1 of 15Dokument9 SeitenQuestion 1 of 15mohamed goudaNoch keine Bewertungen

- Recruitment & Selection of Sales Personnel FinaleDokument45 SeitenRecruitment & Selection of Sales Personnel FinalezampakNoch keine Bewertungen

- Merrill, Peter Do It Right The Second Time, Second Edition Benchmarking Best Practices in The Quality Change ProcessDokument400 SeitenMerrill, Peter Do It Right The Second Time, Second Edition Benchmarking Best Practices in The Quality Change ProcessVathasil VasasiriNoch keine Bewertungen

- Fundamentals of Manufacturing ExcellenceDokument8 SeitenFundamentals of Manufacturing ExcellenceFadi Zaid AlkilaniNoch keine Bewertungen

- Betaforce ™ 2850S: Technical DatasheetDokument3 SeitenBetaforce ™ 2850S: Technical Datasheetenrico_andreoli88Noch keine Bewertungen

- Bottles, Preforms and Closures: A Design Guide for PET PackagingVon EverandBottles, Preforms and Closures: A Design Guide for PET PackagingBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Desmopan 487 ISODokument2 SeitenDesmopan 487 ISOMohammad Doost MohammadiNoch keine Bewertungen

- ENG 110-Task 4 (Unintended Messages)Dokument2 SeitenENG 110-Task 4 (Unintended Messages)Erika Noreen Dela RosaNoch keine Bewertungen

- Yam FlourDokument5 SeitenYam Flouramdbilal123Noch keine Bewertungen

- Drug StudyDokument4 SeitenDrug Studysnowyfingers100% (1)

- Manuscript 1Dokument26 SeitenManuscript 1Juan Paolo CapatiNoch keine Bewertungen

- 2017-12-27 Final Alcohol Task Force ReportDokument288 Seiten2017-12-27 Final Alcohol Task Force ReportShira SchoenbergNoch keine Bewertungen

- Respirator LangmanDokument10 SeitenRespirator LangmanSavu MalinaNoch keine Bewertungen

- Bar Exam Questions Week 1Dokument30 SeitenBar Exam Questions Week 1Mark Bantigue100% (1)

- Finding Clara: Establishing The Biographical Details of Clara Peeters (Ca. 1587-After 1636)Dokument15 SeitenFinding Clara: Establishing The Biographical Details of Clara Peeters (Ca. 1587-After 1636)victoriagalapedroNoch keine Bewertungen

- Myasthenia Gravis DiseaseDokument14 SeitenMyasthenia Gravis Diseaseapi-482100632Noch keine Bewertungen

- API 572 Practise QuestionDokument58 SeitenAPI 572 Practise Questionbelonk_182100% (6)

- AJINOMOTO 2013 Ideal Amino Acid Profile For PigletsDokument28 SeitenAJINOMOTO 2013 Ideal Amino Acid Profile For PigletsFreddy Alexander Horna Morillo100% (1)

- Define and State The Purpose of Therapeutic DietDokument10 SeitenDefine and State The Purpose of Therapeutic DietKen GarciaNoch keine Bewertungen

- Yumiko@Dokument2 SeitenYumiko@api-25886263Noch keine Bewertungen

- This Study Resource Was: Current Asset - Cash & Cash Equivalents CompositionsDokument2 SeitenThis Study Resource Was: Current Asset - Cash & Cash Equivalents CompositionsKim TanNoch keine Bewertungen

- Ear CandlingDokument2 SeitenEar CandlingpowerleaderNoch keine Bewertungen

- The Prosecution of Kim Jong Il - Accountability in A Post 9-11 WorldDokument21 SeitenThe Prosecution of Kim Jong Il - Accountability in A Post 9-11 WorldimpunitywatchNoch keine Bewertungen

- GST15!16!17-Bad Debt Relief RecoverDokument10 SeitenGST15!16!17-Bad Debt Relief RecoverDaud Farook IINoch keine Bewertungen

- The Theory of Motivation in Dog Training: By: Ed FrawleyDokument30 SeitenThe Theory of Motivation in Dog Training: By: Ed Frawleyrodrigue angbohNoch keine Bewertungen

- Geostats Pty LTD: Base Metal AnalysesDokument1 SeiteGeostats Pty LTD: Base Metal AnalysesJhony Enrique Morales LauraNoch keine Bewertungen

- Pinoy Ree - EeDokument138 SeitenPinoy Ree - EeChilvin ChipmunkNoch keine Bewertungen

- Daily Lesson Log Personal Dev TDokument34 SeitenDaily Lesson Log Personal Dev TRicky Canico ArotNoch keine Bewertungen

- Doppler EffectDokument47 SeitenDoppler EffectLouies UngriaNoch keine Bewertungen

- Azure Essentials: Module 5: Azure Cost Management and Service Level AgreementsDokument9 SeitenAzure Essentials: Module 5: Azure Cost Management and Service Level Agreementsrajagopalan19Noch keine Bewertungen

- Evaluation and Comparison of Highly Soluble Sodium Stearyl Fumarate With Other Lubricants in VitroDokument8 SeitenEvaluation and Comparison of Highly Soluble Sodium Stearyl Fumarate With Other Lubricants in VitroSvirskaitė LaurynaNoch keine Bewertungen

- Ans Sheet Chemical 23111Dokument96 SeitenAns Sheet Chemical 23111Aejaz MujawarNoch keine Bewertungen

- Weather and ClimateDokument5 SeitenWeather and ClimateprititjadhavnNoch keine Bewertungen

- Implementation Plan SLRPDokument6 SeitenImplementation Plan SLRPAngelina SantosNoch keine Bewertungen

- Complete Prerequisite Program v2Dokument78 SeitenComplete Prerequisite Program v2Ramasubramanian Sankaranarayanan100% (1)

- EMI Course CatalogDokument645 SeitenEMI Course CatalogFarouk OthmaniNoch keine Bewertungen

- Reviewer Crim 3 FinalsDokument6 SeitenReviewer Crim 3 FinalsMaria Rafaella P. DadoNoch keine Bewertungen