Beruflich Dokumente

Kultur Dokumente

345KV Autotransformer Spec (08.29.2012)

Hochgeladen von

Dante FilhoOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

345KV Autotransformer Spec (08.29.2012)

Hochgeladen von

Dante FilhoCopyright:

Verfügbare Formate

TECHNICAL SPECIFICATION FOR LCRA 345/138/13.

2 kV 477; 672; 800 MVA THREE WINDING AUTOTRANSFORMERS

TECHNICAL SPECIFICATIONS TABLE OF CONTENTS

4.14 4.16

GENERAL PERFORMANCE 4.16.1 4.16.2 4.16.3 4.16.4 4.16.5 4.16.6 4.16.7 4.16.8 4.16.9 Loading Nominal Voltage Taps Dielectric Insulation Levels Vector Relations Transformer Impedance Sound Level Losses Short Circuit Requirements

4.16.10 Auxiliary Power 4.17 ACCESSORIES 4.17.1 4.17.2 4.17.3 4.17.4 4.17.5 4.18 Bushings Bushing Current Transformers (BCT) De-energized Tap Changer Load Tap Changing Equipment Surge Arresters

CONSTRUCTION 4.18.1 4.18.2 4.18.3 4.18.4 4.18.5 Windings and Core Tank Grounding Wiring and Controls Control Cabinet 2

4.18.6 4.18.7 4.18.8 4.18.9

Radiators and Cooling Equipment Autotransformer Nameplate Oil Preservation Oil

4.18.10 Indicating Devices 4.19 4.20 4.21 4.22 CONTRACTOR DATA TESTS SHIPPING SCHEDULES, DRAWINGS, MANUALS, and FACTORY VISITS

4.14

GENERAL: This Technical Specification describes the requirements for one (1) three phase, outdoor, oilimmersed, three winding, 60 Hz, 345/138/13.2 kV, 477; 672; and 800 MVA EHV autotransformers for installation at LCRA TSCs designated Substation (s). The autotransformer covered by this specification shall be designed, built, and tested in accordance with the latest applicable ANSI, NEMA, IEEE and EEI standards and shall include all additional features required by this specification.

4.16

PERFORMANCE REQUIREMENTS: Autotransformer shall be 3 phase, three winding, 60 Hz, with ONAN/ONAF/ONAF cooling. The autotransformer will be used as a system tie autotransformer designed to operate in either a step up or step down mode, but will primarily be used for step-down operation. Contractor shall follow good engineering and manufacturing practices to produce a transformer, including accessories, which in conjunction with normal maintenance will provide safe and reliable service through a 50year life under the rigors of service in an electric utility power system. Contractor shall completely integrate all components into the overall transformer design, including but not limited to the LTC, all controller relays, monitoring, indicators, etc. Please note, ratings below are subject to change depending on project/site requirements, ratings shall be confirmed with LCRA TSC purchasing group and scope documentation. 4.16.1 Loading: 477.7 MVA HV to LV: 672 MVA HV to LV: 800 MVA HV to LV: 477.7 MVA HV to TV: 672 MVA HV to TV: 800 MVA HV to TV: 477.7 MVA LV to TV: 672 MVA LV to TV: 800 MVA LV to TV: 256/341.3/426.6//477.7 MVA @ 55//65 C rise 360/480/600//672 MVA @ 55//65C rise 428.6/571.4/714.3//800 MVA @ 55//65 C rise 68.5/91.3/114.1//70 MVA @ 55//65 C rise (Minimum) 65/86.7/108.3//121 MVA @ 55//65 C rise (Minimum) 65/86.7/108.3//121 MVA @ 55//65 C rise (Minimum) 37.5/50/62.5//70 MVA@ 55//65 C rise (Minimum) 37.5/50/62.5//121 MVA@ 55//65 C rise (Minimum) 37.5/50/62.5//121 MVA@ 55//65 C rise (Minimum)

Voltage 345,000/199,20 0 GRD WYE 138,000/79,670 GRD WYE 13,200 Delta

3 PHASE CONTINUOUS FULL LOAD RATING (477.7 MVA) Class ONAN ONAF ONAF Temp Rise oC Winding MVA 256 341.3 426.6 55 H 286.6 382.2 477.7 65 X Y 256 286.6 37.5 42 341.3 382.2 50 56 426.6 477.7 62.5 70 55 65 55 65

Voltage 345,000/199,20

3 PHASE CONTINUOUS FULL LOAD RATING (672 MVA) Class ONAN ONAF ONAF Temp Rise oC Winding MVA H 360 480 600 55 4

0 GRD WYE 138,000/79,670 GRD WYE 13,200 Delta

403.2 X Y 360 403.2 65 72.6

537.6 480 537.6 86.7 96.8

672 600 672 108.3 121

65 55 65 55 65

Voltage 345,000/199,20 0 GRD WYE 138,000/79,670 GRD WYE 13,200 Delta

3 PHASE CONTINUOUS FULL LOAD RATING (800 MVA) Class ONAN ONAF ONAF Temp Rise oC Winding MVA 428.6 571.4 714.3 55 H 480 640 800 65 X Y 428.6 480 65 72.6 571.4 640 86.7 96.8 714.3 800 108.3 121 55 65 55 65

4.16.1.1

Approximately 1000 KVA of station service load will be installed on the autotransformer tertiary. An additional 60 MVA of reactive compensation, either reactive or capacitive, may be installed in the future. The autotransformer shall be capable of simultaneous three winding operation provided that the MVA rating of any particular set of terminals is not exceeded and that the current in the common winding does not exceed the 65 degree C rise, ONAN/ONAF/ONAF ratings. (Common winding current equals rated LV current minus Series Winding current at highest voltage tap connection). Autotransformer overload capability shall be 110% of maximum forced cooled rating for a period of four (4) continuous hours without increased loss of life. Components such as bushings, tap changers, winding leads, oil expansion capacity, gasketing, stray flux heating, etc. shall not be the limiting factors in the autotransformers capability to meet overloads. This design overload capability will be at an average ambient temperature of 30C during overload and an average ambient temperature during the 24-hour period not exceeding 40C. This design overload capability will be based on a transformer loading condition of 90% of the maximum forced cooled rating during the 24 hour period surrounding the overload. The autotransformer shall be capable of operating above rated voltage as specified by IEEE C57.12. The Contractor shall supply information to help LCRA TSC determine loading capacity and loss of life for the autotransformer. A minimum requirement for this information is as defined in the IEEE C57.115 standard, section 2.6. 1. Top-oil temperature rise over ambient temperature 2. Bottom-oil temperature rise over ambient temperature 3. Average conductor temperature rise over ambient temperature 4. Hottest-spot conductor temperature rise over ambient temperature 5. Load loss at rated load 6. No load loss 7. Confirmation of oil flow design 5

4.16.1.2

4.16.1.3 4.16.1.4

Any other information regarding ratings for bushings, tap changer, connectors and leads, gaskets, oil pressure build up, etc. that would constitute a limiting factor element for consideration in loading and loss of life calculations. 4.16.2 Nominal Voltage: Series Winding Voltage (HV): 345 kV Grd Wye/199.2 kV Common Winding Voltage (LV): 138 kV Grd Wye/79.67 kV Tertiary Winding Voltage (TV): 13.2 kV Delta 4.16.3 Taps: De-Energized or No Load Tap Changer (DETC/NLTC): 345 kV +/- 5% in 2.5% steps with the LTC in Neutral position. The DETC shall be on the high voltage end of the series winding. (See Section 4.17.3) Load Tap Changer (LTC): Common End of Series Winding: LTC +/- 10%. Sixteen 5/8% steps above and Sixteen 5/8% steps below neutral position. (See section 4.17.4) Common Winding (LV): Tertiary Winding (TV): 4.16.4 No Taps Required No Taps Required

Dielectric Insulation Levels: Autotransformer shall be designed to withstand the following impulse levels based on IEEE C57.12 Table 5.

BIL (kV Crest) Chopped Wave Level (kV Crest) BSL (kV Crest) Induced Voltage Test One Hour level (kV, rms) Induced Voltage Test Enhanced Level (kV, rms) Applied Voltage Test level (kV, rms)

345 kv 1050 1155 870 315 360 50

138 kV 650 715 540 125 145 50

15 kV 150 165 ------------50

Neutral 150 ------------50

See Test section for required tests. 4.16.5 Vector Relations: Standard vector relationships shall be used. 4.16.6 Transformer Impedance Impedance shall be as designated on the Purchasers Purchase Order Release.

Tertiary shall be completely self protected. Tertiary impedance shall be designed so the maximum allowable fault on the tertiary does not exceed 750 MVA based on the 345kV and 138kV busses being infinite. If internal reactors are used to limit tertiary short circuit currents, those reactors shall be designed and constructed by the autotransformer contractor using the same high standards as the main windings. Data shall be submitted by the contractor to verify the short circuit capability of the reactor design. 4.16.7 Sound Level: Autotransformer sound level shall not exceed 77dB for Oil Natural Air Natural (ONAN) rating and 80dB for maximum forced cooling rating as measured by procedures in NEMA TR1 for standard average audible sound levels. 4.16.8 Losses: Autotransformer proposals will be evaluated based on total owning costs, including the cost of losses. The following costs will be used to evaluate losses: No-Load: Load Loss: Aux. Loss: $3,020/KW $1,225/KW $810/KW

Guaranteed no-load and load losses shall be at rated voltage and Oil Natural Air Natural (ONAN) loading and at the 1 raise LTC position, or at the 0 LTC position whichever has the highest no-load losses. Guaranteed auxiliary losses shall be at maximum forced cooled rating. Factory tests that yield losses exceeding those guaranteed in the Proposal shall result in a credit to LCRA TSC. The credit will amount to the differences (no-load and load losses only) between the tested and guaranteed losses times the appropriate loss cost. Auxiliary losses will not be used in the credit calculations. No price adjustment will be given to the Contractor for losses less than those guaranteed. The Contractor shall submit with their proposal, the percentage maximum total measurement error for the no load loss measurement and the load loss measurement systems. The errors must contain all components of the error including probable calibration errors and other uncertainties in the measurement system. The data shall be traceable to the United States National Institute of Standards and Technology and calculated per Section 8 of NBS Technical Note 1204. A system check to insure that all errors have been properly applied may be required. Failure to submit a loss measurement system error or the submission of an error that is obviously erroneous will result in the rejection of the proposal. The maximum loss measurement error that is acceptable is + 3 percent as per IEEE C57.12.00-1993. Loss measurement errors greater than + 3 percent will result in the rejection of the Contractors proposal. 4.16.9 Short Circuit Requirements: The autotransformer shall be capable of withstanding the maximum current and associated mechanical and thermal stresses produced by external short circuits under the conditions specified in IEEE C57.12.00 Section 12. 7

The autotransformer shall meet or exceed the requirements of IEEE C57.12.00, Section 7, Short Circuit Characteristics, limited to two seconds. The Contractor shall also show evidence that the design will meet or exceed the requirements stated by either: (1) Submitting certified test reports covering two fully offset shorts per phase at rated voltage with the short circuit current limited only by the autotransformer impedance on a prototype unit, or (2) Submitting data and drawings showing that the successful short circuit strength design has been accomplished. The autotransformer shall be self-protecting without the aid of external impedance from a through fault standpoint. This design criteria shall apply to primary, secondary, and tertiary windings. 4.16.10 Auxiliary Power: 4.16.10.1 A 120/240 volt, 4-wire delta power supply will be provided to handle both three-phase and single-phase loads. Fans shall operate at 240 volts, either single or three-phase. Lights shall operate at 120 volts single phase. Heaters shall operate at 240 volts single-phase. Available fault current in control cabinet may reach 20,000 amps. 4.16.10.2 Instrumentation shall be operated at 125 volts DC which will be supplied by LCRA TSC. 4.16.10.3 The LCRA TSC shall provide the necessary station service power for operating the load tap changer and auxiliary cooling equipment. 4.16.10.4 The Contractor shall state all three-phase and single-phase kVA requirements in the proposal form. 4.16.10.5 The AC neutral shall be electrically isolated from the equipment ground. Incoming AC terminals shall be large enough to accommodate up to and including 2/0 AWG copper conductors. Incoming terminals shall be provided for single phase and three phase, 240 volt with separate neutral and ground conductor. 4.17 ACCESSORIES: 4.17.1 Bushings: ABB, PCORE or LCRA TSC approved equivalent ratings that are required: 477.7 MVA High Voltage (345kV): Low Voltage ( 138 kV): Tertiary Voltage (13.2 kV 362 138 25 BIL(kV) Supplier Cat. # - ABB or PCORE 1300/1050 (Ext./Int.) ABB #362W2000UZ or PCORE Equivalent 650 PCORE #POC650G3000CMS or LCRA TSC approved ABB Equivalent 150 ABB #025V0600WJ or 8

kV): Neutral: HoXo 25 150

LCRA TSC approved PCORE Equivalent ABB #025W3000BF or LCRA TSC approved PCORE Equivalent

672 MVA High Voltage (345kV): Low Voltage ( 138 kV): Tertiary Voltage (13.2 kV): Neutral: HoXo

kV 362 138 25 25

BIL(kV) Supplier Cat. # - ABB or PCORE 1300/1050 (Ext./Int.) ABB #362W2000UZ or LCRA TSC approved PCORE Equivalent 650 PCORE #POC650G3000CMS or LCRA TSC approved ABB Equivalent 150 ABB #025V0600WJ or LCRA TSC approved PCORE Equivalent 150 ABB #025W3000BF or LCRA TSC approved PCORE Equivalent BIL(kV) Supplier Cat. # - ABB or PCORE 1300/1050 (Ext./Int.) ABB #T345Z2000BD or LCRA TSC approved PCORE Equivalent 650 ABB #T138W4000UU or LCRA TSC approved PCORE Equivalent 150 ABB #025V0600WJ or LCRA TSC approved PCORE Equivalent 150 ABB #025W3000BF or LCRA TSC approved PCORE Equivalent

800 MVA High Voltage (345kV): Low Voltage ( 138 kV): Tertiary Voltage (13.2 kV): Neutral: HoXo

kV 362 138 25 25

Ampere requirement based on autotransformer over-loading: 4.17.1.1 4.17.1.2 Bushings shall be furnished in accordance with IEEE C57.19 and C57.19.01. Bushings shall be mounted in a location symmetrical with the centerline of the autotransformer tank. The H2 and X2 bushings shall be in line with the centerline of the autotransformer base. Tertiary bushings shall be located with all three bushings in a straight line. Minimum bushing spacing shall be as follows: 345kV 138 kV 15 kV

4.17.1.3

MINIMUM BUSHING SPACING FOR AUTOTRANSFORMERS Nominal Operating Voltage Minimum centerline-to-centerline dimension (At top of bushing)

128

62

24

4.17.1.4

All bushings shall include a tinned bronze spade type NEMA pad stud connector. Connectors shall be minimum 4 by 4 pad or larger to safely handle maximum current levels on HV, LV, and tertiary applications. Stud connectors shall be threaded type and shall have a minimum of two bolts for clamping. Stud connectors shall be tin plated. All bushings shall be porcelain standard creep and ANSI 70 gray. All bushings shall have test taps and be equipped with nameplates specifying factory Power Factor (%PF) test results. Bushings shall be oriented such that capacitance test taps are perpendicular to the local tank wall for ladder access from the ground. Bushings shall be ABB, PCORE, or LCRA TSC approved equivalent. Contractor state the bushings proposed for each terminal with the proposal. All bushings shall have C1 and C2 test taps. C1 power factor shall not exceed 0.5% and the C2 power factor shall not exceed 1.0%. If a brand name other than ABB or PCORE is proposed, the Contractor shall furnish one spare bushing for each voltage class on the order as part of the base proposal. Additionally, LCRA TSC may elect to purchase spare bushings from the Contractor. Therefore, LCRA TSC requests proposal pricing to supply additional spare bushings for each different type proposed. The Contractor shall provide one PCORE test terminal for field dielectric tests on each bushing. The terminal shall be rated for the continuous current rating of the bushing.

4.17.1.5 4.17.1.6

4.17.1.7

4.17.1.8

4.17.2

Bushing Current Transformers (BCT): The following BCTs shall be provided: 477.7 MVA: H: Four (4) per Bushing 2000:5 amp MR C800 RF=1.2 X: Four (4) per Bushing 3000:5 amp MR C800 RF=2.0 Y: Three (3) per Bushing Two (2) 10000:5 amp SR C800 RF 1.0 and One (1) 5000:5 amp SR C800 RF 1.5 HoXo: Two (2) per Bushing 1200:5 amp MR C800 RF=1.5 Delta Winding: One (1) per phase 3000:5 amp MR C800 RF1.5 672 MVA: H: Four (4) per Bushing 2000:5 amp MR C800 RF=1.0 X: Four (4) per Bushing 3000:5 amp MR C800 RF=2.0 Y: Three (3) per Bushing 10

Two (2) 10000:5 amp SR C800 RF 1.0 and One (1) 5000:5 amp SR C800 RF 1.5 HoXo: Two (2) per Bushing 1200:5 amp MR C800 RF=1.5 Delta Winding: One (1) per phase 3000:5 amp SR C800 RF1.5 800 MVA: H: Four (4) per Bushing 3000:5 amp MR C800 RF=2.0 X: Four (4) per Bushing 4000:5 amp MR C800 RF=2.0 Y: Three (3) per Bushing Two (2) 10000:5 amp SR C800 RF 1.0 and One (1) 5000:5 amp SR C800 RF 1.5 HoXo: Two (2) per Bushing 1200:5 amp MR C800 RF=2.0 Delta Winding: One (1) per phase 3000:5 amp SR C800 RF2.0 4.17.2.1 4.17.2.2 4.17.2.3 4.17.2.4 All current transformers (CTs) shall have fully distributed windings. Relay accuracy bushing current transformers shall be multi-ratio, with ANSI standard ratio taps, as per the latest revision of ANSI C57.13. Each current transformer shall be mounted and wired in the appropriate bushing well. All leads from each current transformer shall be terminated on short circuiting type terminal blocks, Concentric Devices type 30CT04 or LCRA TSC approved equivalent, in the control cabinet. Size 10 AWG, 600V insulation shall be used for CT wiring to terminal blocks. All CT leads shall be grounded in the control cabinet.

4.17.3

De-energized Tap Changer: De-energized tap gauge indication shall read 1-5. Tap 1 to indicate high, tap 3 to indicate neutral, and tap 5 to indicate low. DETC shall be a Reinhausen or LCRA TSC approved equivalent. DETCs shall comply with the requirements of Category 2 DETCs, as specified in IEEE Std. C57.131-2012, Standard Requirements for Tap Changers. Each DETC containing insulation that depends on oil impregnation of any material be subjected, as a routine test, to a partial discharge test with voltage levels, time durations and PD limits as prescribed in C57.131. De-Energized Tap Voltages (with LTC in Neutral-Position) DETC HV LV Position Winding Winding 1 2 3 4 5 362,250 353,625 345,000 336,375 138000 138000 138000 138000 138000 11

327,750

4.17.4

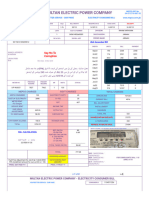

Load Tap Changing Equipment: The autotransformer and the on load tap changer shall be designed to operate in step up and step down modes. The LTC shall be a Reinhausen vacuum type VM or ABB vacuum type VUC or LCRA TSC approved equivalent. The primary mode of operation of the autotransformer will be to maintain a constant low side voltage (138 kV nominal). LTC tap windings shall be located on the common end of the series windings. The load-tap changing equipment shall consist of a low current resistance bridging device; a motordriven mechanism; and control devices. Designs that allow regulation through the core are not acceptable. The regulating winding voltage shall be fully distributed. 1) The LTC shall be provided in accordance with IEEE Std. C57.131-2012. 2) The LTC shall include a protective circuit that senses when the vacuum bottle operates when it should not. 3) Door swings of any doors on the LTC compartments, including doors to be opened on side mounted LTCs, shall be noted on the outline drawing. 4.17.4.1 The LTC shall provide +/- 10% voltage regulation with sixteen - 5/8% steps above and sixteen 5/8% steps below neutral position. The LTC shall be full capacity above rated voltage and reduced capacity (constant current) below rated voltage. Please refer to Figure 1 below for outline of required nameplate example nomenclature. The highlighted region depicts LCRA TSCs scheme of raising and lowering taps based on secondary voltage.

Figure 1 Nameplate Rating Outline Diagram 12

LTC control shall be implemented using the raise and lower scheme (16 RAISE to 16 LOWER). LCRA TSC controls voltage levels based solely on the transformer secondary. (See 4.17.4.12 for additional info). Figure 2 below shows an example of the tap position indicator that conforms to Figure 1. The 16 RAISE to 16 LOWER nomenclature shall be used for LTC tap indication.

Figure 2 Tap Position Indicator 4.17.4.2 LTC shall be located in completely separate compartment(s) from the main autotransformer core and coils, either internal or external to the main tank. Single phase LTC compartments are preferred over three phase. If the LTC compartment is external to the main tank, the bottom of the interrupting compartment shall be located approximately three feet above the base of the autotransformer to facilitate maintenance of the LTC without use of ladders or scaffolds. The inside of each LTC compartment shall be painted white to improve inspection visibility. If an in-tank LTC design is provided, each LTC mechanism shall have provisions for lifting and removal from the LTC compartment to facilitate maintenance of the device. Resistance bridging-type LTC shall include the following features: (1) Transition roller contacts and stationary contacts on the bridging device shall have copper tungsten arcing surfaces. (2) After contact separation the arc between breaking contacts shall be extinguished at the first current zero. (3) The resistance bridging contact life shall be the same as the service life of the autotransformer. 4.17.4.4 Contacts, switches, and all other components of the LTC mechanism shall be capable of continuously carrying the required current at any tap voltage. 13

4.17.4.3

4.17.4.5 4.17.4.6 4.17.4.7 4.17.4.8

Current transformers for LTC shall be sized and provided by the manufacturer. The LTC automatic control unit shall be a Beckwith M-2001B or LCRA TSC approved equivalent. Mode of communication required is DNP. The LTC paralleling control relay shall be a Beckwith M-0115A or LCRA TSC approved equivalent. An excessive circulating current lockout relay shall be provided to stop operation of the load ratio control motor before circulating current reaches an unsafe value. The relay is to lockout the automatic operation only and provides a contact for lockout alarm. The relay shall be Beckwith M-0127A or LCRA TSC approved equivalent low burden, sensitive AC current relay. An Under/Over voltage relay shall be provided to lockout the tap changer on under/over voltage conditions. It shall be a Beckwith M-0329B or LCRA TSC approved equivalent. The relay shall lock out the automatic operation only and provide a contact for lockout alarm. The factory preset fixed dead band shall be one (1) volt.

4.17.4.9

4.17.4.10 The LTC shall have manual, automatic, and remote control capability via LCRA TSC supervisory equipment. The Contractor shall provide one manual, Raise-Off-Lower selector switch for local operation of the LTC. The Contractor shall also provide one manual Remote-Local selector switch to select between local or supervisory control of the LTC. In the Remote position, LCRA TSC will provide dry contact inputs from supervisory interface panels to raise or lower the LTC tap position. In the Local mode, the LTC tap position will be controlled from the LTC automatic control unit. A raise command shall cause the secondary voltage to increase and cause the tap indication to move towards 16 RAISE. A lower command shall cause the secondary voltage to decrease and cause the tap indication to move towards 16 LOWER. 4.17.4.11 The Contractor shall provide a ventilated weatherproof cabinet with hinged doors. The doors shall provide access to the control devices and have provisions for padlocking. All cabinet and door hardware shall be non-rust stainless steel. The LTC manual controls shall be located on the same side of the autotransformer as the tap position indicator. A hand crank or hand wheel for manual operation of the driving mechanism shall be provided. If a hand crank or spoke type of hand wheel is provided, it shall be electrically interlocked to prevent operation by the motor when the crank or spoke type hand wheel is removed from its storage position. If the hand crank or hand wheel is detachable, a storage place shall be provided. 4.17.4.12 The LTC shall have a tap position indicator with maximum/minimum drag hands, resettable from ground level. The tap position indicator will be labeled from 16 LOWER to 16 RAISE with tap position N denotative of the neutral position. A raise command will result in the tap indication moving in the RAISE direction.

14

4.17.4.13 The LTC shall provide tap position indication to both the main LTC controller and LCRA TSC supervisory. A Beckwith M-2025 or LCRA TSC approved equivalent shall be provided for tap position indication into the M2001B main LTC controller and LCRA TSC supervisory. Three separate signals, a 0-1mA signal, a 4-20mA signal, and a resistive network, shall be provided and wired to Contractor terminal blocks for LCRA TSC supervisory indication. 4.17.4.14 A mechanical operations counter shall be provided and shall be accessible from ground level. 4.17.4.15 A separate nameplate shall be provided for and mounted on the LTC mechanism. The nameplate shall include the following minimum data in addition to the IEEE C57.131 specified items: Model number of mechanism Type of drive mechanism Ratio of any series transformer LTC manufacturer name Model number of Mechanism Year of Manufacture Maximum rated through current of mechanism BIL Rating Oil Volume in mechanism compartment Type of transition impedance (resistor) Method of Arc interruption Type of drive mechanism 4.17.4.16 The Contractor shall provide one (1) sudden pressure sensing unit mounted on each LTC compartment. The unit shall be equipped with test plugs to simulate a sudden pressure rise, so that the unit can be tested periodically. Circuitry from this device shall be provided to a seal-in relay. This seal-in relay, reset button, indicating light, and 63X trip and alarm contacts shall be mounted in the main control cabinet. Indicating light shall indicate SPR LTC (Sudden Pressure Relay - LTC) trip and shall remain lit until the sudden pressure relay has been manually reset. All circuitry and relays associated with the sudden pressure relay scheme for the LTC shall be independent from the sudden pressure relay scheme for the main tank. The sudden pressure sensing unit shall be a Qualitrol Series 910 or LCRA TSC approved equivalent Rapid Pressure Rise Relay. The seal-in relay shall be a Qualitrol Series 909 or LCRA TSC approved equivalent Seal-In Relay. Trip contacts shall be identified on the drawings and wired out to terminal blocks for LCRA TSC use. Alarm contacts shall be provided in accordance with Section 4.18.5.13, with one set wired to a terminal block for LCRA TSC use and another set wired to the annunciator, Terminal block points shall be provided for LCRA TSC to supply 125volts DC exclusively to the LTC SPR seal-in relay. 4.17.4.17 The tap changer ratings shall exceed all operating conditions at 110% as described in section 4.16.1.2. However, varistors may be used to provide added voltage protection during transient conditions.

15

4.17.4.18 A separate annunciator alarm shall be provided to indicate when the temperature of the oil in the LTC compartment is 3 degrees Celsius or greater than the oil temperature in the main tank at the corresponding level. The temperature differential monitor device shall be a Barrington Consultants Model TDM System 3, Transformer Temperature Differential Monitor. 4.17.4.19 The LTC Motor shall be 120/240 volt, single phase, 60 Hz. It shall be accessible and replaceable from the control cabinet. The motor shall be equipped with over current protection of 10 amps with a manual reset. No transformer shall be required between the motor and its power source. 4.17.4.20 Mechanically operated electric limit switches and mechanical stops shall be provided on the drive mechanism to prevent over travel beyond the maximum raise and lower positions. 4.17.4.21 An over current automatic-trip air circuit breaker with manual reset for control of the power circuit at the motor drive shall be provided. 4.17.4.22 An over current automatic-trip air circuit breaker with manual reset for control of the potential circuit to the automatic control devices shall be provided. 4.17.4.23 The Contractor shall provide one (1) automatic pressure relief device, which can be reset manually mounted on each LTC compartment. Circuitry from this device shall be routed to the main control cabinet where alarm contacts and a local trip flag shall be provided. The automatic pressure relief device shall be a Qualitrol Series 208 Pressure Relief Device. 4.17.4.24 The Contractor shall provide one (1) magnetic liquid level gauge with low liquid level alarm contacts for the LTC. The contacts set by the Contractor to alarm when the oil level drops below normal operating level. The liquid level gauge shall have a six (6) inch dial. The magnetic liquid level gauge shall be a Qualitrol Series 032 Magnetic Liquid Level Gauge. 4.17.4.25 The Contractor shall supply trip contacts for LCRA TSCs use per LTC manufacturers recommendations, and shall clearly label their purpose. 4.17.5 Surge Arresters: Surge Arrestors shall be provided by the Contractor for all terminals 4.17.5.1 The autotransformer shall be provided with metal oxide station class surge arresters. The housing for all surge arresters shall be porcelain. Surge arresters shall be 5.0BG 7.0/0.4.light gray in accordance with Munsell. Acceptable arresters and their ratings are as follows: (Ohio Brass or LCRA TSC approved equivalent) Arrester Ratings Terminals Brand MCOV (kV) Duty (kV) 16

4.17.5.2

H1, H2, H3 X1, X2, X3 Y1, Y2, Y3 4.17.5.3

Ohio Brass Ohio Brass Ohio Brass

220 88 15.3

276 108 18

The Contractor shall provide rigid mounting for the arresters in accordance with Section 4.18.2.8. The Contractor shall minimize the distance between the surge arrester and the bushing. The Contractor shall provide a surge arrester ground pad for each arrester in accordance with ANSI/IEEE C57.12.10-1988, section 5.5.1. The grounding pad shall be mounted on the side of the tank as close as possible to the arrester. All surge arresters shall be manufactured and tested in accordance with ANSI/IEEE C62.11-2005. All surge arresters shall be designed with a pressure relief rating of 65kA, rms, symmetrical. All surge arresters shall be provided with a NEMA 4" x 4", 4-hole terminal bronze or tin plated bronze pad.

4.17.5.4

4.17.5.5 4.17.5.6 4.17.5.7 4.18 4.18.1 CONSTRUCTION:

Windings and Core: 4.18.1.1 Copper or silver bearing copper conductor is required for all winding, leads, and other current carrying parts. Contractor shall state winding material in their proposal. 4.18.1.2 All windings for Core and Coil type construction, (cross-sections), shall be round. This includes internal current limiting reactors, if used. Please note that tertiary shall be brought out on all MVA classes. Joints are permissible at locations external to the windings, specifically at crossovers between layers or disks. A joint is defined in this context as the physical joining of two or more separate winding conductors by means of welding, brazing, soldering or crimping. Internal joints, i.e., joints made within the body of the winding layer or winding disk, are not permissible unless the joint involves a single strand of a multiple (at least five) strand conductor. Design of conductor joints and connections shall limit circulating currents and overheating such that abnormal aging or deterioration does not occur when the apparatus is operated within the scope of service conditions specified. Contractor shall have an effective quality assurance procedure for verifying that conductors are free from defects in joints and that conductor burr, nicks or indentations, dimensional tolerances and mechanical strength are within acceptable limits for the application.

17

Design shall have the following preferred maximum dielectric stresses in the high-low space(s): 1) 15.0 kV/mm (380 kV/in) during full wave impulse 2) 2.6 kV/mm (66.0 kV/in) during normal operating voltage Exceeding these levels is allowed but shall be discussed during the design review. Internal arrester elements shall not be used to protect any part of the windings. 4.18.1.3 A core ground connection shall be brought out of the autotransformer tank through an appropriate device so that core ground readings may be taken without having to remove a manhole cover. The core ground bushing shall be clearly labeled on the autotransformer and shall be shown on the outline drawing. Each separate core shall have a separate core bushing and ground connection. Core ground bushings shall be housed in a weatherproof metal housing. Magnetic cores shall be directly grounded without any impedance or fuse-like elements connected in series. A warning plate shall be provided near this bushing stating, Core Ground Must Always Be Connected When Equipment Is Energized. All material used or proposed for use in the autotransformer shall be tested and shall have passed the autotransformer oil compatibility test using the method outlined in ASTM D3455. All material used in the autotransformer shall be subject to rigid quality assurance and control standards. The Contractor shall have complete traceability on all material from receiving until final installation in the autotransformer. Material quality assurance reports shall be made available upon request. The maximum allowable burrs on the slit or cut edge of the electrical steel used in the core shall not exceed 0.7 mils. Excessive edge or surface damage during manufacture may result in rejection of the core. The Contractor shall design the core such that the maximum flux magnitude in the core at nominal operating voltage will not exceed 1.7 Tesla. The maximum temperature within the core at nominal operating voltage shall not exceed 125 deg. C at 30 deg. C ambient and 130 deg. C for the condition of highest core over-excitation, full load and 40 deg. C ambient. Coil winding insulation shall be Dennison paper for the entire length and thickness of all windings and leads. Leads and lead supports shall be designed for all dielectric, mechanical, and thermal effects that could be encountered. The design shall not permit permanent deflection of supports and leads due to forces acting on the lead during transport or service. Tap leads and series or parallel crossover leads and supports shall be designed to provide significant safety margins above the worst case dielectric stresses that would occur during specified lightning and switching surge and power frequency voltages, as though these voltages were applied at each tap 18

4.18.1.4

4.18.1.5

4.18.1.6 4.18.1.7

4.18.1.8 4.18.1.9

position. Similarly, line leads shall be designed to provide reasonable safety margins during these conditions. Direct permanent connections shall be used between the series and common windings of autotransformers, rather than using the low voltage bushing as a collection point for these leads. Wooden members used for core, coil or lead supports shall be free from knots and other defects. 4.18.2 Tank: See Indicating Devices section for required gauges and monitoring devices attached to the tank. 4.18.2.1 Main tank cover shall be welded on. Shipping Covers are not acceptable. A base plate to facilitate installation of fall protection equipment shall be welded in the center of the main cover as shown in drawings in Specification Appendix 1. Fall protection equipment will be supplied by LCRA TSC and will consist of a detachable tie off pole mounted to the tank cover. The pole will induce certain shear and bending moment forces to the tank cover, not to exceed 3000 psi. A minimum of two manholes with bolted covers shall be provided in the top cover of the autotransformer. Manholes shall be round and shall be a minimum of 20 inches in diameter. Additional manholes and/or hand holes shall be provided as needed for maintenance and testing. Covers weighing greater than 45 pounds shall be hinged. Tank shall be furnished with 2 NPT, globe type, bottom drain valve with sampling device, and 2" NPT upper filter press valve connections. All valves shall have a pipe plug in the open end. The drain valve shall have a built-in sampling device which shall be located on the side of the valve between the main valve seal and the pipe plug. The sampling device shall be supplied with a 5/16-inch, 32 threads per inch, male connector equipped with a cap. Tank shall be designed for vacuum filling in the field with 3" or 4 NPT connectors. Tank and conservator shall be designed for full vacuum without deformation. Top of autotransformer tank shall be slightly domed to promote water shedding and shall have a skid-resistant surface. Autotransformer tank shall have two pressure relief devices. Devices shall have auto reset, visual indication and alarm contacts terminated in control cabinet.

4.18.2.2

4.18.2.3

4.18.2.4

4.18.2.5 4.18.2.6

4.18.2.7

Autotransformer shall be designed for skidding in any direction. 4.18.2.8 Brackets for mounting three (3) surge arresters near the high, low, and tertiary bushings shall be provided. Brackets shall have three 11/16" mounting holes, 120 degrees apart, on a 10 inch bolt circle. Arrester brackets shall be spaced such that the center of each arrester will be on the same line as the center of the top of each bushing, which the arrester is protecting. The supports for 19

each tertiary voltage arrester shall be extended beyond the arrester mounting plate in such a way as to provide vertical flanges which will be used to attach low voltage bus support mountings. These flanges shall include four 13/16 inch holes on 7 inch bolt circles, with the top pair of holes and the bottom pair of holes on horizontal centerlines respectively. Each flange and support shall be designed to support rated arrester loading and shall be rigid enough to minimize deflection caused by external conditions and forces. 4.18.2.9 Two (2) arrester ground pads shall be located near the top of the tank for each set of arresters; HV, LV, and TV. Six (6) pads total at the top for arrester ground connections.

4.18.2.10 Autotransformer exterior shall be painted with a primary coat applied over a properly prepared surface. Finish shall be two coats of ANSI 70 gray paint for a total thickness of not less than 4 mils. Paint will be inspected and tested on delivery. The top of the autotransformer tank shall have a non-skid surface. The Contractor will be expected to correct any deviation from these specifications. All paint and primer shall be lead-free. The autotransformer tank top shall be covered with protective silicon coating, room temperature vulcanizing (RTV) insulation of silicon rubber technology, Product No. 587, as manufactured by MIDSUN Group, Southington, CT, (Phone 1-800MIDSUN), or LCRA TSC approved equivalent. The coating shall be applied per paint manufacturers instructions and shall have the following characteristics: (a) (b) (c) (d) (e) (f) Dielectric strength (ASTM D149), 375 volts/mil. Volume Resistivity (ASTM D257), ohm-cm 3.0x 1015 Dissipation Factor (ASTM D2m7), 100Hz. 100 kHz: .01 Dielectric constant (ASTM D150), 100Hz 100kHz: 4.0 Shrink factor: Nil Coating shall be adequate to prevent grounding of the low voltage bushing by snakes, varmints, etc. with a minimum thickness of 30 mils. (g) The autotransformer tank top after application of the RTV coating shall be skid resistant and its color shall match the rest of the tank. 4.18.2.11 The inside of the autotransformer tank shall be painted white to improve inspection visibility. Provide picture to depict proper coloring in the test report. 4.18.2.12 The following moving and handling facilities shall be provided: Lifting eyes for lifting the cover only Lifting facilities for the complete autotransformer Lifting facilities for the core and coil Pulling eyes for moving the autotransformer in any direction Lifting eyes for radiators Suitable jacking pads on each corner near the base Smooth base suitable for skidding in any direction Lifting eyes for conservator, if used 4.18.2.13 All gaskets shall be one piece and made of NITRILE rubber. Other gasket material must be approved by LCRA TSC prior to its application. If one piece 20

is not available, the gasket shall have a vulcanized scarf joint. Butt splice joints are not acceptable. 4.18.2.14 A confined space rescue safety plate shall be mounted near each manhole per LCRA TSC drawing UHOIST in Specification Appendix 1. Safety mounting plates shall be welded to the tank cover. 4.18.3 Grounding: 4.18.3.1 4.18.3.2 Grounding pads shall be provided per IEEE C57.12.10 Section 5.5. A copper neutral bus bar shall be furnished and attached to the side of the autotransformer at a location as close to the neutral (HoXo) bushing as possible. The bus bar shall be made of 1/2 by 4 copper bar and shall be connected directly to a four hole pad stud connector on the neutral bushing. The bus bar must be supported approximately every three feet and the bottom of the bus bar shall have a NEMA four hole drilling at 6 inches above the base of the autotransformer. The bus bar shall be painted the same color as the autotransformer. Tank Ground Pads: A NEMA 2-hole, 4-hole, or 6-hole steel based copperfaced pad shall be welded to the tank in each of the following locations: a) b) c) 4.18.3.4 Adjacent to the Xo or HoXo bushing. Six inches up from the bottom on left and right corners when facing low voltage side. Six inches up from tank bottom on left and right corners when facing high voltage side.

4.18.3.3

Surge Arrester Grounding: The surge arresters furnished on the autotransformer shall be grounded to the surge arrester ground pads listed above in Section 4.18.2.9. These grounds shall be copper bars with suitable supports on tank for all bars. LCRA TSC will connect tank ground pads to substation ground grid to complete adequate autotransformer grounding protection.

4.18.3.5 4.18.4

Wiring and Controls: 4.18.4.1 All wiring external to cabinets shall be 600 volt flame resistant, moisture proof wire in rigid galvanized steel (RGS) conduit with all terminals tagged. Crouse Hinds or T&B weatherproof receptacles and plugs shall be furnished for flexible connections to fans. All wiring external to cabinets shall be in rigid galvanized steel conduit except for local connections to individual fans. Use of tank wall bracing wells is acceptable in combination with rigid galvanized conduit. All wire terminals shall be crimp type nylon insulated, with ring tongue ends and shall be electro-tin plated copper. All terminals blocks shall be screw type. 21

4.18.4.2

4.18.4.3 4.18.4.4

4.18.4.5 4.18.5

All control components shall be readily available in the U.S.A.

Control Cabinet: 4.18.5.1 A weatherproof metal control cabinet shall be provided complete with a thermostatically controlled heater and shall follow IEEE C57.142-2011 unless otherwise stated below. Cabinet shall have provisions for termination of insulated auxiliary wiring on screw type terminal blocks. Current transformer circuits shall be wired to terminal strips equipped with shorting bars (Concentric Devices 30CT04 or equivalent). All other control wiring shall be wired to #10-32 barrier type terminal strips properly sized to handle the loads (General Electric Type EB-25 or equivalent). All CT wiring shall be No. 10 AWG copper wire, 600 Volt insulation, NEC THW rated. All other cabinet wiring shall be a minimum size of No. 12 AWG copper wire, 600 volt insulation, NEC THW rated, flame resistant. One side of terminal blocks supplied for LCRA TSCs cable connections shall be completely free of the Contractors wiring. (Exception is for CT shorting jumpers.) Cabinet shall be accessible from ground level and shall be positioned in a safe and convenient location. A scale drawing of the control cabinet internal physical layout shall be provided in the drawing set. Control cabinet shall be furnished with an interior light, a door-operated light switch, and a 120 volt, 20 amp, duplex receptacle with GFI protection. Light shall be furnished with a safety shield to prevent accidental breakage. The inside of the control cabinet shall be painted white. Control cabinet shall have a removable blank conduit plate large enough to accommodate eight (8) 2 conduits located in the bottom center of the cabinet. Cover plate will be field drilled or punched as needed. Control cabinet shall include a metal pocket inside the door for storage of the instruction manuals and drawings. Stainless steel hardware shall be furnished on all doors and panels for all cabinets or enclosures used on the autotransformer. Cabinet doors shall have a weather seal to prevent driving rain from entering the cabinet. Door shall be provided with wind latches. All conduit entrances shall be on the sides or bottom. No conduit shall enter the top of the control cabinet.

4.18.5.2

4.18.5.3

4.18.5.4 4.18.5.5

4.18.5.6 4.18.5.7 4.18.5.8 4.18.5.9

4.18.5.10 All cabinets shall have padlocking provisions. 4.18.5.11 Station Service: (1) The LCRA TSC will provide the necessary station service power for operating the load tap changer and auxiliary cooling equipment. (2) The voltage available is 120/240 volt, 4-wire delta to handle both threephase and single-phase loads. The Contractor shall state the single-phase and three-phase kVA requirements in the Proposal section of this specification. 22

(3) The AC neutral shall be electrically isolated from the equipment ground. Incoming AC terminals shall be large enough to accommodate up to and including 2/0 AWG copper conductors. Incoming terminals shall be provided for single phase, 240 volt with separate neutral and ground conductor. (4) Molded case circuit breakers rated for 240VAC/250VDC shall be used for all control and auxiliary equipment power. Knife switches or fuses are not allowed. (5) The cabinet shall have a grounding connector for safety grounding. 4.18.5.12 Annunciators (1) The Contractor shall provide one or more Puleo Type PE103-48-2B annunciator(s) or LCRA TSC approved equivalent to handle all annunciator points specified. (2) Wiring shall be provided between the alarm contact terminal blocks and the annunciator input point module terminals. (3) The terminals of the annunciators point modules shall be properly and permanently labeled to indicate the alarm function. (4) The Contractor shall provide as many annunciators as is necessary to make available to LCRA TSC all alarm points provided. (5) Each of the annunciator power supply circuits shall be connected to a 125 VDC power supply terminal block. The annunciator power supply(s) will be supplied by a separate LCRA TSC connection from the other 125 VDC devices on the autotransformer. (6) Each of the annunciator's relay module output contact terminals shall be terminated on terminal blocks for LCRA TSC's connections. (7) Annunciator alarms shall include, but are not limited to, the following: a) Sudden pressure relay operation - Main Tank b) Sudden pressure relay operation - LTC c) High winding temperature d) Combustible gas detector relay operation (Buchholz relay) e) Pressure relief device operation - Main Tank f) Pressure relief device operation - LTC g) High liquid temperature h) Low oil level - Main tank i) Low oil level - LTC j) AC failure alarm - 120/240 VAC k) LTC control relay failure alarm l) Combustible Gas-In-Oil alarm m) Cooling Fan Failure - AC Failure n) DC failure alarm 125VDC o) Oil filtration system oil level differential alarm p) Oil filtration system low oil level alarm q) Oil filtration system pressure differential across filter alarm r) Tap changing incomplete 4.18.5.13 Non-grounded minimum-level alarm contacts shall be provided, suitable for interrupting, at 250 VDC, a maximum of: (a) 0.02 amperes direct-current inductive load (b) 0.20 amperes direct-current non-inductive load

23

These alarm contacts and any additional or spare contacts shall be brought out as individual alarms and terminated in the control cabinet on a properly labeled (description and whether Normally Open NO, or Normally Closed NC) terminal block for alarms. The terminal block shall meet the requirements specified herein. 4.18.6 Radiators and Cooling Equipment: 4.18.6.1 All radiators shall be removable and interchangeable and shall be mounted directly on the transformer tank. If radiators cannot be interchanged, they must be labeled and identified in such a way to indicate the proper assembly position. Radiator flanges shall be blanked off and sealed with blanking plates and rubber gaskets prior to shipment and radiators filled with dry air. Each radiator bank shall include upper and lower vent and drain plugs and drain coupling. Coupling shall be APS plug. Top and bottom shut off valves shall be furnished on radiators. All fan motors shall be three-phase delta, 240 volt AC. Fan motors shall be totally enclosed with sealed, permanently lubricated ball bearings and shall be equipped with reset thermal protectors. Replacement fans shall be manufactured and readily available in the U.S.A. All fans shall have one piece blades and galvanized fan guards that meet applicable OSHA standards. Fiberglass fan blades are not acceptable. Fan guards shall prevent birds and other small animals from entering the fan housing. Automatic control for auxiliary cooling actuated from fiber optic recorded winding temperature shall be Qualitrol/Neoptix, or approved equal, with separate contacts for high temperature alarm in accordance with Section 4.18.10.3. All fans shall have waterproof electrical plugs for easy fan removal. A switch shall be provided for manual operation of the fans overriding the winding temperature controls. Controls shall be provided for selection of which fan bank leads the other on ONAN/ONAF/ONAF units. Over current protection with manual reset shall be provided for each fan bank. All fans shall be capable of automatic operation twice during a 24 hour period.

4.18.6.2 4.18.6.3 4.18.6.4

4.18.6.5

4.18.6.6

4.18.6.7 4.18.6.8

4.18.6.9

4.18.6.10 A loss of AC voltage relay with 2 N.O. and 2 N.C. contacts shall be provided for the fan power circuits. This relay shall have an adjustable time delay of up to five (5) minutes. Alarm contacts shall be provided in accordance with Section 4.18.5.13, with one set wired to a terminal block for LCRA TSC use and another set wired to the annunciator. 4.18.7 4.18.7.1 24 Autotransformer Nameplate:

Information to be included shall be per requirements of Nameplate C of Table 7 of C57.12.00-2010, plus the following: 1) Connection diagrams and ratings of all internal electrical components including current limiting reactors, series transformers, tap changers, nonlinear resistors or protective devices, current transformers, fuses, number and general locations of all intentional core grounds, etc. 2) Ratios and accuracy classifications, type and model or style of all CTs, including hot spot CTs 3) Winding form (cylindrical or shell). 4.18.7.2 The nameplate shall be manufactured of stainless steel. An autotransformer nameplate shall be furnished and attached to the autotransformer tank at a point easily accessible from ground level. 4.18.8 Oil Preservation: A conservator type oil preservation system with a rubber bladder bag shall be used to exclude air contact with the oil. Bladder shall have proven 20 year plus life expectancy. The bottom of the expansion tank must be at least 4 above the top of the autotransformer cover and above the highest oil to air gasketed joint. The tank shall be constructed so that the bag will not block the pipe to the autotransformer at low oil levels. Isolation valves shall be provided between the conservator tank and the main tank. Appropriate bleed valves shall be located on the main tank and conservator for filling the autotransformer. A Buchholz-style gas detector relay shall be located in the piping between the conservator tank and main tank. The Buchholz relay shall be wired to a separate seal-In relay inside the control cabinet. The gas detector relay shall be a Qualitrol Series 038 Gas Detector Relay, or a GE Type GEK-4817 Gas Detector Relay. Non-grounded alarm contacts shall be provided in accordance with Section 7.02.07 of this specification. 4.18.9 Oil: 4.18.9.1 4.18.9.2 Oil shall be furnished in the necessary quantity with 0.3% DBPC, (Type II oil). Acid refined oil is preferred if available. Any oil used or supplied to fill the autotransformer shall have PCB content of less than 1part per million. All oil furnished shall be certified as non-PCB and the nameplate shall state that the oil is PCB free. All autotransformer oil shall be in accordance with ANSI/ASTM latest issue standards for new oil.

4.18.9.3

The physical properties of the insulating oil as received shall meet the following requirements:

25

Characteristic Aniline point Color Oxidation Stability (rotating bomb test) Chlorides and Sulfates Corrosive Sulfur Dielectric Breakdown Voltage Dielectric Breakdown Voltage, Impulse Conditions Flash Point Interfacial Tension Moisture Content Neutralization Number Pour Point Power Factor Specific Gravity Viscosity Saturation Concentration Oxidation Inhibitor Poly Chlorinated Biphenyl

Value 63-78oC 0.5, max 195 minutes, min None Noncorrosive 35 kV @ 60 Hz, min 145 kV, min 145oC, min 40 dyne/cm @ 25oC, min 30 PPM max 0.015 mg KOH/g, max -40oC max 0.01% @ 60 Hz, 100oC, max 0.91 @ 15oC/15oC, max 66 SUS @ 40oC, max 60 PPM H2O @ 25oC, max 0.3% by mass DBPC < 1.0 PPM

(Related Standard) (ASTM D611) (ASTM D1500) (ASTM D2112) (ASTM D878) ASTM D1275B) (ASTM D877) (ASTM D3300) (ASTM D92) (ASTM D971) (ASTM D1533) (ASTM D664) (ASTM D97) (ASTM D924) (ASTM D1298) (ASTM D88) (ASTM D1473)

26

OIL TEST ANALYSIS The contractor shall perform an oil analysis and submit a certified test report to LCRA TSC on the contents of oil used for filling the Autotransformer tank. Tests shall be made both at the time of factory filling and at the time of final fill at LCRA TSCs substation site to show that the requirements of the characteristic chart above have been met or exceeded. These test reports shall be submitted to LCRA TSC prior to any oil being placed in the transformer. If oil properties do not meet or exceed the requirements in the Table listed above, corrective action will be taken at the expense of the contractor of the Autotransformer to bring the properties of the oil to the correct specification or drain and change the oil and correct any damage resulting from defective oil. Proof of passing compliance with all tests listed in the table shall be submitted. Of specific interest is test D1275B for corrosive sulfur. The contractor shall provide D1275B test results on all oil prior to placing it in the transformer. 4.18.10 Indicating Devices: All alarm contacts from indicating devices, relays, and other monitoring equipment shall be wired to terminal points inside the control cabinet for LCRA TSCs use. All gauges with manual resets shall be mounted in a position accessible from ground level. All gauges shall be labeled on the dial face of the gauge or have a suitable nameplate attached adjacent to the gauge. Gauges shall have a 6 dial face. The following equipment is required: 4.18.10.1 Liquid Level Gauge(s), dial type, with alarm contacts. Qualitrol CAS-771-1 or LCRA TSC approved equivalent shall be provided for the main tank and LTC tank. The contacts shall be set by the Contractor to alarm when the oil level drops below normal operating level. Alarm contacts shall be provided in accordance with Section 4.18.5.13, with one set wired to a terminal block for LCRA TSC use and another set wired to the annunciator. 4.18.10.2 Two (2) Sudden Pressure Relay (Qualitrol Series 900 or 910 depending on application) shall be provided on opposite sides of the main tank. The relay shall be wired to separate Seal-In relays (Qualitrol 909-200-01) located in the control cabinet and wired for 125V DC operation. Alarm contacts shall be provided in accordance with Section 4.18.5.13, with one set wired to a terminal block for LCRA TSC use and another set wired to the annunciator. Terminal block points shall be provided for LCRA TSC to supply 125 VDC exclusively to the Main Tank SPR seal-in relays. 4.18.10.3 Liquid Temperature Indicator, dial type, with four (4) separate adjustable alarm contacts. Monitor face shall be labeled Liquid Temperature. The monitor shall be a Qualitrol Series 509-DW, or LCRA TSC approved equivalent. Alarm contacts shall be provided in accordance with Section 4.18.5.13, with one set wired to a terminal block for LCRA TSC use and another set wired to the annunciator. 27

4.18.10.4 Winding Temperature Indicators on the H2, X2, and Y2 windings. Dial type with four (4) separate adjustable contacts. Monitor face shall be labeled Winding Temperature. The monitor shall be a Qualitrol Series 509-DW, or LCRA TSC approved equivalent. Alarm contacts shall be provided in accordance with Section 4.18.5.13, with one set wired to a terminal block for LCRA TSC use and another set wired to the annunciator. 4.18.10.5 Fiber Optic Hotspot & Top Oil System The following specifications shall be met for the addition of fiber optic probes and monitoring devices: 4.18.10.5.1 The manufacturer shall furnish and install a fiber optic winding hotspot & top oil monitoring system manufactured by NEOPTIX/Qualitrol or LCRA TSC approved equivalent. The fiber optic system shall include:

4.18.10.5.2 Item 1 2 3 4 Quantity 16 16 8 1

5 6

1 1

Description T2 Fiber optic temperature probe for oil filled power transformer, oil immersed Teflon sheathing reinforced with spiral wrap, temperature range of -80C to 200C Optical feed through to match with Neoptix products, 150C operating temperature, NPT ANSI treads, no moving parts or Orings. External fiber optic extension cable, ST connectors at both ends, 3mm O.D. polyurethane with Kevlar reinforcement, ST-ST mating included. Transformer tank wall mounting plate in stainless steel for 16 Neoptix OFT optical feed throughs, including junction protection box. The OFTs should be assembled on the tank wall plate and leak tested at 100 PSI at the factory by Neoptix. 8-channel fiber optic temperature monitoring system for transformer winding (Model T/Guard Link or MOD-638) with 8 numbers of 4-20 mA analog outputs, 485/DNP 3.0 communication. DIN power supply, 24 volts for T/Guard Link system The Qualitrol 509-DW or LCRA TSC approved equivalent for this application shall have six (6) form C output contacts, or relays. Probes shall be installed in the following locations: Three (3) probes in the series winding, one (1) per phase Three (3) probes in the common winding, one (1) per phase One (1) probe in the Core hot spot per design evaluation One (1) top oil probe, near top of middle phase coil The manufacturer shall guarantee that all probes shall be functional. All fiber optic probes should be routed inside the control cabinet and 8 of them will be connected to the 28

4.18.10.5.3

4.18.10.5.4

4.18.10.5.5

temperature monitor. All 16 probes shall be monitored during the heat run test with results communicated. This data shall be included as part of the certified test report. 4.18.10.5.6 The Transformer Tank Wall Feed through Plates (TWFP) shall be located on the top third of the side wall of the transformer, where they shall be accessible during operation of the transformer. Location of the TWFPs shall be a confirmed by LCRA TSC prior to installation. Each fiber optic probe and cable shall be identified on drawings and tagged. Probe placement and identification are to be determined by manufacturer and shall be communicated to LCRA TSC during design review. The manufacturer shall indicate the exact location of each probe after the hot spot calculation is done. The probe installation details shall be provided for approval and issued along the certified drawings. The Qualitrol 509-DW or LCRA TSC approved equivalent shall provide alarm and trip functions for Top Oil and Winding Hot Spot, control of the cooling system, and provide visibility of the transformer temperatures. All probes installed by the manufacturer shall be secured inside the transformer tank such that the probe cannot be damaged by shipping, seismic or short circuit forces.

4.18.10.5.7

4.18.10.5.8

4.18.10.5.9

4.18.10.5.10 The fiber optic probes inside the tank shall be routed in such a way that they are not subject to damage during assembly or dismantling of the transformer, and shall have sufficient slack to avoid taut internal connections and allow for the interchanging of probes. 4.18.10.5.11 A NEMA 4 box with removable cover shall be mounted over the tank wall plates. A inch or larger rigid conduit shall be routed from the NEMA 4 box to the control cabinet. 4.18.10.5.12 Installation procedure must be validated by Neoptix/Qualitrol prior the beginning of the installation. Neoptix trained professional shall be present on manufacturer site during the installation of FO probes for each first of series. All routing of probes from tank plate shall pass through rigid conduit into the control box. 4.18.10.5.13 The hot-spot monitoring system shall be linked to the Qualitrol 509-DW or LCRA TSC approved equivalent through the auxiliary RS-485 port. 4.18.10.5.14 A yellow panduit and/or FO corrugated plastic conduit shall be used exclusively for the FO extensions inside the control 29

cabinet. The FO extensions shall not be bundled or tie wrapped with the control cable. The FO cables that are not connected to the temperature monitor shall be coiled in a 12 inch (305mm) diameter and secured in a permanent fashion such that they are not subject to damage but are accessible. The manufacturer shall instruct all personnel working on the transformer that the fiber optic cables are glass and must be treated only in accordance with vendor specified procedure. 4.18.10.5.15 During Heat Run: The fiber optic thermometers shall be used to measure the temperatures. Should the fiber optic thermometers record hot spot temperatures in excess of those submitted by calculations the manufacturer shall justify the use of calculated values and LCRA TSC may require the test be repeated. 4.18.10.6 One Serveron model TM8 Autotransformer analyzer or LCRA TSC approved equivalent shall be provided with enclosure cabinet and alarms. All cabling between sensors and alarm cabinet shall be provided. Alarm contacts shall be provided in accordance with section 4.18.5.3 with one set wired to a terminal block for LCRA TSC use and another set wired to the annunciator. Power supply requirements for this device shall be 1.5 times the monitor manufacturers recommendation. (Internally supplied primary and customer provided backup options shall be available). 4.18.10.7 One (1) cover mounted automatic pressure relief device with external target that can be reset manually for each 10,000 gallons of oil. Circuitry from these devices shall be routed to the main control cabinet where alarm contacts and a local trip flag shall be provided. The pressure relief devices shall be located such as to provide equal coverage on the cover. The automatic pressure relief device shall be a Qualitrol Series 208 Pressure Relief Device. Alarm contacts shall be provided in accordance with Section 4.18.5.13, with one set wired to a terminal block for LCRA TSC use and another set wired to the annunciator. 4.18.10.8 One (1) transformer monitor and control unit, Dynamic Ratings DRMCC-E3, or LCRA TSC approved equivalent. The following analog and digital inputs shall be provided to the monitor control unit: a. b. c. d. e. f. g. h. i. j. k. l. Top oil temperature Ambient temperature Primary voltage winding current Secondary voltage winding current Tertiary voltage winding current Terminal blocks to bring in potentials for Primary, Secondary, Tertiary Fan switch position Fan motor current monitoring (provide fan current sensing CT, one per fan bank group.) Multi-gas monitor sensors Moisture-in-oil sensor LTC position sensor Main tank low oil level 30

m. n. o. p.

LTC low oil level LTC sudden pressure alarm Pressure relief alarm Gas detector (Buchholz relay) alarm

A separate NEMA cabinet shall be installed adjacent to the main cabinet with the Dynamic Ratings monitor inside. Conduit from the temperature monitors, gas monitors, and tap changer controllers shall be installed, and communication wire shall be provided from each monitor to the Dynamic Ratings unit. The communication conduit shall be separate from control and power wiring. Communication wiring shall consist of two (2) CAT 6 STP (8 conductors shielded twisted pair) going from each monitor to the Dynamic Ratings cabinet. The Dynamic Ratings monitor shall be utilized as a data concentrator having communications coming from all other monitors installed on the transformer. 4.19 CONTRACTOR DATA: 4.19.1 All Contractor data, after award of contract, shall be submitted to the LCRA TSCs project engineer designated in the purchase order at: Lower Colorado River Authority P.O. Box 220 Austin, Texas 78767 Attn: Substation Engineering 4.19.2 A design review meeting (to be held at LCRA TSCs transmission engineering offices in Austin, Texas) will be required as part of the approval drawing process. Written notice of the meeting shall be supplied to LCRA TSC three weeks in advance of meeting date. LCRA TSC will most likely have a consultant attending the design review that is experienced in the design and manufacture of large autotransformers. The duration of the meeting will be a minimum of two full workdays. Approval drawings defined in section 1.11, items (1), (2), and (3), which are outline, nameplate, and wiring and schematic drawings shall be submitted to the LCRA TSC 3 weeks prior to the design meeting. These drawings, with LCRA TSCs comments and markups will be reviewed with the Contractor as part of the design review meeting agenda.

31

IMPORTANT NOTE REGARDING THE DESIGN REVIEW MEETING Changes may be proposed by LCRA TSC and their consultant that modify core, windings, tank/frame materials, insulation, clearances, spacings, oil flow characteristics, electrical and magnetic fields, and cooling capacity of the autotransformer. These changes shall be included in the final design and manufacture of the autotransformer at no additional charge or time delay to LCRA TSC. The Contractor shall use caution in contracting for any core, coil, frame, tank and insulation materials that may be affected by LCRA TSC initiated design changes prior to the design review meeting. LCRA TSC will not accept any cost increase for design review changes or consider any excuses by the manufacture that they have already bought these materials and cant make proposed changes due to economic or time constraints. ALL VALUES FOR LENGTH, AREA, FORCE, AND PRESSURE SHALL BE IN ENGLISH UNITS WHEN PRESENTED BY THE CONTRACTOR AT THE DESIGN REVIEW MEETING. Metric units are not acceptable except for temperature in degrees centigrade. The Contractor shall make all these conversions on documentation presented prior to the design review meeting. Simply stating conversion factors for use at the meeting is totally unacceptable. If the Contractor arrives at the design review meeting and has failed to carry out the provisions of this paragraph, the meeting will be immediately terminated and rescheduled at the manufactures expense for a future date at the LCRA TSCs offices, once Contractor has made these conversions on all documentation. LCRA TSC will present an agenda format of the design review meeting to the Contractor and the Contractor may add agenda items prior to the design review meeting. All written agenda information that the Contractor will discuss at the design review meeting shall be provided to LCRA TSC a minimum of three weeks prior to the meeting for review. The design review will include, but is not limited to, the following topics that may affect changes to the Contractors design as described above: 1. Contractor analytical tools: a. Transient voltage distribution and calculation methods b. Thermal analysis calculation methods c. Short circuit stress calculation methods 1) Types of through faults considered 2) Calculation of coil stresses 3) Calculation of mechanical structure stresses d. Leakage magnetic field calculation method 2. Core design: a. Core design configuration b. ASTM material specifications for core material and source of supply (Core material data sheet to be supplied) c. Core geometry, thickness and flux density values d. Lamination burr tolerance e. The residual flux density in the core in percent of nominal excitation and times normal inrush current. f. No load loss and excitation parameters g. Number of cooling ducts in the core and calculated hotspot locations with their respective temperatures h. What type of verification is used to determine if hot spot temperatures and locations are accurate 32

i. 3.

Core loss and excitation curve review

Winding design: a. Winding arrangement or construction to be used including description of transpositions and interleaving, number and size of axial and radial spacers used, spacing and insulating barriers between windings, and description of cooling fluid pat within the winding structure b. Winding material ASTM material designation and parameters including tensile and ultimate strength of copper (Provide material data sheet of proposed copper material) c. Ratio of strength to stress for each mode of failure and the method used to calculate these values d. Type of voltage regulation and regulating winding design e. Voltage distribution in windings; turn-to-turn, disk-to-disk, etc. f. Winding conductor eddy and stray loss calculations and determination of need for tank wall shielding, and shielding locations g. Review of all dielectric clearances and impulse distribution calculations h. Review of winding splice and tap locations Insulation design: a. Insulation material used (Provided insulation suppliers data sheet) b. Major insulation clearance locations c. Insulation configuration and materials d. Voltage distribution and electrical stresses at in major insulation thickness locations Load loss and impedance. Thermal design: a. Type and amount and type of cooling equipment used to attain the guaranteed nameplate KVA cooling design b. Winding temperature rise values and locations and how these are calculated. c. Average temperature and hot spot temperature calculations d. Directed or non directed oil flow used in the coil windings and size of oil duct openings e. Fluid flow and heat transfer rates at 65 deg. C rating f. Life expectancy of cooling equipment components Leakage magnetic field analysis: a. Control of leakage fields b. Localized temperature calculation due to leakage fields Sound level design. Tap changer equipment and how selection and sizing of this equipment was made. This includes the effects of a raise/lower command, the direction of movement of the tap indication, the tap position numbering convention and labeling on the nameplate, and the nature of the tap indication output used by the LCRA TSC.

4.

5. 6.

7.

8. 9.

10. Coil and core stabilization methods and description of clamping systems: 33

a.

Materials and geometry used for end rings, pressure plates, and other special components

11. Tank and fitting design: a. Conservator and bladder design b. Weights and dimensions c. Design for transportation including the shipping forces that the clamping and end frame structure is designed to withstand in Gs. d. Number and location of tank welds e. Painting and electrical insulating paint application 12. Accessories: a. Bushings including connections of leads, bolting arrangements and sizes b. Gauges and indication devices c. Controls, wiring, conduit, etc. d. List of recommended spare parts and source locations for obtaining them e. Oil specification data sheet of oil to be supplied 13. Testing and test plan: a. Review of specification testing requirements b. SFRA testing details c. Acceptance criteria d. Applicable test standards 4.20 TESTS: Autotransformer shall be tested completely assembled, including all permanent bushings and cooling equipment. LCRA TSC reserves the right to visit the manufacturing facility and observe any and all tests and inspections. LCRA TSC shall be notified a minimum of three (3) weeks prior to the implementation of the required tests. The following test sequence shall be used: Routine Tests Load Loss Measurements No Load Loss and Excitation Current Measurements Single Phase Excitation Test 110% Excitation Test Temperature Tests Dielectric Tests Impulse Switching Surge Applied No Load Loss and Excitation Current Tests Noise Test Induced Test - The induced test with partial discharge measurement shall be made last. Sweep Frequency Response Analysis (SFRA) 4.20.1 All tests shall be made in accordance with applicable sections of latest revision of IEEE Standard C57.12.90. 34

Required tests shall include the following: 4.20.1.1 4.20.1.2 4.20.1.3 4.20.1.4 Resistance measurements on the rated voltage connection and at all tap extremes. All resistance values shall be converted to 20deg. C temperature. Ratio and regulation tests. Polarity and phase relation tests on all windings and BCTs. No load loss at rated voltage and at 110% rated voltage before and after impulse tests. Tests shall be performed at LTC positions 16L, Neutral, 1R, and 16R.

4.20.1.4.1 Single Phase Excitation Tests Single phase excitation tests shall be performed at 10KV with either Doble M2HD or M4000 test system. Measurements shall be made for each primary winding according to Doble procedures for making such measurements. Measurements shall be performed with DETC on highest voltage tap setting and on all LTC taps. Reports shall be delivered in both the Doble Test Assistant version 5.4 (or later) file format and on printed test reports with the certified test results. 4.20.1.5 Exciting current at rated voltage and at 110% rated voltage. The Contractor shall perform a 24 hour excitation test at 110% voltage. Oil samples shall be taken for gas in oil analysis immediately before and after the excitation test and an additional sample be taken eight to 12 hours after completion of the test. The measured gas levels shall be corrected to an equivalent 10,000 gallon oil level before comparison. The maximum increases in the gas levels based on the 10,000 gallon level are as shown: Ethylene Methane Ethane Acetylene 4.20.1.6 4.20.1.7 1 ppm 2 ppm 2 ppm Non detectable

Measured impedance, both positive and zero sequence. Load loss and auxiliary loss at base 55oC rise over ambient rating, and at maximum 65oC rating. Temperature rise tests at self cooled and maximum forced cooled ratings. A test shall also be performed to verify the 110% overload rating as defined in section 4.16.1.2, unless the Contractor can clearly demonstrate, based on self cooled and forced cooled test results, that the autotransformer is capable of meeting the overload requirement specified. Temperature rise data on duplicate units is not acceptable. Oil samples shall be taken for gas in oil analysis both before and after temperature rise testing. Test results and the Contractors analysis shall be submitted to LCRA TSC prior to acceptance for autotransformer shipment. Any increased level of combustible gases between the before and after tests shall be addressed by the Contractor and presented to LCRA TSC for approval. The measured gas levels shall be 35

4.20.1.8

corrected to an equivalent 10,000 gallon oil level before comparison. The maximum increases in the gas levels based on the 10,000 gallon level are as shown: Hydrogen Ethylene Methane Ethane Acetylene Carbon Monoxide Carbon Dioxide 4.20.1.9 20 ppm 3 ppm 5 ppm 5 ppm Non detectable 75 ppm 250 ppm

Applied potential tests. The applied voltage test shall be made in accordance with the appropriate ANSI/IEEE standards and with the following test voltages: HV LV TV Neutral 50 kV 50 kV 50 kV 50 kV

Partial Discharge (PD) measurements shall be taken during the applied test. PD in picocoulombs should be measured and recorded at 15 second intervals, shall be less than 500 pC and shall not increase by more than 100 pC during the test. 4.20.1.10 Induced potential tests as specified in ANSI C57.12.90-1993, also, partial discharge testing and measurements must be taken during the test, including the one hour duration test. Failure will be as specified in IEEE C57.12.902010, section 10.8.5. Oil samples shall be taken before and after induced tests. a) b) c) d) The corona shall be measured and recorded at the 150% level as the voltage is being increased to the enhancement level of 173%. The corona shall be measured and recorded at the enhancement level. The first reading at 150% following the enhancement shall be taken five (5) minutes after the voltage reaches the 150% level and every five (5) minutes thereafter for one (1) hour. The corona level shall not exceed 100 micro volts during the hour. The corona level shall not increase more than 30 micro volts during the hour using the value at 150% prior to the enhancement as the base reading. There shall be no continuous increase during the hour or during the last 20 minutes of the hour. In the event that the 100 micro volts limit, the 30 micro volts increase, or the continuous increase requirement are exceeded, the cause shall be determined and corrected.

e)

4.20.1.11 Insulation power factor tests by IEEE C57.12.90, Method II, (not to exceed 0.5% corrected to 20oC in accordance with Doble Temperature Charts). 36