Beruflich Dokumente

Kultur Dokumente

Slag

Hochgeladen von

nuwans69Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Slag

Hochgeladen von

nuwans69Copyright:

Verfügbare Formate

Slag

From Wikipedia, the free encyclopedia Jump to: navigation, search For other uses, see Slag (disambiguation).

A path through a slag heap in Clarkdale, Arizona, showing the striations from the rusting corrugated sheets retaining it.

The Manufacture of Iron -- Carting Away the Scori (slag), an 1873 wood engraving

Slag run-off from one of the open hearth furnaces of a steel mill, Republic Steel, Youngstown, Ohio. Slag is drawn off the furnace just before the molten steel is poured into ladles for ingotting. Slag is a partially vitreous by-product of the process of smelting ore, which separates the desired metal fraction from the unwanted fraction. Slag is usually a mixture of metal oxides and silicon dioxide. However, slags can contain metal sulfides and metal atoms in the elemental form. While slags are generally used to remove waste in metal smelting, they can also serve other purposes, such as assisting in the temperature control of the smelting, and minimizing any re-oxidation of the final liquid metal product before the molten metal is removed from the furnace and used to make solid metal.

Contents

1 Ore smelting 2 Ancient slag use 3 Modern slag uses 4 Basic slag 5 See also 6 References 7 Further reading

Ore smelting

In nature, the ores of metals such as iron, copper, lead, nickel and other metals are found in impure states, often oxidized and mixed in with silicates of other metals. During smelting, when the ore is exposed to high temperatures, these impurities are separated from the molten metal and can be removed. Slag is the collection of compounds that are removed. In many smelting

processes, oxides are introduced to control the slag chemistry, assisting in the removal of impurities and protecting the furnace refractory lining from excessive wear. In this case, the slag is termed synthetic. A good example is steelmaking slag: quicklime and magnesite are introduced for refractory protection, neutralising the alumina and silica separated from the metal, and assist in the removal of sulfur and phosphorus from the steel. Ferrous and non-ferrous smelting processes produce different slags. The smelting of copper and lead in non-ferrous smelting, for instance, is designed to remove the iron and silica that often occurs with those ores, and separates them as iron-silicate-based slags. Slag from steel mills in ferrous smelting, on the other hand, is designed to minimize iron loss and so mainly contains oxides of calcium, silicon, magnesium, and aluminium. Any sandy component or quartz component of the original ore automatically carries through the smelting process as silicon dioxide. As the slag is channeled out of the furnace, water is poured over it. This rapid cooling, often from a temperature of around 2,600 F (1,430 C), is the start of the granulating process. This process causes several chemical reactions to take place within the material, and gives the slag its cementitious properties. The water carries the slag in its slurry format to a large agitation tank, from where it is pumped along a piping system into a number of gravel based filter beds. The filter beds then retain the slag granules, while the water filters away and is returned to the system. When the filtering process is complete, the remaining slag granules, which now give the appearance of coarse beach sand, can be scooped out of the filter bed and transferred to the grinding facility where they are ground into particles that are finer than Portland cement.

Ancient slag use

Early slag from Denmark, ca. 200-500 AD During the Bronze Age of the Mediterranean there were a vast number of differential metallurgical processes in use. A slag by-product of such workings was a colorful, glassy, vitreous material found on the surfaces of slag from ancient copper foundries. It was primarily blue or green and was formerly chipped away and melted down to make glassware products and jewelry. It was also ground into powder to add to glazes for use in ceramics. Some of the earliest such uses for the by-products of slag have been found in ancient Egypt.[1]

Historically, the re-smelting of iron ore slag was common practice, as improved smelting techniques permitted greater iron yields--in some case exceeding that which was originally achieved. During the early 20th century, iron ore slag was also ground to a powder and used to make 'Agate Glass', also known as 'Slag Glass'.[2]

Modern slag uses

Ground granulated slag is often used in concrete in combination with Portland cement as part of a blended cement. Ground granulated slag reacts with water to produce cementitious properties. Concrete containing ground granulated slag develops strength over a longer period, leading to reduced permeability and better durability. Since the unit volume of Portland cement is reduced, this concrete is less vulnerable to alkali-silica and sulfate attack.[citation needed] This previously unwanted recycled product is used in the manufacture of high performance concretes, especially those used in the construction of bridges and coastal features, where its low permeability and greater resistance to chlorides and sulfates can help to reduce corrosive action and deterioration of the structure.[3] The slag can also be used to create fibers used as an insulation material named slag wool.

Basic slag

Basic slag is a byproduct of steelmaking using the basic version of the Bessemer process or the Linz-Donawitz process. It is largely limestone or dolomite which has absorbed phosphate from the iron ore being smelted. Because of the slowly released phosphate content, and because of its liming effect, it is valued as fertilizer in gardens and farms in steelmaking areas.

See also

Dross Fly ash Ground granulated blast furnace slag Pozzolan Spoil heap Tailings

References

1. ^ "The chemical composition of glass in Ancient Egypt by Mikey Brass (1999)". Retrieved 2009-06-18. 2. ^ http://www.oldandsold.com/articles02/glass-g.shtml 3. ^ "High Performance Cement for High Strength and Extreme Durability by Konstantin Sobolev". Archived from the original on 2009-08-03. Retrieved 2009-06-18.

Further reading

Dimitrova, S.V. (1996). "Metal sorption on blast-furnace slag". Water Research 30 (1): 228232. doi:10.1016/0043-1354(95)00104-S. Roy, D.M. (1982). "Hydration, structure, and properties of blast furnace slag cements, mortars, and concrete". ACI Journal Proceedings 79 (6). Fredericci, C.; Zanotto, E.D., Ziemath, E.C. (2000). "Crystallization mechanism and properties of a blast furnace slag glass". Journal of Non-Crystalline Solids 273 (13): 64 75. doi:10.1016/S0022-3093(00)00145-9.

Das könnte Ihnen auch gefallen

- Literature Review: Vitreous By-Product Smelting Ore Metal Oxides Silicon Dioxide Sulfides AtomsDokument1 SeiteLiterature Review: Vitreous By-Product Smelting Ore Metal Oxides Silicon Dioxide Sulfides Atomsnuwans69Noch keine Bewertungen

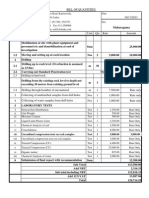

- Typical Floor Structure CostDokument3 SeitenTypical Floor Structure Costnuwans69Noch keine Bewertungen

- Study On The Effect of Silica Fume On Improvement of RCC Pavement Mechanical PropertiesDokument2 SeitenStudy On The Effect of Silica Fume On Improvement of RCC Pavement Mechanical Propertiesnuwans69Noch keine Bewertungen

- Q 11 Nov 27 MaDokument1 SeiteQ 11 Nov 27 Manuwans69Noch keine Bewertungen

- Irrigation Guide: National Engineering HandbookDokument6 SeitenIrrigation Guide: National Engineering Handbooknuwans69Noch keine Bewertungen

- Post Tensioning in Building StructuresDokument21 SeitenPost Tensioning in Building StructuresLuan Truong VanNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- StandardsDokument3 SeitenStandardshappystamps100% (1)

- TDS - Atlac 382 Powder - ENGDokument2 SeitenTDS - Atlac 382 Powder - ENGGoran MalinovicNoch keine Bewertungen

- Cement and Concrete Presentation Lafarge PDFDokument131 SeitenCement and Concrete Presentation Lafarge PDFLou VreNoch keine Bewertungen

- IIT Delhi Placement BrochureDokument7 SeitenIIT Delhi Placement BrochureAnmol SinhaNoch keine Bewertungen

- 3 Frans Knops - XFlow - UF For Safe Drinking Water Final - 2 Oct 2014Dokument26 Seiten3 Frans Knops - XFlow - UF For Safe Drinking Water Final - 2 Oct 2014manojrawat21Noch keine Bewertungen

- 188888Dokument1 Seite188888Sumit PatelNoch keine Bewertungen

- Printmaking NotesDokument16 SeitenPrintmaking Notesapi-279660401100% (1)

- Roscas Métricas: Tolerância Do Diâmetro de Furo para Roscar - Macho de CorteDokument8 SeitenRoscas Métricas: Tolerância Do Diâmetro de Furo para Roscar - Macho de CorteRoberto PrudencioNoch keine Bewertungen

- Plagiarism - ReportDokument42 SeitenPlagiarism - ReportJerick HernandezNoch keine Bewertungen

- Shielded Metal Arc Welding (Stick Welding)Dokument26 SeitenShielded Metal Arc Welding (Stick Welding)Anonymous mRBbdopMKfNoch keine Bewertungen

- Norsok Standard M-501: Rev. 5, June 2004Dokument24 SeitenNorsok Standard M-501: Rev. 5, June 2004Nelson Matos100% (1)

- Process Quality Control Sheet (I)Dokument3 SeitenProcess Quality Control Sheet (I)Ramesh MishraNoch keine Bewertungen

- SK Form 1: Gripper With HolderDokument16 SeitenSK Form 1: Gripper With HolderVladimirAgeevNoch keine Bewertungen

- Korepox Topcoat ET6572Dokument2 SeitenKorepox Topcoat ET6572Isabelo AbaoNoch keine Bewertungen

- Astm A480 Plate ToleranceDokument25 SeitenAstm A480 Plate ToleranceCik NisaNoch keine Bewertungen

- Grabber Screws 5280Dokument0 SeitenGrabber Screws 5280murdicksNoch keine Bewertungen

- Mowital: Technical Data SheetDokument4 SeitenMowital: Technical Data SheetIsidro CM100% (1)

- Rate of Reaction - Grade 8 WorksheetDokument7 SeitenRate of Reaction - Grade 8 Worksheetfrancisca liku-nema0% (1)

- Simazinc Silicate MC: Product Data SheetDokument3 SeitenSimazinc Silicate MC: Product Data SheetMuhammad Mulya JatiNoch keine Bewertungen

- DC TC L 3030, 4030,..., Bosch, 07.98, ENDokument111 SeitenDC TC L 3030, 4030,..., Bosch, 07.98, ENDarkNoch keine Bewertungen

- Applications For Jigs and FixturesDokument10 SeitenApplications For Jigs and FixturesAntay Korakot100% (1)

- Teflon Based GasketsDokument2 SeitenTeflon Based GasketsAndroidNoch keine Bewertungen

- Zam Tech Brochure PDFDokument60 SeitenZam Tech Brochure PDFTowkir AhmmadNoch keine Bewertungen

- BS 2874Dokument1 SeiteBS 2874poydulefya0% (2)

- Shaper Machine (Lab)Dokument2 SeitenShaper Machine (Lab)AbdulNoch keine Bewertungen

- Br20 - B.Tech. - Mechanical Engineering Syllabus: Course ObjectivesDokument2 SeitenBr20 - B.Tech. - Mechanical Engineering Syllabus: Course ObjectivesBashu Dev SanjelNoch keine Bewertungen

- Welding Defect ChartDokument2 SeitenWelding Defect ChartPavan_yoyo100% (4)

- BHP SpecDokument29 SeitenBHP Spectam ngoNoch keine Bewertungen

- Paint Repair ProcedureDokument1 SeitePaint Repair ProcedureJennifer Bradley100% (2)

- Internship ReportDokument34 SeitenInternship Reportsumit sharmaNoch keine Bewertungen