Beruflich Dokumente

Kultur Dokumente

Preventive Maintenanace

Hochgeladen von

Mohammed NerissaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Preventive Maintenanace

Hochgeladen von

Mohammed NerissaCopyright:

Verfügbare Formate

Preventive Maintenance 4.

1 Introduction Preventive maintenance, as its name implies are specific tasks that are designed to prevent the need for corrective or breakdown maintenance, as well as prolong the useful life of capital assets and auxiliary equipment. (Definition) Most preventive maintenance programs are a loose conglomeration of inspections, cleaning, adjustment, lubrication and similar tasks that do little, if anything, to preserve the reliability of critical production assets. Statistically, between 33 percent and 42 percent of so-called preventive maintenance tasks add no value, in terms of reliability or maintenance prevention. Reliability-based preventive maintenance replaces these no-value tasks with specific maintenance activities that both prevents failures and prolong the useful life of plant assets. Preventive maintenance (PM) is an important component of a comprehensive maintenance management plan. Within a maintenance organization it usually accounts for a major proportion of the total maintenance effort. PM may be described as the caring and servicing by individuals involved with maintenance to keep equipment/facilities in satisfactory operational state by performing systematic inspection, detection and correction of incipient failures either prior to their occurrence or prior to their development into major failure. Some of the main objectives of PM are to: Enhance capital equipment productive life. Reduce critical equipment breakdowns. Allow better planning and scheduling of needed maintenance work. Minimize production losses due to equipment failures. Promote health and safety of maintenance personnel. From time to time, PM programs in maintenance organizations end up in failure (i.e. they lose upper management support) because their cost is either unjustifiable or they take a significant time to show results. It is emphasized that all PM must be cost effective. The most important principle to keep continuous management support is: If it is not going to save money, then dont do it!

The preventive maintenance program can be developed using a guided logic approach and is task oriented rather than maintenance process oriented. This eliminates the confusion associated with the various interpretations across different industries. By using a task-oriented concept, it is possible to see the whole maintenance program reflected for any given item. A decision logic tree can be used to identify applicable maintenance tasks. Servicing and lubrication are included as part of the logic diagram since this ensures that an important task category is considered each time an item is analyzed. The content of any maintenance programme consists of at least two groups of tasks: Preventive Maintenance tasks. Non-scheduled maintenance tasks.

The preventive maintenance tasks which include failure-finding tasks, are scheduled to be accomplished at specified intervals or based on condition. The objective of these tasks is to identify and prevent deterioration below inherent safety and reliability levels by one or more of the following means: Lubrication and servicing Operational, visual or automated checking Inspection, functional test or condition monitoring Restoration Discard

This group of tasks is determined by Reliability Centred Analysis, RCM analysis, that is, it constitutes the RCM-based preventive maintenance program. The non-scheduled maintenance tasks result from the following: Findings from the scheduled tasks accomplished at specified intervals of time or usage. Reports of malfunctions or indications of impending failure (including automated detection).

The objective of the second group of tasks is to maintain or restore the equipment to an acceptable condition in which it can perform its required function. An effective program schedules only those tasks necessary to meet the stated objectives.

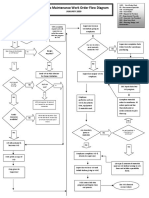

It does not schedule additional tasks that increase maintenance costs without a corresponding increase in the inherent level of reliability. Experience has clearly demonstrated that reliability decreases when inappropriate or unnecessary maintenance tasks are performed due to an increased incidence of maintainer-induced faults. Development of a reliability-based preventive maintenance program follows the logic diagram shown in Fig. 4.1 and the task selection criteria illustrated in Table 4.2 and described in Section 4.6 are its principal tools. The logic diagram are the basis of an evaluation technique applied to each functionally significant item (FSI) using all available technical data, as well as the native knowledge of plant personnel. This module presents important aspects of PM.

Fig. 4.1 Development tasks of a Reliability-based Preventive Maintenance Program

4.2 Preventive maintenance elements, plant characteristics in need a principle for selecting items for PM There are seven elements of PM as shown in Fig. 4.2.

of a PM program and

Fig. 4.2 Seven Elements of Preventive Maintenance. The seven elements of a Preventive Maintenance programmed are as follows: 1) Inspection: Periodically inspecting materials/items to determine their serviceability by comparing their physical, electrical, mechanical, chemical etc., characteristics (as applicable) to expected standards. 2) Servicing: Cleaning, lubricating, charging, preservation, etc., of items/materials periodically to prevent the occurrence of incipient failures. 3) Calibration: Periodically determining the value of characteristics of an item by comparison to a standard.

It is the process of comparing of two instruments, one of which has a certified standard with known accuracy, to detect and adjust any discrepancy in the accuracy of the material/parameter being used to measure a process or operating parameter. 4) Testing: Periodically testing and/or checking out the integrity of critical items of plant to determine their serviceability and detect any electrical/mechanical-related degradation. 5) Alignment: Making changes to an items specified variable or adjustable elements for the purpose of achieving optimum performance. 6) Adjustment: Periodically adjusting specified variable elements of material for the purpose of achieving the optimum system performance. 7) Installation: Periodic replacement of limited-life items or the items wear degradation, to maintain the specified system tolerance.

experiencing time cycle or

Some characteristics of a plant in need of a good preventive maintenance program are as follows: Low equipment use due to failures. Large volume of scrap and rejects due to unreliable equipment. Rise in equipment repair costs due to negligence in areas such as regular lubrication, inspection and replacement of worn items/components. High idle operator times due to equipment failures. Reduction in capital equipment expected productive life due to unsatisfactory maintenance. Table 4.1 presents 17 questions for determining the adequacy of a preventive maintenance program within an organization. The answer yes or no to each question is given 5 or 0 points, respectively. A maybe answer is assigned a score from 1 to 4. A total score of less than 55 points indicates that the preventive maintenance program requires further improvements.

Table 4.1 Preventive Maintenance Evaluation Questions

4.3 Important Steps for establishing a PM program To develop an effective PM program, the availability of a number of items is necessary. Some of those items include the following: Accurate historical records of equipment. Manufacturers recommendations on spares, maintenance requirements etc. Skilled personnel. Past data from similar equipment. Service manuals. Unique identification of all equipment. Appropriate test instruments and tools. Management support and user cooperation. Failure information by problem/cause/action. Consumables and replaceable components/parts. Clearly written instructions with a checklist to be signed off. There are a number of steps involved in developing a PM program. Figure 4.3 presents six steps for establishing a highly effective PM program in a short period.

Fig. 4.3 Six steps for developing a Preventive Maintenance Program Each step is discussed below.

1) Identify and choose the areas. Identify and selection of one or two important areas to concentrate the initial PM effort. These areas should be crucial to the success of overall plant operations and may be experiencing a high degree of maintenance actions. The main objective of this step is to obtain immediate results in highly visible areas, as well as to win concerned management support.

2) Identify the PM needs. Define the PM requirements. Establish a schedule of two types of tasks: daily PM inspections and periodic PM assignments/tasks. The daily PM inspections could be conducted by either maintenance or production personnel. An example of a daily PM inspection is to check the waste water solids concentration. Periodic PM assignments/tasks are usually performed by the maintenance workers. Examples of such assignments/tasks are replacing throwaway filters, replacing drive belts and cleaning steam traps and permanent filters etc. 3) Establish frequency of assignment or tasks. Establish the frequency of the assignments/tasks. This involves reviewing the equipment condition and records. Normally, the basis for establishing the frequency is the experience of those familiar with the equipment and the recommendations of vendors and relevant engineers. It must be remembered that vendor recommendations are generally based on the typical usage of items under consideration. (More details would be provided later in Section 4.7 on establishing the task frequency/interval) 4) Prepare the PM assignments/tasks. Daily and periodic assignments/tasks are identified and described in detail, then submitted for approval. 5) Schedule the PM assignments/tasks on an annual basis. The defined PM assignments/tasks are scheduled on the basis of a twelvemonth period. 6) Expand the PM program as necessary.

After the implementation of all PM daily inspections and periodic assignments in the initially selected areas, the PM can be expanded to other areas. Experience gained from the pilot PM projects is instrumental to expanding the program.

4.4 Reliability-based Preventive Maintenance [Read for general information but can be left out] In the development of a reliability-based preventive maintenance program for both new and inservice equipment, the progressive logic diagram and the task selection criteria are the principal tools. This progressive logic is the basis of an evaluation technique applied to each functionally significant item (FSI) using the technical data available. Principally, the evaluations are based on the items functional failures and failure causes. The development of a reliability-based preventive maintenance program is based on the following: Identification of FSIs Identification of applicable and effective preventive maintenance tasks using the decision tree logic. A functionally significant item is an item whose failure would affect safety or could have significant operational or economic impact in a particular operating or maintenance context. Identification of FSIs is based on the anticipated consequences of failures using an analytical approach and good engineering judgment. The process also use a top-down approach, and is conducted first at the system level, then at the subsystem level and where appropriate, down to the component level. An iterative process should be followed in identifying FSIs. Systems and subsystem boundaries and functions are first identified. This permits selection of critical systems for further analysis which involves a more comprehensive and detailed definition of system, system functions, and systems functional failures. The procedures shown in Fig. 4.1 such as information collection, system analysis and so on, outline a comprehensive set of tasks in the FSI identification process. All these tasks should be applied in the case of complex or new equipment.

However, in the case of well-established or simple equipment, where functions and functional degradation/failures are well recognized, tasks listed under the heading of 4.4.2 System Analysis can be covered very quickly. They should be documented, however, to confirm that they were considered. The depth and rigor used in the application of these tasks also varies with the complexity and newness of the equipment. 4.4.1 Information Collection Equipment information provides the basis for the evaluation and should be assembled prior to the start of the analysis and supplemented as the need arises. The following should be included: Requirements for equipment and its associated systems, including regulatory requirements. Design and maintenance documentation. Performance feedback, including maintenance and failure data. Also, to guarantee completeness and avoid duplication, the evaluation should be based on an appropriate and logical breakdown of the equipment. 4.4.2 System Analysis The tasks just described specify the procedure for the identification of the functionally significant items and the subsequent maintenance task selection and implementation. Note that the tasks can be tailored to meet the requirements of particular industries and the emphasis placed on each task depends on the nature of that industry.

4.4.3 Identification of Systems The objective of this task is to partition the equipment into systems, grouping the components contributing to achievement of well-identified functions and identifying the system boundaries. Sometimes, it is necessary to perform further partitioning into the subsystems that perform functions critical to system performance. The system boundaries may not be limited by the physical boundaries of the systems, which may overlap. Frequently, the equipment is already partitioned into systems through industry-specific partitioning schemes.

This partitioning should be reviewed and adjusted where necessary to ensure that it is functionally oriented. The results of equipment partitioning should be documented in a master system index, which identifies systems, components and boundaries.

4.4.4 Identification of System Functions The objective of this task is to determine the main and auxiliary functions performed by the systems and subsystems. The use of functional block diagrams assist in the identification of system functions. The function specification describes the actions or requirements the system or subsystem should accomplish, sometimes in terms of performance capabilities within the specified limits. The functions should be identified for all modes of equipment operation. Reviewing design specifications, design descriptions and operating procedures, including safety, abnormal operations and emergency instructions may determine the main and auxiliary functions. Functions such as testing or preparation for maintenance, if not considered important, may be omitted. The reason for omissions must be given. The product of this task is a listing of system functions. 4.4.5 Selection of Systems The objective of this task is to select and rank systems to be included in the RCM program because of their significance to equipment safety, availability, or economics. The methods used to select and rank the systems can be divided into Qualitative methods based on past history and collective engineering judgment.

Quantitative methods based on quantitative criteria such as criticality rating, safety factors, probability of failure, failure rate, or life cycle cost, used to evaluate the importance of system degradation or failure on equipment safety, performance and costs. Implementation of this approach is facilitated when appropriate models and data banks exist. A combination of qualitative and quantitative methods.

The product of this task is a listing of systems ranked by criticality. The systems, together with the methods, the criteria used and the results should be documented.

4.4.6 System Functional Failure and Criticality Ranking The objective of this task is to identify system functional degradations and failures and rank them on priority. The functional degradation or failure of a system for each function should be identified, ranked by criticality and documented. Since each system functional failure may have a different impact on safety, availability and maintenance cost, it is necessary to rank and assign priorities to them. The ranking takes into account probability of occurrence and consequences of failure. Qualitative methods based on collective engineering judgment and the analysis of operating experience can be used. Quantitative methods such as Simplified Failure Modes and Effects Analysis (SFMEA) or risk analysis also can be used. The ranking represents one of the most important tasks in RCM analysis. Too conservative a ranking may lead to an excessive preventive maintenance program, and conversely, a lower ranking may result in excessive failures and a potential safety impact. In both cases, a non-optimized maintenance program results. The outputs of this task are the following: List of system functional degradations and failures and their characteristics. Ranked list of system functional degradations and failures.

4.5 Identification of functionally significant items Based on the identification of system functions, functional degradations and failures and their effects and collective engineering judgment, it is possible to identify and develop a list of FSIs. As said before, failure of these items could affect safety, be undetectable during normal operation and have significant operational or economic impact. The output of this task is a list of candidate FSIs.

4.5.1 Functionally Significant Item Failure Analysis Once an FSI list has been developed, a method such as Failure Modes and Effects Analysis (FMEA) should be used to identify the following information which is necessary for the logic tree evaluation of each FSI. The following examples refer to the failure of a pump providing cooling water flow: Function. The normal characteristic actions of the item, a cooling water pump (e.g. to provide cooling water flow at 100 l/s to 240 l/s to a heat exchanger). Functional failure. How the item fails to perform its function (e.g., pump fails to provide required flow). Failure cause. Why the functional failure occurs (e.g., bearing failure). Failure effect. What is the immediate effect and the wider consequence of each functional failure (e.g. inadequate cooling, leading to overheating and failure of the system). The FSI failure analysis is intended to identify functional failures and failure causes. Failures not considered credible such as those resulting solely from undetected manufacturing faults, unlikely failure mechanisms or unlikely external occurrences should be recorded as having been considered and the factors that caused them to be assessed as not credibly stated. Prior to applying the decision logic tree analysis to each FSI, preliminary worksheets need to be completed that clearly define the FSI, its functions, functional failures, failure causes, failure effects and any additional data pertinent to the item (e.g. manufacturers part number, a brief description of the item, predicted or measured failure rate, hidden functions, redundancy). These worksheets should be designed to meet the users requirements. From this analysis, the critical FSIs can be identified (i.e., those that have both significant functional effects and a high probability of failure or have a medium probability of failure but are judged critical or have a significantly poor maintenance record). 4.6 Maintenance Tasks Explanations of the terms used in the possible tasks as shown in Table 4.2 are as follows: Lubrication/servicing (all categories). This involves any act of lubricating or servicing for maintaining capabilities. inherent design

Operational/Visual/Automated check (hidden functional failure categories only). An operational check is to determine that an item is fulfilling its does not require quantitative checks and is a failure-finding task. intended purpose. It

A visual check is an observation to determine that an item is fulfilling its intended purpose and does not require quantitative tolerances. This, again, is a failure-finding task. The visual check could also involve interrogating electronic units that store failure data.

Inspection/functional check/condition monitoring (all categories). An inspection is an examination of an item against a specific standard. A functional check is a quantitative check to determine if one or more functions of an item performs within specified limits. Condition monitoring is a task, which may be continuous or the condition of an item in operation against preset parameters. Restoration (all categories). Restoration is the work necessary to return the item to a specific standard. Since restoration may vary from cleaning or replacement of single parts up to a complete overhaul, the scope of each assigned restoration task has to be specified. Discard (all categories). Discard is the removal from service of an item at a specified life Discard tasks are normally applied to so-called single-cell parts canisters, cylinders, turbine discs, safe life structural members, and the like. Combination (safety categories). Since this is a safety category question and a task is required, all should be analyzed. To do this, a review of the applicable tasks is necessary. From this review, the most effective tasks should be selected. possible avenues limit. such as periodic to monitor

cartridges,

No task (all categories). It may be decided that no task is required in some situations, effect. Each of the possible tasks just defined is based on its effectiveness criteria. Table depending on own applicability the and

4.2 summarizes these task selection criteria.

Table 4.2 Task Selection Criteria

4.7 Task Frequencies/Intervals To set a task frequency or interval, it is necessary to determine the existence of applicable operational experience data that suggest an effective interval for task accomplishment. Appropriate information may be obtained from one or more of the following: Prior knowledge from other similar equipment shows that a scheduled maintenance task has offered substantial evidence of being applicable, effective and economically worthwhile. Manufacturer or supplier test data indicate that a scheduled maintenance task is applicable and effective for the item being evaluated. Reliability data and predictions.

Safety and cost considerations need to be addressed in establishing the maintenance intervals.

Scheduled inspections and replacement intervals should coincide whenever possible and tasks should be grouped to reduce the operational impact. The safety replacement interval can be established from the cumulative failure distribution for the item by choosing a replacement interval that results in an extremely low probability of failure prior to replacement. Where a failure does not cause a safety hazard but causes loss of availability, the replacement interval is established in a trade-off process involving the cost of replacement components, the cost of failure and the availability requirement of the equipment. Mathematical models exist for determining task frequencies and intervals, but these models depend on the availability of the appropriate data. These data are specific to particular industries and those industry standards and data sheets should be consulted as appropriate. If there is insufficient reliability data or no prior knowledge from other similar equipment, or if there is insufficient similarity between the previous and current systems, the task interval frequency can be established initially only by experienced personnel using good judgment and operating experience in concert with the best available operating data and relevant cost data.

4.7 PM Advantages and Disadvantages Some advantages of PM are as follows: Increase in equipment availability. Performed as convenient. i.e. Can be scheduled conveniently. Balanced workload and use of resources. Reduction in overtime costs which are exceptionally high with breakdown maintenance. Increase in production revenue. Consistency in quality. Reduction in need for standby equipment. Increase in preaction (proactive) instead of reaction. Reduction in parts inventory. Improved safety, standardized procedures, times and costs. Scheduled resources on hand. Useful in promoting cost/benefit optimization.

Some disadvantages of PM are as follows: Exposing equipment to possible damage. Using a greater number of parts. Increases in initial costs. Failures in new parts/components.

Demands more frequent access to equipment/item.

Questions 1) Discuss at least five important elements of PM. 2) What are the symptoms of a plant in need of a good PM program? 3) State any five (5) questions that can be asked to determine the adequacy of a PM program? 4) Comment on the principle or formula proposed to decide whether to go ahead with a PM program. 5) List at least ten items whose availability is essential to develop an effective PM program. 6) Discuss important steps for developing a PM program. 7) What are the benefits and drawbacks of performing PM? 8) Using the automobile as an example, list some of the preventive maintenance tasks that are performed and how they improve the performance and minimize breakdown.

Das könnte Ihnen auch gefallen

- Infor EAM OverviewDokument22 SeitenInfor EAM Overviewmunchen88Noch keine Bewertungen

- Stock VerificationDokument26 SeitenStock VerificationRishi MaliNoch keine Bewertungen

- G. Spare Parts ManagementDokument12 SeitenG. Spare Parts ManagementVipul TikekarNoch keine Bewertungen

- Work Order Flow DiagramDokument1 SeiteWork Order Flow DiagramrinthusNoch keine Bewertungen

- UNSPSCDokument991 SeitenUNSPSCJoan AtupNoch keine Bewertungen

- Supplier Assessment Report-Shenzhen Illuman Photoelectronic Co., LTDDokument29 SeitenSupplier Assessment Report-Shenzhen Illuman Photoelectronic Co., LTDAdam Andrew OngNoch keine Bewertungen

- Spir Form Rev3Dokument6 SeitenSpir Form Rev3foamtrailer100% (1)

- P1 Emergency P2 Critical P3 Urgent P4 Routine Total: M-1: Corrective and Reactive MaintenanceDokument8 SeitenP1 Emergency P2 Critical P3 Urgent P4 Routine Total: M-1: Corrective and Reactive Maintenancevishvesh9595Noch keine Bewertungen

- Fieldwork ObservationDokument6 SeitenFieldwork ObservationYesenia SolisNoch keine Bewertungen

- MaintenanceDokument44 SeitenMaintenanceLatifahabubakar Eifa100% (1)

- 6 - Inventory SystemDokument8 Seiten6 - Inventory SystemLancemachang EugenioNoch keine Bewertungen

- Maintenance TechnicianDokument1 SeiteMaintenance TechnicianpushpanjalijNoch keine Bewertungen

- Manufacturing Manager CVDokument3 SeitenManufacturing Manager CVsanjay_lingotNoch keine Bewertungen

- Manpower Calculator Introduction V1.5Dokument18 SeitenManpower Calculator Introduction V1.5lisahunNoch keine Bewertungen

- Key Performance Indicators (KPIs) - WarehousingDokument5 SeitenKey Performance Indicators (KPIs) - WarehousingPerumal DM100% (1)

- Mapcon CMMS Feature ChartDokument6 SeitenMapcon CMMS Feature ChartStar RangerNoch keine Bewertungen

- SAP PM Presentation SlideDokument201 SeitenSAP PM Presentation SlideJohn Bryan AlabataNoch keine Bewertungen

- RE140 Section 2 - Maintenance Policies (NXPowerLite)Dokument39 SeitenRE140 Section 2 - Maintenance Policies (NXPowerLite)Ahmed FaragNoch keine Bewertungen

- Types of Maintenance - A ComparisonDokument18 SeitenTypes of Maintenance - A ComparisonEusebio NavarroNoch keine Bewertungen

- Maintenance Manager 1598637070Dokument4 SeitenMaintenance Manager 1598637070Alyssa ArdeleanNoch keine Bewertungen

- M and S Guide of Mining 200912Dokument47 SeitenM and S Guide of Mining 200912ЦЕНТР ПРОФЕССИОНАЛЬНЫХ КОМПЕТЕНЦИЙ ТОИР ProNoch keine Bewertungen

- Maintenance KPI Short AssignmentDokument10 SeitenMaintenance KPI Short AssignmentGuadagustinNoch keine Bewertungen

- Ujvnl PM Calibration Maintenance User ManualDokument40 SeitenUjvnl PM Calibration Maintenance User ManualSiva Thunga50% (2)

- Breakdown and Preventive MaintenanceDokument19 SeitenBreakdown and Preventive Maintenancevikram2588singh100% (1)

- Effluent Treatment PlantDokument11 SeitenEffluent Treatment Plantmts1234100% (1)

- Predictive MaintenanceDokument9 SeitenPredictive MaintenanceGabo García GranizoNoch keine Bewertungen

- Maintenance PDFDokument632 SeitenMaintenance PDFMargaret DaughertyNoch keine Bewertungen

- Disposition of Non-Capital Scrap and Salvageable Material and EquipmentDokument3 SeitenDisposition of Non-Capital Scrap and Salvageable Material and EquipmentevikrismayantiNoch keine Bewertungen

- Maintenance Procedure PDFDokument6 SeitenMaintenance Procedure PDFAya AbdoNoch keine Bewertungen

- PM OverviewDokument25 SeitenPM Overviewmohitamitabh20Noch keine Bewertungen

- Maintenance Group - Manual - PM PDFDokument346 SeitenMaintenance Group - Manual - PM PDFNarasimha Prasad Bhat100% (1)

- Spark ArrestorDokument6 SeitenSpark Arrestorrania hseNoch keine Bewertungen

- PM CustomisationDokument109 SeitenPM CustomisationvenkatspinnerNoch keine Bewertungen

- Chapter 1pptDokument46 SeitenChapter 1pptEjizen LowNoch keine Bewertungen

- Mechanical ForemanDokument7 SeitenMechanical Foremanbook1616Noch keine Bewertungen

- Presentation1 MaintenanceDokument12 SeitenPresentation1 MaintenanceSteven AdityaNoch keine Bewertungen

- MaintenanceDokument2 SeitenMaintenancepitesoft0% (1)

- 05 - Madinah Hotel Auditing Procedures - Rajhi - 2012 - 2013Dokument19 Seiten05 - Madinah Hotel Auditing Procedures - Rajhi - 2012 - 2013Santo Mulyono100% (1)

- Maintenance Planner Resume Samples - Velvet JobsDokument97 SeitenMaintenance Planner Resume Samples - Velvet JobsVlade Epifanio100% (1)

- OEE ExamplesDokument4 SeitenOEE ExamplesSrinivas N GowdaNoch keine Bewertungen

- Completion Order Creation For Notif. Material Issuance Service Procurement Notification CreationDokument1 SeiteCompletion Order Creation For Notif. Material Issuance Service Procurement Notification Creationbuzz filmsNoch keine Bewertungen

- Reciepts of Fixed AsstesDokument10 SeitenReciepts of Fixed Asstespriya6batra-2Noch keine Bewertungen

- Towards World Class In-Plant Logistics: Hindustan Industries LimitedDokument2 SeitenTowards World Class In-Plant Logistics: Hindustan Industries LimitedAravind Maddireddy100% (1)

- PM OverviewDokument143 SeitenPM OverviewRam KumarNoch keine Bewertungen

- Responsibilities of A FACTORY MANAGERDokument3 SeitenResponsibilities of A FACTORY MANAGERPawan KinnalNoch keine Bewertungen

- Journal of Quality in Maintenance EngineeringDokument20 SeitenJournal of Quality in Maintenance EngineeringJose100% (1)

- SCLM ChecklistDokument38 SeitenSCLM ChecklistMayur GaidhaneNoch keine Bewertungen

- Bachelor of Mechanical Engineering With 10 Years of ExperienceDokument5 SeitenBachelor of Mechanical Engineering With 10 Years of ExperienceChandra ReddyNoch keine Bewertungen

- Computerized Maintenance Management Systems (CMMS)Dokument8 SeitenComputerized Maintenance Management Systems (CMMS)Asep HermanNoch keine Bewertungen

- Fleet Management of Technical ObjectsDokument37 SeitenFleet Management of Technical ObjectsKiran KumarNoch keine Bewertungen

- Plant Operation & MaintenanceDokument19 SeitenPlant Operation & Maintenancejuliyanto88100% (2)

- Maintenance Spares Inventory Management PDFDokument7 SeitenMaintenance Spares Inventory Management PDFsaeedalemveNoch keine Bewertungen

- Production Manager, Plant Superintendent, Plant Manager, ProjectDokument3 SeitenProduction Manager, Plant Superintendent, Plant Manager, Projectapi-76771249Noch keine Bewertungen

- Store ManagementDokument64 SeitenStore ManagementshahzanladiwalaNoch keine Bewertungen

- Amc FormatDokument4 SeitenAmc FormatchennaicmsNoch keine Bewertungen

- Preventive MaintenanceDokument19 SeitenPreventive Maintenancefaizan9970% (1)

- Chapter 4Dokument37 SeitenChapter 4kirubel AlemuNoch keine Bewertungen

- Maintenance ManagementDokument20 SeitenMaintenance ManagementRiya GuptaNoch keine Bewertungen

- CMRTDokument102 SeitenCMRTMukaila IbrahimNoch keine Bewertungen

- Maintenance Terms and DefinitionsDokument47 SeitenMaintenance Terms and DefinitionsSitota Tesfaye100% (1)

- Determine Maintenace StrategyDokument18 SeitenDetermine Maintenace StrategyJalel Bejo GudinaNoch keine Bewertungen

- Course Notes Part 1 - Chapters 1 To 4Dokument94 SeitenCourse Notes Part 1 - Chapters 1 To 4mashabathakgathompho86Noch keine Bewertungen

- b1b8 PDFDokument2 Seitenb1b8 PDFAhmed Daahir AhmedNoch keine Bewertungen

- Reflection 1Dokument6 SeitenReflection 1api-177768681Noch keine Bewertungen

- M 2 Data Analytics LifecycleDokument22 SeitenM 2 Data Analytics Lifecyclebhuvangates100% (1)

- Technology Absorption and AcquisitionfinalDokument33 SeitenTechnology Absorption and AcquisitionfinalChandra Abhishek GuptaNoch keine Bewertungen

- Mineral ResourcesDokument137 SeitenMineral ResourcesAlvaro MadridNoch keine Bewertungen

- Cleanth Brooks - Literary History Vs CriticismDokument11 SeitenCleanth Brooks - Literary History Vs CriticismPayal AgarwalNoch keine Bewertungen

- A Social History of England, 15 - Wrightson, KeithDokument738 SeitenA Social History of England, 15 - Wrightson, KeithThiago Krause100% (3)

- Oracle Demantra OverviewDokument25 SeitenOracle Demantra OverviewVenkata Sambhasiva Rao CheedellaNoch keine Bewertungen

- PDF Converted MISDokument144 SeitenPDF Converted MISElakkiyaNoch keine Bewertungen

- Linear Regression and CorrelationDokument26 SeitenLinear Regression and CorrelationIptysam Al-AlawiNoch keine Bewertungen

- Examining The Determinants ofDokument36 SeitenExamining The Determinants ofKhissey AmaradoNoch keine Bewertungen

- Accepted Manuscript: Computer Methods and Programs in BiomedicineDokument23 SeitenAccepted Manuscript: Computer Methods and Programs in BiomedicineToyota MitsubishiNoch keine Bewertungen

- Research Frameworks, Methodologies, and Assessment Methods Concerning The Adaptive Reuse of Architectural Heritage - A ReviewDokument19 SeitenResearch Frameworks, Methodologies, and Assessment Methods Concerning The Adaptive Reuse of Architectural Heritage - A ReviewAtul GargNoch keine Bewertungen

- Calabrese1999 PDFDokument9 SeitenCalabrese1999 PDFROSNANINoch keine Bewertungen

- Qai 86 200Dokument8 SeitenQai 86 200RishabhNoch keine Bewertungen

- Graph TheoryDokument16 SeitenGraph TheoryMobin MohanNoch keine Bewertungen

- Notice: Agency Information Collection Activities Proposals, Submissions, and ApprovalsDokument2 SeitenNotice: Agency Information Collection Activities Proposals, Submissions, and ApprovalsJustia.comNoch keine Bewertungen

- Terms of ReferenceDokument3 SeitenTerms of ReferenceirdinamarchsyaNoch keine Bewertungen

- Managing NASA in The Apollo EraDokument354 SeitenManaging NASA in The Apollo EraBob AndrepontNoch keine Bewertungen

- Evaluation 3Dokument12 SeitenEvaluation 3api-456090970Noch keine Bewertungen

- Npioh, JURNAL ERIKA 203-207 PDFDokument5 SeitenNpioh, JURNAL ERIKA 203-207 PDFReski AmaliyaNoch keine Bewertungen

- Consult QuestionnaireDokument2 SeitenConsult Questionnairedmartin78Noch keine Bewertungen

- Kalpana ChawlaDokument3 SeitenKalpana ChawlaHari Ka Pin KyNoch keine Bewertungen

- Synopsis of SandeepDokument9 SeitenSynopsis of SandeepsandeepchaurasiyaNoch keine Bewertungen

- Chapter 5Dokument40 SeitenChapter 5Ebisa ChemedaNoch keine Bewertungen

- Understanding SAT Scores 2018 PDFDokument10 SeitenUnderstanding SAT Scores 2018 PDFHo Yiu YinNoch keine Bewertungen

- Modern English GrammarDokument287 SeitenModern English GrammarAnonymous SR0AF3100% (4)

- Lesson Plan in Mathematics 10: Mary Elaine R. GundoyDokument3 SeitenLesson Plan in Mathematics 10: Mary Elaine R. GundoyFERWINA SANCHEZ0% (1)