Beruflich Dokumente

Kultur Dokumente

FIRERAY 2000: Installation Guide

Hochgeladen von

Bassem El HachacheOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

FIRERAY 2000: Installation Guide

Hochgeladen von

Bassem El HachacheCopyright:

Verfügbare Formate

FIRERAY 2000

Installation Guide

Features Range 33ft to 330 ft. 24Vdc operation Selectable alarm thresholds Low current consumption Ground level electronics Manual or Automatic reset

System Description FIRERAY 2000 comprises a transmitter, which projects a modulated infra-red light beam to a receiver. The received signal is analysed by a controller usually located at ground level. If smoke is present in the beam path for more than approx. 8 to 10 seconds, a fire relay is activated. The system is designed to be mounted to project the beam approx. 19ins below and parallel to a roof or ceiling at ranges up to 330ft. The maximum lateral detection range is 25ft either side of the actual beam. Smoke Detection If smoke is present in the beam, the received signal is reduced by a level determined by the density of the smoke. If the smoke reduces the signal strength to between the obscuration threshold and 93%, for more than 8 to 10 seconds, the fire alarm output is activated. The alarm threshold may be set to 25%, 35% or 50%, to suit the installation. Application notes For indoor use only For wall mounting only Do not install in locations where the normal ambient temperature exceeds 1000F Install in accordance with NFPA 72 (National Fire Alarm Code)

Auto Reset: After a Trouble condition is indicated, the control unit automatically resets if the cause is no longer present. The fire alarm may be latching or non-latching (close ALARM switch for latching). Automatic Gain Control (AGC): Long term degradation of the signal strength by component ageing or build up of dirt on optical surfaces will not generate an alarm because of compensation provided by an AGC circuit. This operates by comparing the received signal against a standard at predetermined time intervals. Differences of more than 7% are corrected by the automatic selection of gain stages. The AGC time interval is factory set to nominally 1.5 hours.

22318.02.P JUNE 01

Page 1

Principle of Detection The infra-red signal is projected from the Transmitter via an optical system. At 330ft the diameter of this beam is approximately 10ft. This wide-angle beam arrangement helps to simplify alignment and give alignment stability. It is important that FIRERAY is positioned correctly to minimize the detection time. Experiments have shown that smoke from a fire not only rises upwards, but also fans out in a mushroom shape due to air currents and heat layering effects. A fire alarm condition occurs when the infrared beam is obscured beyond a preset threshold. The indication time depends on the location of FIRERAY within the protected area, the volume of smoke produced, the construction of the roof and the ventilation arrangements. For FIRERAY positioned beneath flat ceilings the smoke has to curl its way into the detection zone from the point on the ceiling directly above the fire. The time taken depends upon the distance of the fire from the beam axis, the height of the beam above the source of the fire and the slope of the ceiling. The maximum distance either side of the beam axis is found to be typically 25ft for satisfactory detection under flat ceilings, providing a maximum total area coverage of 16,500 square feet (50ft x 330ft). Smoke layering is overcome by mounting FIRERAY at the recommended height, so projecting the infra-red beam below the heat layer and into the smoke layer. Detection time will be longer in a building with a peaked roof if a fire occurs at the fringes of the protected area. The recommended installation height is approximately 19 inches below the ceiling. However in all installations the national fire standards for that country must be consulted. Once established, then ensure a clearance of 6 top, bottom and sides of the beam path is maintained for its entire length. If there is any doubt on the correct mounting height, positioning may be determined by smoke tests. RETRO Operation FIRERAY may be configured so as to operate in RETRO mode. For this, the optical heads are mounted adjacent (as close as possible) to each other. The infra-red signal is returned via prisms. This type of operation is useful when access to the opposing wall is restricted, and where wiring is difficult. When installed, a clear line of sight between the heads and the prisms has to be maintained. If a reflective object is placed in the line of sight, then the infra-red signal may be returned via this and not the prisms. As any potential smoke is passing through the projected beam twice, the alarm level should be set accordingly. The recommended positioning of FIRERAY is as shown on page 3. Prisms See Technical data for Prism details. The Prisms should be mounted at right angles to the infrared beam. Alignment FIRERAY is aligned as for conventional operation. There is an extra test that should be performed. When the system is aligned in the normal operating mode, block off the prisms, (at the prism end). FIRERAY should indicate Trouble. If not, it is possible that the signal has been returned via a surface other than the prisms.

22318.02.P JUNE 01

Page 2

Example Installation Details

(Note : Fireray 2000 must be installed in accordance with NFPA72)

SINGLE BEAM SEE NOTE 1 50ft

25ft 25ft 19ins

Tx

MULTIPLE BEAMS 100ft MAX.

25ft 19ins

Tx Tx Tx Tx Tx

150ft AND OVER

25ft 50ft 50ft

A ceiling or roof with a slope in excess of 3.5 degrees should be regarded as an apex roof. Note 1: No more than 10ft approx of the beam path should be within 19ins approx of any wall or partitions. When Firerays are mounted in the apex the horizontal distance may increase by 1% for each degree of ceiling slope, up to 25% maximum, (for Fireray in apex only).

APEX CEILINGS 10 SLOPING ROOF

Tx

30 SLOPING ROOF

Tx

10 Tx

Tx

30

25ft

25ft.+25ft.+2.5ft 25ft.+25ft.+2.5ft

25ft.

62.5ft MAX. (25ft + 25ft + 12.5ft)

SLOPING CEILINGS

20

Tx Tx

19ins

Tx

25ft

50ft

SEE NOTE 1

RECEIVER AND TRANSMITTER SHOULD BE POSITIONED APPROX 19ins BELOW THE CEILING

22318.02.P JUNE 01

Page 3

Pre-installation at Ground Level

Controller : 1. The Controller should be positioned so that it is accessible but such that the cable (screened) connecting the Controller to the Receiver is not more than 330ft long. Care should be taken that this cable is routed away from building electrical cables and any switchgear. 2. There are knock-out holes in the upper, lower, and side faces for cable entries. Four (4), 0.275inch dia. fixing holes are located on the rear face, for installing the box to the building structure. Wiring connections are described on a label inside the controller door. See Figure 1. 3. Select the required options, (alarm threshold, alarm relay latching or not, AGC last stage operation).

Transmitter: 1. A range adjuster (potentiometer) is accessed though a removable grommet. For ranges of 330ft set the potentiometer to fully counter clockwise. Fully clockwise is 33ft. 2. The transmitter must be in the sight of the Receiver and mounted rigid on a secure section of the building. DO NOT INSTALL THE TRANSMITTER DIRECTLY TO CLADDING.

Receiver: 1. FIRERAY is immune to most normal ambient lighting conditions, however, the Receiver should be installed such that strong light sources, (artificial or sunlight), do not project directly into to the Receiver lens.

Installation Transmitters and Receivers 1. Locate the right angle fixing brackets for the Transmitter and Receiver so that they are on the line of sight and are both installed approximately 19inches below the ceiling. 2. Install the Optical heads on the brackets and position on the line of sight. Align Rx as accurately as possible to the Tx (by eye), 3. To avoid any possibility of working loose under vibration, tighten both the Receiver thumbwheel screws securely, using a suitable coin or wide-bladed screwdriver (Ensure it fills the thumbwheel slot completely to avoid slippage and damage).

4. Install all cables and connect as figure 1. (Heads are supplied with 3.3ft of cable & this

should be correctly terminated with the System wiring)

22318.02.P JUNE 01

Page 4

Installation (Continued) 5. Check that the RESET/TEST switch located in the Controller is in the ON position. 6. Position the Gain potentiometer in the Controller to the mid-way position. 7. Connect the supply and check first that it is within limits (13.5Vdc to 28Vdc) at the Transmitter and Controller. 8. At this stage signal High or Low LEDs may be illuminated.

Alignment: Method A Alignment Tool/Range Finder Optional extra (Refer to distributor)

1. Connect a temporary 3 core cable between the Alignment Tool and the Controller :-

Red to +VE SUPPLY Yellow to TEST METER +VE Black to VE SUPPLY

2. Position the Alignment Tool so that it is visible from the transmitter. 3. Move the Transmitter horizontally until a fast flash rate is achieved by the green LED,

or until it glows steadily.

4. Move the Transmitter vertically until the green LED glows steadily. If at any time the

red LED illuminates, then adjust the range pot on the transmitter body by turning clockwise until the the red LED extinquishes and the green LED glows steadily.

5. Go to Method B, Step 4.

Alignment : Method B Voltmeter 1. Connect the required length of two-core cable to the test meter outputs and run to the Transmitter. Connect a DC voltmeter (0 to 10V range) to this cable. 2. Adjust the Transmitter horizontally and vertically until a maximum reading of +5Vdc is obtained, (no signal reading is approximately 2.6V). 3. IF A READING OF GREATER THAN +5Vdc is obtained, reduce transmitter power by adjusting transmitter pot clockwise. 4. To avoid any possibility of working loose under vibration, tighten both the Transmitter thumbwheel screws securely, using a suitable coin or wide-blade screwdriver (Ensure it fills the thumbwheel slot completely to avoid slippage and damage). 5. At the Controller, adjust the Gain control potentiometer anti-clockwise until the high LED just extinguishes (both LEDs now off). 6. Move the RESET/TEST switch to the OFF position. (NOTE: Both the high and low LEDs must be off when switching out of reset, or the AGC will be locked out). 7. Wait at least 45 seconds while the system self-calibrates, before performing any tests.

22318.02.P JUNE 01

Smoke Alarm Test

Page 5

Hold the test filter in the beam path. After approximately 9 seconds the alarm relay will switch over, and the red alarm lamp will light. Remove the test filter, the alarm will reset after approximately 4 seconds (unless in latching mode).

To RESET after a FIRE alarm 1. Automatic (ALARM switch open). 2. Using the RESET/TEST switch. 3. By disconnecting the Controller supply for one (1) second. 4. By taking to 0v the NRST terminal for one second.

Trouble Alarm Test The Trouble relay and the Trouble lamp operate if the beam is totally blocked for approximately 10 seconds. Clearing the beam resets the Trouble indication after approximately 4 seconds.

Trouble Indication Causes of trouble alarms The controller at ground level being in RESET mode Infra-red beam being reduced in signal strength by more than 93% for more than 10 seconds. The AGC reaching the last stage of compensation (see note 1). Loss of power at Ground level Controller or at Transmitter Misalignment resulting in a received low signal.

Note There are two options available when the AGC runs out of compensation. 1. FIRERAY will, at the last stage, signal Trouble, but in the event of further signal loss down to the alarm threshold, a FIRE alarm will be indicated. This is for UK use only. Leave COMP switch open for this option.

2.

FIRERAY will, at the last gain stage, indicate Trouble and inhibit FIRE alarms. Close COMP switch for this option.

22318.02.P JUNE 01

Page 6

Connection and wiring diagram Figure 1

GOOD QUALITY SHIELDED 16/18 GAUGE CABLE BETWEEN CONTROLLER AND RECEIVER HEAD.

RELAY WIRING AS REQUIRED

GLAND

GLAND

Rx

SIGNAL LEVEL LOW HIGH TEST/RESET ON OFF

SW5 A L

R Y B

+V Rx SIGNAL Rx 0V Rx

TROUBLE LED

N/O N/C CO N/O N/C CO

A R M T R O U B L

+ Tx

TEST METER

ALARM LATCH COMP 25% 35% 50%

100MA

S U P P L Y 2 4 V d c

+ -

EXTERNAL RESET

GLAND

GLAND

- VE (0V)

+ VE (24Vdc)

MAY BE SAME P.S.U. AS FOR CONTROL UNIT P.S.U. (24Vdc)

REMOTE RESET SWITCH OR RELAY CLOSE MOMENTARILY TO RESET

- VE (0V)

+ VE (24Vdc)

P.S.U

22318.02.P JUNE 01

Technical Data

Page 7

DC Supply (at the Detector) 24Vdc Total quiescent current approx. 13 mA Total alarm current approx. 20 mA Tolerance to Beam misalignment at 35%: Tx: +/-1.00 , Rx: +/- 40 Fire alarm thresholds 1.25dB (25%) 1.87dB (35%) 3.0 dB (50%) * Moisture : 93%RH max, non-condensing Optical Wavelength 880nm

Service/installation Notes 25% and 35% thresholds are recommended for normal use. 50% threshold is recommended for retro mode. Contains ESD sensitive devices. Service personnel must take appropriate precautions (eg: wrist straps connected to unit door earth terminal) when entering the Controller unit. Not User Serviceable Refer to manufacturer or distributor for repair. For use as a smoke detector only No liability will be accepted for applications not conforming to NFPA regulations. Operating range 33ft to 330 ft. Alarm and Trouble indication by voltage free change over relay contacts. Receiver up to 330 ft cable run from Controller at ground level. Transmitter and Controller may be powered from separate/common supply. Alarm relay may be latching or non latching. Finish : White Rating : IP 50 Max. Sizes: Control unit 8.5 x 10.5 x 3.5 inches. Heads with Brackets 4 x 3.25 x 3.75 inches. Weights: Control Unit - 2.3lbs Heads + Brackets - 1.5lbs. When using prisms set the Transmitter range to maximum. Prisms: Use FFE Part No. 23901 Beam Ranges:6.5ft to 82ft use 1 prism 82ft to 115ft use 4 prisms (Square) 115ft to 148ft use 6 prisms (Rectangle) Parts List Transmitter with a clear lens Receiver with a dark lens Ground level controller Angle brackets + 4 bolts/washers Test Card.

22318.02.P JUNE 01

Page 8

Das könnte Ihnen auch gefallen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- CIRCUIT DIAGRAM Skoda Octavia IV Workshop Manual 2020Dokument3.017 SeitenCIRCUIT DIAGRAM Skoda Octavia IV Workshop Manual 2020Gábor KISPÉTER100% (1)

- Wire PIR Motion Detector To Wired Alarm SystemDokument25 SeitenWire PIR Motion Detector To Wired Alarm Systemkunene07Noch keine Bewertungen

- Touareg 4.2Dokument36 SeitenTouareg 4.2zozo0424Noch keine Bewertungen

- Power CablesDokument120 SeitenPower CablesroyclhorNoch keine Bewertungen

- Manual UPS DPH 80 120kVA en Us - 501328110000 PDFDokument250 SeitenManual UPS DPH 80 120kVA en Us - 501328110000 PDFMohammad KilaniNoch keine Bewertungen

- A Guide To Fire Alarm System Design BS 5839 Part 1 2002Dokument20 SeitenA Guide To Fire Alarm System Design BS 5839 Part 1 2002s525497100% (2)

- Buildings Utilities 2Dokument21 SeitenBuildings Utilities 2Rachel PetersNoch keine Bewertungen

- Arduino Upgraded Learning Kit ManualDokument116 SeitenArduino Upgraded Learning Kit Manualjohn christian de leonNoch keine Bewertungen

- BEAM355 and BEAM355S: Single-Ended, Reflected-Type Addressable Beam Smoke DetectorsDokument4 SeitenBEAM355 and BEAM355S: Single-Ended, Reflected-Type Addressable Beam Smoke DetectorsWilliam DiasNoch keine Bewertungen

- Bersoninline® Uv-System: User'S ManualDokument61 SeitenBersoninline® Uv-System: User'S Manualjanja_prižmićNoch keine Bewertungen

- Antenna Alignment GuideDokument4 SeitenAntenna Alignment GuideDanielle Kyle HudsonNoch keine Bewertungen

- Sd119 ManualDokument2 SeitenSd119 ManualVictor PatsiNoch keine Bewertungen

- Fire Ray 2000Dokument8 SeitenFire Ray 2000Antonio Chillón SeguraNoch keine Bewertungen

- Manual Fireray 50 100 RuDokument12 SeitenManual Fireray 50 100 RuMaria Camila ArenasNoch keine Bewertungen

- FD705RVDS FD710RVDS Instrukcja Instalacji enDokument14 SeitenFD705RVDS FD710RVDS Instrukcja Instalacji enb7246757nwldxcomNoch keine Bewertungen

- Bariera de Fum Fireray 2000Dokument4 SeitenBariera de Fum Fireray 2000Gh1taNoch keine Bewertungen

- 85001-0548 - Optical Beam Smoke DetectorDokument4 Seiten85001-0548 - Optical Beam Smoke Detectorpkgoyal1983Noch keine Bewertungen

- Fire Ray Beam Detector GuideDokument14 SeitenFire Ray Beam Detector GuidesureshkanuboyinaNoch keine Bewertungen

- Smoke Detector: Projected BeamDokument4 SeitenSmoke Detector: Projected Beaminventor_bkNoch keine Bewertungen

- Smoke Detector: Projected BeamDokument4 SeitenSmoke Detector: Projected BeamTer TerteNoch keine Bewertungen

- Gefl & Gefl-Ip Ceiling PIR Presence Detector: DimensionsDokument4 SeitenGefl & Gefl-Ip Ceiling PIR Presence Detector: DimensionsIbrahim SNoch keine Bewertungen

- Fire-Alarm A Guide To Bs5839 Part-1 2002Dokument114 SeitenFire-Alarm A Guide To Bs5839 Part-1 2002Nay Win MaungNoch keine Bewertungen

- Honeywell 997 Install GuideDokument4 SeitenHoneywell 997 Install GuideAlarm Grid Home Security and Alarm MonitoringNoch keine Bewertungen

- Dedicated PIR Light Controller C/W RF Remote Control For LEDPRO FloodlightsDokument20 SeitenDedicated PIR Light Controller C/W RF Remote Control For LEDPRO FloodlightsJohn ThompsonNoch keine Bewertungen

- Modulo 2.4ghz FrSky V8Dokument3 SeitenModulo 2.4ghz FrSky V8Pablo D. RigoNoch keine Bewertungen

- Smoke DetectorDokument2 SeitenSmoke DetectoratharvawazurkarNoch keine Bewertungen

- RF 360 Advanced Ceiling Mount PIR Installation Manual-1Dokument2 SeitenRF 360 Advanced Ceiling Mount PIR Installation Manual-1Imi Michał SmulskiNoch keine Bewertungen

- Honeywell Is2535 Spec SheetDokument5 SeitenHoneywell Is2535 Spec SheetAlarm Grid Home Security and Alarm MonitoringNoch keine Bewertungen

- LC-103PIMSK: Professional Passive Infrared & Microwave Detector With Anti-Mask With Pet ImmunityDokument2 SeitenLC-103PIMSK: Professional Passive Infrared & Microwave Detector With Anti-Mask With Pet ImmunityAndrei PantaNoch keine Bewertungen

- MFJ 1798Dokument30 SeitenMFJ 1798RODOLFONoch keine Bewertungen

- Nikrans NS-250GDW: Installation GuideDokument24 SeitenNikrans NS-250GDW: Installation Guidebasil sharyNoch keine Bewertungen

- Genius Plus: Electronic Engineering LTDDokument2 SeitenGenius Plus: Electronic Engineering LTDpil;zoNoch keine Bewertungen

- NFXI-BEAM Lineare PDFDokument6 SeitenNFXI-BEAM Lineare PDFDanielNoch keine Bewertungen

- Swiss Garde 360 Premium AP User ManualDokument8 SeitenSwiss Garde 360 Premium AP User ManualTonyandAnthonyNoch keine Bewertungen

- F50R Install Standard VDSDokument14 SeitenF50R Install Standard VDSEmir PanjetaNoch keine Bewertungen

- Beam Ray RFX70 ManualDokument16 SeitenBeam Ray RFX70 Manualwalid kawsarNoch keine Bewertungen

- C-9105 Conventional Linear Beam Smoke Detector Installation and Operation ManualDokument14 SeitenC-9105 Conventional Linear Beam Smoke Detector Installation and Operation ManualkatulaNoch keine Bewertungen

- 1 Manual Product 86Dokument21 Seiten1 Manual Product 86MaziyarNoch keine Bewertungen

- FIRERAY3000 - Linear Beam Detector DatasheetDokument4 SeitenFIRERAY3000 - Linear Beam Detector DatasheetdemonlichhNoch keine Bewertungen

- CC1608 - Fire Systems Design GuideDokument20 SeitenCC1608 - Fire Systems Design GuidePhạm Thanh Sơn0% (1)

- FireRay 100 PDFDokument12 SeitenFireRay 100 PDFSchrack SeconetNoch keine Bewertungen

- Installation Instructions: MFP RangeDokument12 SeitenInstallation Instructions: MFP RangevinpugalNoch keine Bewertungen

- The Guide To Fire Alarm Systems - Fire Systems DirectDokument12 SeitenThe Guide To Fire Alarm Systems - Fire Systems DirectSHANDEEPNoch keine Bewertungen

- HFC CATV SECTION5 Pre-InstallationDokument18 SeitenHFC CATV SECTION5 Pre-InstallationpahiescorpNoch keine Bewertungen

- Fireray 3000 DatasheetDokument2 SeitenFireray 3000 DatasheetRahul DevaNoch keine Bewertungen

- Honeywell IS216T CUR Install GuideDokument2 SeitenHoneywell IS216T CUR Install GuideAlarm Grid Home Security and Alarm MonitoringNoch keine Bewertungen

- Nikrans LCD-300GD: Installation GuideDokument21 SeitenNikrans LCD-300GD: Installation GuideGHOST RIDERNoch keine Bewertungen

- BS5839-1 Guide RK RafikiDokument16 SeitenBS5839-1 Guide RK Rafikimicklyons100% (1)

- Cisco Air Ant2544v4m RDokument12 SeitenCisco Air Ant2544v4m RJose Luis GomezNoch keine Bewertungen

- BS5839 GuideDokument19 SeitenBS5839 GuideFire and Security TrainingNoch keine Bewertungen

- Fireray: FeaturesDokument8 SeitenFireray: FeaturesIvan MihajlovicNoch keine Bewertungen

- Technical Manual: NoshokDokument4 SeitenTechnical Manual: NoshokMasagus Sapta RyandaNoch keine Bewertungen

- 1.1.0 General Description of VESDA Aspirating Smoke Detection SystemDokument9 Seiten1.1.0 General Description of VESDA Aspirating Smoke Detection SystemBen Lim100% (1)

- Manual Product 65Dokument21 SeitenManual Product 65AnonymNoch keine Bewertungen

- Infrared DetectorDokument9 SeitenInfrared DetectorMartin EscotoNoch keine Bewertungen

- Firebeam Xtra User GuideDokument16 SeitenFirebeam Xtra User GuideSreten TodorovicNoch keine Bewertungen

- LKS Dust Opacity Analyzer D10 2Dokument19 SeitenLKS Dust Opacity Analyzer D10 2KC WangNoch keine Bewertungen

- Square D Clipsal 90° Indoor PIR Occupancy Sensor: SLC5751L For Use With Wired C-Bus™ NetworksDokument28 SeitenSquare D Clipsal 90° Indoor PIR Occupancy Sensor: SLC5751L For Use With Wired C-Bus™ NetworkskahandawalaNoch keine Bewertungen

- Datong AD370 InstructionsDokument5 SeitenDatong AD370 Instructionsdaniel21667Noch keine Bewertungen

- System Sensor CO1224T - 4-Wire CO Detector Installation ManualDokument4 SeitenSystem Sensor CO1224T - 4-Wire CO Detector Installation ManualAlarm Grid Home Security and Alarm MonitoringNoch keine Bewertungen

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationVon EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNoch keine Bewertungen

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationVon EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNoch keine Bewertungen

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- A 90 PCSCDokument87 SeitenA 90 PCSCnassarkiNoch keine Bewertungen

- Basics of Rotary Encoders: Overview and New Technologies: Print CloseDokument13 SeitenBasics of Rotary Encoders: Overview and New Technologies: Print CloseholaNoch keine Bewertungen

- Corrosion Kinetics BasheerDokument9 SeitenCorrosion Kinetics Basheerchenabeel0% (1)

- ABB Price Book 732Dokument1 SeiteABB Price Book 732EliasNoch keine Bewertungen

- Micropumps-Past, Progress and Future Prospects: Peter WoiasDokument11 SeitenMicropumps-Past, Progress and Future Prospects: Peter WoiasChandra SekarNoch keine Bewertungen

- Hall Thruster Performance Using Low Cost PropellantDokument6 SeitenHall Thruster Performance Using Low Cost PropellantСергей АсмоловскийNoch keine Bewertungen

- Non Sinusoidal Voltage - Non Sinusoidal Current ProblemDokument3 SeitenNon Sinusoidal Voltage - Non Sinusoidal Current ProblemChihiya Fitria Nurhayati100% (1)

- LG Flatron E700SHDokument2 SeitenLG Flatron E700SHjayakarwNoch keine Bewertungen

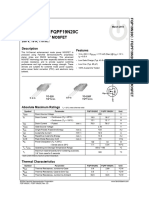

- FQP19N20CDokument10 SeitenFQP19N20CVinicio VieiraNoch keine Bewertungen

- 216B, 226, 232B, 236, 242, 246, 248, 252, 262, and 268 Skid Steer Loaders and 247, 257, 267, 277, and 287 Multi Terrain Loader Sist. Elect.Dokument4 Seiten216B, 226, 232B, 236, 242, 246, 248, 252, 262, and 268 Skid Steer Loaders and 247, 257, 267, 277, and 287 Multi Terrain Loader Sist. Elect.Pablo PorrasNoch keine Bewertungen

- Mos FabricationDokument35 SeitenMos FabricationNhật HoàngNoch keine Bewertungen

- JVC Hxd77uj 494014 15 12 2010Dokument57 SeitenJVC Hxd77uj 494014 15 12 2010Cuthbert MarshallNoch keine Bewertungen

- Photo Electric SensorDokument176 SeitenPhoto Electric SensorAlfiansyah Dharma Setia Djaketra100% (1)

- Datasheet UBECDokument1 SeiteDatasheet UBECjajang_elektro_untirtaNoch keine Bewertungen

- Topic 16 - Muhammad Rizky - 2LBDokument5 SeitenTopic 16 - Muhammad Rizky - 2LBMuhammad RizkyNoch keine Bewertungen

- General InspectionDokument1 SeiteGeneral InspectionPraveenNoch keine Bewertungen

- Exchange InteractionDokument20 SeitenExchange InteractionPranali TalekarNoch keine Bewertungen

- RSH-3 EngDokument4 SeitenRSH-3 Engnewm21Noch keine Bewertungen

- Data Sheet-DG Set - Rev 0Dokument6 SeitenData Sheet-DG Set - Rev 0jhakg_169712275Noch keine Bewertungen

- Micro Assignment 2 (17BEC1009)Dokument12 SeitenMicro Assignment 2 (17BEC1009)Austin NixonNoch keine Bewertungen

- School K 12 GuideDokument60 SeitenSchool K 12 GuideTran HuyNoch keine Bewertungen

- Uee Unit-1 Electrical DrivesDokument99 SeitenUee Unit-1 Electrical Drivessaharsha surviNoch keine Bewertungen

- Technical Data and Curve Characteristics: Technical Guide P12X/En T04/B44 Micom P120/P121/P122/P123Dokument34 SeitenTechnical Data and Curve Characteristics: Technical Guide P12X/En T04/B44 Micom P120/P121/P122/P123Leo TranNoch keine Bewertungen