Beruflich Dokumente

Kultur Dokumente

'Chapter 1

Hochgeladen von

Marshall-tendai Zifa-sire Zuku-chibikaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

'Chapter 1

Hochgeladen von

Marshall-tendai Zifa-sire Zuku-chibikaCopyright:

Verfügbare Formate

`Chapter 1

1.0 Introduction Milling is a common process that is done in the food industry and one of the main companies that does it in Zimbabwe its Blue Ribbon. There are two main types of corn milling namely wet milling and dry-milling. According to Kelly S (2001), wet milling is a process in which feed material is steeped in water, with or without sulphur dioxide, to soften the seed kernel in order to help separate the kernels various components while dry milling is a process in which the feed material. (continue with the things that you need to deal with in other it is just general literature review) 1.1Background Blue Ribbon is a company that is widely known in Zimbabwe and it was founded in 1978 the companys prime raw materials are maize and wheat. It has two main products, Ngwerewere and Chibataura. For every production process a by-product in the form of corn offals is produced and it is sold as stock feed. Corn offals are a mixture of corn germ and bran. Blue Ribbon operates at 24hours a day and the production ratio of the company follows the ratio of 4.5:3.5:2 for Ngwerewere, Chibataura and offals respectively. Blue Ribbon processes 5 040 tonnes per week and of the processed weekly batch 1008 tonnes are for offals. Offals are vulnerable to rancidity and because of that offals cannot be ground to be part of the mealie meal. According to Labuza et al (2002) this case of rancidity is due to high oil content that is found in the germ of the corn. 1.2Statement of the problem Changes in the economic status and in the cases of high drought rate in Zimbabwe have made such companies as Blue ribbon and Grain marketing board (GMB) to starve. Over the years Zimbabwe has been totally depending on neighboring countries for resources and food. Currently most of the maize corn that is being processed is imported mainly from Zambia because of such a scenario it is very important for Zimbabwean grain processing companies to have a way of maximizing on their production rate and as well as bring aid to the boosting of the countrys economy. Survival is what the industry needs and if Blue Ribbon is operating at this particular rate of no maximization of the profits and opportunities then the industry is likely to

suffer a deficiency in the long run. Blue Ribbon does not have a constant supply of raw materials and because of such a condition the full capitalization is greatly deprived. 1.3 Justification The offals sales $120.00 per tonne which means for each particular week the company benefits a total amount of $120,960.00 and this amount seems like a significantly huge return to the company. Breaking the amount per unit, each 50kg of offals costs $6.00 and by evaluation this amount is not proportional, therefore an alternative product other than offals is great needed. This product must be of great help to the company and it must boost the company economic status. An offal based product in the form of offal protein isolate would be a better edge to the company, since the companys production returns based on offals is 5%. Such a percentage does not favor capitalization to Blue Ribbon especially in times of maize corn shortages. 1.4 Aim To investigate the constituents of corn offals and to design the manufacturing process of an offal based product 1.5 Objectives To increase production returns of waste products from 5% to 15% at Blue Ribbon. To determine the constituents of corn offals with high preference on protein content To design the manufacturing process of an offal based product

1.6 Benefits To the researcher - It was to help the designer to partially fulfill his Bachelor of Technology degree in Food Processing Technology. The project also assisted the designer to gain valuable knowledge and experience in the industry especially on the subject under studied To academia It was a way of opening an avenue for further research and improvements to this current research. To the company The project was to assist Blue Ribbon in meeting the current market demands and at the same time increasing its production returns.

1.7 Delimitations The project was limited to fat, moisture and protein tests on the corn offals and not on corn variety evaluation. Focus was mainly on the product design process and the costs of scaling up were not included.

Das könnte Ihnen auch gefallen

- Making Biodiesel How to brew your own fuel at your backyardVon EverandMaking Biodiesel How to brew your own fuel at your backyardNoch keine Bewertungen

- The AG Nutriceutical StoryDokument8 SeitenThe AG Nutriceutical StoryNorina GenistonNoch keine Bewertungen

- GTM RepDokument54 SeitenGTM Repketan171092Noch keine Bewertungen

- A Study On The Production and Marketing of Dairy Products: A Case Study of Kombo North Cooperative Society of West Coast RegionDokument5 SeitenA Study On The Production and Marketing of Dairy Products: A Case Study of Kombo North Cooperative Society of West Coast RegionJon Bisu DebnathNoch keine Bewertungen

- Learing Activity 1 Direction: Search For The Current Dairy Industry Inventory in The PhilippinesDokument2 SeitenLearing Activity 1 Direction: Search For The Current Dairy Industry Inventory in The PhilippinesHarold IdjaoNoch keine Bewertungen

- Business Plan For "Good Grain Wheat Farming Enterprise": Food Security and Health Awareness (AFE 202)Dokument16 SeitenBusiness Plan For "Good Grain Wheat Farming Enterprise": Food Security and Health Awareness (AFE 202)Ugochukwu victorNoch keine Bewertungen

- Term Paper About Rice ProductionDokument5 SeitenTerm Paper About Rice Productionafmabhxbudpljr100% (1)

- Noble Gold Business PlanDokument19 SeitenNoble Gold Business PlanmutegiNoch keine Bewertungen

- Feasibility StudyDokument27 SeitenFeasibility Studymanuel V polidoNoch keine Bewertungen

- A Project Report On Labor Absenteeism at Riddhi Siddhi Gluco Biols LTDDokument75 SeitenA Project Report On Labor Absenteeism at Riddhi Siddhi Gluco Biols LTDBabasab Patil (Karrisatte)Noch keine Bewertungen

- Cassava Business ProposalDokument39 SeitenCassava Business Proposaleducationconsultance2001Noch keine Bewertungen

- International Marketing Plan EDENDokument9 SeitenInternational Marketing Plan EDENBeatriceNoch keine Bewertungen

- Grain & Feed Milling Technology - July - August 2012Dokument52 SeitenGrain & Feed Milling Technology - July - August 2012Milling and Grain magazine100% (1)

- Cocoa FarmingDokument6 SeitenCocoa FarmingJan PolNoch keine Bewertungen

- Value Addition in CoconutDokument31 SeitenValue Addition in Coconutjsphemil100% (1)

- Tiret ExpansDokument35 SeitenTiret Expansmesfin eshete100% (1)

- BSC ThesisDokument89 SeitenBSC ThesisGemechis TolaNoch keine Bewertungen

- Silage Production For FeedDokument19 SeitenSilage Production For Feedabhijitpaymal100% (1)

- Castor Business Plan - enDokument28 SeitenCastor Business Plan - enVpsingh86% (7)

- Mountain Maid Industry Inspection TripDokument5 SeitenMountain Maid Industry Inspection TripGem CarpioNoch keine Bewertungen

- P&G Food LLP ProfileDokument4 SeitenP&G Food LLP Profileshashikant.g84Noch keine Bewertungen

- Agricultural Transformation AgendaDokument22 SeitenAgricultural Transformation AgendaengrgeorgemarcNoch keine Bewertungen

- Soya Powder FFFFFFFFDokument28 SeitenSoya Powder FFFFFFFFabduNoch keine Bewertungen

- Manguguma Sapnayon-GUIDECODokument18 SeitenManguguma Sapnayon-GUIDECOYvonne Jane TanateNoch keine Bewertungen

- Preparation of Biscuts CommerciallyDokument86 SeitenPreparation of Biscuts CommerciallyChakkara VarthyNoch keine Bewertungen

- Global Partnership of Palm Oil PDFDokument21 SeitenGlobal Partnership of Palm Oil PDFiman fakhrudinNoch keine Bewertungen

- Hawirehiwot (1w)Dokument63 SeitenHawirehiwot (1w)JemalNoch keine Bewertungen

- Corn Storage Business PlanDokument7 SeitenCorn Storage Business PlanOkechukwu DikeNoch keine Bewertungen

- Group 8 - Performance TaskDokument8 SeitenGroup 8 - Performance TaskCarl Lewis TongcuaNoch keine Bewertungen

- Kaveri Seed Company LTDDokument9 SeitenKaveri Seed Company LTDinuniversalNoch keine Bewertungen

- A Project Report On "Study of On Time Delivery of Riddhi Siddhi Gluco Biols Limited, Products."Dokument56 SeitenA Project Report On "Study of On Time Delivery of Riddhi Siddhi Gluco Biols Limited, Products."Babasab Patil (Karrisatte)Noch keine Bewertungen

- PGDBST 05 PDFDokument86 SeitenPGDBST 05 PDFTariku TesfayeNoch keine Bewertungen

- Dairy Investment ProposalDokument13 SeitenDairy Investment ProposalRashid IbrahimNoch keine Bewertungen

- Prodoc Draft 1Dokument16 SeitenProdoc Draft 1Jasper MuvezwaNoch keine Bewertungen

- A Case Study of Expeller Production of Soybean Flour in IndiaDokument24 SeitenA Case Study of Expeller Production of Soybean Flour in IndiapertmasterNoch keine Bewertungen

- Tandin EditedDokument24 SeitenTandin EditedTandin TsheringNoch keine Bewertungen

- Doctor Kekalo Pinto Bean Whole Supplier: 1. Executive SummaryDokument12 SeitenDoctor Kekalo Pinto Bean Whole Supplier: 1. Executive Summaryalemayehu tarikuNoch keine Bewertungen

- TMR Business PlanDokument19 SeitenTMR Business PlanRuel PerochoNoch keine Bewertungen

- Enzymes in BakeryDokument23 SeitenEnzymes in Bakeryaditi_nangia_1Noch keine Bewertungen

- Consumer Preception Towards Itc Bingo - 178935952Dokument47 SeitenConsumer Preception Towards Itc Bingo - 178935952Abdul rauf100% (1)

- Customer Satisfaction Tow Ards Swakrushi MilkDokument53 SeitenCustomer Satisfaction Tow Ards Swakrushi MilkgouthamNoch keine Bewertungen

- Mother Dairy Saurabh TyagiDokument40 SeitenMother Dairy Saurabh TyagiSaurabh TyagiNoch keine Bewertungen

- 3000 Word ReportDokument17 Seiten3000 Word ReportDrJyoti AgarwalNoch keine Bewertungen

- Ms Module-2Dokument7 SeitenMs Module-2Mikkilineni Bhavya saiNoch keine Bewertungen

- Tactical Report AnsgaryDokument3 SeitenTactical Report AnsgaryAnsgary KihinjaNoch keine Bewertungen

- Bakery Industry in IndiaDokument5 SeitenBakery Industry in IndiacrypticookieNoch keine Bewertungen

- Project Report On Comparative Analysis of Amul With Other BrandsDokument121 SeitenProject Report On Comparative Analysis of Amul With Other BrandsSheetal YadavNoch keine Bewertungen

- Amul Butter Project 111Dokument45 SeitenAmul Butter Project 111Rejoy John100% (4)

- FS para Graduate AmenDokument57 SeitenFS para Graduate AmenEleah Kim PamplonaNoch keine Bewertungen

- Article Yeast BioFuels Business 2Dokument3 SeitenArticle Yeast BioFuels Business 2Jasraj Singh DhanjuNoch keine Bewertungen

- Mango Seed OilDokument8 SeitenMango Seed OilFrancis Peñaflor0% (1)

- UIA Paper - Vegetable OilDokument10 SeitenUIA Paper - Vegetable Oilnewone404Noch keine Bewertungen

- How To Run Kalonga MillingDokument13 SeitenHow To Run Kalonga MillingDerickMwansa100% (2)

- Coconut Industryd7215b868a875f8Dokument6 SeitenCoconut Industryd7215b868a875f8Igk Adi WinataNoch keine Bewertungen

- AmulDokument41 SeitenAmulParag MaheshwariNoch keine Bewertungen

- Seed Production and Trianing ManualDokument103 SeitenSeed Production and Trianing ManualDario BaronaNoch keine Bewertungen

- Tavistock & DZLDokument5 SeitenTavistock & DZLManjera Makumbinde AlphaaNoch keine Bewertungen

- Assignment On Bunge Case.Dokument4 SeitenAssignment On Bunge Case.Harshad DankeNoch keine Bewertungen

- Aannan Babile Milk Production EnterpriseDokument27 SeitenAannan Babile Milk Production EnterpriseLencho Mamude BaroNoch keine Bewertungen

- Tofu Soya Micro Entreprise BMDokument7 SeitenTofu Soya Micro Entreprise BMmaddyNoch keine Bewertungen

- 0457 Marking MemeoDokument11 Seiten0457 Marking MemeoMarshall-tendai Zifa-sire Zuku-chibikaNoch keine Bewertungen

- MARK SCHEME For The May/June 2006 Question Paper: University of Cambridge International Examinations GCE O LevelDokument2 SeitenMARK SCHEME For The May/June 2006 Question Paper: University of Cambridge International Examinations GCE O Levelkaran79Noch keine Bewertungen

- Vacuum CleanerDokument17 SeitenVacuum CleanerMarshall-tendai Zifa-sire Zuku-chibikaNoch keine Bewertungen

- BioWorld Bioremediation Oil Spill SummaryDokument16 SeitenBioWorld Bioremediation Oil Spill SummaryMarshall-tendai Zifa-sire Zuku-chibikaNoch keine Bewertungen

- Investigating Bacteria On Oil Spots by Developing Bioremediation Measurement MethodsDokument1 SeiteInvestigating Bacteria On Oil Spots by Developing Bioremediation Measurement MethodsMarshall-tendai Zifa-sire Zuku-chibikaNoch keine Bewertungen

- 9702 w04 Ms 1Dokument4 Seiten9702 w04 Ms 1Marshall-tendai Zifa-sire Zuku-chibikaNoch keine Bewertungen

- Cfa Level 1 2011 Practice Exams Vol 1Dokument286 SeitenCfa Level 1 2011 Practice Exams Vol 1Marshall-tendai Zifa-sire Zuku-chibika100% (1)

- RF26 - D-7 SRVC ManDokument137 SeitenRF26 - D-7 SRVC Mandan theman100% (2)

- Hul SwotDokument17 SeitenHul SwotAbhishek KanodiaNoch keine Bewertungen

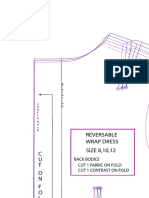

- Wrap Around Dress Pattern PDFDokument8 SeitenWrap Around Dress Pattern PDFStefaniaRosatiNoch keine Bewertungen

- Vardhman VMT Baddi Training Report Hall 2Dokument57 SeitenVardhman VMT Baddi Training Report Hall 2ManishK. NegiNoch keine Bewertungen

- Operations Management SlidesDokument87 SeitenOperations Management SlidesrockstarchandreshNoch keine Bewertungen

- Black Light Naked Yoga Join FKKs Vinyasa FlowintheDarklvlkg PDFDokument2 SeitenBlack Light Naked Yoga Join FKKs Vinyasa FlowintheDarklvlkg PDFpolicearcher19Noch keine Bewertungen

- Haldiram PPT 110113235127 Phpapp01Dokument17 SeitenHaldiram PPT 110113235127 Phpapp01Bharat SahniNoch keine Bewertungen

- Activity No. 2 Evidence Guiding Principle 1Dokument2 SeitenActivity No. 2 Evidence Guiding Principle 1Stephen EstalNoch keine Bewertungen

- Vietnam Accredited ExportersDokument80 SeitenVietnam Accredited Exporterstamchau nguyenngocNoch keine Bewertungen

- Hamelman Appendix Sourdough CultureDokument12 SeitenHamelman Appendix Sourdough CultureCris_tinutzaNoch keine Bewertungen

- Indian Microwave CookingDokument40 SeitenIndian Microwave CookingHarpuneet Ghuman0% (1)

- Virgin and Coca Cola Case Study A - Abdur-Rehman QureshiDokument4 SeitenVirgin and Coca Cola Case Study A - Abdur-Rehman QureshiAbdur-Rehman QureshiNoch keine Bewertungen

- Internal Exam Question Paper OctoberDokument4 SeitenInternal Exam Question Paper OctoberShanmugam VenkateshNoch keine Bewertungen

- Flylady PrintablesDokument8 SeitenFlylady PrintablesRenessie Cullen78% (9)

- The Irresistible OfferDokument17 SeitenThe Irresistible OfferAndrew YakovlevNoch keine Bewertungen

- Food & PackagingDokument24 SeitenFood & PackagingRitika RanjitNoch keine Bewertungen

- The 9 Best Comforters of 2021Dokument11 SeitenThe 9 Best Comforters of 2021Ri SovannaphumiNoch keine Bewertungen

- FurnitureDokument38 SeitenFurnitureSharmaine Roz CarreraNoch keine Bewertungen

- Integrating The Automotive Supply Chain: Where Are We Now?: D.R. Towill, P. Childerhouse and S.M. DisneyDokument17 SeitenIntegrating The Automotive Supply Chain: Where Are We Now?: D.R. Towill, P. Childerhouse and S.M. DisneyPropgp PgpNoch keine Bewertungen

- Swot AnalysisDokument12 SeitenSwot AnalysisLuxObnubilataNoch keine Bewertungen

- Entrepreneur Chapter 12Dokument8 SeitenEntrepreneur Chapter 12CaladhielNoch keine Bewertungen

- Fox FreePattern2Dokument8 SeitenFox FreePattern2Aline DiasNoch keine Bewertungen

- Denim Key Items Fashion A W 20 21 PDFDokument15 SeitenDenim Key Items Fashion A W 20 21 PDFNabarupa BoseNoch keine Bewertungen

- 2014 SPI CatalogDokument36 Seiten2014 SPI Catalog805 CreativeNoch keine Bewertungen

- Adults FC Exam 3rd TermDokument3 SeitenAdults FC Exam 3rd TermEster BarreraNoch keine Bewertungen

- E-Commerce Term Paper: TopicDokument11 SeitenE-Commerce Term Paper: Topicsimar001Noch keine Bewertungen

- 023 Sustainability of Green FashionDokument11 Seiten023 Sustainability of Green FashionVersha PantNoch keine Bewertungen

- 14438+PAYG+TCs+Update+v4 11321Dokument16 Seiten14438+PAYG+TCs+Update+v4 11321AminNoch keine Bewertungen

- Big BasketDokument4 SeitenBig Basketrichie rich67% (3)

- Materials Management by Nagesh L TalekarDokument46 SeitenMaterials Management by Nagesh L TalekarNagesh TalekarNoch keine Bewertungen