Beruflich Dokumente

Kultur Dokumente

Automated Ultrasonic Inspection System

Hochgeladen von

Kmt_AeCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Automated Ultrasonic Inspection System

Hochgeladen von

Kmt_AeCopyright:

Verfügbare Formate

V E LO S I

Automated Ultrasonic Inspection System

Introducing the new PSP-4 automated ultrasonic inspection system. This is the most advance and latest generation of P-scan system with eight (08) channels. It is designed to be easy and fast to set-up with high flexibility for different scanning situations.

This system supports a variety of ultrasonic inspection techniques inline with todays demand for quality, pre-service or in-service inspections:

Projection scans (weld inspection) Corrosion mapping (parent metal inspection) TOFD (quick detection and accurate sizing) Through transmission A-scan (recorded for post-processing)

Projection scans

Projection scan is a projection of comprehensive B-scan data, which gives the side view of the inspected component. It is used for weld inspection with angle probes, where the scan results is shown in projection of top, side and end view, thus provides a three-dimensional visualisation of the defect or corrosion. Different colour codes are used to indicate the origin of each signal, together with its amplitude to facilitate analysis of the scans.

Corrosion mapping

Corrosion mapping is used on parent materials of vessels, pipes, storage tanks and other structures. This is especially useful for corrosion monitoring of large structures or key areas for any pitting, general corrosion or severe corrosion. Each scan is represented by pixels of colour scale that corresponds to its thickness measured. It can be view in top, side and end view to give a visualisation of the components condition. A-scans can also be recorded and exported to other user friendly programs such Microsoft Office to plot a threedimensional view of the scanned area.

>

velosi.com

V E LO S I

Time of Flight Diffraction (TOFD)

Unlike conventional ultrasonic which relies on reflection based techniques, TOFD is based upon diffraction of ultrasound. This increases the probability of detection since it is less affected by the angle of incident with respect to the orientation of the discontinuity. Discontinuities orientated perpendicular to the surface is also detectable as well as discontinuities in the weld fusion faces.

Through Transmission

Operates in a pitch and catch configuration, ultrasound is transmitted on the component and received by a second probe on the opposite side. Variation in received signal amplitude indicates a presence of discontinuity.

Why Our Automated Ultrasonic System?

More than one inspection type or configuration can be included in a single setup and data from all the inspection can be collected concurrently. Up to 8 probes are possible at one particular job. Our scanner is a steerable general purpose magnetic wheel XY scanner, ideal for high speed, long Y-stroke inspection with several probes attached simultaneously. Coupled with rope access method, it enables this system to carry out inspection to cover large and hard to reach areas such as large vessels, storage tanks and spheres, and is much more cost effective than expensive scaffoldings. Qualified Ultrasonic personnel, trained by Force Technology to operate this PSP-4 system. We have wide range of specialised probes to suit different conditions to obtain the best results. All inspection data including A-scans can be recorded and stored in a computer for postprocessing. This also provides a permanent record of the job that enables documentation and traceability for future inspections. The receiver has selectable frequency filters and uses logarithmic amplifier that goes up to 120dB, to achieve better penetration on to course grain material such as duplex stainless steel, etc.

velosi.com

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Pipe Stess Static and Dynamic AnalysisDokument5 SeitenPipe Stess Static and Dynamic AnalysisKmt_AeNoch keine Bewertungen

- World Class ShutdownDokument6 SeitenWorld Class ShutdownKmt_AeNoch keine Bewertungen

- Heat Exchanger Fouling Mitigation TechnologyDokument5 SeitenHeat Exchanger Fouling Mitigation TechnologyKmt_AeNoch keine Bewertungen

- ASME VIII Pressure Vessel MasterclassDokument6 SeitenASME VIII Pressure Vessel MasterclassKmt_AeNoch keine Bewertungen

- Aerosol Adhesives LitDokument18 SeitenAerosol Adhesives LitKmt_AeNoch keine Bewertungen

- API 580 and 581risk Based InspectionDokument5 SeitenAPI 580 and 581risk Based InspectionKmt_Ae100% (1)

- Pressure ReliefDokument207 SeitenPressure ReliefAH100% (1)

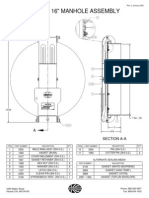

- Ld3310 16" Manhole Assembly: Rev. 0, January 2003Dokument1 SeiteLd3310 16" Manhole Assembly: Rev. 0, January 2003Kmt_AeNoch keine Bewertungen

- Catalog 2001Dokument10 SeitenCatalog 2001Kmt_AeNoch keine Bewertungen

- API 653 - Storage Tank Inspector Certification Examination Preparatory CourseDokument5 SeitenAPI 653 - Storage Tank Inspector Certification Examination Preparatory CourseKmt_AeNoch keine Bewertungen

- Corrosion Control in E&PDokument7 SeitenCorrosion Control in E&PKmt_AeNoch keine Bewertungen

- Corrosion Control in Refining IndustryDokument8 SeitenCorrosion Control in Refining IndustryKmt_Ae0% (1)

- API 653 - Storage Tank Inspector Certification Examination Preparatory CourseDokument5 SeitenAPI 653 - Storage Tank Inspector Certification Examination Preparatory CourseKmt_AeNoch keine Bewertungen

- API 579 Fitness For ServiceDokument5 SeitenAPI 579 Fitness For ServiceKmt_Ae100% (1)

- API 570 Piping InspectorDokument6 SeitenAPI 570 Piping InspectorBuddharaju KiranNoch keine Bewertungen

- API 571 Damage Mechanism Affecting Fixed Refining EquipmentsDokument4 SeitenAPI 571 Damage Mechanism Affecting Fixed Refining EquipmentsKmt_AeNoch keine Bewertungen

- API 510 Inspector CourseDokument6 SeitenAPI 510 Inspector CourseKmt_AeNoch keine Bewertungen

- API 579 Fitness For ServiceDokument5 SeitenAPI 579 Fitness For ServiceKmt_Ae100% (1)

- Acoustic and Flow Induced VibrationDokument5 SeitenAcoustic and Flow Induced VibrationKmt_AeNoch keine Bewertungen

- Tema & HtriDokument5 SeitenTema & HtriKmt_AeNoch keine Bewertungen

- FC Catalogue PDFDokument36 SeitenFC Catalogue PDFIndra FandyNoch keine Bewertungen

- Heat Exchanger Fouling Mitigation TechnologyDokument5 SeitenHeat Exchanger Fouling Mitigation TechnologyKmt_AeNoch keine Bewertungen

- z4 Coupe Roadster CatalogueDokument19 Seitenz4 Coupe Roadster CatalogueKmt_AeNoch keine Bewertungen

- Aboveground Storage Tank Design Masterclass (M'Sia) - LynnDokument5 SeitenAboveground Storage Tank Design Masterclass (M'Sia) - LynnKmt_AeNoch keine Bewertungen

- z4 Coupe Roadster CatalogueDokument19 Seitenz4 Coupe Roadster CatalogueKmt_AeNoch keine Bewertungen

- x3 DatasheetDokument7 Seitenx3 DatasheetKmt_AeNoch keine Bewertungen

- Advanced Pressure Vessels and Other Pressure EquipmentsDokument6 SeitenAdvanced Pressure Vessels and Other Pressure EquipmentsKmt_AeNoch keine Bewertungen

- z4 Coupe Roadster DatasheetDokument8 Seitenz4 Coupe Roadster DatasheetStephenNoch keine Bewertungen

- x5 DatasheetDokument7 Seitenx5 DatasheetKmt_AeNoch keine Bewertungen

- x5 CatalogueDokument18 Seitenx5 CatalogueKmt_AeNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Virgilio S. Delima V. Susan Mercaida Gois GR NO. 178352 - June 17, 2008 FactsDokument6 SeitenVirgilio S. Delima V. Susan Mercaida Gois GR NO. 178352 - June 17, 2008 FactsNikki BarenaNoch keine Bewertungen

- Leyte Geothermal v. PNOCDokument3 SeitenLeyte Geothermal v. PNOCAllen Windel BernabeNoch keine Bewertungen

- DS 20230629 SG3300UD-MV SG4400UD-MV Datasheet V16 ENDokument2 SeitenDS 20230629 SG3300UD-MV SG4400UD-MV Datasheet V16 ENDragana SkipinaNoch keine Bewertungen

- Lab - Activity CCNA 2 Exp: 7.5.3Dokument13 SeitenLab - Activity CCNA 2 Exp: 7.5.3Rico Agung FirmansyahNoch keine Bewertungen

- BC Specialty Foods DirectoryDokument249 SeitenBC Specialty Foods Directoryjcl_da_costa6894Noch keine Bewertungen

- ITIL - Release and Deployment Roles and Resps PDFDokument3 SeitenITIL - Release and Deployment Roles and Resps PDFAju N G100% (1)

- MSDS Metafuron 20 WPDokument10 SeitenMSDS Metafuron 20 WPAndi DarmawanNoch keine Bewertungen

- RS-RA-N01-AL User Manual of Photoelectric Total Solar Radiation TransmitterDokument11 SeitenRS-RA-N01-AL User Manual of Photoelectric Total Solar Radiation TransmittermohamadNoch keine Bewertungen

- Model Paper 1Dokument4 SeitenModel Paper 1Benjamin RohitNoch keine Bewertungen

- Ielts Band 9 Sample Essay NoDokument5 SeitenIelts Band 9 Sample Essay NoNhã NguyễnNoch keine Bewertungen

- 2 - Nested IFDokument8 Seiten2 - Nested IFLoyd DefensorNoch keine Bewertungen

- Difference Between Knowledge and SkillDokument2 SeitenDifference Between Knowledge and SkilljmNoch keine Bewertungen

- Pass Issuance Receipt: Now You Can Also Buy This Pass On Paytm AppDokument1 SeitePass Issuance Receipt: Now You Can Also Buy This Pass On Paytm AppAnoop SharmaNoch keine Bewertungen

- (NTA) SalaryDokument16 Seiten(NTA) SalaryHakim AndishmandNoch keine Bewertungen

- Entrepreneurship and EconomicDokument2 SeitenEntrepreneurship and EconomicSukruti BajajNoch keine Bewertungen

- De Thi Thu THPT Quoc Gia Mon Tieng Anh Truong THPT Hai An Hai Phong Nam 2015Dokument10 SeitenDe Thi Thu THPT Quoc Gia Mon Tieng Anh Truong THPT Hai An Hai Phong Nam 2015nguyen ngaNoch keine Bewertungen

- Specialized Government BanksDokument5 SeitenSpecialized Government BanksCarazelli AysonNoch keine Bewertungen

- Examination: Subject CT5 - Contingencies Core TechnicalDokument7 SeitenExamination: Subject CT5 - Contingencies Core TechnicalMadonnaNoch keine Bewertungen

- Part 9. Wireless Communication Towers and Antennas 908.01 Purpose and IntentDokument12 SeitenPart 9. Wireless Communication Towers and Antennas 908.01 Purpose and IntentjosethompsonNoch keine Bewertungen

- The Causes of Cyber Crime PDFDokument3 SeitenThe Causes of Cyber Crime PDFInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Critical Values For The Dickey-Fuller Unit Root T-Test StatisticsDokument1 SeiteCritical Values For The Dickey-Fuller Unit Root T-Test Statisticswjimenez1938Noch keine Bewertungen

- Corena s2 p150 - Msds - 01185865Dokument17 SeitenCorena s2 p150 - Msds - 01185865Javier LerinNoch keine Bewertungen

- Lead Magnet 43 Foolproof Strategies To Get More Leads, Win A Ton of New Customers and Double Your Profits in Record Time... (RDokument189 SeitenLead Magnet 43 Foolproof Strategies To Get More Leads, Win A Ton of New Customers and Double Your Profits in Record Time... (RluizdasilvaazevedoNoch keine Bewertungen

- StrutsDokument7 SeitenStrutsBatrisyialya RusliNoch keine Bewertungen

- IT support tips for non-tech colleaguesDokument7 SeitenIT support tips for non-tech colleaguesLeo KrekNoch keine Bewertungen

- Tambunting Pawnshop Vs CIR Re VATDokument7 SeitenTambunting Pawnshop Vs CIR Re VATMark Lester Lee AureNoch keine Bewertungen

- Company's Profile Presentation (Mauritius Commercial Bank)Dokument23 SeitenCompany's Profile Presentation (Mauritius Commercial Bank)ashairways100% (2)

- Method Statement of Static Equipment ErectionDokument20 SeitenMethod Statement of Static Equipment Erectionsarsan nedumkuzhi mani100% (4)

- 2014 March CaravanDokument48 Seiten2014 March CaravanbahiashrineNoch keine Bewertungen

- How To Open and Convert An .SCM FileDokument5 SeitenHow To Open and Convert An .SCM FilejackNoch keine Bewertungen