Beruflich Dokumente

Kultur Dokumente

Sec-I 126

Hochgeladen von

Panchal ShaileshCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sec-I 126

Hochgeladen von

Panchal ShaileshCopyright:

Verfügbare Formate

2007 SECTION I

PW-19.7 The welding shall be postweld heat treated in accordance with PW-39. PW-19.8 Telltale holes are not required in staybolts attached by welding.

PW-27.5 When welding UNS N06230 with filler metal of the same nominal composition as the base metal, only GMAW or GTAW processes are allowed.

FABRICATION

PW-26 GENERAL The rules in the following paragraphs apply specifically to the fabrication of boilers and parts thereof that are fabricated by welding and shall be used in conjunction with the general requirements for fabrication in Part PG, as well as with the specific requirements for fabrication in the applicable Parts of this Section that pertain to the type of boiler under consideration.

WELDING QUALIFICATION AND WELD RECORDS PW-28.1 Requirements for Qualification of Welding Procedures, Welders, and Welding Operators PW-28.1.1 The Welding Procedure Specifications, the welders, and the welding operators used in welding pressure parts and in joining load-carrying nonpressure parts, such as all permanent or temporary clips and lugs, to pressure parts shall be qualified in accordance with Section IX. PW-28.1.2 Except as provided in PW-28.1.2(a) and (b), the Welding Procedure Specification, the welders and the welding operators used in welding nonpressure-bearing attachments which have essentially no load-carrying function (such as extended heat transfer surfaces, insulation support pins, etc.) to pressure parts shall be qualified in accordance with Section IX. (a) When the welding process is automatic, welding procedure and performance qualification testing is not required. (b) When the material used for the nonpressure part makes the mechanical test requirements for procedure qualification and performance qualifications impracticable (i.e., insufficient material ductility), a weld test coupon may be evaluated using the macro-examination method for both groove and fillet welds. The test coupon may be of production configuration and shall be of sufficient length to contain a specimen for macro-examination. Heat treatment shall be considered a nonessential variable. The weldable quality of the nonpressure part materials shall be verified by the macro-examination of a single cross-section of the weld. Visual examination of the weld metal and heataffected zone of both the pressure part and nonpressure part material shall show complete fusion and freedom from cracks. PW-28.1.3 Welding of all test coupons shall be conducted by the Manufacturer. Testing of all test coupons shall be the responsibility of the Manufacturer. Qualification of a welding procedure, a welder, or a welding operator by one Manufacturer shall not qualify that procedure, welder, or the welding operator for any other Manufacturer except as provided in QW-201 and QW-300 of Section IX and PW-28.5. PW-28.2 No production work shall be undertaken until the procedures, the welders, and the welding operators have been qualified, except that performance qualification by radiography, in conformance with Section IX, QW-304 for welders or QW-305 for welding operators, may be

88

PW-28

PW-27

WELDING PROCESSES

The welding processes that may be used under this Part shall meet all the test requirements of Section IX and are restricted to PW-27.1 through PW-27.4. PW-27.1 The following welding processes may be used for any Section I construction: shielded metal arc, submerged arc, gas metal arc, flux cored arc, gas tungsten arc, plasma arc, atomic hydrogen arc, oxyhydrogen, oxyacetylene, laser beam, electron beam, flash, induction, pressure thermit, pressure gas, and inertia and continuous drive friction welding. Resistance welding is permitted within the thickness and diameter limitations given in PG-9.5, except that circumferential butt welds and pressure-bearing attachment welds are not restricted. Resistance welding of nonpressure-bearing attachments is not restricted, except as provided in PW27.2. PW-27.2 Arc stud welding and resistance stud welding may be used for nonpressure-bearing attachments having a load- or nonload-carrying function. Stud size shall be limited to 1 in. (25 mm) diameter maximum for round studs or an equivalent cross-sectional area for studs with other shapes. For load-carrying attachments, the requirements of PW-28.6 shall be met prior to the start of production welding, and the postweld heat treatment requirements of PW-39 shall also be complied with. PW-27.3 The electroslag welding process may be used for butt welds only in austenitic stainless steels of types listed in PW-5.3 and ferritic steels. Electroslag welds in ferritic steels require special NDE [Table PW-11, General Notes (a) and (b)] and special heat treatment (PW-39.7). PW-27.4 Definitions are given in Section IX, which include variations of these processes.

Das könnte Ihnen auch gefallen

- Wps PQR GuideDokument40 SeitenWps PQR GuideBalakumar100% (10)

- Asme Section IxDokument47 SeitenAsme Section Ixمحمودالوصيف100% (8)

- Weld Like a Pro: Beginning to Advanced TechniquesVon EverandWeld Like a Pro: Beginning to Advanced TechniquesBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantVon EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantBewertung: 3.5 von 5 Sternen3.5/5 (3)

- BS en 00480-2-2006Dokument14 SeitenBS en 00480-2-2006Shan Sandaruwan Abeywardene100% (1)

- Image Processing Math Prob1Dokument13 SeitenImage Processing Math Prob1MunmunNoch keine Bewertungen

- Asme 9 DatosDokument47 SeitenAsme 9 Datosvichu_villamarNoch keine Bewertungen

- Procedure Qualification Record (PQR)Dokument2 SeitenProcedure Qualification Record (PQR)Ankit KumarNoch keine Bewertungen

- Asme Sec 9Dokument12 SeitenAsme Sec 9ckkashyap0007Noch keine Bewertungen

- Asme Section IxDokument71 SeitenAsme Section Ixranjitkumar1977100% (2)

- Q210 Welding of Power PipingDokument7 SeitenQ210 Welding of Power Pipingpragmatix100% (2)

- Asme 9 TipsDokument13 SeitenAsme 9 TipsnasrpkNoch keine Bewertungen

- Essential and Non-Essential Variables For WPS - PQRDokument4 SeitenEssential and Non-Essential Variables For WPS - PQRNatarajan MurugesanNoch keine Bewertungen

- 8 WeldingDokument43 Seiten8 WeldingLopez BetoNoch keine Bewertungen

- Procedure Qualification RecordDokument10 SeitenProcedure Qualification Recordlamia97Noch keine Bewertungen

- Welder Qualifications and The ASME CodeDokument2 SeitenWelder Qualifications and The ASME CodeWaqas WaqasNoch keine Bewertungen

- Boon Asme Ix NotesDokument31 SeitenBoon Asme Ix NotesPRAVEENNoch keine Bewertungen

- API - STD - 650 - 2020 - 13 TH Ed - WELDING PROCEDUREDokument3 SeitenAPI - STD - 650 - 2020 - 13 TH Ed - WELDING PROCEDUREsarlsnmplastNoch keine Bewertungen

- Asme Sec Ix - Short NotesDokument20 SeitenAsme Sec Ix - Short NotesParvee K NakwalNoch keine Bewertungen

- ASME IX ExplanationsDokument13 SeitenASME IX ExplanationsManju Juno100% (4)

- Asme 9Dokument11 SeitenAsme 9H_DEBIANENoch keine Bewertungen

- ASMEDokument20 SeitenASMENorazzah AbdullahNoch keine Bewertungen

- Asme Section II A Sa-234 Sa-234mDokument10 SeitenAsme Section II A Sa-234 Sa-234mAnonymous GhPzn1xNoch keine Bewertungen

- Asme Sec Ix - Short Notes ReferenceDokument29 SeitenAsme Sec Ix - Short Notes Referencekart_rl0% (1)

- Asme Sec Ix WPS PQRDokument41 SeitenAsme Sec Ix WPS PQRwentroprem100% (1)

- Welding Procedures and Welding Qualiy Control For PipingDokument18 SeitenWelding Procedures and Welding Qualiy Control For PipingImam BuchairiNoch keine Bewertungen

- M 102Dokument18 SeitenM 102Shankar GurusamyNoch keine Bewertungen

- Codes and StandardsDokument33 SeitenCodes and StandardsMohd AmaniNoch keine Bewertungen

- Welding Procedures and Welding Qualiy Control For PipingDokument17 SeitenWelding Procedures and Welding Qualiy Control For PipingImam BuchairiNoch keine Bewertungen

- 2-Asme BPVC Section Ix-2013Dokument2 Seiten2-Asme BPVC Section Ix-2013Reda ElsawyNoch keine Bewertungen

- Q100 General Welding RequirementsDokument13 SeitenQ100 General Welding Requirementspragmatix100% (1)

- Fabrication - Assembly & ErectionDokument83 SeitenFabrication - Assembly & ErectionRengga Andryastama100% (2)

- Welder and Procedure QualificationDokument26 SeitenWelder and Procedure Qualification'Izzad AfifNoch keine Bewertungen

- Welder and Procedure QualificationDokument25 SeitenWelder and Procedure QualificationRamón G. Pacheco100% (3)

- ASMEDokument1 SeiteASMEmuhammad chilmiNoch keine Bewertungen

- 6 Welding ProcedureDokument74 Seiten6 Welding Procedureadel100% (5)

- Ix+ 3. (WPQ) Welding Performance QualificationsDokument7 SeitenIx+ 3. (WPQ) Welding Performance QualificationsAMAL VISHNUNoch keine Bewertungen

- Welding Procedure SpecificationDokument30 SeitenWelding Procedure Specificationrahman196011100% (1)

- WpsDokument14 SeitenWpsstanley100% (1)

- STD Spec For Piping WeldingDokument14 SeitenSTD Spec For Piping WeldingknsaravanaNoch keine Bewertungen

- Understanding API 582 & PTS 30106018 - Metal WeldingDokument44 SeitenUnderstanding API 582 & PTS 30106018 - Metal Weldingrosli2503Noch keine Bewertungen

- Tank Welding Details1Dokument5 SeitenTank Welding Details1Dilip PatilNoch keine Bewertungen

- 0001 Lesson API-510Dokument26 Seiten0001 Lesson API-510erick CfNoch keine Bewertungen

- WELDINGDokument4 SeitenWELDINGArputharaj Maria LouisNoch keine Bewertungen

- SAIC-W-2006 Rev 0Dokument4 SeitenSAIC-W-2006 Rev 0philipyap100% (2)

- SISGuide WPS & PQTDokument11 SeitenSISGuide WPS & PQTjohnsonNoch keine Bewertungen

- Shortcut To A WPSDokument18 SeitenShortcut To A WPSCepi Sindang Kamulan100% (1)

- HFY-3800-0000-GEN-PD-0013 - 0 Welding and Welding Consumable Control Procedure-Code ADokument14 SeitenHFY-3800-0000-GEN-PD-0013 - 0 Welding and Welding Consumable Control Procedure-Code ANashaat DhyaaNoch keine Bewertungen

- PQRDokument4 SeitenPQRmoonstar_dmeNoch keine Bewertungen

- Welding Procedures and Welders QualificationDokument41 SeitenWelding Procedures and Welders QualificationDhayalan Nethiranantham100% (14)

- How to prepare Welding Procedures for Oil & Gas PipelinesVon EverandHow to prepare Welding Procedures for Oil & Gas PipelinesBewertung: 5 von 5 Sternen5/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AVon EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANoch keine Bewertungen

- Pipeline and Energy Plant Piping: Design and TechnologyVon EverandPipeline and Energy Plant Piping: Design and TechnologyBewertung: 5 von 5 Sternen5/5 (2)

- Spot Welding Interview Success: An Introduction to Spot WeldingVon EverandSpot Welding Interview Success: An Introduction to Spot WeldingNoch keine Bewertungen

- Sec-I 140Dokument1 SeiteSec-I 140Panchal ShaileshNoch keine Bewertungen

- Table Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Coiijt'D)Dokument1 SeiteTable Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Coiijt'D)Panchal ShaileshNoch keine Bewertungen

- Sec-I 139Dokument1 SeiteSec-I 139Panchal ShaileshNoch keine Bewertungen

- Sec-I 138Dokument1 SeiteSec-I 138Panchal ShaileshNoch keine Bewertungen

- Table Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Conrd)Dokument1 SeiteTable Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Conrd)Panchal ShaileshNoch keine Bewertungen

- Sec-I 136Dokument1 SeiteSec-I 136Panchal ShaileshNoch keine Bewertungen

- Table Pw-39 (Cont'D) Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and AttachmentsDokument1 SeiteTable Pw-39 (Cont'D) Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and AttachmentsPanchal ShaileshNoch keine Bewertungen

- Sec-I 133Dokument1 SeiteSec-I 133Panchal ShaileshNoch keine Bewertungen

- Sec-I 129Dokument1 SeiteSec-I 129Panchal ShaileshNoch keine Bewertungen

- Sec-I 130Dokument1 SeiteSec-I 130Panchal ShaileshNoch keine Bewertungen

- Sec-I 131Dokument1 SeiteSec-I 131Panchal ShaileshNoch keine Bewertungen

- Sec-I 132Dokument1 SeiteSec-I 132Panchal ShaileshNoch keine Bewertungen

- Sec-I 127Dokument1 SeiteSec-I 127Panchal ShaileshNoch keine Bewertungen

- Sec-I 128Dokument1 SeiteSec-I 128Panchal ShaileshNoch keine Bewertungen

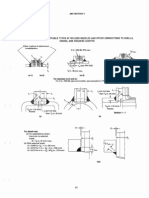

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Dokument1 SeiteFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Panchal ShaileshNoch keine Bewertungen

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Cot/Inections To Shells, Drums, and HeadersDokument1 SeiteFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Cot/Inections To Shells, Drums, and HeadersPanchal ShaileshNoch keine Bewertungen

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Co NT'D)Dokument1 SeiteFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Co NT'D)Panchal ShaileshNoch keine Bewertungen

- FIG. PW-19.4 (A) Some Acceptable Types of Diagonal Braces For Installation by WeldingDokument1 SeiteFIG. PW-19.4 (A) Some Acceptable Types of Diagonal Braces For Installation by WeldingPanchal ShaileshNoch keine Bewertungen

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Dokument1 SeiteFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Panchal ShaileshNoch keine Bewertungen

- Sec-I 121Dokument1 SeiteSec-I 121Panchal ShaileshNoch keine Bewertungen

- Sec-I 117Dokument1 SeiteSec-I 117Panchal ShaileshNoch keine Bewertungen

- Sec-I 119Dokument1 SeiteSec-I 119Panchal ShaileshNoch keine Bewertungen

- FIG. PW-15 Examples of Weld Strength Calculations: 2007 Section IDokument1 SeiteFIG. PW-15 Examples of Weld Strength Calculations: 2007 Section IPanchal ShaileshNoch keine Bewertungen

- Design: FIG. PW-9.1 Butt Welding of Plates of Unequal Thici NessDokument1 SeiteDesign: FIG. PW-9.1 Butt Welding of Plates of Unequal Thici NessPanchal ShaileshNoch keine Bewertungen

- Sec-I 113Dokument1 SeiteSec-I 113Panchal ShaileshNoch keine Bewertungen

- Sec-I 116Dokument1 SeiteSec-I 116Panchal ShaileshNoch keine Bewertungen

- Sec-I 114Dokument1 SeiteSec-I 114Panchal ShaileshNoch keine Bewertungen

- Sec-I 112Dokument1 SeiteSec-I 112Panchal ShaileshNoch keine Bewertungen

- Manufacturer'S Data Report Forms: 2007 Section IDokument1 SeiteManufacturer'S Data Report Forms: 2007 Section IPanchal ShaileshNoch keine Bewertungen

- Random Numbers in PythonDokument3 SeitenRandom Numbers in PythonShubham RawatNoch keine Bewertungen

- AlternatorDokument14 SeitenAlternatorTaraknath MukherjeeNoch keine Bewertungen

- Production of Hard Grade Bitumen For Using in High Modulus Asphalt ConcreteDokument18 SeitenProduction of Hard Grade Bitumen For Using in High Modulus Asphalt ConcretePanjiNoch keine Bewertungen

- Javascript Date ObjectDokument5 SeitenJavascript Date Objectshivi08Noch keine Bewertungen

- Central Tendency, Position, and VariationDokument37 SeitenCentral Tendency, Position, and VariationCeline Joy PolicarpioNoch keine Bewertungen

- PHASE TEST PHYSICS Fiitjee Class 8Dokument3 SeitenPHASE TEST PHYSICS Fiitjee Class 8SahejNoch keine Bewertungen

- Deflection of BeamsDokument109 SeitenDeflection of BeamsNadir Khattak Jr.100% (1)

- Elasticity Measurement of Local Taxes and Charges in Forecast of Own-Source Revenue (PAD) of Provincial Government in IndonesiaDokument27 SeitenElasticity Measurement of Local Taxes and Charges in Forecast of Own-Source Revenue (PAD) of Provincial Government in Indonesiaayu desiNoch keine Bewertungen

- Silvaco ATHENA Description 1 PDFDokument18 SeitenSilvaco ATHENA Description 1 PDFRahul JaiswalNoch keine Bewertungen

- KippZonen Manual Datalogger COMBILOG1022 V104 PDFDokument173 SeitenKippZonen Manual Datalogger COMBILOG1022 V104 PDFHaimeNoch keine Bewertungen

- Experiment - 1: Aim: Create Webpage Using HTML Form To Demonstrate Student Information FormDokument29 SeitenExperiment - 1: Aim: Create Webpage Using HTML Form To Demonstrate Student Information FormModi rutvikNoch keine Bewertungen

- About The MS Regression ModelsDokument17 SeitenAbout The MS Regression ModelsLars LarsonNoch keine Bewertungen

- Wrong Number Series 23 June by Aashish AroraDokument53 SeitenWrong Number Series 23 June by Aashish AroraSaurabh KatiyarNoch keine Bewertungen

- MT-LXX Parallel Manual PDFDokument120 SeitenMT-LXX Parallel Manual PDFJunior Alexander Rodriguez Rodriguez0% (1)

- Conectar A BD en SeleniumDokument4 SeitenConectar A BD en SeleniumCristhian Andrés GonzálezNoch keine Bewertungen

- Calibar Plate3Dokument10 SeitenCalibar Plate3Gerald FernandezNoch keine Bewertungen

- A Deep Dive Into The Latest HPC SoftwareDokument38 SeitenA Deep Dive Into The Latest HPC SoftwareSundar NilNoch keine Bewertungen

- Biology Paper 6 NotesDokument5 SeitenBiology Paper 6 NotesbNoch keine Bewertungen

- Supercritical CO2: Properties and Technological Applications - A ReviewDokument38 SeitenSupercritical CO2: Properties and Technological Applications - A ReviewXuân ĐứcNoch keine Bewertungen

- Amta5 8 Applying Tungsten Inert Gas Tig Welding TechniquesDokument115 SeitenAmta5 8 Applying Tungsten Inert Gas Tig Welding TechniquesAbu RectifyNoch keine Bewertungen

- Contoh SRSDokument46 SeitenContoh SRSFatur RachmanNoch keine Bewertungen

- Zipato MQTTCloudDokument34 SeitenZipato MQTTClouddensasNoch keine Bewertungen

- 2-Way Doherty Amplifier With BLF888ADokument27 Seiten2-Way Doherty Amplifier With BLF888AerdemsecenNoch keine Bewertungen

- Electricity: ElectromagnetsDokument17 SeitenElectricity: ElectromagnetsAyushJaiswalNoch keine Bewertungen

- Vinco Lesson Plan CO2 2022 EditedDokument8 SeitenVinco Lesson Plan CO2 2022 EditedAdrianalover RescofanaticsNoch keine Bewertungen

- Red Bin Analysis PDF Notes - 10020477 - 2023 - 10 - 13 - 09 - 28Dokument7 SeitenRed Bin Analysis PDF Notes - 10020477 - 2023 - 10 - 13 - 09 - 28Sameer SutarNoch keine Bewertungen

- Calibration of The Continuous Surface Cap Model For ConcreteDokument19 SeitenCalibration of The Continuous Surface Cap Model For ConcreteAbhijit KulkarniNoch keine Bewertungen