Beruflich Dokumente

Kultur Dokumente

DNLS

Hochgeladen von

shrutiagarwal9229Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

DNLS

Hochgeladen von

shrutiagarwal9229Copyright:

Verfügbare Formate

Double needle lock stitch machine:

1) Brand and make: a) Manufacturer of this machine is Brother. b) The model No. of this machine is LT2-B845-3 2) Machine bed: a) Size of the machine is [40(l) * 19(b) * 10.5(h)] inch. b) The machine bed is flat bed c) Dimensions from the needle(bed)= (510*180)mm 3) Right-395mm, left-115mm, back-90mm, front-90mm, upright-270mm, underarm295mm. 4) a) b) c) d) Head pulley The diameter of the head pulley is 105mm. The direction of rotation of head pulley is towards the operator i.e. anticlockwise. It is situated to right side of the machine. The v-belt pulley cover is a safety feature of the head pulley.

5) Stitch a) The stitch type is lockstitch b) Stitch number is 301*2 c) Stitch mechanism is interlacing. 6) Needle a) There are two needles in this machine. b) The type of the needle is DP*5#14. c) Mounting mechanism: The needle is attached into the needle clamp and is tightened with screw. d) Since it is a double needle lockstitch machine, there are two needle clamps e) The position of the needle on either side is opposite to each other. f) The scarf position of the right needle is at 3 oclock and scarf position of the left needle is at 9 oclock. g) The needle point is regular round point(FST-301) 7) Bobbin: a) Assembly: Consists of bobbin, bobbin case and rotary hook. b) Movement of the bobbin is in the clockwise direction

c) There are two bobbins in this machine which are placed below the flat bed on either sides of the throat plate and they are visible through the two circular gaps (BOBBIN WINDOWS) seen on either sides of the throat plate. 8) Threading sequence: a) Needle threading sequence: the thread is passed in the following sequence; thread stand- thread guide- stud screw- cylindrical rod- tension spring- metal tension disk- check spring- thread take-up two thread guides-needle eye. b) Bobbin threading sequence: the bobbin is inserted in rotary hook and thread is passed through slot under the tension spring. The thread is passed through the needle plate and 50mm (approx.) thread is pulled out. 9) Tension devices: a) The tension devices in a double needle lockstitch machine consists of tension disk, spring and stud screw. b) The tension devices are attached on the mid-left of the machine. c) The check springs in the tension devices are mainly essential for regulating the thread tension with help of screw. 10) Take up lever: a) The take-up lever consists of thread take-up which assists the thread in an oscillating motion. 11) Throat plate: a) The throat plate is fixed with help of two screws on the flat bed b) It is situated below the pressure foot. 12) Feeding mechanism: a) Feed dog: i. Feed dog is situated below the throat plate and is attached to the rocker shaft which controls its elliptical movement. ii. There are two numbers of rows and there are 16 teeth in the feed dog. iii. The pitch is 1mm. b) Presser foot: i. It is a standard presser foot. ii. The presser foot is attached with the presser bar. iii. The presser foot is used for applying optimum amount of pressure on the fabric depending upon the type of fabric which can be adjusted with help of presser foot adjustment screw.

The presser foot can be manually lifted with help of hand lever situated behind the presser bar bush. v. Also presser foot can be lifted with help of knee lifter situated below the machine bed. c) Needle movement is elliptical. 13) Stitch regulator: a) The stitch regulator is situated on the right side of machine, on the left of back tack lever. b) Stitch regulator, as the name suggests regulates the number of stitches. c) There are 5 divisions on the stitch regulator. 14) Lubrication: a) The oil manufacturer is Juki. b) The oil number of oil used in double needle lockstitch machine for lubrication is New Defrix No.1. c) Type of lubrication: minimum lubrication.

iv.

DNLS:

A double needle lockstitch machine works on the same principle as the single needle lockstitch machine while using two needles and two bobbins thus resulting in two parallel rows of lockstitch. The distance between two stitches depends upon the distance between the two needles on the needle bar which can be adjusted. In our machine the distance between two stitches is inch. Stitch formed appears as:

When the stitch forms correctly equal amounts of bobbin and needle thread are used. Needle thread can exceed up to 10%. Upper and lower threads interlock in the centre of the fabric. LT2-B845-3 Model is used for stitching thin and thick material.

The double needle lockstitch machine consists of clutch motor. The machines motor is especially designed with powerful performance for industrial sewing machines purpose. Vibration and noise are minimal. The temperature rising of the motor is extremely low. The double needle lockstitch machine is mainly used for box pockets, top stitch front collar edges, box pocket pleats, topstitch the collars, cuffs, inseam of trousers. The double needle lockstitch machine is the tightest and most secure stitch which makes it a good choice for stitching the in seams of the trousers.

Das könnte Ihnen auch gefallen

- Carr and Latham's Technology of Clothing ManufactureVon EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerBewertung: 4 von 5 Sternen4/5 (1)

- Knit Asia Operation ProcessDokument12 SeitenKnit Asia Operation ProcessParvezMridhaNoch keine Bewertungen

- UAQ 2nd Assignment (Pooja Kumari)Dokument14 SeitenUAQ 2nd Assignment (Pooja Kumari)Reena VermaNoch keine Bewertungen

- Dnls MMDokument19 SeitenDnls MMpriyal100% (1)

- Plant Layout - IDokument16 SeitenPlant Layout - ITanya rajNoch keine Bewertungen

- Automation in Spreading and Cutting - Mansi, Akriti, Khushi, Nisha PDFDokument30 SeitenAutomation in Spreading and Cutting - Mansi, Akriti, Khushi, Nisha PDFMansi ChandNoch keine Bewertungen

- Methods of SpreadingDokument10 SeitenMethods of Spreadingarunkadve67% (3)

- Chapter One PDFDokument24 SeitenChapter One PDFKibromGereNoch keine Bewertungen

- Fabric Structure & Design: Assignment On Basic WeavesDokument6 SeitenFabric Structure & Design: Assignment On Basic WeavesSanthosh KannanNoch keine Bewertungen

- Automation in Garment ManufacturingDokument43 SeitenAutomation in Garment ManufacturingvagueNoch keine Bewertungen

- Sewn Products Machinery and Equipments-: Assignment Ii PresentationDokument7 SeitenSewn Products Machinery and Equipments-: Assignment Ii PresentationNiharika SinhaNoch keine Bewertungen

- Sewing Machine Beds: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKDokument9 SeitenSewing Machine Beds: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKP. Lakshmanakanth100% (1)

- Assignment On Different Kinds of Knitting Faults Causes and Their RemediesDokument4 SeitenAssignment On Different Kinds of Knitting Faults Causes and Their RemediesRaihan Moner Manush0% (2)

- What Is Deference Between Feeder Stripe Knit Fabric With Engeenering Stripe Knit FabricsDokument1 SeiteWhat Is Deference Between Feeder Stripe Knit Fabric With Engeenering Stripe Knit FabricsMoktar Hossain0% (1)

- Yarn Count Used According To Grey GSM - Textile CalculationDokument3 SeitenYarn Count Used According To Grey GSM - Textile CalculationSZNoch keine Bewertungen

- Adidas and Automated Sewbots!Dokument7 SeitenAdidas and Automated Sewbots!Akanksha MishraNoch keine Bewertungen

- Spme IIIDokument202 SeitenSpme IIIYogesh SharmaNoch keine Bewertungen

- Naisargi SCAP End TermDokument11 SeitenNaisargi SCAP End TermNaisargiNoch keine Bewertungen

- Viva Questions and Answers For Garments and Merchandising Job (Part-1) - Textile Learner PDFDokument1 SeiteViva Questions and Answers For Garments and Merchandising Job (Part-1) - Textile Learner PDFMABVUTO TEMBONoch keine Bewertungen

- Improving Quality of Men'S Shirt Using Training Module at Arvind Smart Textiles LTD, RanchiDokument51 SeitenImproving Quality of Men'S Shirt Using Training Module at Arvind Smart Textiles LTD, RanchiyuktiNoch keine Bewertungen

- Formal Trouser: Feasibility Report PresentationDokument64 SeitenFormal Trouser: Feasibility Report Presentationbolaaajiii100% (1)

- Testing Procedures For Fabrics and TrimsDokument48 SeitenTesting Procedures For Fabrics and Trimsshivanift100% (1)

- I K G TDokument37 SeitenI K G TAbhishek kushwahaNoch keine Bewertungen

- Garments DefectDokument6 SeitenGarments DefectRajvi GhoghaniNoch keine Bewertungen

- SCAP Session 10 Fabric LossesDokument21 SeitenSCAP Session 10 Fabric LossesReena VermaNoch keine Bewertungen

- Methods of Fabric CuttingDokument11 SeitenMethods of Fabric CuttingMOHAMADSNoch keine Bewertungen

- Understanding Apparel Quality: Abhinav Krishna Bft/18/1044 Amisha Sahu Bft/18/734Dokument10 SeitenUnderstanding Apparel Quality: Abhinav Krishna Bft/18/1044 Amisha Sahu Bft/18/734kashorina AgarwalNoch keine Bewertungen

- Internship ReportDokument20 SeitenInternship Reportveenaos0% (1)

- An Overview of QualityDokument18 SeitenAn Overview of QualityIndika DissanayakeNoch keine Bewertungen

- Industry Visit Report of Sai Baba Garments: BY - Ashish Bhuwania BFT/17/381Dokument8 SeitenIndustry Visit Report of Sai Baba Garments: BY - Ashish Bhuwania BFT/17/381ravikantNoch keine Bewertungen

- Industrial EngineeringDokument32 SeitenIndustrial Engineeringpradeep_vsp1077100% (1)

- Understanding The Global Apparel Manufacturing ProcessDokument18 SeitenUnderstanding The Global Apparel Manufacturing Processyasin husen100% (1)

- Page1 8Dokument21 SeitenPage1 8Yuvraj PahujaNoch keine Bewertungen

- Anti Treatment Knits PrintDokument22 SeitenAnti Treatment Knits Printn.tNoch keine Bewertungen

- Stitch 140503091259 Phpapp01Dokument35 SeitenStitch 140503091259 Phpapp01Steve ShamNoch keine Bewertungen

- Advantages of Shuttleless LoomsDokument8 SeitenAdvantages of Shuttleless LoomsTanzeel Areeb0% (1)

- Presentation On Fabric CuttingDokument28 SeitenPresentation On Fabric CuttingNitta Mallik100% (1)

- Controlling and Check Points in Spinning ProcessDokument10 SeitenControlling and Check Points in Spinning ProcessBithy Paul100% (1)

- Cycle Sewing Machines: Simple AutomaticsDokument31 SeitenCycle Sewing Machines: Simple AutomaticsPrashant Gaurav75% (4)

- Marker PlanningDokument6 SeitenMarker PlanningAnkit KumarNoch keine Bewertungen

- Stree MGMT of T.C Terrytex Ltd.Dokument55 SeitenStree MGMT of T.C Terrytex Ltd.Mahfooz IlahiNoch keine Bewertungen

- Complete Care LabellingDokument12 SeitenComplete Care Labellingimran24Noch keine Bewertungen

- Santoni SeamlessDokument2 SeitenSantoni SeamlessSudheer SinghNoch keine Bewertungen

- Internship @naharDokument26 SeitenInternship @naharGourab Mondal100% (1)

- Project On Knitted Fabric ParametreDokument58 SeitenProject On Knitted Fabric ParametreMozzammal Hossain Shaown100% (3)

- Fabric Consumption CalculationDokument1 SeiteFabric Consumption CalculationSabrul JamilNoch keine Bewertungen

- Product Analysis and Developement: Presented by Parul Vashist Divya Rani DFT Sem ViiDokument29 SeitenProduct Analysis and Developement: Presented by Parul Vashist Divya Rani DFT Sem Viimaduvats100% (1)

- Sample Room DepartmentDokument5 SeitenSample Room DepartmentRajib DasNoch keine Bewertungen

- Method Study of Cuff AttachmentDokument12 SeitenMethod Study of Cuff AttachmentKshitij LauNoch keine Bewertungen

- Thread Consumption FormulaDokument4 SeitenThread Consumption Formulayuganshu_soni100% (1)

- Evaluation of Sewing OperatorDokument14 SeitenEvaluation of Sewing OperatorMd ShaheenNoch keine Bewertungen

- Final Ob of TrouserDokument24 SeitenFinal Ob of TrouserNiveditaKumari100% (1)

- Apparel Merchandising & Sourcing and Costing of Apparel ProductsDokument34 SeitenApparel Merchandising & Sourcing and Costing of Apparel Productssrishty dhanukaNoch keine Bewertungen

- Amm 301Dokument58 SeitenAmm 301asadshekhNoch keine Bewertungen

- Band KnifeDokument30 SeitenBand Knifeshrutiagarwal922967% (3)

- Textile Internship Report: Ocm Private Limited Textile Unit, AmritsarDokument49 SeitenTextile Internship Report: Ocm Private Limited Textile Unit, AmritsarJyoti Rawal100% (1)

- Pad Harshita Kartik PPT Assignment 1Dokument23 SeitenPad Harshita Kartik PPT Assignment 1kaarthikayaNoch keine Bewertungen

- Apparel Production ParametersDokument54 SeitenApparel Production ParametersVishnu Arjun100% (5)

- Nike CSR Case StudyDokument6 SeitenNike CSR Case Studyshrutiagarwal9229100% (3)

- Spreading DetailsDokument20 SeitenSpreading Detailsshrutiagarwal9229Noch keine Bewertungen

- Calculation of Warp and Weft Count of A FabricDokument3 SeitenCalculation of Warp and Weft Count of A Fabricshrutiagarwal9229Noch keine Bewertungen

- Plant Layout - Emergency Exit StandardsDokument14 SeitenPlant Layout - Emergency Exit Standardsshrutiagarwal9229100% (1)

- Thermal Comfort Properties of FabricDokument3 SeitenThermal Comfort Properties of Fabricshrutiagarwal9229Noch keine Bewertungen

- Band KnifeDokument30 SeitenBand Knifeshrutiagarwal922967% (3)

- Make Through Production SystemDokument9 SeitenMake Through Production Systemshrutiagarwal9229100% (1)

- Control ChartDokument4 SeitenControl Chartshrutiagarwal9229Noch keine Bewertungen

- National Institute of Fashion TechnologyDokument1 SeiteNational Institute of Fashion Technologyshrutiagarwal9229Noch keine Bewertungen

- Introduction To Operations Management: Random Fluctuations Monitor Output Adjustment Needed?Dokument11 SeitenIntroduction To Operations Management: Random Fluctuations Monitor Output Adjustment Needed?Shweta Yadav100% (1)

- Product Life CycleDokument28 SeitenProduct Life Cycleshrutiagarwal9229Noch keine Bewertungen

- Uk SizeDokument13 SeitenUk Sizeshrutiagarwal9229Noch keine Bewertungen

- Production and Operation ManagementDokument11 SeitenProduction and Operation Managementshrutiagarwal9229Noch keine Bewertungen

- Different Types of Manufacturing ProcessDokument23 SeitenDifferent Types of Manufacturing Processshrutiagarwal9229Noch keine Bewertungen

- Viscose WashcareDokument6 SeitenViscose Washcareshrutiagarwal9229Noch keine Bewertungen

- Swot Analysis of ARROWDokument1 SeiteSwot Analysis of ARROWshrutiagarwal9229Noch keine Bewertungen

- 08 Method StudyDokument25 Seiten08 Method Studyshrutiagarwal9229Noch keine Bewertungen

- Cloth Drills and NotchersDokument27 SeitenCloth Drills and Notchersshrutiagarwal9229100% (1)

- Industrial Design NoteDokument10 SeitenIndustrial Design Noteshrutiagarwal9229Noch keine Bewertungen

- Fabric ClassificationDokument7 SeitenFabric Classificationshrutiagarwal92290% (1)

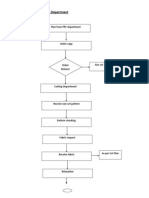

- Process Flow in Cutting Department: Plan From PPC DepartmentDokument2 SeitenProcess Flow in Cutting Department: Plan From PPC Departmentshrutiagarwal9229Noch keine Bewertungen

- CSEC SocStud CoverSheetForESBA Fillable Dec2019Dokument1 SeiteCSEC SocStud CoverSheetForESBA Fillable Dec2019chrissaineNoch keine Bewertungen

- Audi R8 Advert Analysis by Masum Ahmed 10PDokument2 SeitenAudi R8 Advert Analysis by Masum Ahmed 10PMasum95Noch keine Bewertungen

- P. E. and Health ReportDokument20 SeitenP. E. and Health ReportLESSLY ABRENCILLONoch keine Bewertungen

- Unit 4Dokument15 SeitenUnit 4David Lopez LaraNoch keine Bewertungen

- Paramount Healthcare Management Private Limited: First Reminder Letter Without PrejudiceDokument1 SeiteParamount Healthcare Management Private Limited: First Reminder Letter Without PrejudiceSwapnil TiwariNoch keine Bewertungen

- Villamaria JR Vs CADokument2 SeitenVillamaria JR Vs CAClarissa SawaliNoch keine Bewertungen

- Microeconomics Term 1 SlidesDokument494 SeitenMicroeconomics Term 1 SlidesSidra BhattiNoch keine Bewertungen

- 01 - A Note On Introduction To E-Commerce - 9march2011Dokument12 Seiten01 - A Note On Introduction To E-Commerce - 9march2011engr_amirNoch keine Bewertungen

- Understanding The Marshall AttackDokument6 SeitenUnderstanding The Marshall Attacks.for.saad8176Noch keine Bewertungen

- Life in The Ancient WorldDokument48 SeitenLife in The Ancient Worldjmagil6092100% (1)

- Specification Sheet: Case I Case Ii Operating ConditionsDokument1 SeiteSpecification Sheet: Case I Case Ii Operating ConditionsKailas NimbalkarNoch keine Bewertungen

- UntitledDokument13 SeitenUntitledTestNoch keine Bewertungen

- Electric Motor Cycle and ScooterDokument9 SeitenElectric Motor Cycle and ScooterA A.DevanandhNoch keine Bewertungen

- Obara BogbeDokument36 SeitenObara BogbeOjubona Aremu Omotiayebi Ifamoriyo0% (1)

- Activity Evaluation Form: "Where Children Come First"Dokument1 SeiteActivity Evaluation Form: "Where Children Come First"TuTitNoch keine Bewertungen

- BS en Iso 06509-1995 (2000)Dokument10 SeitenBS en Iso 06509-1995 (2000)vewigop197Noch keine Bewertungen

- Progress Report 1Dokument3 SeitenProgress Report 1api-302815786Noch keine Bewertungen

- Daikin FUW Cabinet Fan Coil UnitDokument29 SeitenDaikin FUW Cabinet Fan Coil UnitPaul Mendoza100% (1)

- Timetable - Alton - London Timetable May 2019 PDFDokument35 SeitenTimetable - Alton - London Timetable May 2019 PDFNicholas TuanNoch keine Bewertungen

- Presentation Municipal Appraisal CommitteeDokument3 SeitenPresentation Municipal Appraisal CommitteeEdwin JavateNoch keine Bewertungen

- 100 20210811 ICOPH 2021 Abstract BookDokument186 Seiten100 20210811 ICOPH 2021 Abstract Bookwafiq alibabaNoch keine Bewertungen

- Bushcraft Knife AnatomyDokument2 SeitenBushcraft Knife AnatomyCristian BotozisNoch keine Bewertungen

- BioremediationDokument21 SeitenBioremediationagung24864Noch keine Bewertungen

- UnixDokument251 SeitenUnixAnkush AgarwalNoch keine Bewertungen

- Planning EngineerDokument1 SeitePlanning EngineerChijioke ObiNoch keine Bewertungen

- Nuclear Power Engineering (MEE 2027) : Fall Semester (2020-2021)Dokument13 SeitenNuclear Power Engineering (MEE 2027) : Fall Semester (2020-2021)AllNoch keine Bewertungen

- Rare Malignant Glomus Tumor of The Esophagus With PulmonaryDokument6 SeitenRare Malignant Glomus Tumor of The Esophagus With PulmonaryRobrigo RexNoch keine Bewertungen

- Tree PruningDokument15 SeitenTree Pruningrita44Noch keine Bewertungen

- Five Kingdom ClassificationDokument6 SeitenFive Kingdom ClassificationRonnith NandyNoch keine Bewertungen

- Stewart, Mary - The Little BroomstickDokument159 SeitenStewart, Mary - The Little BroomstickYunon100% (1)

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiVon EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiBewertung: 4 von 5 Sternen4/5 (3)

- Crochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeVon EverandCrochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeBewertung: 5 von 5 Sternen5/5 (2)

- Edward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsVon EverandEdward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsNoch keine Bewertungen

- House Rules: How to Decorate for Every Home, Style, and BudgetVon EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNoch keine Bewertungen

- The Martha Manual: How to Do (Almost) EverythingVon EverandThe Martha Manual: How to Do (Almost) EverythingBewertung: 4 von 5 Sternen4/5 (11)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiVon Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiBewertung: 5 von 5 Sternen5/5 (2)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsVon EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Swatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersVon EverandSwatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Crochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestVon EverandCrochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestBewertung: 5 von 5 Sternen5/5 (2)

- Crochet Impkins: Over a million possible combinations! Yes, really!Von EverandCrochet Impkins: Over a million possible combinations! Yes, really!Bewertung: 4.5 von 5 Sternen4.5/5 (10)

- Shetland Fine Lace Knitting: Recreating Patterns from the Past.Von EverandShetland Fine Lace Knitting: Recreating Patterns from the Past.Bewertung: 2 von 5 Sternen2/5 (1)

- The Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsVon EverandThe Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Upcycling: 20 Creative Projects Made from Reclaimed MaterialsVon EverandUpcycling: 20 Creative Projects Made from Reclaimed MaterialsNoch keine Bewertungen

- Hello Hexie!: 20 Easy Crochet Patterns from Simple Granny HexagonsVon EverandHello Hexie!: 20 Easy Crochet Patterns from Simple Granny HexagonsBewertung: 5 von 5 Sternen5/5 (3)

- The Beading Bible: A Comprehensive Guide to Beading TechniquesVon EverandThe Beading Bible: A Comprehensive Guide to Beading TechniquesNoch keine Bewertungen

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)Von EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)Noch keine Bewertungen

- Harter's Picture Archive for Collage and IllustrationVon EverandHarter's Picture Archive for Collage and IllustrationBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastVon EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastBewertung: 5 von 5 Sternen5/5 (1)

- How to Make Workbenches & Shop Storage Solutions: 28 Projects to Make Your Workshop More Efficient from the Experts at American WoodworkerVon EverandHow to Make Workbenches & Shop Storage Solutions: 28 Projects to Make Your Workshop More Efficient from the Experts at American WoodworkerBewertung: 5 von 5 Sternen5/5 (2)

- Crochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsVon EverandCrochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsBewertung: 4 von 5 Sternen4/5 (5)

- Crochet Lace: Techniques, Patterns, and ProjectsVon EverandCrochet Lace: Techniques, Patterns, and ProjectsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Japanese Wonder Knitting: Timeless Stitches for Beautiful Hats, Bags, Blankets and MoreVon EverandJapanese Wonder Knitting: Timeless Stitches for Beautiful Hats, Bags, Blankets and MoreBewertung: 4 von 5 Sternen4/5 (4)

- Modern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeVon EverandModern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeBewertung: 5 von 5 Sternen5/5 (1)

- Artisan Sourdough Made Simple: A Beginner's Guide to Delicious Handcrafted Bread with Minimal KneadingVon EverandArtisan Sourdough Made Simple: A Beginner's Guide to Delicious Handcrafted Bread with Minimal KneadingBewertung: 5 von 5 Sternen5/5 (4)

- Celtic Line Drawing - Simplified InstructionsVon EverandCeltic Line Drawing - Simplified InstructionsBewertung: 5 von 5 Sternen5/5 (4)

- Paper Cutting: Contemporary Artists, Timeless CraftVon EverandPaper Cutting: Contemporary Artists, Timeless CraftBewertung: 5 von 5 Sternen5/5 (1)

- Crochet Donut Buddies: 50 easy amigurumi patterns for collectible crochet toysVon EverandCrochet Donut Buddies: 50 easy amigurumi patterns for collectible crochet toysBewertung: 4.5 von 5 Sternen4.5/5 (7)