Beruflich Dokumente

Kultur Dokumente

Dense Silica Based Coatings Prepared From Colloidal Silica

Hochgeladen von

Natalia JaramilloOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Dense Silica Based Coatings Prepared From Colloidal Silica

Hochgeladen von

Natalia JaramilloCopyright:

Verfügbare Formate

Surface & Coatings Technology 190 (2005) 110 114 www.elsevier.

com/locate/surfcoat

Dense silica-based coatings prepared from colloidal silica

s-Arellano a,c, J.F. Pe n-Guille n a,b,*, L.M. Avile rez-Robles a, J.A. Caldero lez-Herna ndez a, E. Ramos-Ram rez c J. Gonza

taro, Libramiento Norponiente No. 2000, Fracc. Real de Juriquilla, 76010 Quere taro, Qro., Mexico CINVESTAV-IPN, Unidad Quere b ngel Flores y Riva Palacio s/n, Col, centro, C.P. 81010, Culiaca noma de Sinaloa, A n, Sinaloa, Mexico Universidad Auto c n en Qu mica Inorga nica, Universidad de Guanajuato. Noria Alta s/n, Col Noria Alta, C.P. 36050 Guanajuato, Gto., Mexico Centro de Investigacio Received 15 July 2003; accepted in revised form 8 April 2004 Available online 2 June 2004

a

Abstract Two sets of silica-based coatings have been prepared using two different wet methods. Set A was obtained using the conventional sol gel method from thetraethyl-orthosilicate (TEOS) as the main precursor. Set B was produced from commercial colloidal silica added with two structural modifiers, KOH and sodium metasilicate (Na2SiO3S5H2O). The structure of both sets of coatings was characterized using infrared absorption, X-ray diffraction and nitrogen adsorption isotherms measurements. The results show a much lower surface area and a slower oxygen diffusion rate for coatings of set B, indicating that these coatings have a denser structure and therefore are more effective as oxygen barriers. D 2004 Elsevier B.V. All rights reserved.

Keywords: Sol gel; Colloidal silica; Diffusion of oxygen; Dense silica

1. Introduction In recent years, several publications have described lowtemperature preparation and processing of ceramic coatings on various types of substrates. Due to their versatility and low cost, the synthesis of inorganic oxides by wet chemistry methods, such as the sol gel technique, has been largely used for the preparation of these oxides. In particular, silicabased coatings with various structural characteristics have been prepared for multiple applications [1 4]. In the traditional sol gel method, the synthesis of inorganic oxides starts from molecular precursors (metal alkoxides); the oxide network is obtained via hydrolysis and condensation reactions, which occur in the solution [1]. However, in general, the sol gel-derived amorphous coatings usually have a low density and a large surface area due to their opened porous structure [5,6]. The pore texture arises from the preparation method, which involves the elimination of volatile materials during condensation. These cavities are produced as a result of both solid rearrangement and exit

taro, Libra* Corresponding author. CINVESTAV-IPN, Unidad Quere taro, miento Norponiente No. 2000, Fracc. Real de Juriquilla, 76010 Quere Qro., Mexico. Tel.: +52-442-4414925; fax: +52-442-4414939. n-Guille n). E-mail address: cajoel_99@yahoo.com (J.A. Caldero 0257-8972/$ - see front matter D 2004 Elsevier B.V. All rights reserved. doi:10.1016/j.surfcoat.2004.04.068

way of the removed materials. Many applications of silica films, such as oxygen barriers, anticorrosive barriers, optical and electronic coatings require dense films. A curing process may achieve densification of these coatings; nevertheless, in general, relatively high temperatures are required. There are some examples of densification of silica coatings using low temperatures [7 10]. For instance, partial densification in not intentionally heated sol gel-derived coatings have been achieved by UV irradiation [7,8], ion implantation [9] and laser radiation [10]. Few reports have been published concerning the use of another method employed to produce silica-based coatings with different characteristics. The method is based on the use of aqueous colloidal silica suspensions combined with inorganic binding and/or structural modifier agents [11 14]. The use of appropriate binders may produce coatings with dense structures. The term colloidal silica refers to a stable dispersion or sols of discrete nanometric particles of amorphous silica, commonly suspended in water with a size of about 5 nm in diameter. During the evaporation of water, in which the colloidal silica particles and binders are suspended, some polymerization/condensation reactions take place, and a solid dried coating is obtained after the drying process is completed. This process differs from the conventional sol gel method because a great variety of compounds

n-Guille n et al. / Surface & Coatings Technology 190 (2005) 110114 J.A. Caldero

111

that are compatible with the aqueous system can be added and no hydrolysis reactions take place. The coatings are formed via condensation and/or polymerization reactions. The study of the mechanical properties of thin coatings has gained considerable interest in recent years. The aim of this work is to compare the properties of coatings prepared using the conventional sol gel method with those of coatings prepared using colloidal silica. The first set was prepared from precursor solutions known to produce dense coatings. The preparation of coatings using the colloidal silica includes the addition of two specific inorganic structure modifier agents, which produce dense films at low curing temperatures with a closed porous structure and a low surface area.

2. Experimental procedure For this study, two sets of samples were prepared: set A, consisted of samples prepared by the traditional sol gel process; and set B, formed by samples prepared using colloidal silica. Both sets of samples were prepared in the form of powders and of coatings on silicon wafers and on polished copper substrates. The samples were heated in air, the powders at 100 jC and the coatings in the range of 100 to 500 jC. Samples of set A were prepared from precursor solutions formed by mixtures of thetraethyl-orthosilicate (TEOS), water and ethanol. The molar ratios of water-to-TEOS and ethanol-to-TEOS were 11.7 and 4, respectively. These preparation conditions are known to produce coatings with dense structures; more details about the preparation of these samples can be found elsewhere [15]. To catalyze the reactions, a small amount (0.03 mol) of HNO3 was added to the solutions. The substrates were deposited on microscope slide glasses using a conventional dipping apparatus when the viscosity of the precursor suspensions was about 3 cP. The coating were immersed into the precursor suspensions, maintained there for about 30 s and then removed at a constant speed of about 5 mm/s. At this removal speed, the coating thickness was about 500 nm. Samples in the form of powders were obtained from the same solutions after they were dried at 100 jC for about 5 h. Samples of set B were prepared from the condensation of aqueous suspensions consisting of a mixture of colloidal silica added with two structural modifiers, KOH and sodium metasilicate (Na2SiO3S5H2O). The aqueous colloidal silica xico, D.F), with was obtained from the company OPTA (Me 40 wt.% of silica particles of about 20 nm in diameter. The structural modifiers were commercial grade. The aqueous suspension was prepared in the following way: 50 ml of colloidal silica was added to 70 ml of distilled water, the suspension was homogenized using magnetic stirring for 5 min, then 2.4 g of KOH was added to this suspension under magnetic stirring for another 10 min. In a separate vessel, 12.5 g of sodium metasilicate was dissolved in 60 ml of

distilled water. This solution was mixed using magnetic stirring for 20 min, with the suspension containing the colloidal silica to form the starting materials. More details about the procedure used in the preparation of these samples can be found elsewhere [16]. The coatings were obtained using the same apparatus and the same removal speed used for samples in set A. Under these conditions, the coating thickness was about 500 nm. Samples in the form of powders were obtained by drying the precursor suspension in air at a temperature of 100 jC for about 5 h. The X-ray diffraction measurements were carried out using a 2100-Rigaku diffractometer equipped with the Cu radiation. The IR measurements were performed in a Ka Perkin Elmer 1600 with software Spectrum 80. The atomic composition of coatings of set B deposited on copper substrates was determined using electron dispersive spectroscopy (EDS) from a Phillips environmental scanning electron microcopy model XL30ESEM. The determined percentage atomic composition was O (45%), Si (38%), Na (12%) and K (5%).

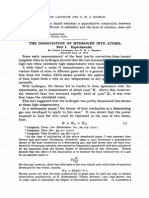

3. Experimental results Fig. 1 shows typical IR spectra for samples deposited on Si substrates heated in air at 100 jC for 1 h. Spectra A and B correspond to samples of set A and B, respectively. Similar spectra have been reported in previous IR investigations for silica-based materials [17 19]. In Fig. 1, the most prominent absorption bands have been denoted with the letters r at 450 cm 1, b at 800 cm 1, s in the range of 1000 1300 cm 1 and OH in the range of 3000 4000 cm 1. The r, b and s bands have been assigned to bond rocking, bond bending and bond stretching vibrations of the Si O bonds in the three-dimensional SiO2 network, respectively [17,20], and the broad OH band with stretching vibrations of the O H bond in hydroxyl groups of varying strengths. The hydroxyl groups are generally attached to the internal walls of the oxide [21]. The band at about 1630 cm 1, marked with an asterisk in spectrum A, is associated with vibrations

Fig. 1. IR absorption for samples of set A and B after annealing at 100 jC.

112

n-Guille n et al. / Surface & Coatings Technology 190 (2005) 110114 J.A. Caldero

of molecular water adsorbed on internal walls of voids in the oxide matrix [22]. Notice that in sample of set B, the hydroxyl band is weaker and the adsorbed H2O signal does not appear. Fig. 2 shows details of the s band, in the range of 800 to 1400 cm 1, for the same samples shown in Fig. 1; that is, spectra A and B correspond to samples of set A and B, respectively. Both spectra have been decomposed into four Gaussian bands, which provide the best fit to the experimental data. For spectrum A, the bands 1, 2, 3 and 4 are located at about 928, 1079, 1210 and 1280 cm 1, and for spectrum B, at 965, 1068, 1200 and 1300 cm 1, respectively. In both spectra, band 2 is the most intense and has been assigned to transverse optical (TO) asymmetric stretching vibrations of Si O Si units [17,20]. This band has been reported in the range of 1060 to 1085 cm 1, depending on the structural ordering and purity of the SiO2 network [7,17,20,23,24]. For bands 3 and 4, different assignments have been documented. Some authors relate them with longitudinal optical (LO) modes of the same structural units [25], while others, with breathing vibrations of rings formed by five and six Si O Si units [24]. Band 1 in spectrum A is associated with silanol (Si OH) vibrations, which has been reported in the range of 920 940 cm 1 depending on the specific configuration of the local environment [15,19, 20,26]. Band 1 in spectrum B is assigned to TO asymmetric stretching vibrations of Si O Na units [26]; this agrees with other reports in silica glasses containing sodium, where a similar band was observed at about 970 cm 1 [27]. Notice that this band is near the Si OH absorption range, and therefore it could be erroneously assigned to vibrations of this type; however, if this were the case, one would expect a much larger intensity of the hydroxyl and adsorbed water bands in spectrum B of Fig. 1. Fig. 3 shows the nitrogen adsorption isotherms for powders corresponding to the samples of set A and B. Nitrogen adsorption at boiling temperature ( 196 jC) represents the most widely used technique to determine surface area and to characterize porous structure. Brunauer,

Fig. 3. Nitrogen adsorption isotherms for powder corresponding to samples of sets A and B.

Emmet and Teller (BET) developed a model to determine the surface area using the adsorption isotherm plots [28]. The starting point is the determination of the adsorption isotherm, that is, the nitrogen adsorbed volume against its relative pressure P/Po, where Po is the saturated vapor pressure of nitrogen at 196 jC. Following the BET method, the surface area for the two samples in Fig. 3 was determined, being of 216 and 0.55 m2/g for samples of set A and B, respectively. For sol gel-derived samples, a surface area in the range of 18 [28] to about 550 m2/g [5] have been previously reported. Figs. 4 and 5 show the X-ray diffraction data in the range of 30j to 60j for coatings, on copper substrates, of sets A and B, respectively. Both samples were annealed in air at the indicated temperatures for 1 h. A weak and broad X-ray signal, from the thin amorphous coating, was observed at about 22j (not shown in Figures). In the patterns corresponding to the samples annealed at 200 jC, only the (111) at about 43j and the (200) at about 51j diffraction lines from the copper substrate are observed. After the annealing

Fig. 2. IR absorption in the range of 800 1400 cm 1 for the samples in Fig. 1.

Fig. 4. X-ray diffraction patterns for samples of set A on copper substrates, heat treated at the indicated temperatures.

n-Guille n et al. / Surface & Coatings Technology 190 (2005) 110114 J.A. Caldero

113

Fig. 5. X-ray diffraction patterns for samples of set B on copper substrates, heat treated at the indicated temperatures.

at 300 jC, besides the copper lines, the pattern corresponding to the coating of set A (Fig. 3) shows the (111) line at 36j from the Cu2O cubic phase. The latter phase does not appear in samples of set B (Fig. 5) annealed at the same temperature. With the annealing at 400 jC, the intensity of the diffraction lines corresponding to the Cu2O phase increases, and this phase starts to appear in samples of set B. After the annealing at 500 jC, the CuO phase appears in the patterns corresponding to both sets of samples. The formation of the copper oxides is due to the reaction of atmospheric oxygen, diffusing through the silica coating, with the copper substrate at the silica/substrate interface.

4. Discussion of results The larger surface area found in samples of set A, or in other words the smaller volume fraction of voids in samples of set B, is supported by the IR results. In the latter, the absence of silanol and hydroxyl absorption bands in the spectra of samples of set B also indicates that these samples have less amount of pores than those corresponding to samples of set A. According to the X-ray data, oxygen diffuses through the silica coating, reaches the copper substrate and forms a copper oxide layer at the coating/substrate interface. The diffusion of oxygen has been previously used to characterize the structure of several vitreous silica coatings [29 31]. From these works, values for the diffusion coefficient (D), as low as 10 19 cm2/s in silica glass at T = 1000 jC [30] and as high as 10 3 at room temperature in largely porous silica gel glasses [31], have been reported. In porous materials, the value of D depends on the porous structure of the material. Assuming that the diffusion process is thermally activated, that is, D = Doexp( Q/kT), an average activation energy Q

of about 1 eV has been found for the diffusion process of oxygen in silica-based materials [29 31]. In a previous report, a model has been developed to calculate D in sol gel-derived silica samples deposited on copper substrates [29] and heated in air at various temperatures. The authors have proposed an expression which relates Q, Do and to, where to is the minimum time required at a given temperature to observe the X-ray signal from the Cu2O formed at the coating/copper substrate interface. The expression describing the model is, 1/to=(CDo/Nd)exp( Q/kT) [29], C = 5.4 1018 cm 3 is the amount of oxygen atoms in the atmosphere, N = 1.2 1016 cm 2 is the total amount of oxygen atoms in the copper oxide layer formed at the coating/copper interface at the time to, and d = 500 nm is the coating thickness. From the X-ray data, we estimate the temperature necessary to observe the Cu2O signal for to = 1 h as 500 K for samples of set A and as 700 K for samples of set B. Taking Q = 1 eV from the expression above, we estimate that Do has a value of about 4.5 10 2 and 5 10 4 cm2/s for samples corresponding to set A and B, respectively. The estimated D values, at room temperature, are of 1.2 10 16 and 1.3 10 18 cm2/s for samples of set A and B, respectively. The latter means that in samples of set B, the copper oxide layer at the coating/copper interface will start forming after about 10 years of exposure to atmospheric conditions (25 jC). At the present time, we do not have enough elements that allow us to fully understand the lower oxygen diffusion rate in the colloidal silica-derived coatings. However, in previous works [29 31], it has been reported that in silica-based coating, the diffusion coefficient may be used as a qualitative measured of their porous structure. According to these results, denser materials have lower diffusion rates, therefore one could conclude that the structure of the coatings of set B is denser or with fewer voids than that of the coatings of set A. A possible explanation to this observation are the following. It is known that the introduction of sodium or any other alkali metal (M) into silica glasses produces significant changes in glass structure. In pure SiO2 glasses, all the O2 ions are bound to two Si4 + ions. Thus, the O2 ions form bridges between neighboring Si4 + ions. The incorporation of an alkali ion M+ splits open the oxygen bridging bonds, and each M+ ion gets attached to a neighboring Si 4 + ion, forming u Si O M structures [32,33]. The addition of a few percentage of randomly distributed alkali metals into the glass structure will break up the SiO2 structure into chains cross-linked among each other, forming an entangled type structure. This structure is probably denser than that of pure SiO2 coatings, where the small silica particles aggregate to form a granular structure leaving intraparticle cavities that facilitate the diffusion of oxygen. Knowing that the diffusion of oxygen is faster at cracks and at grain boundaries, we analyzed the surface of both types of coatings (using Scanning Electron Microscopy) before and after heat treated at various temperatures. No

114

n-Guille n et al. / Surface & Coatings Technology 190 (2005) 110114 J.A. Caldero [8] S. Maekawa, T. Ohishi, J. Non-Cryst. Solids 169 (1994) 207. [9] T.E. Levine, J.L. Keedie, P. Revesz, J.W. Mayer, E.P. Giannelis, J. Am. Ceram. Soc. 76 (19993) 1369. [10] C. Fiori, R.A.B. Devine, Phys. Rev., B 33 (1986) 2972. [11] T. Mori, J. Non-Cryst. Solids 100 (1988) 523. [12] R.G. Horn, J. Am. Ceram. Soc. 73 (1988) 1117. [13] J.M. Fitzgibbons, E. James-French, United State Patent No. 5,626,923, May 6 (1997). [14] C. Williams Perkins, W. Lewis, United State Patent, No. 5,221,560, June (1993) 22. rez-Robles, L.A. Garc a-Cerda, F.J. Espinoza-Beltra n, M. [15] J.F. Pe z-Limo n, J. Gonza lez-Herna ndez, J.R. Parga-Torres, F. Ruiz, J. e Yan Mendez-Nonell, Phys. Status Solidi 172 (1999) 49. nchez, J. Alvarez-Quintana, C. Araujo-Andrade, [16] J.L. Almaral-Sa n-Guillen, H. Carrillo-Esquivel, E.A. Elizalde-Pen a, J.A. Caldero rez, F.A. Garcia-Pastor, O. Go mez-Guzma n, L. N. Flores-Ram nez, D. Meneses-Rodr guez, A.E. Pen ndez, a-Herna Licea-Jime rez-Garcia, J.C. Rubio-Avalos, A. Salazar-Flores, M. TalaS.A. Pe a, L.D. Va zquez-Santoyo, J. Gonvera-Ortega, G. Vazquez-Garc lez-Herna ndez, Thin Solid Films 423 (2003) 196. za [17] F.L. Galeener, Phys. Rev., B 15 (1979) 4292. [18] R.J. Bell, P. Dean, Nature 121 (1966) 1353. [19] G. Lucovsky, J.T. Fitch, E. Kobeda, E.A. Irene, in: R. Helms, B.E. Deal (Eds.), The Phys. and Chem. of SiO2 and the Si SiO2 Interfaces, Plenum Press, 1998, p. 139. [20] P. Shen, M.F. Thorpe, Phys. Rev., B 15 (1979) 4030. [21] D.L. Wood, E.M. Rabinovich, J. Non-Cryst. Solids 107 (1989) 199. [22] G. Cordoba, R. Arroyo, J.L.G. Fierro, M. Viniegra, J. Solid State Chem. 123 (1996) 93. [23] I.W. Boyd, J.I.B. Wilson, Appl. Phys. Lett. 50 (1987) 320. nez, F. Ruiz, Y.V. Vorobiev, F. Pe rez-Robles, J. Gonza lez[24] J.R. Mart ndez, J. Chem. Phys. 109 (1998) 7511. Herna [25] C.M. Parler, J.A. Ritter, M.D. Amiridis, J. Non-Cryst. Solids 279 (2001) 119. ndez-Navarro, J. Non-Cryst. [26] A. Duran, C. Serna, V. Fornes, J.M. Ferna Solids 63 (1984) 45. [27] H. Isobe, I. Tokunga, N. Nagai, K. Kaneko, J. Mater. Res. 11 (1996) 2908. [28] S. Brunauer, P.H. Emmet, J. Am. Chem. Soc. 60 (1938) 309. [29] M. Jaroniec, M. Kruk, J.P. Oliver, Langmuir 15 (1999) 5410. a-Rodr guez, F. Pe rez-Robles, A. Manzano-Ram rez, Y.V. [30] F.J. Garc lez-Herna ndez, Solid State Commun. 111 (1999) Vorobiev, J. Gonza 717. [31] J.C. Mikkelsen Jr., Appl. Phys. Lett. 45 (1984) 1187. [32] S. Satoh, I. Matsuyama, K. Susa, J. Non-Cryst. Solids 190 (1995) 206. [33] Glass, Nature, Structure and Properties, Horst Scholze, Springer-Verlag, New York, 1991.

cracks and no granular structure were detected in the film, which indicates that the diffusion of oxygen is uniform through the whole front surface of the coatings.

5. Conclusions In summary, silica-based coatings were prepared at low temperature from the condensation of a suspension of commercial colloidal silica added with two specific structural modifiers. According to the characterization, these coatings have a dense structure which acts as an effective oxygen barrier for temperatures lower that about 300 jC. According to the results, these coatings have a closer structure than those prepared using the traditional sol gel method.

Acknowledgements ndezWe acknowledge the assistance of M.A. Herna Landaverde and I.E.J. Eleazar Urbina-Alvarez in the X-ray and ESEM measurements. This work was partially sup xico. ported by CONACyT of Me

References

[1] C.J. Brinker, G.W. Sherer, Sol Gel Science: The Physics and Chemistry of the Sol Gel Process, Academic Press, San Diego, 1990. lez-Herna ndez, F. Pe rez-Robles, A. Manzano-Ram rez, R. [2] J. Gonza rez-Bon, E. Prokhorov, Y.V. Vorobiev, F.J. Garc a-Rodr guez, Ram Appl. Phys. Lett. 75 (1999) 3192. [3] T.P. Ma, K. Miyauchi, Appl. Phys. Lett. 34 (1979) 88. [4] R.A. Weimer, P.M. Lenahan, T.A. Marchione, Appl. Phys. Lett. 51 (1987) 1179. [5] S.L. Hietala, D.M. Smith, J.L. Golden, C.J. Brinker, Comm. Am. Ceram. Soc. 72 (1989) 2354. [6] P.M. Glaser, C.G. Pantano, J. Non-Cryst. Solids 63 (1984) 209. [7] H. Imai, M. Yasumori, H. Hirashima, K. Awazu, H. Onuki, J. Appl. Phys. 79 (1996) 8304.

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Haber Schaim PDFDokument10 SeitenHaber Schaim PDFAnonymous cMwPQ0caQTNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Detailed Lesson Plan Work and HeatDokument13 SeitenDetailed Lesson Plan Work and Heatronamae villanuevaNoch keine Bewertungen

- HSC Physics Space WorkbookDokument32 SeitenHSC Physics Space Workbookphil megroin100% (1)

- 2306 9MA0-32 A Level Mechanics - June 2023 PDFDokument20 Seiten2306 9MA0-32 A Level Mechanics - June 2023 PDFkong99999seifalikong99999100% (3)

- Heat Exchanger Handbook - Heat Exchangers PDFDokument66 SeitenHeat Exchanger Handbook - Heat Exchangers PDFhonghai_dl100% (3)

- Quantum Physics and ReligionsDokument31 SeitenQuantum Physics and Religionsahmad qutbiNoch keine Bewertungen

- Martin Schmal (Auth.) - Heterogeneous Catalysis and Its Industrial Applications-Springer International Publishing (2016)Dokument382 SeitenMartin Schmal (Auth.) - Heterogeneous Catalysis and Its Industrial Applications-Springer International Publishing (2016)Rebeca Albino100% (1)

- The Effects of Hydroxyapatite Coatings On Stress Distribution Near The DentalDokument3 SeitenThe Effects of Hydroxyapatite Coatings On Stress Distribution Near The DentalNatalia JaramilloNoch keine Bewertungen

- Nanoscale Hydroxyapatite Particles For Bone Tissue Engineering¡¡¡¡¡¡¡Dokument13 SeitenNanoscale Hydroxyapatite Particles For Bone Tissue Engineering¡¡¡¡¡¡¡Natalia JaramilloNoch keine Bewertungen

- Nanoscale Hydroxyapatite Particles For Bone Tissue Engineering¡¡¡¡¡¡¡Dokument13 SeitenNanoscale Hydroxyapatite Particles For Bone Tissue Engineering¡¡¡¡¡¡¡Natalia JaramilloNoch keine Bewertungen

- Controlling Drug Nanoparticle Formation by Rapid PrecipitationDokument10 SeitenControlling Drug Nanoparticle Formation by Rapid PrecipitationNatalia JaramilloNoch keine Bewertungen

- Dense Silica Based Coatings Prepared From Colloidal SilicaDokument5 SeitenDense Silica Based Coatings Prepared From Colloidal SilicaNatalia JaramilloNoch keine Bewertungen

- Nanoencapsulation I. Methods For Preparation of Drug-Loaded ¡¡¡¡Dokument14 SeitenNanoencapsulation I. Methods For Preparation of Drug-Loaded ¡¡¡¡Natalia JaramilloNoch keine Bewertungen

- Aptamer-Conjugated Nanoparticles For The Collection and Detection of Multiple Cancer CellsDokument8 SeitenAptamer-Conjugated Nanoparticles For The Collection and Detection of Multiple Cancer CellsNatalia JaramilloNoch keine Bewertungen

- Biodegradable Nanoparticles For Drug Delivery and TargetingDokument9 SeitenBiodegradable Nanoparticles For Drug Delivery and TargetingTanveer HussainNoch keine Bewertungen

- Nanoencapsulation I. Methods For Preparation of Drug-Loaded ¡¡¡¡Dokument14 SeitenNanoencapsulation I. Methods For Preparation of Drug-Loaded ¡¡¡¡Natalia JaramilloNoch keine Bewertungen

- Encapsulation of Drug Nano Particles in Self-AssembledDokument8 SeitenEncapsulation of Drug Nano Particles in Self-AssembledNatalia JaramilloNoch keine Bewertungen

- Teflon MsdsDokument3 SeitenTeflon MsdsTajul Islam SabojNoch keine Bewertungen

- Density Pepsi Vs Diet PepsiDokument6 SeitenDensity Pepsi Vs Diet PepsiMarcel VerstraeteNoch keine Bewertungen

- What Is Efflorescence in Concrete?Dokument18 SeitenWhat Is Efflorescence in Concrete?Santosh Kumar GoudaNoch keine Bewertungen

- The Comparison of Three Isomers of ButanolDokument5 SeitenThe Comparison of Three Isomers of ButanolLilly0% (2)

- Download Photoionization And Photo Induced Processes In Mass Spectrometry Fundamentals And Applications Ralf Zimmermann all chapterDokument68 SeitenDownload Photoionization And Photo Induced Processes In Mass Spectrometry Fundamentals And Applications Ralf Zimmermann all chapterross.thompson693100% (6)

- Extractive Distillation of TrimethylamineDokument97 SeitenExtractive Distillation of TrimethylamineacetilenaNoch keine Bewertungen

- Dissociation of Hydrogen 1 LangmuirDokument15 SeitenDissociation of Hydrogen 1 LangmuirpomodoroNoch keine Bewertungen

- Vol 2Dokument559 SeitenVol 2erbhaveshparmarNoch keine Bewertungen

- Science Form1 Chapter 7Dokument27 SeitenScience Form1 Chapter 7Sue Suraya Naza100% (1)

- T800 PDFDokument10 SeitenT800 PDFRenato CampoverdeNoch keine Bewertungen

- UPLCDokument33 SeitenUPLCrat001Noch keine Bewertungen

- Malt Extract MsdsDokument7 SeitenMalt Extract MsdsSorin LazarNoch keine Bewertungen

- Welding Toolbox Talk FINALDokument18 SeitenWelding Toolbox Talk FINALJohan CárdenasNoch keine Bewertungen

- EMCDokument1 SeiteEMCAditya GurunathanNoch keine Bewertungen

- SolutionsDokument33 SeitenSolutionsMircea PanteaNoch keine Bewertungen

- Lect 17Dokument26 SeitenLect 17vatsalp3Noch keine Bewertungen

- Programmand AbstrctsDokument272 SeitenProgrammand Abstrctsvitis12Noch keine Bewertungen

- Roldana Barba-Johannis PDFDokument13 SeitenRoldana Barba-Johannis PDFantedluvianoNoch keine Bewertungen

- Pharmaceutical EmulsionsDokument28 SeitenPharmaceutical EmulsionsEph RemNoch keine Bewertungen

- Vtu Previous Year Question PapersDokument26 SeitenVtu Previous Year Question Papersprashanth prabhuNoch keine Bewertungen

- Acknowledgement PageDokument9 SeitenAcknowledgement PagePrashant BarveNoch keine Bewertungen

- KRUPA SINDU 6000 LPH Fully Automatic Two LineDokument31 SeitenKRUPA SINDU 6000 LPH Fully Automatic Two LineVinod DadannavarNoch keine Bewertungen

- CHEMISTRY - CHEMICAL BONDINGDokument6 SeitenCHEMISTRY - CHEMICAL BONDINGChemistry ClassNoch keine Bewertungen