Beruflich Dokumente

Kultur Dokumente

Wireless Based System For Monitoring and Controlling Industrial Parameters

Hochgeladen von

vinoliabenitaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Wireless Based System For Monitoring and Controlling Industrial Parameters

Hochgeladen von

vinoliabenitaCopyright:

Verfügbare Formate

Wireless Based System for Monitoring and Controlling Industrial Parameters

ABSTRACT

The use of wireless sensor networks in industrial automation sector is proving to be advantageous over traditional wired industrial monitoring and control systems, owing to lesser wiring, ease of deployment, increased safety, decreased installation and maintenance cost, in addition to feature like inherent intelligent processing capability. A wireless sensor network consists of sensor nodes, deployed across a wide area (industrial environment), senses various parameters in the field and forwards it to a base station or sink. Automation of an industrial area requires monitoring by a large number of nodes spread across a wide area. This large scale wireless sensor network usually consists of hundreds or thousands of nodes which have low-memory, low processing power, and limited communication capacity. However, to collaboratively monitor and obtain information, centralized data processing and transmission by Base Station is necessary. A Base Station is a powerful device which has much higher processing power, more memory and much higher communication capabilities. The Industrial Wireless Base Station (iWase) is a standalone panel mountable device which can acquire and process sensor readings from nodes in the wireless sensor network and make it available to the external world (user) via wireless or wired interface. This project deals with the development of an wireless base station for monitoring and controlling industrial parameters using wireless sensor networks. Here in this project the wireless base station acquires and process sensor values from sensor nodes in the wireless sensor network of Industry and direct the information to a server (or user) for monitoring or data acquisition purposes using Xbee protocol and GSM interface. In this project, temperature of the industrial furnace and carbon dioxide content in the smoke emitted by the factories are analysed using respective sensors and sent to controlling section so that if any potential problems are notified to the plant personnel as an advanced warning system, it enables plant personnel to control before their efficiency drops or they fail entirely. If the temperature exceeds the threshold level the power supply to the furnace is automatically turned off and in addition Blower circuit can be switched ON/OFF according to the industrial requirements to maintain the plant operation stable.

EXISTING SYSYTEM

The wireless sensor nodes, installed across the industrial environment, monitor the parameters critical to the efficiency of equipments, based on combination of measurements such as vibration, temperature, pressure, coolant level, lubrication oil level and power quality. Sensor nodes have very limited energy and computational resources , low data rate and communication over short distances. The hardware ability of sensor nodes is limited by its small size and battery system which is a drawback indeed.

PROPOSED SYSYTEM

In this system the wireless sensor nodes records the Gas level (CO2) of the industrial furnace. Then the data is then wirelessly transmitted to a Base Station that analyzes the data from each sensor and relays the information to a central monitoring station. Using Ethernet interface or to a remote monitoring station using GSM interface. If any potential problems are notified to the plant personnel as an advanced warning system, it enables plant personnel to monitor and control before their efficiency drops or they fail entirely.

BLOCK DIAGRAM User Mobile

POWER SUPPLY

(((

MESSAGE

XBEE )))

GSM )))

LPC 2148 ARM CONTROLLER DAC

A D C

TEMPERATURE SENSOR GAS SENSOR

(((

XBEE

FURNACE

LOCAL HOST

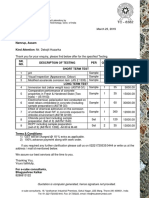

HARDWARE REQUIREMENTS

LPC2148 ARM PROCESSOR TEMPERATURE SENSOR AND GAS SENSOR WITH CLOSED LOOP GSM AND XBEE MODULE POWER SUPPLY CIRCUIT DAC

SOFTWARE REQUIREMENTS

IAR software FLASH MAGIC

ADVANTAGES

Lesser wiring Inherent intelligent capability Supports long distance protocols Resistant to Electromagnetic Interference

DISADVANTAGE

The Xbee module used in this project covers only a small range (10-20m). To overcome this disadvantage,

APPLICATION

This concept can be used to monitor the furnace setup in industries and a safe environment can be maintained.

FUTURE ENHANCEMENTS

Zigbee module which offers a larger coverage area (upto 100m) can be used instead of the Xbee module. Fuzzy Logic can be used in which in stead of setting up only one set point for the temperature value, two or more indication levels can be added along so that the controlling of tempetature can be more accurate.

Das könnte Ihnen auch gefallen

- PIC Based Wireless Sensor NetworkDokument5 SeitenPIC Based Wireless Sensor NetworkMustafa KhairallahNoch keine Bewertungen

- Sensors: A Wireless Sensor System For Real-Time Monitoring and Fault Detection of Motor ArraysDokument5 SeitenSensors: A Wireless Sensor System For Real-Time Monitoring and Fault Detection of Motor ArraysAbhijeet KeerNoch keine Bewertungen

- Sensors 17 00469Dokument21 SeitenSensors 17 00469TejaNoch keine Bewertungen

- Totally Integrated Power ProtectionDokument38 SeitenTotally Integrated Power Protectionvthiseas100% (1)

- Field BusDokument5 SeitenField BusEdwin AguilarNoch keine Bewertungen

- Sensor Networks v4Dokument15 SeitenSensor Networks v4Marcus LittlewoodNoch keine Bewertungen

- Wireless SummaryDokument3 SeitenWireless Summaryأحمد المرزوقيNoch keine Bewertungen

- Brochure - Substation AutomationDokument16 SeitenBrochure - Substation AutomationMartin Garcia AtienciaNoch keine Bewertungen

- Pmma 3Dokument8 SeitenPmma 3MancamiaicuruNoch keine Bewertungen

- Ijert Ijert: Zigbee Based Wireless Sensor Network For Monitoring An Agricultural EnvironmentDokument5 SeitenIjert Ijert: Zigbee Based Wireless Sensor Network For Monitoring An Agricultural EnvironmentbalabooksNoch keine Bewertungen

- Design of A Wireless Medical Monitoring System: Computer and Management (CAMAN), 2011 International Conference OnDokument8 SeitenDesign of A Wireless Medical Monitoring System: Computer and Management (CAMAN), 2011 International Conference Onbopparajuswathi_8787Noch keine Bewertungen

- Substation AutomationDokument5 SeitenSubstation AutomationRavi RaikarNoch keine Bewertungen

- Ethernet OverDokument36 SeitenEthernet OverRaj ChavanNoch keine Bewertungen

- Background To SCADA: 1.1 Introduction and Brief History of SCADADokument9 SeitenBackground To SCADA: 1.1 Introduction and Brief History of SCADAAhmedNoch keine Bewertungen

- Scada OverviewDokument77 SeitenScada OverviewAnonymous Oh1pxYX3Noch keine Bewertungen

- Wireless InstrumentationDokument11 SeitenWireless InstrumentationBNoch keine Bewertungen

- Scada IeeeDokument5 SeitenScada IeeeVarsha PaiNoch keine Bewertungen

- Smart Grid Solution OverviewDokument2 SeitenSmart Grid Solution OverviewsefovarajaNoch keine Bewertungen

- Industrial Parameter Monitoring and Controlling Using GSM and Web ServerDokument3 SeitenIndustrial Parameter Monitoring and Controlling Using GSM and Web ServerInternational Organization of Scientific Research (IOSR)Noch keine Bewertungen

- Remote Data Acquisition Using WirelessDokument3 SeitenRemote Data Acquisition Using WirelessGoutham RajNoch keine Bewertungen

- Harmful Gases Wireless Network Monitoring System DesignDokument2 SeitenHarmful Gases Wireless Network Monitoring System DesignArunodayaprojectsNoch keine Bewertungen

- SCADAPack Product BrochureDokument16 SeitenSCADAPack Product BrochureAqua Technology Group100% (1)

- Scad ADokument10 SeitenScad AKhaddavi KhalifNoch keine Bewertungen

- Substation Automation SystemDokument5 SeitenSubstation Automation SystemganeshNoch keine Bewertungen

- Background To SCADA: 1.1 Introduction and Brief History of SCADADokument10 SeitenBackground To SCADA: 1.1 Introduction and Brief History of SCADABrant XuNoch keine Bewertungen

- Background To SCADA: 1.1 Introduction and Brief History of SCADADokument10 SeitenBackground To SCADA: 1.1 Introduction and Brief History of SCADABrant XuNoch keine Bewertungen

- Medidores TRON - EM420i en 02-14Dokument4 SeitenMedidores TRON - EM420i en 02-14JuanRosas100% (1)

- Kathrein'S Remote Electrical Tilt System: Overview of Related Products, Installation and Control PossibilitiesDokument20 SeitenKathrein'S Remote Electrical Tilt System: Overview of Related Products, Installation and Control PossibilitiesVítor Lopes100% (1)

- Integrating SCADA and Sap Operations For Electricity Process AutomationDokument3 SeitenIntegrating SCADA and Sap Operations For Electricity Process AutomationHakim BenmajidNoch keine Bewertungen

- 90 - Radius A5 1 Fully Passive Off The Air GSM InterceptingDokument8 Seiten90 - Radius A5 1 Fully Passive Off The Air GSM Interceptingjacques_henry666Noch keine Bewertungen

- An Application of Wireless Standards For Remote Monitoring of Electric Drive SystemsDokument7 SeitenAn Application of Wireless Standards For Remote Monitoring of Electric Drive SystemsIJERDNoch keine Bewertungen

- Csi 9420 enDokument10 SeitenCsi 9420 enAldo RomanNoch keine Bewertungen

- A Smart Zigbee Based Wireless Weather Station Monitoring SystemDokument6 SeitenA Smart Zigbee Based Wireless Weather Station Monitoring SystemHachem ElyousfiNoch keine Bewertungen

- Remote Notice Board Using GSM With SmsDokument14 SeitenRemote Notice Board Using GSM With SmsMikroc Thupati SrinivsNoch keine Bewertungen

- Environmental Monitoring: Monitoring and Control of Photovoltaic SystemsDokument11 SeitenEnvironmental Monitoring: Monitoring and Control of Photovoltaic SystemsVasluianuNoch keine Bewertungen

- Your Benefit: Optimal UseDokument6 SeitenYour Benefit: Optimal UserifqysiagianNoch keine Bewertungen

- IEC 62591 WirelessHART System Engineering GuidelinesDokument112 SeitenIEC 62591 WirelessHART System Engineering Guidelinesargix69Noch keine Bewertungen

- Design of A Wireless Medical Monitoring System 5880 AqzbA2oDokument7 SeitenDesign of A Wireless Medical Monitoring System 5880 AqzbA2oB. MaheshNoch keine Bewertungen

- Erl Scada BrochureDokument12 SeitenErl Scada BrochureBehzadNoch keine Bewertungen

- A Project Report On "GSM Based Device On-Off Control Especially Designed For Agricultural Needs"Dokument13 SeitenA Project Report On "GSM Based Device On-Off Control Especially Designed For Agricultural Needs"ilveyouNoch keine Bewertungen

- An Real Time IWSN Based SCADA Network For Industrial AutomationDokument5 SeitenAn Real Time IWSN Based SCADA Network For Industrial Automationchittaranjan baralNoch keine Bewertungen

- Wireless Sensor Network For Monitoring Control ofDokument12 SeitenWireless Sensor Network For Monitoring Control ofkristine cruzNoch keine Bewertungen

- DCS Vendors ListDokument4 SeitenDCS Vendors ListchetanNoch keine Bewertungen

- Ace-6000 CT R4 LDDokument4 SeitenAce-6000 CT R4 LDThomas ReedNoch keine Bewertungen

- GSM Based Device ControlDokument9 SeitenGSM Based Device ControlsubucudNoch keine Bewertungen

- 02 DCS Architecture IODokument10 Seiten02 DCS Architecture IOJOSEPH LORENZ RODRIGUEZNoch keine Bewertungen

- TP013 Wireless Vibration Monitoring SystemDokument4 SeitenTP013 Wireless Vibration Monitoring SystemKonradNoch keine Bewertungen

- IAS 2009 Vfinal2Dokument7 SeitenIAS 2009 Vfinal2Cinthya BorgesNoch keine Bewertungen

- Scada 2Dokument4 SeitenScada 2Ammulya AmmuNoch keine Bewertungen

- RF Research Paper-1Dokument4 SeitenRF Research Paper-1Ghilman HabibNoch keine Bewertungen

- Unit 3 - InpDokument20 SeitenUnit 3 - Inpniya enzieNoch keine Bewertungen

- Smart Sensor Plug and PlayDokument10 SeitenSmart Sensor Plug and Playanuj1166Noch keine Bewertungen

- Applying Wireless Sensor Networks in An Online Monitoring and Energy Management System For Industrial MotorsDokument9 SeitenApplying Wireless Sensor Networks in An Online Monitoring and Energy Management System For Industrial MotorsluanleNoch keine Bewertungen

- Industrial Networks For Communication and ControlDokument49 SeitenIndustrial Networks For Communication and ControlanubstephenNoch keine Bewertungen

- Adam SeriesDokument9 SeitenAdam Serieslaap85Noch keine Bewertungen

- Practical Data Acquisition for Instrumentation and Control SystemsVon EverandPractical Data Acquisition for Instrumentation and Control SystemsNoch keine Bewertungen

- How Was Your Day After UPSC Selection Agam JainDokument5 SeitenHow Was Your Day After UPSC Selection Agam JainvinoliabenitaNoch keine Bewertungen

- 000 Preface Ten Facts 2017-18 Vol 1-18 PagesDokument18 Seiten000 Preface Ten Facts 2017-18 Vol 1-18 PagesAbhilashMaNoch keine Bewertungen

- Embedded MicrocontrollerDokument30 SeitenEmbedded MicrocontrollervinoliabenitaNoch keine Bewertungen

- Notification NEIIPP 2007Dokument5 SeitenNotification NEIIPP 2007api-3711789Noch keine Bewertungen

- NG Teng Fong Discharge DocumentsDokument14 SeitenNG Teng Fong Discharge DocumentsAnonymous yGwMIPJRawNoch keine Bewertungen

- READING 4 UNIT 8 Crime-Nurse Jorge MonarDokument3 SeitenREADING 4 UNIT 8 Crime-Nurse Jorge MonarJORGE ALEXANDER MONAR BARRAGANNoch keine Bewertungen

- Congenital Flexural Deformity in CalfDokument6 SeitenCongenital Flexural Deformity in CalfBibek SutradharNoch keine Bewertungen

- ASD Diagnosis Tools - UpToDateDokument3 SeitenASD Diagnosis Tools - UpToDateEvy Alvionita Yurna100% (1)

- Crime Data Analysis 1Dokument2 SeitenCrime Data Analysis 1kenny laroseNoch keine Bewertungen

- Employee Final SettlementDokument1 SeiteEmployee Final SettlementZeeshan Mirza0% (1)

- TC 10 emDokument7 SeitenTC 10 emDina LydaNoch keine Bewertungen

- Report in Per Dev CorrectedDokument34 SeitenReport in Per Dev CorrectedJosh lyan RiveraNoch keine Bewertungen

- Soal UAS Bahasa Inggris 2015/2016: Read The Text Carefully! Cold Comfort TeaDokument5 SeitenSoal UAS Bahasa Inggris 2015/2016: Read The Text Carefully! Cold Comfort TeaAstrid AlifkalailaNoch keine Bewertungen

- Introduction and Vapour Compression CycleDokument29 SeitenIntroduction and Vapour Compression Cycleمحسن الراشدNoch keine Bewertungen

- QA-QC TPL of Ecube LabDokument1 SeiteQA-QC TPL of Ecube LabManash Protim GogoiNoch keine Bewertungen

- Blueprint Huynh My Ky Duyen 2022 McDonald'sDokument2 SeitenBlueprint Huynh My Ky Duyen 2022 McDonald'sHuỳnh Mỹ Kỳ DuyênNoch keine Bewertungen

- Potato Storage and Processing Potato Storage and Processing: Lighting SolutionDokument4 SeitenPotato Storage and Processing Potato Storage and Processing: Lighting SolutionSinisa SustavNoch keine Bewertungen

- Current Concepts of Enzyme Histochemistry in Modern PathologyDokument11 SeitenCurrent Concepts of Enzyme Histochemistry in Modern PathologyRosa AquinoNoch keine Bewertungen

- Basic Electrical Engineering NotesDokument25 SeitenBasic Electrical Engineering NotesAnas AnsariNoch keine Bewertungen

- Sanctuary Policy PomonaDokument3 SeitenSanctuary Policy PomonaGabriel EliasNoch keine Bewertungen

- MajorProjects 202112 e 1Dokument64 SeitenMajorProjects 202112 e 1xtrooz abiNoch keine Bewertungen

- Pe 3 Syllabus - GymnasticsDokument7 SeitenPe 3 Syllabus - GymnasticsLOUISE DOROTHY PARAISO100% (1)

- 41 Assignment Worksheets For SchoolDokument26 Seiten41 Assignment Worksheets For Schoolsoinarana456Noch keine Bewertungen

- Dungeon World ConversionDokument5 SeitenDungeon World ConversionJosephLouisNadeauNoch keine Bewertungen

- Neurocisticercosis PDFDokument7 SeitenNeurocisticercosis PDFFiorella Alexandra HRNoch keine Bewertungen

- What Is A VolcanoDokument2 SeitenWhat Is A VolcanonatachaNoch keine Bewertungen

- 2020 ROTH IRA 229664667 Form 5498Dokument2 Seiten2020 ROTH IRA 229664667 Form 5498hk100% (1)

- G1 Series User Manual Ver. 1.2Dokument101 SeitenG1 Series User Manual Ver. 1.2unedo parhusip100% (1)

- 6 Kuliah Liver CirrhosisDokument55 Seiten6 Kuliah Liver CirrhosisAnonymous vUEDx8100% (1)

- Reaction Paper-RprDokument6 SeitenReaction Paper-Rprapi-543457981Noch keine Bewertungen

- Advances of Family Apocynaceae A Review - 2017Dokument30 SeitenAdvances of Family Apocynaceae A Review - 2017Владимир ДружининNoch keine Bewertungen

- Weld Metal Overlay & CladdingDokument2 SeitenWeld Metal Overlay & CladdingbobyNoch keine Bewertungen

- Nitric AcidDokument7 SeitenNitric AcidKuldeep BhattNoch keine Bewertungen

- Outlook 2Dokument188 SeitenOutlook 2Mafer Garces NeuhausNoch keine Bewertungen