Beruflich Dokumente

Kultur Dokumente

Active Energy Efficiency Using Speed Control Outline

Hochgeladen von

Michael MorrisOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Active Energy Efficiency Using Speed Control Outline

Hochgeladen von

Michael MorrisCopyright:

Verfügbare Formate

Active Energy Efficiency Using Speed Control Outline Course description: Many motors only have two settings:

on and off. They operate at constant speed. If a motor turning at constant speed is driving a device or process that requires less output, adjustments are required to achieve the desired output level. This adjustment is often achieved by letting the motor run at full speed, while using downstream devices to block part of the output. This is like driving your car by having one foot fully depressing the accelerator pedal, and the other on the brake to constantly control the speed. It sounds absurd, but this is still one of the most common control methods. An estimated 60% of motors are not speed controlled. The focus of this course is to explore the different ways we can control motor speed efficiently and with minimal physical stress on equipment. In addition, we'll discuss other advantages such as controlled starting and regulated torque. Course Outline: Learning objectives At the completion of this course you will be able to: Identify main motor starting methods Recognize the frequency converter principle and its advantages Realize substantial energy savings using speed control Reduce harmonic distortion generated by frequency converters Calculate the payback of an investment in a variable speed drive

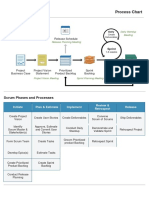

Course content or material 1) Introduction a. Affinity laws 2) Motor starting methods a. Direct-on-line b. Star/delta c. Soft starting d. Electrical variable speed control 3) Starting methods compared 4) Advantages of VSD a. Controlled start and stop

2013 Schneider Electric. All rights reserved. All trademarks provided are the property of their respective owners.

5) 6)

7)

8) 9)

10) 11)

b. Reduced investment c. Comfort / accuracy d. Mechanical protection e. Convenient user interface f. Communication for control g. Reduced operating costs How to waste energy a. Flow regulation with a damper How to save energy a. Speed control i. Potential energy savings with pumps ii. Potential energy savings with fans Economic factors a. Variable speed drives i. Less expensive ii. More flexible iii. Energy savings: 20% - 50% iv. Flexible v. Allows for future speed changes vi. Can be integrated with a minimum of disruption vii. Generally pay for themselves within 1 to 2.5 years b. Economic factors example Available tools a. Energy consumption simulator b. ECO2 energy calculator Harmonics a. Mitigation i. Choke ii. Passive filters iii. Active filters iv. 12-pulses system v. Clean drives Conclusions Summary

2013 Schneider Electric. All rights reserved. All trademarks provided are the property of their respective owners.

Das könnte Ihnen auch gefallen

- Electric Motor Control: DC, AC, and BLDC MotorsVon EverandElectric Motor Control: DC, AC, and BLDC MotorsBewertung: 4.5 von 5 Sternen4.5/5 (19)

- iHorizon-Enabled Energy Management for Electrified VehiclesVon EverandiHorizon-Enabled Energy Management for Electrified VehiclesNoch keine Bewertungen

- VFD Energy Efficiency GuideDokument100 SeitenVFD Energy Efficiency Guidevijayk1968Noch keine Bewertungen

- Motors A Performance Opportunity RoadmapDokument18 SeitenMotors A Performance Opportunity RoadmapAtiq_2909Noch keine Bewertungen

- Green Motor Drive©: by Dr. Abe Shahrodi Power Magnetronics SolutionsDokument14 SeitenGreen Motor Drive©: by Dr. Abe Shahrodi Power Magnetronics Solutionsalex696Noch keine Bewertungen

- Motors Best Practice ToolDokument8 SeitenMotors Best Practice ToolAngshuman DuttaNoch keine Bewertungen

- Energy Answers For MotorsDokument4 SeitenEnergy Answers For Motorsdetroit44Noch keine Bewertungen

- Total Motor MaintenanceDokument6 SeitenTotal Motor MaintenanceWilson PinacateNoch keine Bewertungen

- International Journal of Research Publication and Reviews International Journal of Research Publication and ReviewsDokument3 SeitenInternational Journal of Research Publication and Reviews International Journal of Research Publication and ReviewsSaurabh DeshmukhNoch keine Bewertungen

- What Is A Variable Speed DriveDokument6 SeitenWhat Is A Variable Speed DriveTerdy MNNoch keine Bewertungen

- Shvs Micro Hybrid ExplainedDokument7 SeitenShvs Micro Hybrid ExplainedAshNoch keine Bewertungen

- Galco Tech Tips - Motor Control Selection GuideDokument2 SeitenGalco Tech Tips - Motor Control Selection GuideGalco IndustrialNoch keine Bewertungen

- Electrical Motor Control TrainingDokument4 SeitenElectrical Motor Control TrainingdenramrNoch keine Bewertungen

- FalknerDokument10 SeitenFalknerAnonymous NGXdt2BxNoch keine Bewertungen

- Control Systems Project Report (180501008) (180501016) (180501018) (180501020)Dokument19 SeitenControl Systems Project Report (180501008) (180501016) (180501018) (180501020)Shahzaib Anwar OffNoch keine Bewertungen

- IRJET Research On Clutchless Quick GearDokument3 SeitenIRJET Research On Clutchless Quick Gearscdindar3838Noch keine Bewertungen

- Regenerativ BrakingDokument5 SeitenRegenerativ BrakingAnkit SinghNoch keine Bewertungen

- Regenerative Braking SystemDokument6 SeitenRegenerative Braking SystemVivek SinghNoch keine Bewertungen

- Mechatronic Analysis Improves EfficiencyDokument2 SeitenMechatronic Analysis Improves EfficiencyMilan PavlovicNoch keine Bewertungen

- Best Energy Management For Electric MotorDokument11 SeitenBest Energy Management For Electric MotorAnielle John MonteroNoch keine Bewertungen

- Horn Opportunities and Challenges enDokument10 SeitenHorn Opportunities and Challenges enamisha2562585Noch keine Bewertungen

- Ijsrdv4i10408 PDFDokument2 SeitenIjsrdv4i10408 PDFHáŗï HářäņNoch keine Bewertungen

- Efficiency For Motors and PumpsDokument6 SeitenEfficiency For Motors and Pumpsyamaha100% (1)

- Valvetronic EngineDokument5 SeitenValvetronic EngineHafis SayedNoch keine Bewertungen

- Irjet V7i10282Dokument4 SeitenIrjet V7i10282scdindar3838Noch keine Bewertungen

- Cob 2015 0926Dokument8 SeitenCob 2015 0926Di M. BraNoch keine Bewertungen

- Project 2Dokument52 SeitenProject 2rajuNoch keine Bewertungen

- Seminar 1-6Dokument15 SeitenSeminar 1-6gng0309.workNoch keine Bewertungen

- Department of Mechanical EngineeringDokument23 SeitenDepartment of Mechanical EngineeringMail ManNoch keine Bewertungen

- Design of VFD Drive For AC MotorDokument8 SeitenDesign of VFD Drive For AC MotorralphholingsheadNoch keine Bewertungen

- A Scope and Study of Automatic Transmission System in Context of Operating Parameter and Professional Requirement"Dokument8 SeitenA Scope and Study of Automatic Transmission System in Context of Operating Parameter and Professional Requirement"RaymondNoch keine Bewertungen

- Wepik Optimizing Motor and Pump Efficiency The Benefits of Variable Frequency Drives Vfds 20230929071149o5rkDokument12 SeitenWepik Optimizing Motor and Pump Efficiency The Benefits of Variable Frequency Drives Vfds 20230929071149o5rkManish sutharNoch keine Bewertungen

- Guide To Variable Speed Drives (VSD) : Why Using A VSD Can Help You Save Money and The EnvironmentDokument20 SeitenGuide To Variable Speed Drives (VSD) : Why Using A VSD Can Help You Save Money and The EnvironmentfelipeNoch keine Bewertungen

- Project Presentation FinalDokument25 SeitenProject Presentation Finalapi-337447562Noch keine Bewertungen

- Ac 2007-429: An Innovative Hybrid-Electric Drivetrain Concept and Student ProjectDokument13 SeitenAc 2007-429: An Innovative Hybrid-Electric Drivetrain Concept and Student ProjectAbdul HakeemNoch keine Bewertungen

- Energies 07 06459Dokument21 SeitenEnergies 07 06459Ahmad FadlunNoch keine Bewertungen

- Automatic Pneumatic BumperDokument86 SeitenAutomatic Pneumatic BumperpramodassNoch keine Bewertungen

- Variable Speed Pumping, A Guide To Successful ApplicationDokument6 SeitenVariable Speed Pumping, A Guide To Successful Applicationongjoel0% (1)

- Fuel Efficiency Evaluation Series HEVDokument5 SeitenFuel Efficiency Evaluation Series HEVVarun TalwalkarNoch keine Bewertungen

- Energies-16-01950-Vf (Artículo Modelo)Dokument29 SeitenEnergies-16-01950-Vf (Artículo Modelo)Jorge CarrionNoch keine Bewertungen

- Energy-Optimal Control of Plug-In Hybrid Electric Vehicles For Real-World Driving CyclesDokument14 SeitenEnergy-Optimal Control of Plug-In Hybrid Electric Vehicles For Real-World Driving CyclesAndreea StefanaNoch keine Bewertungen

- Solenoid Engine ReportDokument36 SeitenSolenoid Engine ReportHarsh mouryNoch keine Bewertungen

- Electric Vehicle Conversion Based On Distance, Speed and Cost RequirementsDokument9 SeitenElectric Vehicle Conversion Based On Distance, Speed and Cost RequirementsVo SantosNoch keine Bewertungen

- Chapter 3.10: Energy Efficient Technologies in Electrical SystemsDokument8 SeitenChapter 3.10: Energy Efficient Technologies in Electrical SystemsdineshvhavalNoch keine Bewertungen

- Regen Braking PresentationDokument12 SeitenRegen Braking Presentationvthiagu90_267718230Noch keine Bewertungen

- Automatic Speed Control in 4-Wheeler To Avod Rash DrivingDokument18 SeitenAutomatic Speed Control in 4-Wheeler To Avod Rash Drivingsuh_ahmd100% (1)

- Energy EfficiencyDokument3 SeitenEnergy EfficiencymrfxitNoch keine Bewertungen

- Design and Development of Automatic Pneumatic Bumper SystemDokument6 SeitenDesign and Development of Automatic Pneumatic Bumper SystemSahaya robin singh MNoch keine Bewertungen

- Automatic Acceleration Controlling System in Traffic SignalsDokument4 SeitenAutomatic Acceleration Controlling System in Traffic Signalsieee4mybusinessonlyNoch keine Bewertungen

- Energy Saving Using Mitsubishi VFDDokument4 SeitenEnergy Saving Using Mitsubishi VFDkashinathNoch keine Bewertungen

- Fuzzy Logic Speed ControlDokument12 SeitenFuzzy Logic Speed ControlRasheed AhamedNoch keine Bewertungen

- Energy Conservation PresentationDokument23 SeitenEnergy Conservation PresentationAbdullah TariqNoch keine Bewertungen

- Camless EngineDokument17 SeitenCamless EngineSarvesh Mhatre100% (1)

- VSD Advantages, Disadvantages, Selection Criteria and Installation Tips and TricksDokument18 SeitenVSD Advantages, Disadvantages, Selection Criteria and Installation Tips and TricksMike CerreroNoch keine Bewertungen

- Literature Review of Speed Control of Induction MotorDokument4 SeitenLiterature Review of Speed Control of Induction MotoraflsmperkNoch keine Bewertungen

- Power Management FinalDokument25 SeitenPower Management FinallogeshsegolNoch keine Bewertungen

- Stop-Start System Using Micro-Hybrid Technology For Increasing Fuel EfficiencyDokument7 SeitenStop-Start System Using Micro-Hybrid Technology For Increasing Fuel EfficiencySantoshNoch keine Bewertungen

- CEATI VFD 7025 - PrintableDokument100 SeitenCEATI VFD 7025 - PrintableÖnder PolatNoch keine Bewertungen

- Reyn Lab Visit - Report - 1Dokument4 SeitenReyn Lab Visit - Report - 1RAJESH MNoch keine Bewertungen

- Introduction to Hybrid Vehicle System Modeling and ControlVon EverandIntroduction to Hybrid Vehicle System Modeling and ControlBewertung: 4 von 5 Sternen4/5 (1)

- Is 1786Dokument5 SeitenIs 1786Jeevan ShendreNoch keine Bewertungen

- TN 1473Dokument63 SeitenTN 1473Meisam TabrizNoch keine Bewertungen

- A Business Intelligence Framework For The FutureDokument10 SeitenA Business Intelligence Framework For The Futuremcalbala100% (1)

- Procesos SCRUMDokument2 SeitenProcesos SCRUMRoseNoch keine Bewertungen

- Job Report 2Dokument6 SeitenJob Report 2Sahr, Cyprian FillieNoch keine Bewertungen

- Maxstar140str (KK013519)Dokument52 SeitenMaxstar140str (KK013519)mrtans0% (1)

- MRT PrjectDokument59 SeitenMRT PrjectFahrul 2394Noch keine Bewertungen

- Handling An Maintenance of Construction Machineries, Equipments and InstrumentsDokument13 SeitenHandling An Maintenance of Construction Machineries, Equipments and InstrumentsVelmurugan BalasubramanianNoch keine Bewertungen

- AMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Dokument5 SeitenAMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Andre SanarNoch keine Bewertungen

- Standards of MeasurementDokument12 SeitenStandards of MeasurementShubham KheraNoch keine Bewertungen

- GAPS Guidelines: Deep Fat FryersDokument4 SeitenGAPS Guidelines: Deep Fat FryersAsad KhanNoch keine Bewertungen

- Cryogenics Handbook PDFDokument227 SeitenCryogenics Handbook PDFmangyanNoch keine Bewertungen

- Sigma Marine Coatings Manual - Part44Dokument2 SeitenSigma Marine Coatings Manual - Part44EngTamerNoch keine Bewertungen

- Quest CCS ProjectDokument10 SeitenQuest CCS ProjecttruehemingwayNoch keine Bewertungen

- Lab 2Dokument8 SeitenLab 2Hamid SaeedNoch keine Bewertungen

- ACI 517-2R-87 Standard Specification For Tolerances For Accelerated Curing at Atmospheric PressureDokument17 SeitenACI 517-2R-87 Standard Specification For Tolerances For Accelerated Curing at Atmospheric PressureKiramat ShahNoch keine Bewertungen

- Digital Signal Processing R13 Previous PapersDokument5 SeitenDigital Signal Processing R13 Previous PapersPrasannaKumar KaraNam100% (1)

- Led Linear Emergency 2021Dokument4 SeitenLed Linear Emergency 2021Sugumaran LakshmananNoch keine Bewertungen

- Bomet CountyDokument1 SeiteBomet CountyPrince AliNoch keine Bewertungen

- Die Casting Process & Design Gate & ParametersDokument113 SeitenDie Casting Process & Design Gate & ParametersEr Tarun Patel100% (1)

- Raman Spectroscopy SetupDokument13 SeitenRaman Spectroscopy SetupRafael RamosNoch keine Bewertungen

- Catapult Ref ManDokument372 SeitenCatapult Ref ManBiplab RoyNoch keine Bewertungen

- Implementing Routing Facilities For Branch Offices and Mobile WorkersDokument180 SeitenImplementing Routing Facilities For Branch Offices and Mobile WorkersAlejandro Cordero OrdoñezNoch keine Bewertungen

- Chemistry, Intermediate II Year Model Question PapersDokument3 SeitenChemistry, Intermediate II Year Model Question PapersAkshay PandeyNoch keine Bewertungen

- Hexadecimal To DecimalDokument7 SeitenHexadecimal To DecimalMushfik ArafatNoch keine Bewertungen

- 496 - SSP481 - Audi A7 Onboard Power Supply and Networking PDFDokument40 Seiten496 - SSP481 - Audi A7 Onboard Power Supply and Networking PDFbenjaminhuku100% (5)

- VSSUT (EEE) SyllabusDokument47 SeitenVSSUT (EEE) SyllabusAshutosh GuptaNoch keine Bewertungen

- Soccer Field Lighting DesignDokument22 SeitenSoccer Field Lighting DesigndevakaNoch keine Bewertungen

- Elevated Intz Tank 279Dokument23 SeitenElevated Intz Tank 279Navasivayam Sankar100% (2)

- Unit-1 - Spur Gears - Lecture - 6 - Problems Spur Gear - Mahesh GaikwadDokument13 SeitenUnit-1 - Spur Gears - Lecture - 6 - Problems Spur Gear - Mahesh GaikwadNikhil JadhavNoch keine Bewertungen