Beruflich Dokumente

Kultur Dokumente

Air Density PDF

Hochgeladen von

Dhirendra Singh RathoreOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Air Density PDF

Hochgeladen von

Dhirendra Singh RathoreCopyright:

Verfügbare Formate

providing insights for todays hvac system designer

Engineers Newsletter

Effects of Altitude

on psychrometric calculations and fan selections

volume 39 4

For this EN we're pulling from the archives to address a subject that still causes confusion within the industry and continues to be the subject of frequently asked questions. This EN investigates the effects of altitude on psychrometric calculations and fan selections.

"Standard Air"

As altitude increases, the average barometric pressure drops and air density decreases. "Standard air" has historically been defined by ASHRAE as having a density of 0.075 lb/ft3, which equates to air density at sea level (barometric pressure of 29.92 in. Hg). The 2009 ASHRAE Handbook of Fundamentals (page 18.13) states that this condition is represented by either saturated air at 60F dry bulb or dry air at 69F dry bulb. Since the performance of heating, cooling, and air-moving equipment is commonly rated at "standard air" conditions, cataloged performance data cannot be used directly for higher altitude applications. For instance, at a barometric pressure of 24 in. Hg (approximately 6000 ft altitude), cataloged data may be off by as much as 20 to 40 percent. While areas above 6000 ft are statistically limited, a number of states and cities have barometric pressures in the range of 29 to 27 in.

Hg. In this range, cataloged ratings may differ from actual conditions by 3 to 20 percent.

Psychrometric Calculations

The equations used in psychrometric calculations remain the same for all altitudes. However, some of the factors used in these equations are affected by altitude. The sensible heat gain (Qs) equation is often displayed as follows:

Qs = 1.085 cfm T

However, the 1.085 in this equation is not a constant. Rather, it is the product of the density () and specific heat (Cp) of the air at "standard air" conditions, and the conversion factor of 60 minutes per hour.

Qs = ( Cp 60 min/hr) cfm x T

The specific heat for 69F dry air at sea level is 0.241 Btu/lbF . Therefore, at "standard air" conditions, these properties result in the value 1.085.

0.075 lb/ft3 0.241 Btu/lbF 60 min/hr = 1.085

2010 Trane, a business of Ingersoll Rand. All rights reserved.

The latent heat gain (QL) equation is often displayed as follows:

QL = 0.69 cfm W (gr/lb)

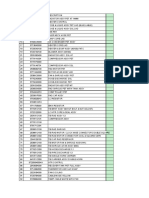

Figure 1. Air density ratios

Elevation Sea level 1000 ft. 2000 ft. 3000 ft. 4000 ft. 5000 ft. 6000 ft. Air Density Ratio

Barometer 29.92 in. Hg. 28.86 in. Hg. 27 .82 in. Hg. 26.81 in. Hg. 25.84 in. Hg. 24.89 in. Hg. 23.98 in. Hg. 23.09 in. Hg.

However, the 0.69 in this equation is not a constant. Rather, it is the product of the density and latent heat of vaporization (hvap) of the air at "standard air" conditions, and the conversion factors of 60 minutes per hour and 7000 grains/lb.

QL = ( hvap 60 min/hr / 7000 gr/lb) cfm W

7000 ft.

The latent heat of vaporization for 69F dry air at sea level is 1076 Btu/lb. Therefore, at "standard air" conditions, these properties result in the value 0.69.

(0.075 lb/ft3 1076 Btu/lb 60 min/hr) / 7000 gr/lb = 0.69

The total heat gain (QT) equation is often displayed as follows:

QT = 4.5 cfm h

However, the 4.5 in this equation is not a constant. Rather, it is the product of the density of the air at "standard air" conditions and the conversion factor of 60 minutes per hour.

QT = ( 60 min/hr) cfm h

Air Temperature, F

For "standard air" density, the result is the value 4.5.

0.075 lb/ft3 60 min/hr = 4.5

application is stated at non-standard conditions, a density correction must be made prior to selecting a fan. The procedure for selecting a fan at actual altitude (or temperatures) is outlined in the following steps: 1 Determine the actual air density and calculate the air density ratio, which is the density at actual conditions divided by density at standard conditions. Figure 1 provides a useful chart for determining the air density ratio based on altitude and air temperature.

Air Density Ratio = Densityactual Densitystandard

Air at other conditions and other altitudes will cause these factors to change.

3 Use the actual design airflow (cfm) and the static pressure corrected for standard conditions (see Step 2) to select the fan from the performance tables/charts and to determine the speed (rpm) and horsepower requirement of the fan at standard conditions. 4 The fan speed (rpm) is the same at both actual and standard conditions.

RPMactual = RPMstandard

Fans

Fans are considered to be constantvolume devices. That is, a given fan will deliver a specific volumetric flow rate (cfm) at a specific fan rotational speed (rpm). The mass of air that the fan moves at a given speed will vary based on the density of the air being moved. Air density also changes the static pressure that the fan will develop and the horsepower needed to drive it. Fan and air handler manufacturers typically catalog fan performance data at "standard air" conditions. If the airflow requirement for a given

5 Multiply the input power requirement by the air density ratio to determine the actual input power required.

Poweractual = Air Density Ratio X Powerstandard

2 Divide the design static pressure at actual conditions by the air density ratio determined in Step 1.

SPstandard = SPactual Air Density Ratio

Trane Engineers Newsletter volume 394

providing insights for todays HVAC system designer

It is important to note that most pressure-loss charts for other system components (such as ducts, filters, coils, and dampers) are also based on standard air conditions.

Summary

Although the wide-scale use of computer software to select HVAC equipment has made the process of correcting for altitude simpler, a fundamental understanding is still important to prevent mistakes and troubleshoot problems.

By Trane Applications Engineering. You can find this and previous issues of the Engineers Newsletter at www.trane.com/ engineersnewsletter. To comment, e-mail us at comfort@trane.com.

View the latest on-demand courses:

ASHRAE Standard 90.1-2010. Energy-Saving Strategies for Rooftop VAV Systems. ASHRAE Standard 62.1: Ventilation Rate Procedure. LEED 2009 Modeling and Energy Savings. The courses were developed and are offered free of charge to demonstrate Tranes commitment to sustainable design. LEED Accredited Professionals (APs) and AIA members can participate and earn an average of 1.5 Continuing Education (CE) hours per program. Visit www.trane.com/ continuingeducation to view all current courses and details.

Trane Engineers Newsletter volume 394

providing insights for todays HVAC system designer

New application manuals now available

Central Geothermal Design and Control. (SYS-APM009-EN, April 2010) Chilled-Water VAV Systems. (SYS-APM008-EN, August 2009) Chiller System Design and Control. (SYS-APM001-EN, May 2009) Visit www.trane.com/bookstore to order and view a complete list of resources.

Engineers Newsletter LIVE!

To register, contact your local Trane office.

March 2011

Upgrading Existing Chilled-Water Systems

June 2011

High-Performance VAV Systems

October 2011

Dedicated Outdoor Air Units

Trane, A business of Ingersoll Rand For more information, contact your local Trane office or e-mail us at comfort@trane.com

Trane believes the facts and suggestions presented here to be accurate. However, final design and application decisions are your responsibility. Trane disclaims any responsibility for actions taken on the material presented.

Trane Engineers Newsletter volume 394

ADM-APN039-EN (December 2010)

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Xa Guide PDFDokument33 SeitenXa Guide PDFBlessing MukomeNoch keine Bewertungen

- Subject ChemistryDokument15 SeitenSubject ChemistryDhirendra Singh RathoreNoch keine Bewertungen

- Renewable Energy in India Growth and TargetsDokument34 SeitenRenewable Energy in India Growth and TargetsmitulNoch keine Bewertungen

- Taco Phe PDFDokument4 SeitenTaco Phe PDFDhirendra Singh RathoreNoch keine Bewertungen

- Green Building MaterialDokument40 SeitenGreen Building MaterialDhirendra Singh RathoreNoch keine Bewertungen

- A Basic Design Guide For Clean Room ApplicationsDokument61 SeitenA Basic Design Guide For Clean Room ApplicationsAlex Chin67% (3)

- FXSQ-A Concealed Ceiling Unit UKEPLEN15-945 Tcm511-393388Dokument2 SeitenFXSQ-A Concealed Ceiling Unit UKEPLEN15-945 Tcm511-393388Dhirendra Singh RathoreNoch keine Bewertungen

- VRV IV - Leaflet - HA - FINAL LR - tcm582-400473 PDFDokument36 SeitenVRV IV - Leaflet - HA - FINAL LR - tcm582-400473 PDFDhirendra Singh RathoreNoch keine Bewertungen

- VRV Heat Recovery Systems: Application and Sales GuideDokument36 SeitenVRV Heat Recovery Systems: Application and Sales GuideDhirendra Singh RathoreNoch keine Bewertungen

- Characterising Roof Ventilators: P 2 A Q CDokument4 SeitenCharacterising Roof Ventilators: P 2 A Q CDhirendra Singh RathoreNoch keine Bewertungen

- (Ashrae) Understing Clean Room Design (BookFi) PDFDokument5 Seiten(Ashrae) Understing Clean Room Design (BookFi) PDFsubruaNoch keine Bewertungen

- Oau PRC001G en - 06172016Dokument96 SeitenOau PRC001G en - 06172016Dhirendra Singh RathoreNoch keine Bewertungen

- High Performance Glass PDFDokument4 SeitenHigh Performance Glass PDFBrajesh MishraNoch keine Bewertungen

- Boiler System EfficiencyDokument7 SeitenBoiler System EfficiencyDhirendra Singh RathoreNoch keine Bewertungen

- Be Tech Guide Horizontal High Performance Fan Coil Units Form 115-26-Eg5 (1014)Dokument28 SeitenBe Tech Guide Horizontal High Performance Fan Coil Units Form 115-26-Eg5 (1014)Dhirendra Singh RathoreNoch keine Bewertungen

- VRV Integration With: Ahu For Special ApplicationsDokument4 SeitenVRV Integration With: Ahu For Special ApplicationsDhirendra Singh RathoreNoch keine Bewertungen

- FTN Leaflet 08 11 2015 - tcm582 405647Dokument4 SeitenFTN Leaflet 08 11 2015 - tcm582 405647Dhirendra Singh RathoreNoch keine Bewertungen

- Modeling of Stack Effect in High-Rise Buildings 2015Dokument21 SeitenModeling of Stack Effect in High-Rise Buildings 2015Dhirendra Singh RathoreNoch keine Bewertungen

- Efficiency of Air Curtains Used For Separating Smoke Free Zones in Case of FireDokument6 SeitenEfficiency of Air Curtains Used For Separating Smoke Free Zones in Case of FireDhirendra Singh RathoreNoch keine Bewertungen

- Green Hospitals PDFDokument4 SeitenGreen Hospitals PDFDhirendra Singh RathoreNoch keine Bewertungen

- Be Tech Guide Horizontal Low Profile Fan Coil Units - Form 115-26-Eg5 (1014)Dokument32 SeitenBe Tech Guide Horizontal Low Profile Fan Coil Units - Form 115-26-Eg5 (1014)Dhirendra Singh RathoreNoch keine Bewertungen

- 04 581067 01Dokument6 Seiten04 581067 01Dhirendra Singh RathoreNoch keine Bewertungen

- Carrier VRF PDFDokument12 SeitenCarrier VRF PDFThếSơnNguyễnNoch keine Bewertungen

- Commercial Kitchen GuideDokument32 SeitenCommercial Kitchen GuideDhirendra Singh RathoreNoch keine Bewertungen

- JT Report Interzonal Airflow ModellingDokument61 SeitenJT Report Interzonal Airflow ModellingDhirendra Singh RathoreNoch keine Bewertungen

- F.Pearson 102013 04022015featureDokument5 SeitenF.Pearson 102013 04022015featureDhirendra Singh RathoreNoch keine Bewertungen

- Energy SimulationDokument12 SeitenEnergy SimulationDhirendra Singh RathoreNoch keine Bewertungen

- HVAC Systems & Air Side EconimizersDokument59 SeitenHVAC Systems & Air Side EconimizersDhirendra Singh RathoreNoch keine Bewertungen

- FM ApprovalsDokument167 SeitenFM ApprovalsDhirendra Singh RathoreNoch keine Bewertungen

- Application of Hydronic Radiant & Beam SystemsDokument86 SeitenApplication of Hydronic Radiant & Beam SystemsDhirendra Singh RathoreNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Models - Chem.multicomponent Tubular ReactorDokument23 SeitenModels - Chem.multicomponent Tubular ReactorHectorNoch keine Bewertungen

- 4 Quarter: Technical Drafting 9Dokument18 Seiten4 Quarter: Technical Drafting 9severiano pamplonaNoch keine Bewertungen

- Eurovent ARUM160LTE5Dokument2 SeitenEurovent ARUM160LTE5aandresleo86Noch keine Bewertungen

- Form Monitoring SuhuDokument4 SeitenForm Monitoring SuhuYuliana MaulidaNoch keine Bewertungen

- Microsoft PowerPoint - Flaresim 3Dokument25 SeitenMicrosoft PowerPoint - Flaresim 3ijaz fazilNoch keine Bewertungen

- Engineering Thermodynamics E-Note 04112015 044130AMDokument189 SeitenEngineering Thermodynamics E-Note 04112015 044130AMDipesh Patel100% (3)

- Sheet (2) Reheat Rankine CycleDokument4 SeitenSheet (2) Reheat Rankine CycleHamadaMohassabNoch keine Bewertungen

- Assignment: 1. Role and Purpose of HVAC System in Everyday UseDokument6 SeitenAssignment: 1. Role and Purpose of HVAC System in Everyday UseAswajith K BabuNoch keine Bewertungen

- Hyundai - Parts - Aftermarket - Product List (HASI) PDFDokument6 SeitenHyundai - Parts - Aftermarket - Product List (HASI) PDFSprinter Transit VanNoch keine Bewertungen

- PFD DPCU & GuidelineDokument2 SeitenPFD DPCU & GuidelineTifano Khristiyanto100% (1)

- Energy For The BuildingsDokument75 SeitenEnergy For The Buildingssasikala100% (1)

- Therminol® 55 Heat Transfer Fluid - TDS - Eastman Chemical CompanyDokument3 SeitenTherminol® 55 Heat Transfer Fluid - TDS - Eastman Chemical CompanyDhvanit JoshiNoch keine Bewertungen

- Earth and Life Science: Quarter 1 - Module 3 Earth's Internal Heat MagmatismDokument32 SeitenEarth and Life Science: Quarter 1 - Module 3 Earth's Internal Heat MagmatismChristopher Agustin Tambogon Lpt50% (2)

- Work and Heat Concepts in ThermodynamicsDokument13 SeitenWork and Heat Concepts in ThermodynamicsAkol MajookNoch keine Bewertungen

- Shell and Tube + Double PipeDokument1 SeiteShell and Tube + Double PipeKartik ChopraNoch keine Bewertungen

- Cooling Water Requirement For Molding MachinesDokument5 SeitenCooling Water Requirement For Molding MachinesPinak ProjectsNoch keine Bewertungen

- Es2008 54190Dokument6 SeitenEs2008 54190Selvaraji MuthuNoch keine Bewertungen

- Solutions For Heat Transfer Quiz-II: D. Height of The CylinderDokument2 SeitenSolutions For Heat Transfer Quiz-II: D. Height of The CylindermkvemulaNoch keine Bewertungen

- Boliers and Pressure VesselsDokument33 SeitenBoliers and Pressure VesselsMarcelo Chaves RestrepoNoch keine Bewertungen

- Lennox MS8C-MS8H Mini-Split SystemsDokument4 SeitenLennox MS8C-MS8H Mini-Split SystemsChristian Chalco GonzalesNoch keine Bewertungen

- Compressir Lubrication Theory DanfossDokument7 SeitenCompressir Lubrication Theory DanfossSlavikNZNoch keine Bewertungen

- Heat - Pumps - Up - To - 2000 KW PDFDokument50 SeitenHeat - Pumps - Up - To - 2000 KW PDFsemarasik_651536604Noch keine Bewertungen

- Ducting Measurement Sheet: Blue Star LTD Kalyan SilksDokument7 SeitenDucting Measurement Sheet: Blue Star LTD Kalyan SilksKen AbrahamNoch keine Bewertungen

- HFT - Expansion TankDokument2 SeitenHFT - Expansion Tanknpinzon26Noch keine Bewertungen

- Industrial Waste Heat RecoveryDokument29 SeitenIndustrial Waste Heat RecoveryFebry AhmadNoch keine Bewertungen

- HVAC Turning Vanes ApplicationDokument5 SeitenHVAC Turning Vanes ApplicationQfg Proiect SrlNoch keine Bewertungen

- Odyssey Duct Type R-407CDokument4 SeitenOdyssey Duct Type R-407CThathaNoch keine Bewertungen

- Axaciat Va - Brosura TehnicaDokument6 SeitenAxaciat Va - Brosura TehnicaCatalin BombeaNoch keine Bewertungen

- Glossary of Physics TermsDokument33 SeitenGlossary of Physics TermsDjoanna Joy Carandang100% (1)

- Edtvn042038a Ftka-VDokument100 SeitenEdtvn042038a Ftka-VHang Nguyen Thi KimNoch keine Bewertungen