Beruflich Dokumente

Kultur Dokumente

Unit 2

Hochgeladen von

Mohammed IsmailOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Unit 2

Hochgeladen von

Mohammed IsmailCopyright:

Verfügbare Formate

Unit II Industrial Applications of Laser: 1. Hole drilling 2. Laser welding 3. Laser cutting 4.

. Lidar ( Light detection and ranging) 5. Laser in Isotopic separation 6. Laser tracking Hole Drilling :- A laser pulse having a pulse width of about 1/1000th of a second and an energy of nearly 0.05J can burn through a thick steel plate whose dimensions are 1mm leaving behind a hole of radius 0.1mm. If the drilling is less than 250m in diameter by using bits which are of metal becomes very hard and is accompanied by frequent breakage of drill bits. Lasers are used to drill holes as small as 10m through the hardest of substances. Normally Nd-YAG laser is used to drill in ruby stones. Advantages: - 1. Absence of drill breakage 2. Precise location of holes Laser welding: - it is used in electronics and micro electronics field which require precise welding of very thin wires (i.e. <10m) or welding of two thin films. Laser welding is extremely short time process and can be easily weld two dissimilar metals. Laser welding can be done in regions adjacent to heat-sensitive areas without affecting the elements. Nd-YAG and CO2 lasers are widely used.

Laser cutting: - CO2 laser is very common laser applicable in cutting due to its high O/P power. The efficiency of laser cutting can be increased by including a gas just co-axial with the laser. This method is used to cut materials like stainless steel plate, low carbon steel, Titanium etc Using a CO 2 laser 0.13cm thick stainless steel plate can be cut at the rate of 0.8m/min using an O 2 jet. It is also used to cut up to

50mm depth in wood products, used in textile Industry for cloth cutting.

LIDAR: (Light Detection and Ranging)

It is used for monitoring the environment and to study the visibility. It studies a laser beam scattered through the atmosphere. Pulses of laser lights are sent and the radiation is scattered by various particles present. The background sunlight is eliminated by using filters. The nature of aerosols present in the atmosphere can also be studied using pulsed LIDAR system. It can measure the time dependence of the intensity of the back scattered laser light using a photo detector. The time changed can be easily corrected into the height form the laser has been unscattered. A typical time dependence of the back scattered laser radiation is plotted in fig. which

corresponds to an atmosphere which has no back scattering is by pure molecular gases like Nitrogen (N2), oxygen (O2) and argon(Ar). If the atmosphere contained aerosols the time dependence of back scattered laser radiance will be roughly of the fig. where at joints between h1 and h2 there are aerosols of back scattered laser light. LIDAR is useful to detect small particles which are hard to detect with microwave. Laser in Isotopic separation: - isotopes are atoms having the same atomic number i.e. no. of protons but different number of neutrons i.e. mass number. Lasers are used to determine the electrons surrounding the nucleus as a result separating the isotopes

Laser tracking: - laser tracking is used to measure the time taken to travel to and fro for a sharp laser pulse sent by the observer to be reflected by the object and received back by the observer. Principle is same as that of microwave radar, where an electronic counter is used for starting, sending and collecting the pulses.

Advantages over a microwave radar system: 1. Smaller in size and less cost 2. Retro reflector is cube corner which is placed on surface of the target for reflection 3. Detector is a simple Photo multiplier 4. For tracking a moving object, both the laser and telescope can be moved. Disadvantage: When fog or snow is present in the atmosphere, it is extremely difficult to work at optical frequencies.

Biomedical Applications of Lasers 1. Lasers in diagnosis 2. Lasers in nephelometry 3. detection of cancer 4. Lasers in surgery 5. lasers in phototherapy Lasers in Diagnosis: - it is used to detect a disease, the properties of laser such as coherence, low divergence and spectral purity are used in medical diagnosis Here laser is used to label the diseased parts by by scattering of fluorescence studies. Laser Nephelometry: - Nephelometry is an instrument based on light which is scattered by turbid or cloudy solution providing the quantitative data on proteins associated with immune reactivity. It measures the extent or degree of cloudiness. The light from the laser is He-Ne is made to incident on the

sample, placed in a cuvette and forward scattered light is measured at 512deg. It has been used in Immunology. The pattern distribution of scattered light is interpreted by a computer making it a very fast analyzer. The diagrammatic representation is shown in fig., used to measure the extent or degree of cloudiness.

Detection of cancer: - lasers are applicable in detection of cancer in two ways A) This way depends on a dye called as Hemato Propyline derivative which is injected, gets quickly attached to the cells. The cells which are healthy flush out the dye leaving it concentrated in cancer cells. The dye fluoresces(produces) under UV excitation making it possible to maximize the location of cancer cells B) The second method is the early detection of cancer applicable in the diagnosis of tissue or organ. This technique is known as laser trasillumination (to pan light through a body part for medical examination) of tissues. These images are illuminated by laser light. Lasers used here are He-Ne, He-Cd etc. Advantages:- they do not damage the young cells when exposed as compared to X-rays Laser in surgery: - here the basic mechanism is the vaporization of the living tissue due to heat generated by absorption of the laser radiation. The absorption of the laser radiation is characterized by absorption coefficient. Eg:- a) Surgery where high blood loss is dominant b) Excision of Tumours c) Eye surgery

a) In blood less orthopedic surgery and plastic surgery, liver and kidney surgery, where blood loss is more. CO 2 Laser is used to reduce to minimum blood loss. Blood vessels of dia 0.5mm or less are vaulterized by CO 2 Laser radiation automatically. b) Excision of tumours: - CO 2 is used as a scalpel in which symphatic and vascular channels get automatically sealed unable in case of operation using regular scalpel. c) Eye surgery:- A tear or hole may develop in the retina due to degeneration towards the retinal periphery. This can lead to retinal detachment which causes total blindness.

An Argon(Ar)/Krypton(Kr) ion laser is used to make a number of lesions(burns) around the hole or tear so as to effectively wail off the threatening hole or tear. This problem is serious for diabetic patients.

Holography The technique to produce a hologram is called holography. A hologram is a 3-D image that has been captured and projected on a 2-D surface. The technique can be understood as follows.

Laser light as we know is highly monochromatic. We use two beams of laser light which are coherent and pan through the lens to make them parallel. This light is then made to pan through the glass which reflects half of light thus acting as a beam splitter and splits the beam into two. One beam is directed onto the object while the other reflected one is directed at the photographic film from an angle where the reflected and direct laser light

intersect, interference patterns are created that are recorded on the surface of the film. In order to reconstruct the image the holograph is now illuminated by the original reference beam. This reference beam is now diffracted by the hologram to produce a diffracted light field which is identical to the light field which was scattered by the object. Thus someone looking into the hologram sees the object even though it is no longer present.

Interferometer Michelsons Interferometer: - An interferometer is an instrument in which the phenomenon of interference is used to make precise measurements of wavelength or distance.

Principle:- A beam of light from an extended source is divided into two parts of equal intersection by partial reflection and refraction. These beams travel in two mutually perpendicular directions and come together after reflection

from plane mirrors. The beams overlap on each other and produce interference fringes. Construction: - the schematic of a simple Michelsons interferometer is shown. It consists of a beam splitter G1 a compensating plate G2 and two plane mirrors M! and M2. the beam splitter G1 is a partially silvered plane parallel glass plate having the same thickness as G2. The two plates G1 and G2 are held parallel to each other and are inclined at an angle of 45deg w.r.t. the mirror M2. The mirror is mounted on a carriage and can be mounted exactly parallel to itself with the help of micro meter screw. The distance through which the mirror M1 is moved can be read with the help of a graduated drum attached to the screw. Displacements of the order of 0.1m (1000Angstroms) can be

easily read. The plane mirrors M1 & M2 can be made perfectly perpendicular with the help of the fine screen attached to them. The interference bands are observed in the field of view the telescope T. Working: - monochromatic light from an extended source S is rendered parallel by means of a collimating lens L and is made incident on the beam splitter G1. It is partially reflected at the back surface of G1 along AC and partially transmitted along AB. The beam AC travels normally towards the plane mirror M1 and is reflected back along the same path and comes out along AT. The transmitted beam travels towards the mirror M1 and is reflected along the same path. It is reflected at the back surface of G1 and proceeds along AT. The two beams received along AT are produced from a single source through division of amplitude and are hence coherent.

From fig. it is clear that a light ray starting from the source S and undergoing reflection at the mirror M1 passes through the glass plate G1 three times on the other hand, in the absence of plate G2, the ray reflected at M2 travels through the glass plate G1 only once. For compensating this path difference a compensating plate G2 of the same thickness is inserted into the path AB and is held exactly parallel to G1. If we look into the instrument things T, we see mirror M1 and in addition we see a virtual image M2 of mirror M2. Depending on the positions of the mirrors image M2 may be in front of or behind or exactly consistent with mirror M1. Circular Fringes: - These are produced with monochromatic light when the mirror M1 and M2 are exactly perpendicular to each other. Localized fringes: - when the two mirrors are tilted they are not exactly perpendicular to each other. In this case the air path between them is wedge shaped and the fringe appears to be straight. If one of the mirror is moved the fringe moves around the field. The portion of any particular bright fringe is taken up by the one next to it. The fringe can be counted as they pass a reference mark. If m fringes move across the field of view when M1 moves through a distance d, then

d=m/2 =2d/m White Light Fringes: - Instead of a monochromatic source. If a white light source is used a few coloured fringes with a central dark fringe can be observed. In observing these fringes, the mirrors are slightly tilted as for localized fringes position of M1 is found where it intersects M2. These fringes are useful for the determination of zero path difference. Applications of Michelsons Interferometer. 1 wavelength of a given monochromatic source of light 2 The difference between two neighbouring wavelengths or resolution of the spectral lines 3 Refractive Index and thickness of various thin transparent materials 4 For measurement of standard materials in terms of wavelength of light

Measurement of wavelength: - it is used to determine the wave length of light from a monochromatic source. The monochromatic source is kept at S. If the mirrors are kept exactly perpendicular to each other circular fringes are obtained. If the mirror M1 is moved forward or backward the circular fringes appear or disappear at the centre. Now as the mirror is moved through a distance d and the no. of fringes disappearing at the centre is counted. Suppose d is the initial thickness of the air film between the mirror M1 and the image of M2 corresponding to the bright fringe of order mn in the same position then we have 2d1=m1 2d2=mn By subtracting we get 2(d2 - d1)=( mn - m1)

2d=N =2d/N 2. Determination of the difference in the wavelength of the two waves If a source of light consists of two wavelengths 1 and 2 which differ slightly then the two set of fringes corresponding to the wavelength are produced in michelsons Interferometer. By adjusting the position the mirror M1 of the interferometer the position is found when the fringes are very bright In this position the bright fringe due to 1 coincides with the bright fringe due to 2 when the mirror M1 is moved the two set of fringes get out of step because their wavelengths are different. When the mirror M1 has been moved through a certain distance the bright fringe due to one set will coincide with the dark fringe due to other set or no fringe will be seen in this case. Again by moving the mirror M1 a position is reached when a bright fringe of one set falls on the bright fringe of the other and the fringes are again distinct. This is possible when the m th order of the longer wavelength coincides with the (m+1)th order of the shorter wavelength. Let m1 and m2 be the changes in the order at the centre of the field when the mirror is displaced through a distance d between two consecutive positions of max distinction of the fringes. 2d= m11= m22 If 1 is greater than 2 m2= m1+1 2d= m11= (m1+1) 2 m1= 2/ 1- 2 2d= 12/ 1- 2 1- 2= 12/2d

Taking as the mean wavelength of 1 and 2 the small difference D is given by D= 1- 2= 2/2d: -

Thickness of a thin transparent slit: Let a transparent slit of thickness t and refractive index be inserted in the path of one of the interfering beams of Michelsons Interferometer. The

optical path of that beam increases because of the slit. It becomes t instead of t. The increase in the optical path is (t- t) or (-1)t. since the beam transverses the medium the extra path difference between the two interfering beams is 2(-1)t. If m is the number of fringes by which the fringes is displaced then

2(-1)t=m t= m /2(-1) Determination of refractive Index of gases When a tube containing a gas is introduced in the path of the beam going towards M1, a path difference equal to 2(-1)l is introduced between the two interfering beams. Here is refractive Index of the gas and l is length of tube. If m fringes are at the centre of the field of view. The path difference introduced between the two interfering beams is 2(-1)l 2(-1)l=m =m /2l + 1 Problem: In a Michelsons interferometer 200 fringes are in the field of view when the movable mirror is moved through 0.0589mm. Calculate the wavelength of light used??? Ans) =2d/m = 2 X 0.058 X 10-3 / 200 = 5890 Angstroms Laser strain gauge: Laser strain gauges can be defined as those which are fundamentally based on some form of interferometry i.e; mutual interference and where speckles pattern is used. Operation: When a laser beam is scattered of a rough surface and by mutual interference of random waves a speckles pattern is created. The speckles pattern carry information about the specimens surface. A captured image is taken by the CCD. When the surface area undergoes movement or deformation, the speckles pattern in the image can also move or deform accordingly. Thus the displacement or deformation information of object surface can be extracted by measuring the speckles pattern movement. A cross-correlation between the speckled pattern for test specimen in reference state and stressed state gives information on strain undergone

by test specimen so that by analyzing the position of cross-correlation speckles calculated with image taken before and after deformation. Mathematically, strain can be measured using m =ax /2 L0 tan(0) Where; m=strain ax=difference of speckles displacement 0=observation angle Lo=observation distance (b/w speckles &camera)

Advantages & Application: The main advantage of this strain gauge is that the strain mapped is of non-contact type. It is useful for measuring strain on rotatory blades of jet engine.

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Bactericidal Activity of Silver Nanoparticles - A Mechanistic ReviewDokument14 SeitenBactericidal Activity of Silver Nanoparticles - A Mechanistic ReviewCristianNoch keine Bewertungen

- Lab Manual 02Dokument158 SeitenLab Manual 02Stephen VivekNoch keine Bewertungen

- Lignocellulosic Biomass A Sustainable Platform For Production of Bio-Based - Isikgor2015 PDFDokument62 SeitenLignocellulosic Biomass A Sustainable Platform For Production of Bio-Based - Isikgor2015 PDFNatasha Mgt JoharNoch keine Bewertungen

- Chemical Content of FertilizersDokument22 SeitenChemical Content of FertilizersJohn DAcquisto, D.Sc.100% (1)

- Shell Gadus s1 Og 200 PDFDokument1 SeiteShell Gadus s1 Og 200 PDFMiskaDarainiNoch keine Bewertungen

- Diffusiophoresis Migration of Colloidal Particles in Gradients of Solute ConcentrationDokument38 SeitenDiffusiophoresis Migration of Colloidal Particles in Gradients of Solute ConcentrationPrateek DwivediNoch keine Bewertungen

- Material Safety Data Sheet - Calcium CarbideDokument11 SeitenMaterial Safety Data Sheet - Calcium Carbidegodfrey kiyinjaNoch keine Bewertungen

- EmileorConcerningEducation 10106815Dokument165 SeitenEmileorConcerningEducation 10106815Túlio Coelho SampaioNoch keine Bewertungen

- Chemistry Fun FactsDokument2 SeitenChemistry Fun FactsBabitha MonteiroNoch keine Bewertungen

- Stabilityindicating HPTLC Method For Simultaneous Estimation of Amoxicillin Trihydrate and Ambroxol Hydrochloride in Bulk and Pharmaceutical Dosage Form 2153 2435-4-261Dokument5 SeitenStabilityindicating HPTLC Method For Simultaneous Estimation of Amoxicillin Trihydrate and Ambroxol Hydrochloride in Bulk and Pharmaceutical Dosage Form 2153 2435-4-261Fadhil Muhammad AwaluddinNoch keine Bewertungen

- C100E Resin PUROLITEDokument3 SeitenC100E Resin PUROLITEmilaNoch keine Bewertungen

- PS1Dokument4 SeitenPS1cptudorNoch keine Bewertungen

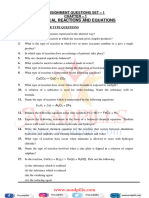

- Chemical Reactions and Equations Assignment Questions Set - 1Dokument6 SeitenChemical Reactions and Equations Assignment Questions Set - 1kayace8055Noch keine Bewertungen

- D-113 Ductility of BitumenDokument2 SeitenD-113 Ductility of BitumenHisham khanNoch keine Bewertungen

- Gasha International School Homework PolicyDokument12 SeitenGasha International School Homework PolicyOmar KhidhirNoch keine Bewertungen

- L9 Fastening System PDFDokument6 SeitenL9 Fastening System PDFMarcel BaqueNoch keine Bewertungen

- Hasil Uji Emisi Incenerator.2Dokument2 SeitenHasil Uji Emisi Incenerator.2UrlialyNoch keine Bewertungen

- Synthesis of 2 - (2,4-Diaminothiazol-5-Oyl) BenzothiazolesDokument4 SeitenSynthesis of 2 - (2,4-Diaminothiazol-5-Oyl) BenzothiazolesABBS FEN REJI T. F.Noch keine Bewertungen

- MSDS Songnox - 1680Dokument8 SeitenMSDS Songnox - 1680Seshagiri KalyanasundaramNoch keine Bewertungen

- Fire Resistant 08Dokument36 SeitenFire Resistant 08mehdi227Noch keine Bewertungen

- Interlab g26 User's Manual 1.2Dokument61 SeitenInterlab g26 User's Manual 1.2Ali AminiNoch keine Bewertungen

- ChemicalsDokument72 SeitenChemicalsMrudulaNoch keine Bewertungen

- Introduction To Chemistry 4th Edition Bauer Birk Marks Test BankDokument52 SeitenIntroduction To Chemistry 4th Edition Bauer Birk Marks Test Bankcasey100% (21)

- Essential Variables API 1104Dokument4 SeitenEssential Variables API 1104Madidj_2014Noch keine Bewertungen

- Iso 9606 4 1999Dokument11 SeitenIso 9606 4 1999Lino Alves InácioNoch keine Bewertungen

- Solef Hylar PVDFDokument60 SeitenSolef Hylar PVDFribeiro30Noch keine Bewertungen

- Pyro FormulasDokument121 SeitenPyro FormulasMichael Beasley100% (4)

- F748669CT Process TechnologyDokument6 SeitenF748669CT Process Technologyতুহিন ভট্টাচার্য্যNoch keine Bewertungen

- Year 9 Study Guide ChemistryDokument15 SeitenYear 9 Study Guide Chemistryreem halawiNoch keine Bewertungen

- Ionic and Covalent BondsDokument5 SeitenIonic and Covalent Bondsapi-233981890Noch keine Bewertungen