Beruflich Dokumente

Kultur Dokumente

Chapter 13

Hochgeladen von

Bimbit PattanaikCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Chapter 13

Hochgeladen von

Bimbit PattanaikCopyright:

Verfügbare Formate

CHAPTER -13

Operation & Maintenance Instruction for Rotary Equipment

1.0 Introduction This manual addresses those specific areas relative to the proper operation and maintenance of Tekno-Kom Rotary equipment.

NOTE

All Commercial Purchased Vendor Equipment Instruction Sheet and Manuals for specific components such as speed reducers shall be referred to used in conjunction with this document.

2.0

General Maintenance Schedule. The following is a suggested General Maintenance Schedule for Tekno-Kom rotary equipment. Depending upon the specific equipment characteristics and service, the general maintenance schedule may require customer modification.

NOTE

A regular General Maintenance Schedule is both critical to personnel safety and the expected life cycle of the equipment.

2.1 Daily Maintenance Tasks 1. Conduct a walk-by inspection of the unit. Are there any noticeable differences since the last inspection? Is there any discoloration or hot spots evident on the shell? Listen for any unusual sounds. 2. Check condition of discharge and feed end seals. Is there any leakage of excess air or product? What is the condition of the seal?

Operation & Maintenance Instructions for Rotary Equipment

3. Check condition of each pier top. Do tires and rollers have full-face contact? Is there any movement between the pier top and support frame? Are there any loose anchor bolts on the support frame?

4. Check the condition of the tire on each pier. Is there any spalling or ridging on the tire face? Has the tire developed a wobble? Since the last inspection, has the tire position changed relative to the stop blocks or wedges? Are there any broken welds on the wedges, retaining bands, or between the tires and filler bars? Is the tire centered over the carrying roller?

5. Check the condition of the carrying rollers on each pier. Are the rollers thrusting uphill or downhill? Is there spalling or ridging on the roller face? Is oil leaking from the roller housing? Does the surface of the bearing housing feel unusually warm? Do the bearing have adequate lubrication? 6. Check the condition of the thrust rollers. Is the unit against the uphill or downhill thrust roller? Is there spalling or ridging on the roller surface? 7. Check the condition of the drive system. Has the pattern of gear/sprocket contact changes? Are there any loose or missing flange bolts or gear mounting lugs? Is the automatic gear/sprocket lubrication system functioning properly? Is there adequate gear lubrication? Are their any unusual sounds coming from the drive system? Is there any new noticeable vibration?

2.2 Weekly Maintenance Tasks 1. Check creep or gap of tires on all piers. Has level of creep increased since the last inspection?

2

Operating & Maintenance Instruction for Rotary Equipment

2. Check the condition of the rollers at each pier. Are the rollers thrusting uphill or downhill?

3. Clean the pier tops of dirt, oil or product spillage.

2.3 Monthly Maintenance Tasks 1. 2. 3. 4. Check for pitch line separation of gear and pinion. Check for pitch line run-out of gear and pinion. Check condition of welds on gear flange or mounting lugs. Check for excessive ring and roller wear.

2.4 Semi-Annual Maintenance Tasks a) General 1. Inspect drive-coupling members. Refer to manufactures instructions. 2. Inspect shell for cracks under rings. 3. Check the alignment of the unit. Refer to Tekno-Kom, Installation Instruction For Rotary Equipment. b) Chain Drives 1. Check radial alignment of drive chain and driver sprocket adjust as required. 2. Check chain lubricant and clean area if needed. c) Gear Drives 1. Change gear lubricant and clean gear area if needed. 2. Change grease on pinion shaft and support roller bearings. 3. Check radial alignment of gear and pinion. 2.5 Annual Maintenance Tasks a) General 1. Check the alignment of the unit. Refer to Tekno-Kom, Installation Instruction For Rotary Equipment. 2. Weld repair cracks in shell, wedges ( Tire support blocks) and support bands. 3. Check drive train coupling for wear and replace if needed. Refer to manufactures instruction. 4. Check drive motor. Refer to manufactures instructions. 5. Flush gearbox (speed reducer) Oil and replace. Refer to manufactures instructions. 6. Clean and inspect all bearings. Refer to bearing manufactures instructions.

3

Operating & Maintenance Instruction for Rotary Equipment

b) Chain Drives 1. Check radial alignment and wear of drive chain and driver sprocket. Adjust alignment or replace as required. Refer to Tekno-Kom installation manual for chain replacement. 2. Check chain lubricant and clean area if needed. 3. Check for loose nuts or bolts on the chain mounting sprocket and pedestals. c) Gear Drives 1. 2. 3. 4. 5. 6. 7. 8. Change gear lubricant and clean sump and gear area if needed. Change grease on pinion shaft and support roller bearings. Check radial alignment of gear and pinion. Clean and inspect gear. Check gear teeth for abnormal wear. Check and repair welds on gear flange or mounting lugs and gear if needed. Check for loose nuts or bolts on gear mounting flange. Inspect, clean, repack and change lubrication on pinion bearings. Refer to bearing manufactures instructions.

Operating & Maintenance Instruction for Rotary Equipment

3.0 Lubrication The following lubrication instructions although based on operational experience may very depending upon special site conditions.

NOTE

3.1 Lubrication Chart Lubrication Chart Recommended Lubricant Service Frequency Mobilgear SHC-150 New Reducers-after intial 250 Temp - 30 F to +250 F. Or Equivalent Operation hours; therefore, every 6months top-up. EXXON RONEX MP or Based on 12 hours as per Day Equivalent every 3 months. Temp- 20F (-29C) to + 325F (+163C) General Brush Every 40 hours for 8 hours Application: Refer to 3.0 Daily operation (General) Table 1. SAE 20 OR 30 as applicable Refer to paragraph 3.2.6 Specific Auto Lubricators: Refer to 3.0 Table 1. SAE 20 OR 30 as applicable

Component Speed Reducers

Thrust & Trunnion Bearings

Trunnion & Tire ( Riding Ring) Conact Surface

Operating & Maintenance Instruction for Rotary Equipment

Table 1. Recommended Oil Viscosities for Various Temperatures

Recommended Grade

SAE 10 SAE 20 SAE 30 SAE 40 SAE 50

Temperature, F

-20 to + 80 +10 to +110 +20 to + 130 +30 to +140 +40 to + 150

Temperature, C

-29 to + 27 -12 to +43 -7 to + 54 -1 to + 60 +4 to + 66

Note : When the temperature range permits a choice, the heavier grade should be used.

3.2.1 Needed for Lubrication Chain lubrication is needed mainly to slow the wear between the pins and bushings in the chain joint, to flush out wear debris and foreign materials, and to smooth the chains engagement with the sprocket. Additionally, lubrication may be needed to inhibit rust and corrosion, to carry away heat, and to cushion impact forces. 3.2.2 Chain Lubricants A chain lubricant should have low enough viscosity to penetrate into critical internal surfaces and high enough viscosity, or necessary additives, to maintain an effective film at the prevailing temperature and pressure. Recommended viscosity for various surrounding temperature ranges are shown in Table 1. The lubricant should have the capability to maintain the desired lubricating qualities under prevailing operating conditions, and be clean and free of corrodents. A good grade of non-detergent petroleum base oil usually is acceptable. While detergents are not normally needed, antifoaming, anti-oxidizing and extreme pressure additives are often helpful. Impure oils should be avoided. Acids or abrasives in the oil can permanently damage the chain. The chain manufacturer often uses grease or petroleum jelly as an initial lubricant. However, users generally should not apply greases to chains in service because they are too thick to penetrate into the internal bearing surfaces of the chain. Users should use grease only when fittings for injecting the grease into the chain joints are provided.

Operating & Maintenance Instruction for Rotary Equipment

3.2.3 Lubrication of Chain Drives The recommended method of lubrication for chain drives is indicated in the power rating tables published in ASME B29 Series Standards and in various manufactures catalogs. The methods normally listed are manual, drip, and oil bath. In all methods, the oil,should be applied to the upper edges of the link plate or sidebar in the lower span of the chain. This enables gravity and centrifugal foce to carry the lubricant into the critical bearing areas. 3.2.4 Manual Lubrication In manual lubrication, the user applies oil periodically with a brush or spout can. The preferred frequency is once every eight hours, but a longer interval may be used if experience shows it is adequate for that particular drive. The amount of oil and the frequency of its application must be adequate to prevent the formation of a reddish brown discoloration in the chain joints. That discoloration indicated that red iron oxide (rust, hematite, etc.) is being generated in the chain joints because they are not receiving sufficient lubrication. 3.2.5 Drip Lubrication In drip lubrication, oil is dripped between the link plate or sidebar edges at a rate from four to 20 drops per minute, depending on speed. Again, the amount of oil and the frequency of its application must be adequate to prevent the formation of a reddish brown discoloration in the chain joints. In drip lubrication of multiple strand chains, a wick-packed distribution pipe may be used to uniformly distribute oil to all rows of link plates or sidebars. 3.2.6 Oil Bath Lubrication In oil bath lubrication, a short section of the chain runs through the oil in the bottom of the chain casing. The oil level should extend only to the pitch-line of the chain at its lowest operating point. Having long sections of chain run through the oil bath can cause oil forming and overheating. 3.3 Gear Drive Lubrication As recommended by your lubrication supplier, contact for details

Operating & Maintenance Instruction for Rotary Equipment

4.0 4.1 Troubleshooting General

Type of Failure

Thrust Wear Roll-

Probable Cause

Corrective Action

tracking Align Shell See Installation Manual. Recondition or replace Thrust Roll. tracking Align Shell See Installation Manual. Replace bearing. Align Shell See Installation Manual. Resuface Trunnion/Tire Surface (Contractor) Replace Bearings or Rebuild Trunnion Roll.

Premature Improper shell (alignment)

Thrust RollBearing Failure

Premature Improper shell (alignment)

Trunnion Roll/ Tire Premature Wear Shell will not Track Properly after Alignment

Improper Shell tracking (alignment) Worn Trunnion Roll/Tire Surface No Flat/Flush Trunnion Bearings Worn

4.2

Chain Drives

4.2.1 Chain Failure The three most common ways that a chain may fail are tensile, fatigue and wear. In a tensile failure, the chain is overloaded in tension until it is stretched so badly it will not function properly, or it is literally pulled apart. In a fatigue failure, the chain is loaded repeatedly in tension, at a load below the yield strength (the chain is not stretched), until microscopic cracks develop in the link plates or sidebars. These cracks continue to grow until the chain breaks. In a wear failure, material is removed by sliding, or sliding combined with abrasion or corrosion, until the chain will not function properly (will not fit the sprockets) or the remaining material is so thin that it lets the chain break. 4.2.2 Chain Wear Most often, wear between the pin and bushing causes the chain to elongate (grow longer but not stretch) until the chain will not fit the sprockets correctly or will not maintain correct spacing or timing. Sometimes wear between the roller and bushing or wear between the link plates or sidebars and guides causes the chain to malfunction. Chain wear elongation usually progresses through three stages as shown in Figure 2. First, there is a short period of rapid initial, or run-in wear. In this first stage, high spots are worn off the pins and bushings and minor misalignments are quickly worn away. Second, there is a period of constant slow, or lubricated wear. In this second stage, the pins are seated properly in the bushings and the bearing areas

8

Operating & Maintenance Instruction for Rotary Equipment

are normally well lubricated. And finally, there is another period of rapid, or terminal wear. In this final stage, lubrication may have become ineffective or failed completely, or the hard case on pins and bushings may have worn through, or chain elongation on the sprocket may have caused loads on individual joints to increase dramatically. 4.2.3 Chain Troubleshooting Table Type Maintenance Inspect for Wear and Alignment What To Do Initial inspection 24 hours, second 100 hours, third 500 hours. Once a year thereafter. Check sprocket contact pattern for even wear. Corrective Action Check environmental abrasiveness, provide cover as needed Check for proper lubrication. Check Alignment and adjust as required. Check cylinder tracking. Misaligned drive. Worn chain or sprockets, replace as necessary. Eliminate overload or shock load condition. Provide adequate cover for environmental material surrounding drive.

Troubleshooting Excessive Chain or Sprocket Wear

Excessive Drives Noise

Chain Breakage

Operating & Maintenance Instruction for Rotary Equipment

4.3 Gear Drives Type Maintenance Inspect for wear and Alignment What To Do Initial inspection 24 hours, second 100 hours, third 500 hours. Once a year thereafter. Check tooth contact pattern for full-face contact Corrective Action Check environmental abrasiveness, provide cover as necessary. Misaligned drive. Worn gears, replace as necessary. Eliminate overload or shock load conditions. Provide adequate cover for environmental material surrounding drive. Remove overload condition.

Troubleshooting Excessive Gear Wear

Gear Breakage

Disfiguration of Gear Tooth 5.0 Trunnion Roll Rebuilding Instructions. 1) Introduction

The following instructions are for the purpose of providing basic guidelines for the rebuilding of the trunnion rolls. For those special conditions or questionable clarify of the instructions. Engineering department should be consulted. 2) Required Parts and Tools The following parts and tools are required for re-building the trunnion roll: Box wrenches 2 Shim sets 2 roller bearing sets Bearing grease ( refer to instruction sheets with bearings)

3) Disassembly Jack-up the drum Inspect the trunnion roll face for galling or irregular flatness. It is recommended if these conditions are observed that the trunnion roll be refaced. Clean out any debris from the trunnion roll and cast hubs. Inspect for noticeable wear that may inhibit normal operation.

10

Operating & Maintenance Instruction for Rotary Equipment

4) Reassemble Pack the Pedestal and cup bearings with grease and install. The following instructions are trial and error: o Match the new shims against the old shims that were removed and install the new shims as a starting point. o Bolt on the Pedestals and torque the bolts down in a systematic diagonal manner. o Try to rotate the trunnion roll by hand. The trunnion roll should rotate with minor resistance.

5.0

Thrust Roll Rebuilding Instructions for Rotary Equipment 1) Introduction The following instructions are for the purpose of providing basic guidelines for the rebuilding of the Tekno-Kom Engineers internal bearing thrust rolls. For those special conditions or questionable clarify of the instructions Tekno-Kom Engineers engineering department should be consulted. 2) Required Parts and Tools The following parts and tools are required for re-building the trunnion roll: Box wrenches 2 shim sets 2 roller bearing sets Bearing grease (refer to instruction sheets with bearings) 3) Disassebly Study the general bearing diagram included with these instructions: Un-bolt the cast hubs on both sides of the thrust roll. Remove the retaining ring, flinger, collar, bearing sets and shims. Save the shims for later reference. Inspect the condition of the retaining ring, flinger and collar. Replace these items excessive wear is observed. Inspect the thrust roll face for galling or irregular flatness. It is recommended if these conditions are observed that the thrust roll be refaced. Clean out any debris from inside the thrust roll and cast hubs. Inspect for noticeable wear that may inhibit normal operation.

11

Operating & Maintenance Instruction for Rotary Equipment

4) Reassemble Pack the cone and cup bearings with grease and install. Reassemble the retainer, flinger and collar. The following instructions are trial and error: o Match the new shims against the old shims that were removed and install the new shims as a starting point. o Bolt on the cast hubs and torque the bolts down in a systematic diagonal manner. o Try to rotate the trunnion roll by hand. The trunnion roll should rotate with some resistance. If the trunnion roll rotates freely disassemble and add shims as required. If the trunnion roll is difficult to turn or is locked disassemble and remove shims as required.

12

ANNUAL CHECK LIST ROTARY DRUM

Ok? ITEM TO CHECK

Check the slope of the drum. Make sure that is according to the specifications. Make sure that the trunnions are square and parallel to each other. Check the trunnion jacking bolts. Make sure that none are missing or loose. Check the trunnion jacking bolt lock nuts. Make sure that none are missing. Check the thrust roller jacking bolts. Make sure that none are missing or loose. Check the thrust rollers jacking bolt lock nuts. Make sure that none are missing. Before rotating the drum for the first time, check each trunnion. Make sure that there are no gaps between the trunnion rolls and the Tires. Check the drum seal rings on the feed end. Make sure that there is clearance around the entire circumference. Check the drum seal ring bolts on the discharge end. Make sure that none are missing or loose. Check the gap between each thrust roller and the tire. Make sure there is approximately 3/8 gap on each side of the tire when the tire is centered on the trunnion rolls. Check the drive base jacking bolts. Make sure that none are missing or loose. Check the drive base jacking bolt lock nuts. Make sure that none are missing or loose. Check the motor mounting bolts. Make sure that none are missing or loose. Check the reducer mounting bolts. Make sure that none are missing or loose. Make sure the gear reducer has the correct lubricant and filled to the correct level. Check the alignment of the coupling between the motor and reducer. Check all coupling bolts and set screws. Make sure that none are missing or loose. Where applicable, make sure that fluid coupling has the correct lubricant and filled to the correct level. Check the alignment and slopes of the driver and girth sprockets

13

COMMENTS

OK

ITEM TO CHECK Make sure that the coupling guard is in place. Make sure that the driver sprocket setscrews are tight. Check the key steel that holds the driver sprocket to the reducer output shaft. Make sure it is not missing or loose. Check the tension and condition of the drive chain Chain the pedestal to drum mounting bolts. Make sure that none are missing or loose. Check the sprocket to pedestal mounting bolts. Make sure that none are missing or loose. Check the feed breeching assembly bolts. Make sure that none are missing or loose. Check the feed breeching anchor bolts. Make sure that none are missing or loose. Check the discharge breeching anchor bolts. Make sure that none are missing or loose. Check the discharge breeching assembly bolts. Make sure that none are missing or loose. Make sure the drum is cleaned of all debris Make sure the feed breeching is cleaned of all debris. Make sure the discharge breeching is cleaned of all debris. Make sure the Trunnions are flushed with grease. Make sure the Thrust Rollers are flushed with grease. Where applicable make sure that the oil drip pans are in place. Check the chain guards. Make sure that they are installed and will clear the chain and pedestals across the entire range of the trunnion roll. While the drum is rotating, make sure the trunnions and tires are well lubricated before adjusting the position of the drum rotating empty. While the drum is rotating, make sure the drive chain is well lubricated before adjusting the chain tension and position of the drum rotating empty. Check the rpms of the drum. While the drum is rotating, adjust the position of the drum running empty. Check the trunnion guards. Make sure that they are installed and will clear the tire across the entire range of the trunnion roll. Check all lubrication cups. Make sure that they are all installed and that none of the mounting bolts are missing or loose.

COMMENTS

14

Ok?

ITEM TO CHECK Check all lubrication cups. Make sure that they are all filled with lubricant. Check all lubrication cup assemblies. Make sure that all of the brushes are set to the correct position. Check all lubrication cups. Make sure that all of the drip rates are set correctly. Record full amp rating on the motor nameplate. Check the condition of the motor wiring connections in the junction box mounted on the motor. Check for the correct rotation of the motor. Check the motor amperage with the drum running empty, without fertilizer. Check the motor amperage with the drum running loaded, with fertilizer. While the drum is rotating, adjust the position of the drum running loaded. Check all trunnion jacking bolt lock nuts. Make sure that they are all tight. Check all thrust roller jacking bolt lock nuts. Make sure that they are all tight. Check all drive base jacking bolt lock nuts. Make sure that they are all tight.

COMMENTS

Note:

Under all circumstances, the following safety precautions must be strictly adhered to. All units must be de-energized and the motor starter for the unit must be turned off and tagged (use of the starter lockout is under the control of the maintenance personnel performing the work) WARNING, DO NOT PUT HAND INSIDE OR NEAR THE UNIT OR MOVING PARTS WHILE THE UNIT IS RUNNING. DO NOT ROTATE THE SHEAVES BY TURNING THE BELTS BY HAND.

15

INSTALLATION INSTRUCTIONS FOR ROTARY EQUIPMENT

Prepared by: Tekno-Kom Engineers F-II Block, Plot No. 19/4, MIDC, Pimrpi, Pune 411 019 Phone : 020- 27468779,

16

Installation Instructions for Rotary Equipment Manual Revision Log Date Rev. No. Page (s) Description of Revisions Number Approved By

2012

All

New Issue

S.V. Doshi

17

Installation instructions for Rotary Equipment

1. 0 this section addresses those specific areas relative to Rotary Equipment. The following installation instructions are to be used in conjunction with the appropriate general subject matter sections as identified in the Table of Contencts. Unloading & Lifting Instructions. The drawings in Addendum A shows the proper lifting points for truck unloading and lifting for installation. Rubber Sheet is provided between the trunnion Rolland the riding tire when the shell assembly is shipped setting on the trunnion roll bases. REMOVE THE RUBBER SHEET PRIOR TO START-UP. Failure to so will damage the equipment.

2.0

WARNIING

3.0

The following is a systematic approach to the proper erection of the subject equipment. Individual job site conditions or unique construction crew constraints may warrant deviation from the following procedure. In such an event, Both. Common Sense & Rules of Good Practice must be applied. The Tekno-Kom Engineers field representative should be consulted in any questionable matter requiring clarity. The Tekno-Kom Engineers Equipment tagging, Handling & Installation General manual shall be considered inclusive with this manual.

NOTE

Step #1 Check Foundation Elevation. Prior to installation the dryer base, check to see that the top of the concrete or the top of the support steel is correct per the design.

NOTE

It is imperative that the top of the foundation is within plus or minus 1/8. Excessive Deviation will inhibit the ability to properly level the rotary equipment at the required elevation.

18

Installation instructions for Rotary Equipment

Step #2 Check Dryer Anchors for Rotary Equipment a) When supported on Concrete Foundation: When supported on concrete foundations, it is recommended anchor bolts and pipe sleeves, in conjunction with a minimum of 1 inch thick of grout be employed. The anchor bolt should protrude a minimum of 3 inches above the concrete pier. For purpose of leveling, two heavy-duty hex nuts will be used on each anchor bolt. One nut is to be beneath the trunnion base for jacking purposes, and the other hex nut is to be used above trunnion base to snug down and lock the dryer frame into the set position. Refer to illustration, Dryer Installation Arrangement

NOTE

The threads of the anchor bolts should be clean and greased for leveling purposes.

19

Installation instructions for Rotary Equipment

Run one nut down on each anchor bolt with a flat washer loose on top of it. The flat washer should be positioned approximately 1 inch above the top of the concrete. Generally, six heavy hex nuts and washers will be required per trunnion base. b) When supported on a Steel Foundation: When supported on a steel foundation, it is recommended threaded studs be welded to the steel in conjunction with base support shims be employed. The threaded studs should protrude a minimum of 3 inches above the steel support deck. For purposes of leveling, two heave-duty hex nuts will be used on each anchor bolt. One nut is to be beneath the trunnion base for jacking purposes, and the other hex nut is to be used above the trunnion base to snug down and lock the dryer frame into the set position. Refer to illustration, Dryer Installation Arrangement, for reference for steel support foundations. The threads of the anchor bolts should be clean and greased for leveling purposes.

NOTE

Step #3 Position Trunnion Assembly. Position the trunnion assembly on the foundation. Place a straight edge across the top of the trunnion rollers, then place a bubble level on top of the straight edge. The level should be positioned at the center point of the distance between the rollers. Step #4 Horizontal Leveling. Having observed the position of the bubble, use the jacking nuts or shims to raise the lower end of the trunnion assembly. This should be performed in a systematic procedure. First, starting with the farthest corner on the low side. Then, repeat the same procedure to the far side of the trunnion assembly. Finger-tighten the jack nuts (or shim) at the center of the trunnion base until they are snug against the base.

20

Installation instructions for Rotary Equipment Observe the bubble in the level. Repeat the above procedure as frequently as necessary until the bubble in the level appears to be approaching the center marks. Step #5 Setting the Dryer Pitch. The required dryer pitch, or fall per foot, is shown on the field assembly drawing. Span the trunnion rollers with straight edges of equal size, such as a pair of nominal 2-1/2 x angles about 5-1/2 feet long. Cross the angles perpendicularly with a four-foot level that has a bubble indicator. This level should be extended in the direction of illustration, Trunnion Assembly Pitch Trunnion Assembly Pitch

21

Installation Instructions for Rotary Equipment

Provide a level surface about four feet from the high edge of the Trunnion towards the low side. This area should be the width of the trunnion rollers. A temporary batter-board may be set up for this task. As an alternative, s straight piece of 1 x 4 or 1 x 6 lumber held plumb on a level surface will suffice. Assuring a desired fall of inch per foot, four feet would result in a 1 inch fall. Hold the level down on the straight edge (or angle), on the high side of the trunnion roller, while moving the opposite end to the true level position. Mark the upright board (or batterboard). Measure down from this mark 1 inch. Let the level lie down across and bear on each of the two angles for straight edges. Mark the low-end position on he batter-board. Using the jack nut on the low side, while holding the level firmly in place, the lower side of the trunnion assembly can be raised or lowered until the 1-inch mark is reached. At this point, the base should be level lengthwise and titled to the right. Step #6 Securing the Trunnion Base a) When Supported on Concrete Foundation: Put the washers and top-heavy hex nuts on all anchor bolts and snugdown. Check leveling again and compensate if necessary, for deviations created by securing the nuts. When the trunnion base is securely down to a concrete foundation suitable non-shrinking grout should be poured between the trunnion base and the concrete foundation.

NOTE

Make sure the trunnion bases are set to the drum pitch that is called out on the erection drawing

Refer to Illustration, Dryer Installation Arrangement.

22

Installation Instructions for Rotary Equipment

b) When Supported on a Steel Foundation: Put the washers and top-heavy hex nuts on all threaded studs and snug down. Check leveling again and compensate if necessary, for deviations created by securing the nutes. When the trunnion base is securely bolted down to a steel support foundation steel shim stock should be placed between the trunnion base and the steel support foundation.

NOTE

Make sure the trunnion bases are set to the drum pitch that is called out on the erection drawing

Weld the bottom of the support base to the shim stock, then weld where practical the bottom of te support base and shim stock to the top of the steel support foundation.

Refer to Illustration, Dryer Installation Arrangement, for reference for the support on a steel foundation.

Step #7 Cylinder Installation. Lower the cylinder carefully into place. The thrust rolls should position the tire (riding ring) into the centroid of the trunnion rollers, on the thrust roll end of the cylinder. The opposite tire edge should be flush with the trunnion roller edge nearest to the thrust assembly. The thrust rolls are then set to allow for -inch drift of the cylinder. If the tire is seated on the center of the trunnion, move each thrust roller away from the side of the tire, approximately 1/8 inch.

Step #8 Check Tire to Trunnion Contact. Using light between the trunnions and under the tire, inspect for full-face contact between the tire and the trunnion. Use the jacking nuts carefully to eliminate any light seen due to the tire not being flush against the trunnion surface. Check all four trunnions for full contact.

23

Installation Instructions for Rotary Equipment

Step #9 Installing the Chain Drive

Bolt on the saddles that support the sprocket segments torque the bolts tight based on the size and grade furnished. Refer to Tekno-Kom installation instructions General, for bolt identification markings and torque values.

Three sets of shims are usually included with the sprocket assembly; a shim, 1/8 shim and a 1/16 shim. Put the shim on first, then the 1/8 shim and the 1/16 shim to the top, between the saddle and the sprocket. This provided the desired circumference of the completed sprocket to suit the pitch of the sprocket chain. It may be necessary to remove the top, or 1/16 shim, after a trial run in order for the chain to seat properly between segment teeth.

Align the motor drive base on its pad on the same plane as the cylinder Use the jack nuts on the anchor bolts to adjust to the proper pitch. When grouted (or shimmed), align the motor and reducer squarely with the cylinder. Align the drive sprocket with the cylinder sprocket and secure.

Install the chain and leave some slack in the chain at the bottom. Use the adjustable motor base for setting the chain tension. The chain should be taught on the top of the driver sprocket with some slack on the bottom of the driver sprocket.

NOTE

After completion of the following steps, recheck the chain alignment and slack and adjust as necessary.

Step #10 Install The Feed & Discharge Breechings Position the feed and discharge breeching. Inspect the clearance between the shell outside diameter and where the shell enters the breeching. There should be uniform clearance around the shell outside diameter with in 3/8. Shim the breeching support base if required.

24

Installation Instructions for Rotary Equipment

Step #11 Check Lubrication

CAUTION

Gearboxes are normally shipped DRY. Oil must be added prior to operation. Failur to do so may result in equipment damage and/or personal injury.

NOTE

Trunnion rolls and thrust roller bearings are normally shipped packed with grease.

a) Clean Atmosphere. Chains operating in a relatively clean atmosphere can be lubricated by brush or drip feed oilers, or by applying the lubricant manually with a brush or oilcan. b) Atmosphere Laden with Lint or Non-Abrasive Dust. Where large volumes of lint or non-abrasive dust are present, a brush or wiper can be used to clean the chain and apply new lubricant. Otherwise, the lint or dust will clog the chain joint clearances and prevent penetration of the oil into the joints. c) Abrasive Atmosphere. If abrasives come in contact with the chain, lubrication becomes more difficult. When lubricants are applied externally, abrasive particles tend to adhere to the chain surfaces and act as a lapping or grinding compound. Under extreme conditions it is sometimes advisable to avoid chain lubrication.

25

Installation Instructions for Rotary Equipment

d) The following is a recommended lubrication chart for normal conditions: Lubrication Chart Recommended Lubricant EXXON RONEX MP or Equal NLGI Grade 2 for use at temperatures at or above -29OC (-29OF) SAE 10W Oil Refer to Manufacturers Instruction Manual SAE

Component Trunnions & Thrust Rollers Fluid Couplings Speed Reducers Chain

Step #12 Tracking & Aligning the Cylinder

NOTE

The following procedure is tie consuming and requires patience. This procedure may take several hours.

NOTE

The objective alignment condition is to have the shell rotating where the tire on each end continuously just humps the thrust roller and the thrust roller only turns momentarily.

Rotate the cylinder slowly under power. With a light under the tire and between the trunnions, observe the tire and trunnion face contact. There should be no light showing between them. If some light is seen, indicating a gap of .005 inches or so of surface contact on one side of a trunnion tighten the set screws on that side to push the trunnion up to the tire. This may only take a or turn of setscrew. If more than a full turn of the set screw is required to push the trunnion up to the tire, it is better to return the set screw to its original position, jack the dryer slightly off the trunnion and put a thin shim under the trunnion bearing.

Rotate the cylinder under power. Inspect for floating or drifting between the thrust rollers, or if the cylinder tends to bear hard contiuously one way or the other. See Illustration, Cylinder Movement.

26

Installation Instructions for Rotary Equipment

Cylinder Movement.

27

Installation Instructions for Rotary Equipment

To move the cylinder towards the feed end, (in case a tire is hearing hard against the down hill thrust roller) follow the procedures shown above to adjust the gudgeons or pillow blocks. Turn all setscrews turn. Results might become apparent immediately, or the cylinder may run several minutes before it starts its movement. After obtaining desired movement, check each set of trunnions as shown on Illustration Trunnion Assembly Alignment, to ensure the shafts are still exactly parallel.

To move the cylinder towards the discharge end, reverse the adjustments described above.

Assume a counter-clockwise rotation towards the thrust roller end. If the cylinder tends to run towards the thrust roller end, turn all #1 set screws turn. Re-start and observe. (When possible, without danger, it is preferable and easier to adjust these screws while the cylindere is turning).

Results may be immediate. However, a cylinder may have to run several minutes before it will begin to move in the new direction.

28

29

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Kartika Mahatmya Damodar LilaDokument233 SeitenKartika Mahatmya Damodar Lilacorons100% (2)

- Biomedical Short Learning Article CompleteDokument169 SeitenBiomedical Short Learning Article Completenebiyu mulugetaNoch keine Bewertungen

- Strike RiskDokument4 SeitenStrike RiskAdilson Leite ProençaNoch keine Bewertungen

- Keystone Retaining WallsDokument98 SeitenKeystone Retaining WallsWorld Outdoor Emporium100% (1)

- Copula Modeling: An Introduction For Practitioners: Pravin K. Trivedi and David M. ZimmerDokument111 SeitenCopula Modeling: An Introduction For Practitioners: Pravin K. Trivedi and David M. ZimmervinizioNoch keine Bewertungen

- Centum VP System Overview HMIDokument46 SeitenCentum VP System Overview HMIBimbit PattanaikNoch keine Bewertungen

- Bhagabata Odiya 1Dokument58 SeitenBhagabata Odiya 1Bimbit PattanaikNoch keine Bewertungen

- Effective Team BuildingDokument44 SeitenEffective Team BuildingBimbit PattanaikNoch keine Bewertungen

- Atrological InterpretationDokument72 SeitenAtrological InterpretationBimbit PattanaikNoch keine Bewertungen

- Bagging Plant Zypmite Plant Mop Bagging Rilway In-Motion: Bimbit Kumar PattanaikDokument9 SeitenBagging Plant Zypmite Plant Mop Bagging Rilway In-Motion: Bimbit Kumar PattanaikBimbit PattanaikNoch keine Bewertungen

- Bagging Plant Presentation - PpsDokument5 SeitenBagging Plant Presentation - PpsBimbit Pattanaik100% (1)

- Houses From Arudha LagnaDokument10 SeitenHouses From Arudha LagnaBimbit PattanaikNoch keine Bewertungen

- Simon India Limited,: Dupont Sustainable SolutionsDokument1 SeiteSimon India Limited,: Dupont Sustainable SolutionsBimbit PattanaikNoch keine Bewertungen

- Giving Thanks: "Chance Favors The Prepared Mind."Dokument1 SeiteGiving Thanks: "Chance Favors The Prepared Mind."Bimbit PattanaikNoch keine Bewertungen

- Fakir Mohan Senapati Odiya ShortStories PDFDokument172 SeitenFakir Mohan Senapati Odiya ShortStories PDFBimbit Pattanaik73% (33)

- Mantrapuspam OdiDokument3 SeitenMantrapuspam OdiBimbit PattanaikNoch keine Bewertungen

- Pid 321 121 1C - R3 PDFDokument1 SeitePid 321 121 1C - R3 PDFBimbit PattanaikNoch keine Bewertungen

- Safety: Chapter - 1Dokument2 SeitenSafety: Chapter - 1Bimbit PattanaikNoch keine Bewertungen

- Technokom Contents PDFDokument1 SeiteTechnokom Contents PDFBimbit PattanaikNoch keine Bewertungen

- 03 Traversing Gear SlaveDokument69 Seiten03 Traversing Gear SlaveDeMen NguyenNoch keine Bewertungen

- Failure Modes For Flooded & VRLA BatteriesDokument46 SeitenFailure Modes For Flooded & VRLA Batteriesazhagaan100% (1)

- Structural Evaluation TechniquesDokument6 SeitenStructural Evaluation TechniquesMohan NaikNoch keine Bewertungen

- Reviewer MathDokument6 SeitenReviewer MathLuna Ronquillo100% (1)

- Conveyor Chain and SprocketsDokument5 SeitenConveyor Chain and Sprocketsmartc35Noch keine Bewertungen

- Notation Composer 3 Users GuideDokument690 SeitenNotation Composer 3 Users GuideSvedot MakedonecNoch keine Bewertungen

- Commissioning Example 797Dokument15 SeitenCommissioning Example 797linkangjun0621Noch keine Bewertungen

- An Experimental and Statistical Study of Olfactory PreferencesDokument7 SeitenAn Experimental and Statistical Study of Olfactory Preferencesjungseong parkNoch keine Bewertungen

- 05 - A Statistical Analysis of Body Measurements of Filipino WomenDokument15 Seiten05 - A Statistical Analysis of Body Measurements of Filipino WomenJenberrose G TrelinskiNoch keine Bewertungen

- Syllabus For Admission Test For Admission To Class Xi 2020-21 Physics ChemistryDokument2 SeitenSyllabus For Admission Test For Admission To Class Xi 2020-21 Physics ChemistryAdhara MukherjeeNoch keine Bewertungen

- Physics 20 Formula SheetDokument2 SeitenPhysics 20 Formula SheetcallalilNoch keine Bewertungen

- ATV13 User Manual VECON PDFDokument126 SeitenATV13 User Manual VECON PDFSuleyman OzyurtNoch keine Bewertungen

- What Is A Determiner?Dokument15 SeitenWhat Is A Determiner?Brito Raj100% (4)

- Dam From: Safety Valve For A DamDokument28 SeitenDam From: Safety Valve For A DamRashmi SahooNoch keine Bewertungen

- KW Kwh/YrDokument3 SeitenKW Kwh/YrHaris BaigNoch keine Bewertungen

- IR SensorDokument9 SeitenIR Sensorujjwal sahaNoch keine Bewertungen

- Pokropivny 2007Dokument4 SeitenPokropivny 2007vasanthanilNoch keine Bewertungen

- MATERI 7aDokument56 SeitenMATERI 7aFriska SologiaNoch keine Bewertungen

- Modeling of Reinforced Concrete BeamDokument28 SeitenModeling of Reinforced Concrete BeamNGUYEN89% (27)

- Omnipeek GettingStartedDokument85 SeitenOmnipeek GettingStartedchris100% (1)

- PDS Example Collection 24-01-11 - Open PDFDokument52 SeitenPDS Example Collection 24-01-11 - Open PDFMichael GarrisonNoch keine Bewertungen

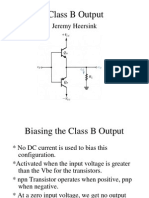

- Class B Output: Jeremy HeersinkDokument10 SeitenClass B Output: Jeremy Heersinkdummy1957jNoch keine Bewertungen

- Inductiveand Deductive Reasoning in Geometry October 27 2022Dokument9 SeitenInductiveand Deductive Reasoning in Geometry October 27 2022Seif DelawarNoch keine Bewertungen

- Summative Test Ist (2nd G)Dokument2 SeitenSummative Test Ist (2nd G)Rosell CabalzaNoch keine Bewertungen

- Inertia FormulasDokument4 SeitenInertia FormulasLoysa Agtarap MataNoch keine Bewertungen

- 2 Roisum ENDokument99 Seiten2 Roisum ENorhm100% (2)