Beruflich Dokumente

Kultur Dokumente

Patent US7036394 - Wire Winding Tool Article and Method - Google Patents

Hochgeladen von

DbaltCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Patent US7036394 - Wire Winding Tool Article and Method - Google Patents

Hochgeladen von

DbaltCopyright:

Verfügbare Formate

Patent US7036394 - Wire winding tool article and method - Google Patents

http://www.google.com/patents/US7036394?dq=7,036,394&hl=en&sa=X&ei=ukJ_UY...

+Zero

Search

Images

Maps

Play

YouTube

News

Gmail

Drive

Calendar

More 0

7,036,394

Zero One

Share

Patents

Find prior art

Discuss this patent

Wire winding tool article and method

US 7036394 B2

ABSTRACT

In an article and method for enabling a wire winding tool to wind a loop of wire about a workpiece and secure the wire loop to the workpiece, the wire winding tool includes a body element which includes a tapered wire-holding end and a hollow cylindrical shaft with interior threads and side slots. The tool further includes a threaded shaft including a distal end and transverse pins which extend therefrom through the body element side slots and are moveable therein, and about which free ends of the wire are wound. Also, the tool includes a nut threadably connected to the threaded shaft, which is threadably moveable to enable the threaded shaft to retract and pull the wire free ends so as to wind and secure the wire to the workpiece.

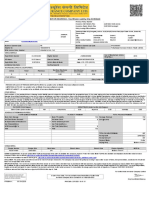

Publication number Publication type Application number Publication date Filing date Priority date Also published as

US7036394 B2 Grant 10/886,018 May 2, 2006 Jul 6, 2004 Jul 6, 2004 US20060005666 WO2006014327A1 Senora Early Senora Early Dba Clamptite-Ray Silvey Company

Inventors Original Assignee

U.S. Classification

81/9.3 24/27 International Classification B25B25/00 Cooperative Classification B25B25/005 European Classification B25B25/00B References External Links Patent Citations (12) USPTO 2 More

DRAWINGS (2)

1 of 8

4/30/2013 12:05 AM

Patent US7036394 - Wire winding tool article and method - Google Patents

http://www.google.com/patents/US7036394?dq=7,036,394&hl=en&sa=X&ei=ukJ_UY...

DESCRIPTION

BACKGROUND OF THE INVENTION 1. Field of the Invention The present invention relates generally to hand tools, and, more particularly, to a new and improved hand tool for enabling a wire clamp to be tightly wound about a workpiece. 2. General Background and State of the Art It has been known to wrap a clamp about a workpiece such as a rubber hose which in turn may extend about a pipe, and to enable the clamp to be tightened about the hose and pipe to tightly bind the hose to the pipe. The clamp may include a screw which may be threadably advanced so as to tighten the clamp. It has also been known to wrap a loop of wire about the workpiece to form a wire loop clamp, and to use a hand tool to apply pressure to and tighten the wire loop. The loop of wire may include a plurality of windings of the wire about the workpiece. However, it would be desirable to provide a hand tool which would enable effective, convenient and efficient tightening of a wire loop clamp about a workpiece. Moreover, the tool may hang up on the wire loop upon movement of the tool thereabout in forming the wire loop clamp, interfering therewith. Furthermore, it may be difficult to get a good grip on the tool in instances

CLAIMS

1. An article for enabling a wire to be wound about a workpiece, comprising a wire winding tool, wherein the wire includes opposed free ends, and is adapted to form a loop, and is further adapted to form a winding, adapted to extend about the workpiece and through the loop and to be wound about the workpiece, wherein the wire winding tool comprises: a body element, which includes a distal end which is generally taperedshaped to form a tapered end, adapted to hold the wire loop in position during winding of the wire, and a cylindrical shaft, which is hollow, and includes interior threads and side slots, and from which the tapered end extends, wherein the cylindrical shaft of the body element further includes a proximal end, which includes flat side surfaces for enabling securing of a gripping member thereto; a threaded shaft, adapted to extend in and threadably engage the interior threads of the hollow portion of the cylindrical shaft, and to be threadably movable relative to the body element, which threaded shaft includes a distal end, and transverse pins extending therefrom through the side slots in the body element, adapted to be moveable in the body element side slots and to enable the wire free ends to be secured thereto; and a nut, adapted to be threadably connected to the threaded shaft, and, upon threaded movement of the nut, to enable the threaded shaft to retract relative to the body element such that the transverse pins pull on

2 of 8

4/30/2013 12:05 AM

Patent US7036394 - Wire winding tool article and method - Google Patents

http://www.google.com/patents/US7036394?dq=7,036,394&hl=en&sa=X&ei=ukJ_UY...

where such may be required to enable effective moving of the tool for forming and securing the wire loop clamp. In addition, it would be desirable to enable convenient carrying of the tool. In view of these considerations, effective winding and securing of a wire loop clamp about a workpiece may be implemented in a wire winding tool which enables efficient tightening of a wire loop clamp, effective operation of the tool without hanging up on the wire loop, and convenient carrying of the tool. Therefore, there has existed a need for an article and method for enabling a wire clamp to be wound about a workpiece in an effective and efficient manner, while preventing interference with the wire loop clamp and enabling convenient access thereto. Accordingly, the present invention fulfills these needs by providing an efficient and effective wire loop clamp winding tool with enhanced gripping and carrying thereof. INVENTION SUMMARY Briefly, and in general terms, the present invention provides an article for enabling a wire clamp to be wound about a workpiece, comprising a wire winding tool, wherein the wire includes opposed free ends, and is able to form a loop, and is further able to form a winding which is extendable about the workpiece and through the loop, and to be wound about and secured to the workpiece. More particularly, the present invention includes a body element, which includes a distal end which is generally tapered-shaped to form a tapered end, able to hold the wire loop in position during winding of the wire, and a cylindrical shaft, which is hollow, and includes interior threads and side slots, and from which the tapered end extends. The article, in accordance with the present invention, also includes a threaded shaft, extendable in and threadably engageable with the interior

the wire free ends secured thereto so as to wind the wire about the workpiece and enable the wire winding to be secured to the workpiece. 2. The article of claim 1, wherein the threaded shaft further includes a proximal end which is non-threaded, adapted to enable extension of a loop therethrough. 3. The article of claim 2, wherein the non-threaded proximal end of the threaded shaft has a hole therethrough for enabling extending a loop therethrough. 4. A method of enabling a wire to be wound about a workpiece, wherein the wire includes opposed free ends, and is adapted to form a loop, and is further adapted to form a winding, adapted to extend about the workpiece and through the loop and to be wound about the workpiece, in an article which comprises a wire winding tool, comprising a body element, which includes a distal end which is generally tapered-shaped to form a tapered end, adapted to hold the wire loop in position during winding of the wire, and a cylindrical shaft, which is hollow, and includes interior threads and side slots, and from which the tapered end extends, wherein the cylindrical shaft of the body element further includes a proximal end, which includes flat side surfaces for enabling securing of a gripping member thereto, a threaded shaft, adapted to extend in and threadably engage the interior threads of the hollow portion of the cylindrical shaft, and to be threadably movable relative to the body element, which threaded shaft includes a distal end, and transverse pins extending therefrom through the side slots in the body element, adapted to be moveable in the body element side slots and to enable the wire free ends to be secured thereto, and a nut, adapted to be threadably connected to the threaded shaft, and, upon threaded movement of the nut, to enable the threaded shaft to retract relative to the body element such that the transverse pins pull on the wire free ends secured thereto so as to wind the wire about the workpiece and enable the wire winding to be secured to the workpiece, wherein the method comprises:

3 of 8

4/30/2013 12:05 AM

Patent US7036394 - Wire winding tool article and method - Google Patents

http://www.google.com/patents/US7036394?dq=7,036,394&hl=en&sa=X&ei=ukJ_UY...

threads of the hollow portion of the cylindrical shaft, and threadably movable relative to the body element, which threaded shaft includes a distal end, and transverse pins extending therefrom through the side slots in the body element, moveable in the body element side slots and able to enable the wire free ends to be secured thereto. The article of the present invention further includes a nut, threadably connected to the threaded shaft, and, upon threaded movement of the nut, able to enable the threaded shaft to retract relative to the body element such that the transverse pins pull on the wire free ends secured thereto so as to wind the wire about the workpiece and enable the wire winding to be secured to the workpiece. Therefore, one aspect of the present invention is that it provides a wire winding tool for effectively forming and securely winding a wire loop clamp about a workpiece. Another aspect of the present invention is that it includes a unitary cylindrical shaft for preventing the tool from hanging up on the wire loop clamp during movement thereof. A further aspect of the present invention is that it includes gripping-enabling surfaces and threadable movement-enabling members to enable effective gripping and tightening movement of the tool. Still another aspect of the invention is that it enables the tool to be connected to a loop for convenient carrying thereof. These and other aspects and features of the invention will become apparent from the following more detailed description, when taken in conjunction with the accompanying drawings of illustrative embodiments. BRIEF DESCRIPTION OF THE DRAWINGS

forming a loop and a winding adapted to extend about the workpiece and through the loop and to be wound about the workpiece by the wire; holding the wire loop in position during winding of the wire, by the body element tapered end; enabling securing of a gripping member to the flat side surfaces of the proximal end of the body element cylindrical shaft; threadably moving the threaded shaft along the interior threads of the cylindrical shaft hollow portion; moving the threaded shaft transverse pins with the wire free ends secured thereto along the body element side slots; and threadably moving the nut along the threaded shaft and retracting the threaded shaft relative to the body element, so as to pull the transverse pins with the wire free ends secured thereto, wind the wire about the workpiece, and secure the wire winding to the workpiece. 5. The method of claim 4, wherein the threaded shaft further includes a proximal end which is non-threaded, adapted to enable extension of a loop therethrough, further comprising enabling extension of a loop through the non-threaded proximal end of the threaded shaft. 6. The method of claim 5, wherein the non-threaded proximal end of the threaded shaft has a hole therethrough for enabling extension of a loop therethrough, and wherein enabling extension of the loop includes enabling extension of the loop through the hole in the non-threaded proximal end of the threaded shaft.

FIG. 1 is an elevational partly-fragmentary view of a wire winding tool and a wire wound about a workpiece in

4 of 8

4/30/2013 12:05 AM

Patent US7036394 - Wire winding tool article and method - Google Patents

http://www.google.com/patents/US7036394?dq=7,036,394&hl=en&sa=X&ei=ukJ_UY...

accordance with the present invention. FIG. 2 is a side elevational partly-sectional view of a wire winding tool and a wire wound about a workpiece in accordance with the present invention. FIG. 3 is a fragmentary view of the distal end of a winding wire tool in accordance with the present invention. FIG. 4 is a fragmentary view of a wire loop wound about and secured to a workpiece in accordance with the present invention. DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention is directed to an improved article and method for providing a wire winding tool, which is able to wind a formed loop clamp securely about a workpiece in an effective and efficient manner. Referring to the drawings, wherein like numerals denote like or corresponding parts, and in particular to FIGS. 14, there is shown an article 10 for enabling a wire 12 to be wound about a workpiece 14, comprising a wire winding tool, wherein the wire 12 includes opposed free ends 16, and is able to form a loop 18, and is further able to form a winding 20, extendable about the workpiece 14 and through the loop 18 and able to be wound about and secured to the workpiece 14. The tool 10 may be utilized for emergency repairs or permanent fixes. It is lightweight, substantially lighter than worm gear and tension clamps. The wire 12 for example may be comprised of stainless steel, safety wire, welding, electric fence, or bailing wire. The workpiece 14 about which the wire 12 is to be wound and secured may for example comprise high pressure hose, hydraulic hose, power steering hose, broken poles, pieces of a broken tool handle, fences and gates, farm machinery, fishing poles, mufflers and tail pipes, furniture and flower pots, toys and sporting equipment, cooking pots and pans, leaky hoses, or irrigation and sprinkler systems. In the present invention, the wire winding tool 10 includes a body element 22, which includes a distal end 24 which is generally tapered-shaped to form a tapered end 26, able to hold the wire loop 18 in position during winding of the wire 12, and guide pins 28, for guiding the wire 12 thereover. The body element 22 further includes a cylindrical shaft 30, which is hollow, and includes interior threads 32 and side slots 34, and from which the tapered end 26 extends. The side slots 34 of the body element 22 are elongated. The cylindrical shaft 30 of the body element 22 further includes a proximal end 36, which includes flat side surfaces 38 for enabling securing of a gripping member thereto. The cylindrical shaft 30 may for example be comprised of a single unitary piece of machined stainless steel, with a

5 of 8

4/30/2013 12:05 AM

Patent US7036394 - Wire winding tool article and method - Google Patents

http://www.google.com/patents/US7036394?dq=7,036,394&hl=en&sa=X&ei=ukJ_UY...

gradual taper to the tapered end 26, to provide a smoother transition such that hangup of the tool 10 with the wire 12 is prevented while pivoting the tool 10. The flat side surfaces 38 enable enhanced stability in gripping and moving the tool 10. As shown in FIGS. 12, the wire winding tool 10 further includes a threaded shaft 40, able to extend in and threadably engage the interior threads 32 of the hollow cylindrical shaft 30, and to be threadably movable relative to the body element 22. The threaded shaft 40 includes a distal end 42, and transverse pins 44 extending therefrom through the side slots 34 in the body element 22, able to be moveable in the body element side slots 34 and to enable the wire free ends 16 to be secured thereto. The threaded shaft 40 further includes a proximal end 46 which is non-threaded. The threaded shaft 40 is elongated to enable elongated movement of the transverse pins 44 in the elongated side slots 34. The non-threaded proximal end 46 of the threaded shaft 40 has a hole 48 therethrough for enabling extending a loop 50 therethrough. The loop which is extendable through the hole 46 may comprise a key ring, for enabling connection of the tool 10 thereto. In accordance with the invention, the wire winding tool 10 also includes a nut 52, able to be threadably connected to the threaded shaft 40, and, upon threaded movement of the nut 52, to enable the threaded shaft 40 to retract relative to the body element 22, such that the transverse pins 44 pull on the wire free ends 16 secured thereto, so as to wind the wire 12 about the workpiece 14 and enable the wire winding 20 to be secured to the workpiece 14. The nut 52 includes side wing-shaped projections 54 for enabling gripping and leveraging for movement thereof. Also, the tool 10 includes a washer 56 positionable between the nut 50 and the body element 22. The washer 56 may be comprised of nylon. As illustrated in FIGS. 14, in a method for use of the wire winding tool 10, the operation of the tool 10 is enabled by forming a loop, 18 and forming a winding 20 adapted to extend about the workpiece 14 and through the loop 18 and to be wound about the workpiece 14, by the wire 12. The operation is further enabled by holding the wire loop 18 in position during the winding of the wire 12, by the body element tapered end 26, and by threadably moving the threaded shaft 40 along the interior threads 32 of the cylindrical shaft hollow portion. As seen in FIGS. 12, the operation of the wire winding tool 10 is further enabled by moving the threaded shaft transverse pins 44 with the wire free ends 16 secured thereto along the body element side slots 34. Moving the threaded shaft transverse pins 44 further includes moving along the elongated body element side slots 34. Moving the threaded shaft transverse pins 44 includes elongated travel of the transverse pins 44 in the elongated side slots 34 of the threaded shaft 40.

6 of 8

4/30/2013 12:05 AM

Patent US7036394 - Wire winding tool article and method - Google Patents

http://www.google.com/patents/US7036394?dq=7,036,394&hl=en&sa=X&ei=ukJ_UY...

In the present invention, the operation of the tool 10 further includes threadably moving the nut 52 along the threaded shaft 40 and retracting the threaded shaft 40 relative to the body element 22, so as to pull the transverse pins 44 with the wire free ends 16 secured thereto, wind the wire 12 about the workpiece 14, and secure the wire winding 20 to the workpiece 14. Threadably moving the nut 52 further includes enabling gripping of the side wing-shaped projections 54 of the nut 52. Threadably moving the nut 52 further includes enabling moving of the washer 56. As depicted in FIG. 4, upon pulling the wire 12 tightly about the workpiece 14, the tool 10 is pivoted upwardly at the distal end 24 thereof to bend the wire 12 over the loop 18. The wire 12 is then cut off to form ends 58 which may then be pinched down over the loop 18 for securing the loop 18 to the workpiece 14. In accordance with the invention, operation of the tool 10 also includes enabling securing of a gripping member to the flat side surfaces 38 of the proximal end 36 of the body element cylindrical shaft 30, and enabling extension of a loop 50 through the non-threaded proximal end 46 of the threaded shaft 40. Enabling extension of the loop 50 includes enabling extension thereof through the hole 48 in the non-threaded proximal end 46 of the threaded shaft 40. Forming, holding, threadably moving the threaded shaft 40, moving the threaded shaft transverse pins 44, and threadably moving the nut 52 may be enabled relative a stainless steel tool 10. In accordance with the present invention, the system and method provide for a wire winding tool which enables the effective forming and securing of a wire loop clamp about a workpiece, which enables efficient gripping and carrying thereof. It will be apparent from the foregoing that, while particular forms of the invention have been illustrated and described, various modifications can be made without departing from the spirit and scope of the invention. Accordingly, the invention is not to be limited, except by the following claims.

PATENT CITATIONS

Cited Patent US1012282 US1078533 US1347579 US1453940 Filing date Sep 20, 1909 Feb 7, 1913 Sep 21, 1918 May 16, 1922 Publication date Dec 19, 1911 Nov 11, 1913 Jul 27, 1920 May 1, 1923 Applicant Simon Schlangen Romeo A. Beaudette Bernhardt Henrikson John A. S. Rogers Title Hose-tie wrench. Clamping device. Hose-clamp tool Hose-clamping tool

7 of 8

4/30/2013 12:05 AM

Patent US7036394 - Wire winding tool article and method - Google Patents

http://www.google.com/patents/US7036394?dq=7,036,394&hl=en&sa=X&ei=ukJ_UY...

Cited Patent US1783123 US2362112 US2421878 US4084625 US4794827 US4997194 US5090277 US5148577

Filing date Apr 5, 1928 Nov 9, 1942 Feb 10, 1944 Aug 3, 1976 Mar 24, 1987 Sep 5, 1989 Oct 11, 1990 Aug 5, 1991

Publication date Nov 25, 1930 Nov 7, 1944 Jun 10, 1947 Apr 18, 1978 Jan 3, 1989 Mar 5, 1991 Feb 25, 1992 Sep 22, 1992

Applicant Joel Kiviaho Capra Benedetto G Anton Broder Brinegar; Claude E. Poling; Denzil C. Krohn; Timothy L. Spiller; Mildred E. Silvey; Elmer R.

Title Hose-clamp-applying tool Wire tightening tool Device for tying wire around an article Wire banding tool and cable splice Drain plug removing device Drill chuck key Ski boot key Forming tool for wire clamp

Google Home - Sitemap - USPTO Bulk Downloads - Privacy Policy - Terms of Service - About Google Patents - Send Feedback Data provided by IFI CLAIMS Patent Services 2012 Google

8 of 8

4/30/2013 12:05 AM

Das könnte Ihnen auch gefallen

- Hippocampus User'S Guide: Subject PagesDokument33 SeitenHippocampus User'S Guide: Subject PagesDbaltNoch keine Bewertungen

- FTB 14 Horse Ev Jastrow EtDokument5 SeitenFTB 14 Horse Ev Jastrow EtDbaltNoch keine Bewertungen

- Tenebrio Molitor Exposed To Environmental Bacteria and Fungi atDokument17 SeitenTenebrio Molitor Exposed To Environmental Bacteria and Fungi atDbaltNoch keine Bewertungen

- Tese RitaDokument135 SeitenTese RitaDbaltNoch keine Bewertungen

- Laughing KookaburraDokument3 SeitenLaughing KookaburraDbaltNoch keine Bewertungen

- Journal of Petroleum Science and EngineeringDokument8 SeitenJournal of Petroleum Science and EngineeringDbaltNoch keine Bewertungen

- Mcdonald Et Al 2007 BesDokument13 SeitenMcdonald Et Al 2007 BesDbaltNoch keine Bewertungen

- Tillage and Slug Management in No Till Corn WhalenDokument0 SeitenTillage and Slug Management in No Till Corn WhalenDbaltNoch keine Bewertungen

- Fact Sheet KookaburraDokument4 SeitenFact Sheet KookaburraDbaltNoch keine Bewertungen

- Snails and Slugs Ipm 09Dokument2 SeitenSnails and Slugs Ipm 09DbaltNoch keine Bewertungen

- Snails and Slugs: Pest Control Bulletin No. 37Dokument2 SeitenSnails and Slugs: Pest Control Bulletin No. 37DbaltNoch keine Bewertungen

- Cane ToadDokument4 SeitenCane ToadDbaltNoch keine Bewertungen

- Reproductive Specializations in A Viviparous African Skink: Implications For Evolution and Biological ConservationDokument9 SeitenReproductive Specializations in A Viviparous African Skink: Implications For Evolution and Biological ConservationDbaltNoch keine Bewertungen

- The Snail Darter Versus Tellico Dam: Environmental Case StudyDokument2 SeitenThe Snail Darter Versus Tellico Dam: Environmental Case StudyDbaltNoch keine Bewertungen

- 10 Bright OmbarDokument54 Seiten10 Bright OmbarDbaltNoch keine Bewertungen

- J Exp Biol 2002 Girguis 3055 66Dokument12 SeitenJ Exp Biol 2002 Girguis 3055 66DbaltNoch keine Bewertungen

- Appl. Environ. Microbiol. 2008 Harmer 3895 8Dokument5 SeitenAppl. Environ. Microbiol. 2008 Harmer 3895 8DbaltNoch keine Bewertungen

- Giant Tube Worm: (Riftia Pachyptila)Dokument2 SeitenGiant Tube Worm: (Riftia Pachyptila)DbaltNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- ATPDraw 5 User Manual UpdatesDokument51 SeitenATPDraw 5 User Manual UpdatesdoniluzNoch keine Bewertungen

- Test & Drain Valve Model 1000Dokument2 SeitenTest & Drain Valve Model 1000saifahmed7Noch keine Bewertungen

- Chapter 5Dokument3 SeitenChapter 5Showki WaniNoch keine Bewertungen

- HRO (TOOLS 6-9) : Tool 6: My Family and My Career ChoicesDokument6 SeitenHRO (TOOLS 6-9) : Tool 6: My Family and My Career ChoicesAkosi EtutsNoch keine Bewertungen

- Executive Summary - Pseudomonas AeruginosaDokument6 SeitenExecutive Summary - Pseudomonas Aeruginosaapi-537754056Noch keine Bewertungen

- Level 3 Repair: 8-1. Block DiagramDokument30 SeitenLevel 3 Repair: 8-1. Block DiagramPaulo HenriqueNoch keine Bewertungen

- Gardner Denver PZ-11revF3Dokument66 SeitenGardner Denver PZ-11revF3Luciano GarridoNoch keine Bewertungen

- MOTOR INSURANCE - Two Wheeler Liability Only SCHEDULEDokument1 SeiteMOTOR INSURANCE - Two Wheeler Liability Only SCHEDULESuhail V VNoch keine Bewertungen

- LMU-2100™ Gprs/Cdmahspa Series: Insurance Tracking Unit With Leading TechnologiesDokument2 SeitenLMU-2100™ Gprs/Cdmahspa Series: Insurance Tracking Unit With Leading TechnologiesRobert MateoNoch keine Bewertungen

- Unit 1Dokument3 SeitenUnit 1beharenbNoch keine Bewertungen

- 4 Bar LinkDokument4 Seiten4 Bar LinkConstance Lynn'da GNoch keine Bewertungen

- Form Three Physics Handbook-1Dokument94 SeitenForm Three Physics Handbook-1Kisaka G100% (1)

- Sample Annual BudgetDokument4 SeitenSample Annual BudgetMary Ann B. GabucanNoch keine Bewertungen

- Mid Term Exam 1Dokument2 SeitenMid Term Exam 1Anh0% (1)

- Microwave Drying of Gelatin Membranes and Dried Product Properties CharacterizationDokument28 SeitenMicrowave Drying of Gelatin Membranes and Dried Product Properties CharacterizationDominico Delven YapinskiNoch keine Bewertungen

- ARUP Project UpdateDokument5 SeitenARUP Project UpdateMark Erwin SalduaNoch keine Bewertungen

- Ikea AnalysisDokument33 SeitenIkea AnalysisVinod BridglalsinghNoch keine Bewertungen

- Applied-Entrepreneurship PPTDokument65 SeitenApplied-Entrepreneurship PPTJanice EscañoNoch keine Bewertungen

- Oem Functional Specifications For DVAS-2810 (810MB) 2.5-Inch Hard Disk Drive With SCSI Interface Rev. (1.0)Dokument43 SeitenOem Functional Specifications For DVAS-2810 (810MB) 2.5-Inch Hard Disk Drive With SCSI Interface Rev. (1.0)Farhad FarajyanNoch keine Bewertungen

- SILABO 29-MT247-Sensors-and-Signal-ConditioningDokument2 SeitenSILABO 29-MT247-Sensors-and-Signal-ConditioningDiego CastilloNoch keine Bewertungen

- Ytrig Tuchchh TVDokument10 SeitenYtrig Tuchchh TVYogesh ChhaprooNoch keine Bewertungen

- POST TEST 3 and POST 4, in ModuleDokument12 SeitenPOST TEST 3 and POST 4, in ModuleReggie Alis100% (1)

- KSU OGE 23-24 AffidavitDokument1 SeiteKSU OGE 23-24 Affidavitsourav rorNoch keine Bewertungen

- CodebreakerDokument3 SeitenCodebreakerwarrenNoch keine Bewertungen

- T1500Z / T2500Z: Coated Cermet Grades With Brilliant Coat For Steel TurningDokument16 SeitenT1500Z / T2500Z: Coated Cermet Grades With Brilliant Coat For Steel TurninghosseinNoch keine Bewertungen

- CI Principles of EconomicsDokument833 SeitenCI Principles of EconomicsJamieNoch keine Bewertungen

- 500 Logo Design Inspirations Download #1 (E-Book)Dokument52 Seiten500 Logo Design Inspirations Download #1 (E-Book)Detak Studio DesainNoch keine Bewertungen

- Shubham RBSEDokument13 SeitenShubham RBSEShubham Singh RathoreNoch keine Bewertungen

- Methodical Pointing For Work of Students On Practical EmploymentDokument32 SeitenMethodical Pointing For Work of Students On Practical EmploymentVidhu YadavNoch keine Bewertungen

- Cancellation of Deed of Conditional SalDokument5 SeitenCancellation of Deed of Conditional SalJohn RositoNoch keine Bewertungen