Beruflich Dokumente

Kultur Dokumente

FluidFlow3 Brief Overview

Hochgeladen von

jjirwinCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

FluidFlow3 Brief Overview

Hochgeladen von

jjirwinCopyright:

Verfügbare Formate

FluidFlow3

Piping Systems analysis and simulation by design. FluidFlow3 is the first and only software for piping system design, calculation and optimisation that supports liquids, gases, slurries, 2-phase, and non-Newtonian fluids. FluidFlow3 is a truly original software program for the complete hydraulic design, network analysis, trouble-shooting and optimisation of piping systems. The solution includes flows, pressures, temperatures and phase states through out your piping networks. FluidFlow3 means efficient and accurate modelling for the design of energy efficient, safe, reliable flow systems that are easy to operate and maintain. A very wide variety of industries depend on FluidFlow3 to successfully model new and existing systems, size pipes, select boosters, controllers and other fluid equipment. All modules have, as standard, the ability to include heat loss/gain from pipes. Temperature change or heat transfer to or from equipment is also included.

Contents:

FluidFlow3 - Liquid module .............................................................................................. 2 FluidFlow3 - Gas module .................................................................................................. 3 FluidFlow3 Slurry module .............................................................................................. 4 FluidFlow3 - 2-Phase Liquid/Gas module .......................................................................... 5 FluidFlow3 Dynamic Analysis, Scripting module ............................................................. 6

FluidFlow3 - Liquid module

Over 1050 pre-defined fluids in the database included as standard. For liquid (incompressible flow) calculations, FluidFlow3 solves the fundamental conservation equations of mass, energy, and momentum. Accurate steady state solutions using Darcy-Weisbach, Continuity and Bernoulli equations. Hazen Williams can be used if required.

Communicate designs by exporting in Html, Word, Pdf and Excel format. FluidFlow3 can model any component (fluid equipment item) you are likely to come across, these include: boosters (positive displacement and centrifugal types), valves (including 3-way), flow controllers, pressure sustainers, pressure reducers, differential pressure controllers, check and non return valves, orifice plates, reducers & expanders, venturi tubes, inline nozzles, filters, packed beds, cyclones, centrifuges, labyrinth seals, pipe coils, relief valves, bursting disks, shell & tube exchangers, plate exchangers, auto-claves, knock-out pots, as well as rigorously modelling junctions (tees, wyes, bends, & crosses). For items not covered by the above you can define your own.

FluidFlow3 - Gas module

As gas flows in any network the pressure, temperature, density, enthalpy, velocity and other physical properties are constantly changing. FluidFlow3 calculations take this fully into account to provide an accurate solution without the need to make simplifying assumptions.

A solution approach often used in the literature is to assume ideal gas laws so that analytical equations for energy, momentum and continuity equations can be derived. Rather than make these simplifying assumptions FluidFlow3 uses a calculation procedure that solves the conservation equations together with an equation of state for small pressure loss increments. This means FluidFlow3 obtains a rigorous solution. Available equations of state are: Benedict-Webb-Rubin Peng-Robinson Lee Kesler The flowsheet is the "visual engine" which allows building, navigation, interpretation and analysis of a pipe system.

FluidFlow3 Slurry module

Can be used to model settling or non-settling non-Newtonian fluids. Settling slurry calculation methods available are Wilson-Addie-Sellgren-Clift, WASP, and Durand. Non-settling slurry calculations methods depend on rheology data. This can be described as Power Law, Bingham Plastic, Hershel Buckley or Casson.

Simulating the performance of settling slurries is dependant on the solid density, concentration, particle shape and size distribution, as well as the properties of the carrier fluid. Selecting the optimum pipeline velocity is usually the most important factor in the design and operation of slurry systems. Operating with velocities too high wastes energy, while operating with velocities too low can lead to pipeline blockage. Fluids can be mixed on the flowsheet. This allows for gas or liquid mixtures, two phase mixtures or dilution effects in slurries to be considered. The fluids database also allows for pre-mixing of single phase liquid or gases. You can define your own fluids and add them to the database in minutes (http://www.fluidflowinfo.com/Videos/AddSimpleFluid.htm) .

FluidFlow3 - 2-Phase Liquid/Gas module

Can be used to model fixed or changing quality systems, with heat transfer included. FluidFlow3 can analyse systems where the vapor quality changes with pipe position as well as two phase flow where the vapor quality is fixed Calculation methods available are Lockhart-Martinelli, Friedel, Muller Steinberg and Heck, Drift Flux, Beggs Brill or Chisholm Baroczy.

FluidFlow3 uses a modelling approach for the pressure loss calculation, this is a hybrid between the rigorous and empirical methods. By this, we mean, that we use well known empirical correlations and apply them to a differential pipe length. This allows for a flash calculation, liquid holdup and flow regime to be determined for each segment and acknowledges that the pressure loss per unit length changes as the two phase mixture flows down the pipe. Over 85 fluid equipment items (elements) are available to construct any network. This means FluidFlow3 can be used in any industry or application where fluids need to be moved.

FluidFlow3 Dynamic Analysis, Scripting module

See how your design operates over a period of time, with different initial conditions, different settings or operating parameters Scripting allows extended time analysis or what-if scenarios to be considered.

You can write your own scripts using Basic or Pascal. Scripting is used to look at scenarios such as pump station optimisation, flare stack depressurising, or equipment performance over time. You can call external programs and COM modules from script. This means you can start Excel, export results and plot a chart all from script. Flite Software also offers script writing and scenario help as a service. Please contact us to discuss your dynamic analysis needs.

Das könnte Ihnen auch gefallen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- NPS Official Park Map-11Dokument1 SeiteNPS Official Park Map-11jjirwinNoch keine Bewertungen

- AutoPIPE Version ComparisonDokument4 SeitenAutoPIPE Version ComparisonjjirwinNoch keine Bewertungen

- Fathom 9 Slurry ModelDokument12 SeitenFathom 9 Slurry ModeljjirwinNoch keine Bewertungen

- Safety Relief Valve Sizing EquationsDokument7 SeitenSafety Relief Valve Sizing EquationsjjirwinNoch keine Bewertungen

- Asme PTC 1986Dokument4 SeitenAsme PTC 1986AmalAhmed0% (1)

- Paper 1578355 SET ProbstDokument8 SeitenPaper 1578355 SET ProbstjjirwinNoch keine Bewertungen

- Building Energy Modeling GuidebookDokument14 SeitenBuilding Energy Modeling Guidebookjjirwin0% (1)

- ASHRAE Journal May 2015Dokument121 SeitenASHRAE Journal May 2015jjirwinNoch keine Bewertungen

- ASME Piping Stress Analysis RequirementsDokument8 SeitenASME Piping Stress Analysis RequirementsjjirwinNoch keine Bewertungen

- Identification and Prediction of Piping System NoiseDokument7 SeitenIdentification and Prediction of Piping System NoisejjirwinNoch keine Bewertungen

- HP-11C Owner's Handbook and Problem-Solving Guide 1984 ColorDokument264 SeitenHP-11C Owner's Handbook and Problem-Solving Guide 1984 Colorjjirwin100% (9)

- HP-19C & 29C Quick Reference Guide 1977 ColorDokument2 SeitenHP-19C & 29C Quick Reference Guide 1977 ColorjjirwinNoch keine Bewertungen

- HP 75 Owner's HandbookDokument348 SeitenHP 75 Owner's HandbookjjirwinNoch keine Bewertungen

- HP-19C & 29C Solutions Mathematics 1977 B&WDokument40 SeitenHP-19C & 29C Solutions Mathematics 1977 B&WjjirwinNoch keine Bewertungen

- HP-15C Owner's Handbook 1985 B&WDokument293 SeitenHP-15C Owner's Handbook 1985 B&WjjirwinNoch keine Bewertungen

- HP-19C & 29C Solutions Games 1977 B&WDokument42 SeitenHP-19C & 29C Solutions Games 1977 B&WjjirwinNoch keine Bewertungen

- HP-11C Quick ReferenceDokument4 SeitenHP-11C Quick ReferencejjirwinNoch keine Bewertungen

- HP-11C Solutions Handbook 1981Dokument101 SeitenHP-11C Solutions Handbook 1981jjirwin0% (1)

- HP-10C Owner's Handbook 1982 ColorDokument128 SeitenHP-10C Owner's Handbook 1982 Colorjjirwin100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 2.0 Psychrometry ApplicationDokument26 Seiten2.0 Psychrometry ApplicationMuhd ShazanyNoch keine Bewertungen

- ResearchpaperDokument4 SeitenResearchpaperapi-314857944Noch keine Bewertungen

- Fluid Mechanics PDFDokument184 SeitenFluid Mechanics PDFctguyoungNoch keine Bewertungen

- Chapter 4 Isothermal Reactor Design (Class Discussion)Dokument6 SeitenChapter 4 Isothermal Reactor Design (Class Discussion)FakhrulShahrilEzanieNoch keine Bewertungen

- 1 Introduction of EOR LecturesDokument19 Seiten1 Introduction of EOR LecturessereptNoch keine Bewertungen

- PFR CSTR - Systems Overview and Protocols FinalDokument20 SeitenPFR CSTR - Systems Overview and Protocols Finalfmachour9316Noch keine Bewertungen

- Pipeline Virtual Anchor Length Calculations: VariablesDokument3 SeitenPipeline Virtual Anchor Length Calculations: Variablesromvos8469Noch keine Bewertungen

- Enhanced Wastewater Treatment TechnologyDokument12 SeitenEnhanced Wastewater Treatment TechnologySid Esterico SestosoNoch keine Bewertungen

- Newtonian and NON - Newtonian FluidsDokument42 SeitenNewtonian and NON - Newtonian FluidsEdy SagithaNoch keine Bewertungen

- Presentation On IoclDokument39 SeitenPresentation On IoclRashmi AgrawalNoch keine Bewertungen

- Module 5 WearDokument23 SeitenModule 5 WearrohanNoch keine Bewertungen

- Chapter 4 WcuDokument29 SeitenChapter 4 WcuKuba100% (3)

- TM-WW009 AQUADYN UA420 RevaDokument29 SeitenTM-WW009 AQUADYN UA420 RevaSy Nguyen VietNoch keine Bewertungen

- Flottweg Questionarrie (797) 2028634550033784393Dokument2 SeitenFlottweg Questionarrie (797) 2028634550033784393Saro HNoch keine Bewertungen

- Design Performance Evaluation of Wastewater Treatment Plant D at TirumalaDokument17 SeitenDesign Performance Evaluation of Wastewater Treatment Plant D at Tirumalaviqrisyam rizky100% (1)

- Hydraulics CalculationDokument1 SeiteHydraulics CalculationSudish BhatNoch keine Bewertungen

- Chapter 6-Multiple Evaporator and CompressorDokument27 SeitenChapter 6-Multiple Evaporator and Compressorm_alodat6144Noch keine Bewertungen

- Lecture 3: Operation Involving Particulate MatterDokument25 SeitenLecture 3: Operation Involving Particulate MatterTaytoNoch keine Bewertungen

- Sand Control 2. Introduction To Coiled Tubing: Damilola V. AinaDokument49 SeitenSand Control 2. Introduction To Coiled Tubing: Damilola V. AinaAkande AyodejiNoch keine Bewertungen

- OF TO: Oxidation Acetaldehyde Acetic Acid In1 A Sparger ReactorDokument8 SeitenOF TO: Oxidation Acetaldehyde Acetic Acid In1 A Sparger Reactorarpit gargNoch keine Bewertungen

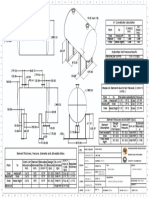

- Naphtha Reflux - DRUMDokument1 SeiteNaphtha Reflux - DRUMToniNoch keine Bewertungen

- ESP ComponentsDokument78 SeitenESP ComponentsCarlos Alberto Viancha SalazarNoch keine Bewertungen

- Basic Hydraulics: Module 1: Introduction To HydraulicsDokument43 SeitenBasic Hydraulics: Module 1: Introduction To HydraulicsBayu RafliNoch keine Bewertungen

- Physical and Chemical Hydrogeology: Second Edition Patrick A. DomenicoDokument8 SeitenPhysical and Chemical Hydrogeology: Second Edition Patrick A. DomenicoNuranyNoch keine Bewertungen

- EJ pdf0Dokument20 SeitenEJ pdf0Yogendran GanesanNoch keine Bewertungen

- Energy Saving Potential of Thermoelectric Radiant Cooling Panels With A Dedicated Outdoor AirDokument41 SeitenEnergy Saving Potential of Thermoelectric Radiant Cooling Panels With A Dedicated Outdoor AirFernando Manuel Gómez CastroNoch keine Bewertungen

- CL-7 CH-4 NotesDokument2 SeitenCL-7 CH-4 NotesYograj sharmaNoch keine Bewertungen

- FMECA Worksheet: No. Functional Failures Failure Modes Causes EffectDokument15 SeitenFMECA Worksheet: No. Functional Failures Failure Modes Causes EffectBarathNoch keine Bewertungen

- Drilling HydraulicsDokument36 SeitenDrilling HydraulicsSohaib RashidNoch keine Bewertungen

- Unconfined Compression TestDokument4 SeitenUnconfined Compression TestMc CyHewNoch keine Bewertungen