Beruflich Dokumente

Kultur Dokumente

HOS Frame and Running Gear Data Standard Frame and Running Gear Assemblies

Hochgeladen von

Jose Luis RattiaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

HOS Frame and Running Gear Data Standard Frame and Running Gear Assemblies

Hochgeladen von

Jose Luis RattiaCopyright:

Verfügbare Formate

HOS Frame and Running Gear Data Standard Frame and Running Gear Assemblies

A. Performance Characteristics 5HOS 6HOS 7HOS 1.0 General Stroke (in.) 5.0 6.0 7.0 Rod Diameter 2.50 2.50 2.50 (in.) Max. Allowable 60,000 60,000 60,000 Operating Rod Load (lbs) Max. Allowable Gas 60,000 60,000 60,000 Load (lbs) 2.0 Ratings Number of 2/4/6 2/4/6 2/4/6 Throws Rated Speed 1500 1200 1000 (RPM) Minimum Operating 500 500 500 Speed (RPM) Nominal BHP/Throw at 1200/1200/1200 1000/1000/1000 1100/1100/1000 Rated Speed Angle Between Pairs 0/90/120 0/90/120 0/90/120 of Compressor cranks (degrees) Average Compressor 1250 1200 1167 Piston Speed at Rated Speed (ft./min) Rod Length / 6.40 5.33 4.57 Crank Radius Crankshaft rotation is counter clockwise from pump end view. B. Product Specification for HOS Frames 1.0 Frame Multi-throw, balanced-opposed rigid alloy-iron frame heavily Configuration - ribbedand reinforced with integrally cast crosshead extensions. Openframe top construction with steel tie rods and individually fitted castiron spacers over each main bearing. Gasketed doors in top and sides permit easy access to running gear. Inside painted with oil proof white primer paint. Lower part of frame forms sump for lubricating oil.

Options -

Explosion relief device (Bicera Relief Valve) Frame liquid level controller (with Alarm and Shutdown Switch) Temperature control valve Dry sump configuration Lifting lugs (Standard on Export only)

2.0 Crankshaft Forged, alloy-steel crankshaft with passages for pressure Configuration - lubrication. One-piece construction. Two and four throw have counterweights. 3.0 Connecting Forged, alloy-steel 2 piece construction, I-beam sections, Rod rifledrilled passages for pressurized oil lubrication to crosshead Configuration - and crosshead guide. Two bolt configuration.

4.0 Crosshead and Crosshead Pin Nodular iron box type crossheads with shim adjustable Configuration - aluminum shoes at top and bottom. Crosshead pin is full floating type,secured in place by cap pin and bolt. Where required, positive-lockdisc-type weights are bolted to crosshead for balancing within twopounds maximum.

5.0 Distance Piece -

Cast iron one piece design, 13.00" long, 18.00" long on high pressure (MAWP > 2000 psig) 8.00" cylinders and smaller, sealedto 25 psig. Gasketed solid covers on both sides. Stainless steelfittings with either stainless steel braided hose, tubing or acombination thereof. Inside painted with oil proof white primerpaint. Cast iron wiper rings and Teflon sealing rings.

Options -

Cast iron one piece design, 18.00" long, sealed to 25 psig.Gasketed solid covers on both sides. Required on high pressurecylinders (MAWP > 2750). Also required on 8.00" cast iron boreand smaller if an oil slinger is required. Cast iron one piece design, 18.00" long, sealed to 25 psig.Gasketed solid covers on both sides. Distance piece can beprovided with purged wiper assembly and purged packing. 22.00"long distance piece is required on high pressure cylinders (MAWP> 2750) and on 8.00" bores and smaller, when using purged wiperand packing..

Cast iron two piece design, 26.00" long sealed to 25 psig. Consistsof 1 - 8.00" on frame end and 1 - 18.00" on cylinder end. Stainlesssteel braided hose, tubing or combination thereof are standard in18.00" distance piece only. Partition packing is non-lubricatedwith three pairs of double acting tangent cut rings

- glass andgraphite-filled PTFE. 6.0 Bearings and Bushings 6.1 Frame Horizontally - split, aluminum alloy with pressure lubricated Main mainbearings. Options Temperature detection system (RTD or "K" type thermocouple) formain bearings, including tubing fittings, brackets and bolting.

Terminal connection at frame. 6.2 Connecting Rod Crankpin Two piece, tri-metal precision bearing. Bearing Connecting One piece, solid, steel backed bronze bushing, interference Rod Bushing - fit,shrunk into place. 6.3 Crosshead Crosshead Consists of two, solid, steel backed bronze bushings, Bushings interferencefit, shrunk into place. 6.4 Frame Thrust Bearing Two piece high-leaded tin bronze thrust shoe. 7.0 Frame Lubrication 7.1 Oil Pump Positive displacement, internally mounted, direct driven off end ofcrankshaft by dowel and hub arrangement complete with pressurerelief valve for cold start protection and main bearing pressureregulating valve. 7.2 Oil Filter - 12 micron, full-flow oil filter with disposable type element; cartridgeshave a collapse pressure rating of 150 psig. Oil filter is framemounted with stainless steel external piping downstream of filter. Options - - Dual oil filter with transfer valve. (Shipped loose). - Stainless steel piping upstream of standard filter. 7.3 Oil Cooler Fixed bundle shell and tube watercooled oil cooler. Steel shell(housing), carbon steel tube sheets welded to shell, 4 pass designwith cast iron bonnets, seamless admiralty tubes 25 BWG, 3/8".Oil in shell. (Shipped loose). Option 7.4 Prelube Pump (Option) 7.5 Frame Oil Heater (Option) Tema C Hand operated, frame mounted, positive displacement pump. Immersion oil heaters available for all frame sizes. Watt density is15W/sqin. Standard is 440/480 volt, 3 phase.

8.0 Crankshaft Prevents oil leakage from frame, non-pressure Seal Assembly containingdesign. Consists of a weather seal pressed into frame end coveraround crankshaft. On 2 and 4 throw frames, the crankshaftcounterweight inboard of seal acts as a slinger throwing oil backinto frame. On 6 throw frames, there is a split slinger ring clampedon crankshaft inboard of oil seal for this same purpose.

9.0 Tool Kit 10.0 Paint -

Consisting of crosshead nut wrench, piston rod entering sleeve andpiston nut adapter. One set provided per frame. All castings are shot blast, chipped and cleaned. Internal surfacesof frame, frame extensions and distance pieces are painted with anoil-proof white primer. All external surfaces are painted with a redoxide primer.

Lubricated Cylinder Applications - For domestic (North 11.0 Preservation America)applications, all internal components within the cylinder for Shipment - and frameare coated with a rust preventative light oil. For overseas shipmentor extended storage (6+ months), the compressor frame andcylinder internals are coated with a heavy oil. Critical componentswithin the cylinder such as piston and rods and valves are removedand boxed separately for better preservation. It is recommendedthat most of the heavy preservative be removed prior to start-up.

Special Note: If the compressor is a domestic shipment, but thepackage is export, and the packager will be run testing the packagein house, it is then up to the packager to insure overseaspreservation measures are taken on the compressor prior tooverseas shipment. Non-Lube Cylinder Applications - For domestic (North America)applications, aluminum paint is used in the cylinder gas passagewayand heads as a corrosion preventative. On export shipmentsor extended storage, the gas passages and heads will be sprayedwith a mineral rust preventative after the aluminum paint is applied.Pressure, partition packing and oil wiper rings are removed andplaced into a greaseproof, waterproof, flexible barrier materialfollowed by an outerwrap. Export or extended storage also requirethe piston and rod assembly to be removed for shipment. Pistonand rider rings are to be removed and packed like the packing ringsmentioned earlier. Piston and rod are sprayed with a fingerprintneutralizer, then the piston, rod and jamnut are spayed with a rustpreventative and finally wrapped like the packing rings mentionedabove.

12.0 Quality Assurance -

All major components are visually and dimensionally inspectedand their material content reviewed for compliance. Proceduresare per D-R Standard manufacturing specifications (See GFP28).Any records generated as a result are maintained at the factory.

Compressor - Running clearances and balancing checked and verified. Bar-over and rod run out. 1 hour no-load mechanical run test. Documentation provided: QAF-262 (assembly/test record). Frame Chemical and physical. Leak tested. Documentation provided: None Crankshaft - Chemical, physical, magnetic particle and ultra-sonic. Documentation provided: None Connecting Chemical and physical. Rod Documentation provided: None Connecting Chemical, physical and magnetic particle. Rod Bolts Documentation provided: None Crossheads - Chemical and physical. Documentation provided: None Crosshead Chemical physical and magnetic particle. Pins Documentation provided: None Distance Chemical and physical. Pieces Documentation provided: None NOTE: Additional dollars are required for the following (see pricing pages): QA/QC requirements outside the standard plan. Supplying documentation that normally isnt provided. Witnessing any tests or inspection points.

C. Component Specification 1.0 Connecting Rod Assembly 1.1 Connecting Rod - Length (in.) 1.2 Bearing - Diameter (in.) - Length (actual surface in.) - Proj. Area (sq. in.) (LxD) - Bearing Pressure at MARL (psi) 1.3 Bushing - Diameter (in.) 16.00

7.00 2.47 17.29 3470 4.25

- Length (actual surface in.) - Proj. Area (sq. in.) (LxD) - Bearing Pressure at MARL (psi) 3 1.4 Bolting - Thread Size - Stretch Required (in.) 2.0 Crosshead Assembly 2.1 Crosshead - Diameter (in.) - Piston Rod Thread Size - Piston Rod Root Stress (psi) (MARL/Tensile Stress Area) 2.2 Crosshead Running Surface - Length (actual surface in.) - Proj. Surface Width (in.) - Proj. Bearing Area (sq. in.) (LxW) - Maximum Bearing Pressure at MARL (psi) 2.3 Crosshead Pin Bolt - Thread Size - Torque (ft-lbs) 3.0 Frame Assembly 3.1 Main Bearing - Shell - Diameter (in.) - Length (actual surface in.) - Proj. Area (sq. in.) (LxD) - Bearing Pressure at MARL (psi) 3.2 Main Bearing Cap Bolt - Thread Size - Torque (ft-lbs) 3.3 Frame Tie Rod Nut - Thread Size 4.0 Lubrication System 4.1 Frame & Running Gear - Crankcase Capacity (gal)

3.897 16.56 623 1.750-12UNJS .018-.020

13.00 2.50-8 UNJ

14,000

9.57 6.19 59.24 190

.750-10UNC 100 - 110

7.00 3.22 22.54 2662 1.00" - 8 UNC 400 - 420

1.500 - 8 UN-3B 2/4/6

21/57/96

- Pump Capacity at 1000 RPM (gpm) - Oil Flow to Cooler (gpm) - Oil Flow to Filter (gpm) - Oil Temperature (F) - Normal - Maximum - Oil Pressure (psig) - Normal - Minimum - Shutdown Setting - Oil Cooler - Type

40/70/110 23/46/69 23/46/69

150 - 170 180

55-60 40 35 Shell and Tube

4.2 Cylinder (Divider Block System Standard w/Pressures >3000 psig) - Oil Source - No. of pumps provided - No. of Usable Pump Locations - Maximum Output/(1/4") Pump at 1200 RPM (PPD) - Maximum Pressure (psi) Options: - Distribution System - Oil Source - No. of Pumps - Maximum Pressure (psi) Pump-To-Point Internal or External As Required 6000 Frame 1/2/3 2-4 20 3500

- Electric Motor Driven Lubrication System (Shipped Loose)

D. Materials of Construction of Major Frame Components CODES/STANDARDS COMPONENT MATERIAL (TYPICAL) Bearing Caps Bearing, Crankpin Bearings, Main Bolts, Bearing Caps Bolts, Conn Rod Bolts, X-HD Pin Gray Cast Iron Tri-metal Aluminum Alloy Steel Forging Alloy Steel Forging Calcium-Aluminum Treated Alloy Steel ASTM A48 Class 30 SAE 1010, 49,19 SAE 781 ASTM A193 Grade B7 ASTM A193 Grade B7 ASTM A193 Grade B7

Bushing, Conn Rod Bushing, X-HD Pin Capscrews, Covers Connecting Rod Covers, Extensions Covers, Oil Ring Covers, Top Crankshaft (6" Stroke) Crankshaft (7" Stroke) Crosshead Distance Piece Frame Pin, Crosshead Rings, Oil Wipers Shoe, Crosshead Spacer, Tie Rod Tie Rod

Tri-metal Tri-metal Carbon Steel Alloy Steel Forging Carbon Steel Plate Carbon Steel Plate Carbon Steel Plate Forged Steel Forged Steel Nodular Iron Casting Gray Cast Iron Gray Cast Iron Calcium-Aluminum Treated Alloy Steel Cast Iron Aluminum Alloy Casting Gray Cast Iron Calcium-Aluminum Treated Alloy Steel

SAE 1026, 792 or 797 SAE 1010, 792 or 797 ASTM A307 Grade B ASTM A370; AISI 4142 ASTM A285 Grade C ASTM A285 Grade C ASTM A285 Grade C AISI 4140 AISI 4340 ASTM A536 Grade 65-4512 ASTM A48 Class 30 ASTM A48 Class 30 ASTM A193 Grade B7 --ASTM A108 ASTM A48 Class 25 ASTM A193 Grade B7

Contact Us | Privacy Policy & Terms of Use | Site Map 2013 Dresser-Rand. All Rights Reserved.

Das könnte Ihnen auch gefallen

- HOS (Heavy Oilfield Separable Compressor) BrochureDokument6 SeitenHOS (Heavy Oilfield Separable Compressor) BrochureakamalapuriNoch keine Bewertungen

- Sigma Compression ENDokument7 SeitenSigma Compression ENJose100% (1)

- D VipDokument6 SeitenD VipClemente Rafael Marval EscalonaNoch keine Bewertungen

- NUOVO PIGNONE Compressor Spares (2010-37)Dokument4 SeitenNUOVO PIGNONE Compressor Spares (2010-37)sianas1706Noch keine Bewertungen

- DS CF90D4Dokument1 SeiteDS CF90D4arieprachmanNoch keine Bewertungen

- 1 1Dokument9 Seiten1 1Ankush SehgalNoch keine Bewertungen

- Howden - FFP Free Floating Piston Lowres PDFDokument4 SeitenHowden - FFP Free Floating Piston Lowres PDFdigecaNoch keine Bewertungen

- Global Reciprocating Compressor Market Research Report 2016Dokument3 SeitenGlobal Reciprocating Compressor Market Research Report 2016Shaun MartinNoch keine Bewertungen

- A-VIP Compressor BrochureDokument6 SeitenA-VIP Compressor BrochureAvrinFakherniaNoch keine Bewertungen

- Manual 99 LDDokument20 SeitenManual 99 LDCristianNoch keine Bewertungen

- LPG Compressors: Sales CatalogDokument40 SeitenLPG Compressors: Sales CatalogAn IkhrandiNoch keine Bewertungen

- JC-364-TSKS IOM EN Final HiRes NoCropsDokument12 SeitenJC-364-TSKS IOM EN Final HiRes NoCropsFabio StuiNoch keine Bewertungen

- Screw Compressor GH-series Instruction Manual: GH250S/L, GH320SDokument111 SeitenScrew Compressor GH-series Instruction Manual: GH250S/L, GH320SManh PhamNoch keine Bewertungen

- Ariel Coporate BrochureDokument17 SeitenAriel Coporate BrochurehugoheloNoch keine Bewertungen

- Compressor Over-Lubrication PresentationDokument38 SeitenCompressor Over-Lubrication Presentation1mmahoneyNoch keine Bewertungen

- Ingersol-Rand-Air-Compressor PHE Booster Eng DataDokument46 SeitenIngersol-Rand-Air-Compressor PHE Booster Eng Datadevilsharma100% (1)

- JOY SUPERIOR and Cooper MH-66 PDFDokument2 SeitenJOY SUPERIOR and Cooper MH-66 PDFcarlos felipe botello paezNoch keine Bewertungen

- C Tuthill PDFDokument37 SeitenC Tuthill PDFRaulEfrainCharrezCastilloNoch keine Bewertungen

- ELP End User Rev10Dokument38 SeitenELP End User Rev10hugoheloNoch keine Bewertungen

- Mantenimiento SruDokument22 SeitenMantenimiento SruDaineris HernandezNoch keine Bewertungen

- Your Extras and Medical Claim Form: SECTION A: Your DetailsDokument3 SeitenYour Extras and Medical Claim Form: SECTION A: Your DetailsTGNoch keine Bewertungen

- Dresser RandDokument4 SeitenDresser RandBams ArifinNoch keine Bewertungen

- Altronic V Installation Manual (FORM AV II)Dokument12 SeitenAltronic V Installation Manual (FORM AV II)francis_mouille_iiNoch keine Bewertungen

- CLLK07 & 08 Technical Parameters BrochureDokument2 SeitenCLLK07 & 08 Technical Parameters BrochureAlmario Sagun0% (1)

- SEBU8099 Maint PDFDokument102 SeitenSEBU8099 Maint PDFAhmed KamalNoch keine Bewertungen

- Metastream TSC Coupling IOMDokument4 SeitenMetastream TSC Coupling IOMthanhphamNoch keine Bewertungen

- DDDokument3 SeitenDDAnkush Sehgal100% (1)

- Automation of Reciprocating Gas Engine Compressor Packages UsingDokument7 SeitenAutomation of Reciprocating Gas Engine Compressor Packages UsingGnanaSekar0% (1)

- Recip Overview Brochure HSR OnlyDokument11 SeitenRecip Overview Brochure HSR OnlyMuhammad ImranNoch keine Bewertungen

- Kinney Vacuum Pump OilDokument4 SeitenKinney Vacuum Pump OilhibhavuNoch keine Bewertungen

- PPI 2072 Diaphragm Compressor ManualDokument86 SeitenPPI 2072 Diaphragm Compressor ManualJohn Rey Payunan100% (1)

- DXR75 1000 June 1996Dokument2 SeitenDXR75 1000 June 1996SergiSerranoNoch keine Bewertungen

- Gaumer Process - Heat Control SystemDokument8 SeitenGaumer Process - Heat Control Systemharry_chemNoch keine Bewertungen

- Chicago Pneumatic Compressor 7.5 - 120HP WUX PDFDokument17 SeitenChicago Pneumatic Compressor 7.5 - 120HP WUX PDFIpenu Sujarwo100% (1)

- Product Overview-WH FramesDokument43 SeitenProduct Overview-WH FramesArzyman100% (1)

- Rotary Twin Scew Brochure UK HRDokument20 SeitenRotary Twin Scew Brochure UK HRNguyễn Hữu DũngNoch keine Bewertungen

- Rod Loading of Reciprocating CompressorsDokument18 SeitenRod Loading of Reciprocating Compressors최승원Noch keine Bewertungen

- Twin Screw Compressor PLC Operation Manual (PDFDrive)Dokument158 SeitenTwin Screw Compressor PLC Operation Manual (PDFDrive)sola sidoNoch keine Bewertungen

- المستندDokument5 SeitenالمستندMahdi HassanNoch keine Bewertungen

- Hertz Piston Type Compressor ManuelDokument31 SeitenHertz Piston Type Compressor Manueligor_sandulenkoNoch keine Bewertungen

- Flushing Oil Flooded Rotary Screw Air Compressors Procedure enDokument2 SeitenFlushing Oil Flooded Rotary Screw Air Compressors Procedure enSergiSerrano100% (1)

- WP 3325 B 3 - 5 Basbooster Incl. N - Pack: Technical DataDokument2 SeitenWP 3325 B 3 - 5 Basbooster Incl. N - Pack: Technical DataMarcos AssialdiNoch keine Bewertungen

- Metastream TSC Coupling Iom PDFDokument4 SeitenMetastream TSC Coupling Iom PDFVíctor Hugo Morales Curay100% (1)

- Superior - Cylinder Databook - ValvesDokument8 SeitenSuperior - Cylinder Databook - ValvesJake NavarreteNoch keine Bewertungen

- UPA Type Series BookletDokument122 SeitenUPA Type Series BookletRicardo BarrosNoch keine Bewertungen

- Caterpillar CG260 - 60 y 50 HZDokument5 SeitenCaterpillar CG260 - 60 y 50 HZEdutam50% (2)

- Altronic DD20 Annunciator and TachmotersDokument31 SeitenAltronic DD20 Annunciator and TachmotersVladimirNoch keine Bewertungen

- Intermech Bbrfbrvip CNG Compressors 55 450 KW 75 600 HP Tcm1143-3540245Dokument13 SeitenIntermech Bbrfbrvip CNG Compressors 55 450 KW 75 600 HP Tcm1143-3540245Chakravarthy BharathNoch keine Bewertungen

- ALTRONIC DD Series Annunciator Installation InstructionsDokument14 SeitenALTRONIC DD Series Annunciator Installation InstructionsCNorris505Noch keine Bewertungen

- Manual Champion Pl70Dokument32 SeitenManual Champion Pl70De Luna BraulioNoch keine Bewertungen

- VRT Training PresentationDokument14 SeitenVRT Training PresentationdonyaNoch keine Bewertungen

- Installation - Operation - Maintenance: S70-101 IOM/JAN 2000Dokument66 SeitenInstallation - Operation - Maintenance: S70-101 IOM/JAN 2000arielfernandomaxNoch keine Bewertungen

- Atmospheric Relief Valve ManualDokument12 SeitenAtmospheric Relief Valve ManualTarun ChandraNoch keine Bewertungen

- Manual de Operacion Secadores Ra 100 y Ra 125Dokument76 SeitenManual de Operacion Secadores Ra 100 y Ra 125Ricardo López BernalNoch keine Bewertungen

- MEL470-L12 Knocking in SI EngineDokument31 SeitenMEL470-L12 Knocking in SI EngineGaurav GuptaNoch keine Bewertungen

- Air Starters - Series 150bmpDokument16 SeitenAir Starters - Series 150bmpAntonio SerranoNoch keine Bewertungen

- Hydroseal Relief Valve Threaded High CapacityDokument4 SeitenHydroseal Relief Valve Threaded High Capacitytxlucky80Noch keine Bewertungen

- Alfa LavalDokument24 SeitenAlfa Lavaldroid11Noch keine Bewertungen

- Procedure To Detect Misalignment Between Engines and Gas Compressors - by Jose Luis RattiaDokument8 SeitenProcedure To Detect Misalignment Between Engines and Gas Compressors - by Jose Luis RattiaJose Luis RattiaNoch keine Bewertungen

- $XWR6WDWIRU$06 6XLWH 0Dfklqhu/+Hdowk 0dqdjhu: Automated Statistical LimitsDokument108 Seiten$XWR6WDWIRU$06 6XLWH 0Dfklqhu/+Hdowk 0dqdjhu: Automated Statistical LimitsluisrosavNoch keine Bewertungen

- Rev.6 MotorViewDokument286 SeitenRev.6 MotorViewdford8583Noch keine Bewertungen

- Rim and Face AlignmentDokument8 SeitenRim and Face Alignmentnazir305Noch keine Bewertungen

- Orbit v27n207 RunoutDokument14 SeitenOrbit v27n207 Runoutsant_100% (1)

- Gear WearsDokument13 SeitenGear WearsJose Luis RattiaNoch keine Bewertungen

- Testing: Valvetrain Systems For Combustion EnginesDokument48 SeitenTesting: Valvetrain Systems For Combustion EnginesJose Luis RattiaNoch keine Bewertungen

- 868843Dokument6 Seiten868843Jose Luis RattiaNoch keine Bewertungen

- Conecting RodDokument1 SeiteConecting RodJose Luis RattiaNoch keine Bewertungen

- Practical BalancingofflexiblerotorsforpowergenerationDokument10 SeitenPractical BalancingofflexiblerotorsforpowergenerationJose Luis RattiaNoch keine Bewertungen

- Windrock PortableDokument4 SeitenWindrock PortableJose Luis RattiaNoch keine Bewertungen

- Understanding Vibration Can Help Prevent Pump FailuresDokument4 SeitenUnderstanding Vibration Can Help Prevent Pump FailuresvfrpilotNoch keine Bewertungen

- 868844Dokument7 Seiten868844Jose Luis RattiaNoch keine Bewertungen

- Limites Ariel CompressorDokument1 SeiteLimites Ariel CompressorJose Luis RattiaNoch keine Bewertungen

- Gile NT Eautiful UtterflyDokument7 SeitenGile NT Eautiful UtterflyPedagogíaNoch keine Bewertungen

- Discussion Enpac 2500Dokument13 SeitenDiscussion Enpac 2500Jose Luis RattiaNoch keine Bewertungen

- Reciprocating Compressor BasicsDokument5 SeitenReciprocating Compressor BasicsJose Luis RattiaNoch keine Bewertungen

- Nominal Pipe - SpecificationsDokument2 SeitenNominal Pipe - SpecificationsJose Luis RattiaNoch keine Bewertungen

- Motocompressor Cooper BessemerDokument1 SeiteMotocompressor Cooper BessemerJose Luis RattiaNoch keine Bewertungen

- 3 Steps To Establish An Effective Lubrication ProgramDokument5 Seiten3 Steps To Establish An Effective Lubrication ProgramJose Luis RattiaNoch keine Bewertungen

- Piston Speed Lube ChartDokument1 SeitePiston Speed Lube ChartJose Luis RattiaNoch keine Bewertungen

- 3 Steps To Establish An Effective Lubrication ProgramDokument5 Seiten3 Steps To Establish An Effective Lubrication ProgramJose Luis RattiaNoch keine Bewertungen

- 3 Steps To Establish An Effective Lubrication ProgramDokument5 Seiten3 Steps To Establish An Effective Lubrication ProgramJose Luis RattiaNoch keine Bewertungen

- Reciprocating Compressor BasicsDokument5 SeitenReciprocating Compressor BasicsJose Luis RattiaNoch keine Bewertungen

- Rutina At-25Dokument3 SeitenRutina At-25Jose Luis RattiaNoch keine Bewertungen

- Theory of MachineDokument1 SeiteTheory of MachineJose Luis RattiaNoch keine Bewertungen

- Phase MeasurementDokument2 SeitenPhase MeasurementJose Luis RattiaNoch keine Bewertungen

- 02 Effects of Amplitude and Phase 7Dokument1 Seite02 Effects of Amplitude and Phase 7Jose Luis RattiaNoch keine Bewertungen

- Con RodDokument15 SeitenCon Rodgaurav311098Noch keine Bewertungen

- JGP650P5 Jgp700e5 PDFDokument875 SeitenJGP650P5 Jgp700e5 PDFAya JiboNoch keine Bewertungen

- PDF Bobcat t190 Parts Manual SN 527711001 and Above SN 527811001 and AboveDokument377 SeitenPDF Bobcat t190 Parts Manual SN 527711001 and Above SN 527811001 and AboveJager Gonzalez86% (14)

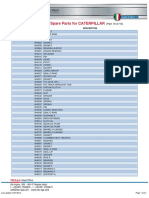

- Replacement Spare Parts For CATERPILLAR: O.E.M. REF. DescriptionDokument21 SeitenReplacement Spare Parts For CATERPILLAR: O.E.M. REF. DescriptionlionkinghdNoch keine Bewertungen

- Marketing Strategy of Bajaj AutomobilesDokument60 SeitenMarketing Strategy of Bajaj AutomobilesSachin GargNoch keine Bewertungen

- Sellos SKFDokument2 SeitenSellos SKFEver RiveraNoch keine Bewertungen

- RAM Parts CatalogDokument162 SeitenRAM Parts CatalogJuanOñateNoch keine Bewertungen

- A6 - 1 Understanding Principles of Operation of Internal Combustion EnginesDokument16 SeitenA6 - 1 Understanding Principles of Operation of Internal Combustion EnginesAlghazee Abo-jlalNoch keine Bewertungen

- TAD941GE: Volvo Penta Industrial DieselDokument2 SeitenTAD941GE: Volvo Penta Industrial DieselGiangDoNoch keine Bewertungen

- 2 Pneumatic SystemsDokument46 Seiten2 Pneumatic SystemsHanif HamidNoch keine Bewertungen

- Nissan CD17Dokument3 SeitenNissan CD17jose luis calixto requisNoch keine Bewertungen

- Ex 047 18 PDFDokument22 SeitenEx 047 18 PDFLeo RenantoNoch keine Bewertungen

- Ready Reckoner For Kits - DBUDokument60 SeitenReady Reckoner For Kits - DBUkhan khadarNoch keine Bewertungen

- Grasshopper Kohler Command 18 ConversionDokument9 SeitenGrasshopper Kohler Command 18 ConversionBrianCookNoch keine Bewertungen

- Motor de Popa - IntroducaoDokument337 SeitenMotor de Popa - IntroducaoSilveirabmNoch keine Bewertungen

- Inlinesecondedition - Sample Power ManualDokument21 SeitenInlinesecondedition - Sample Power Manualbaralaijiko75% (4)

- 99924-2093-03 FR730V FS730V FX730V English eBook-Kawasaki PDFDokument177 Seiten99924-2093-03 FR730V FS730V FX730V English eBook-Kawasaki PDFRabab Siddiqui100% (2)

- Man 48 60b Imo Tier II Marine PDFDokument428 SeitenMan 48 60b Imo Tier II Marine PDFSimon Orr100% (1)

- Yak 52 Maitenance ManualDokument38 SeitenYak 52 Maitenance Manualranickng1Noch keine Bewertungen

- Chapter 7 - Lubricants and Lubrication SystemsDokument34 SeitenChapter 7 - Lubricants and Lubrication SystemsRi AlvesNoch keine Bewertungen

- L23-30H GenSet TierII PDFDokument856 SeitenL23-30H GenSet TierII PDFvesper100% (1)

- Chapter 6 PDFDokument10 SeitenChapter 6 PDFBelayneh TadesseNoch keine Bewertungen

- MAN Biogas EngineDokument16 SeitenMAN Biogas EngineMuhammad rizkiNoch keine Bewertungen

- W01 358 7830Dokument29 SeitenW01 358 7830MROstop.comNoch keine Bewertungen

- Engine Vibration Is Excessive: Shutdown SISDokument4 SeitenEngine Vibration Is Excessive: Shutdown SISEshop ManualNoch keine Bewertungen

- Hydraulic Spring Stiffness Testing Machine: Nagre N.P., Bhosale M.S., Prof. Patil S.CDokument5 SeitenHydraulic Spring Stiffness Testing Machine: Nagre N.P., Bhosale M.S., Prof. Patil S.CShivam MishraNoch keine Bewertungen

- Piaggio Fly 125-150 I.E. MY 2012 (EN)Dokument252 SeitenPiaggio Fly 125-150 I.E. MY 2012 (EN)Manualles67% (6)

- ME 314 Design of Machine Elements (3-0-0-6) : TextsDokument9 SeitenME 314 Design of Machine Elements (3-0-0-6) : TextsKrishna MurthyNoch keine Bewertungen

- Tad 1240 GeDokument2 SeitenTad 1240 GeFedor GrigorievNoch keine Bewertungen

- Gasoline Engine Performance TestDokument7 SeitenGasoline Engine Performance TestaljhonNoch keine Bewertungen

- Pneumatic Water Pumping SystemDokument46 SeitenPneumatic Water Pumping SystemAjithNoch keine Bewertungen