Beruflich Dokumente

Kultur Dokumente

5.7 Asmeviii A-2 & Tema Split Backing Ring

Hochgeladen von

pastylOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

5.7 Asmeviii A-2 & Tema Split Backing Ring

Hochgeladen von

pastylCopyright:

Verfügbare Formate

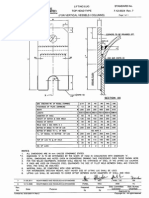

ASME VIII Div.

1 A-2-TEMA

SPLIT BACK RING TUBE PRESS

SPLIT BACKING RING

SPLIT RING UNDER INTERNAL PRESSURE 1 DESIGN CONDITIONS P= T= 47.00 bar

o 90.00 C

Allowable Stress Flange Sfo (Oper.) (G. Seat.) E 1379.00 bar 1379.00 bar 202.00 GPa 2 GASKET AND FACING DETAILS 4 LOADS AND BOLT CALCULATION Total hydrostatic force = 0.785G2P H= Total joint-contact surface compression load = HP= +2Pm'b r Wm1= Minimum required bolt 2bx3.14GmP load for the operating = H+H= W = Minimum required bolt load conditions for gasket seating m2 3.14GbY+b r Y' Total required cross sectional area of the bolts, Am1= for the operating conditions=W /S A = Total required cross sectional area of the bolts, m2 for gasket conditions=W /S A = total required crossseating sectional area the of bolts,

m

Bolting Sbo (Oper.) Sba (G. Seat.) 1720.00 bar 1720.00 bar

Attached Nozzle Sno (Oper.) Sna (G. Seat.) N/A N/A bar bar

Flange Mat.l SA-350LF2 Bolt. Mat. SA-193 B7 c= 3.20 mm

3 TABLES 2.5.1 and 2.5.2 GO.D.= GI.D.= N= b0= b= G= m= y= m'= y'= N of pass partition br= rl= Nmin= Load W= 3004930.90 N 777.69 mm 739.59 mm 19.05 mm 9.53 mm 7.72 mm 762.25 mm 4.00 64.00 Mpa 4.00 64.00 Mpa 12.00 mm 6.00 mm 739.59 mm 10.60 mm x hG=(C-B)/2

5. FLANGE DESIGN (A-2,Fig.2-4) 2143712.78 N 861218.12 N 3004930.90 N 1465903.18 N

2 174.71 cm 2 85.23 cm 2 174.71 cm 2 187.87 cm

thick small end g0 thick back of fl g1 inside diame B corr. thick. g0corr corr. thick. g1corr Flange thickness T Hube length h Out. diam. of flange A Flang thick t at shear Flange bolt circle C TEMA type No of splits No of rings Tubesheet OD

0.00 mm 0.00 mm 779.29 mm 0.00 mm 0.00 mm 99.55 mm 0.00 mm 876.21 mm 25.40 mm 819.06 mm A 1 1 777.69 mm

greater A the and A A= cross- sectional area of the bolts of using least b unthreaded diameter Number of bolts N= Bolts nominal diameter 1 1/8 Flange design full bolt load for gasket seating W= conditions=(A +A )S /2 Flange design bolt load for the operating W= conditions=W

40 28.575 mm 3231364.00 N 3004930.90 N

6 MOMENT CALCULATION Lever Arm Operating 19.89 mm

Comp. moment due to HG MG=

Moment WhG 59760.56 Nm

Total moment acting upon the flange for operating conditions Mo=WhG Gasket Seating W= 3231364.00 N hG=(C-B)/2 19.89 mm

Comp. moment due to HG MG=

59760.56 Nm WhG 64263.75 Nm 64263.75 Nm

Total moment acting upon the flange for gasket seating conditions Mo=MG 7 K AND HUB FACTORS K= d= T= Z= Y= U= L= 1.124

3 N/A mm

factor g1/g0 g1/g0= factor ho =(Bg0) ho= factor h/h0 h/ho=

N/A 0.00 mm N/A N/A N/A N/A

-1 hub e= stress correction factor N/A mm as a function of g1/g0 and h/h0 f=

Factor 1.868F as a function of g1/g0 and h/h0 F= Factor 8.569V as a function of g1/g0 and h/h0 V= 16.571 18.210 N/A 8 STRESS CALCULATION Operating Sallowable

60 50 40 30 20 10 0 -10 0 -20 -30

50

100

150

Sshear=W/(OD)t ST=YMo/t2B W/Ab

484.47 bar 1282.37 bar 1599.47 bar Gasket Seating

1103.20 OK 1379.00 OK 1720.00 OK SKETCH Sallowable

Sshear=W/(OD)t ST=YMo/t2B W/Ab

520.98 bar 1379.00 bar 780.28 bar

1103.20 OK 1379.00 OK 1720.00 OK Minimum Weight (kg) Bmax(mm) B(mm) 189.88 64.30 fabricated unfabricated 98.27 98.27

Maximum allowable working pressurew M.A.W.P. (Operating): 47 barg Maximum allowable working pressurew M.A.W.P. (Gasket-seating): barg

PStylianopoulos

Pressure Vessel Engineer

1 of 1

Das könnte Ihnen auch gefallen

- U-V-673 - Manual Flange and GussetDokument8 SeitenU-V-673 - Manual Flange and GussetDarshan PanchalNoch keine Bewertungen

- Sample FLG CalcDokument6 SeitenSample FLG CalcameyyammaiNoch keine Bewertungen

- Weld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersDokument25 SeitenWeld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersLipika GayenNoch keine Bewertungen

- Design of large diameter slip on flangeDokument6 SeitenDesign of large diameter slip on flangeAKSHAY BHATKARNoch keine Bewertungen

- Trunnion 6 TonDokument3 SeitenTrunnion 6 TonEngr Khurram Jaan RamayNoch keine Bewertungen

- Studding Outlet Calculation - PV Elite 2016Dokument8 SeitenStudding Outlet Calculation - PV Elite 2016Liu YangtzeNoch keine Bewertungen

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Dokument32 SeitenPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNoch keine Bewertungen

- Lug SupportDokument2 SeitenLug SupportSachin5586Noch keine Bewertungen

- Analysis of a rectangular pressure vesselDokument7 SeitenAnalysis of a rectangular pressure vesselPressure VesselNoch keine Bewertungen

- CalBOM - Formed ConicalDokument5 SeitenCalBOM - Formed ConicalRey FiedacanNoch keine Bewertungen

- Weld stress check for FAVID clips and demister clipsDokument3 SeitenWeld stress check for FAVID clips and demister clipsrsubramaniNoch keine Bewertungen

- Flange Pad CalcsDokument4 SeitenFlange Pad CalcstomNoch keine Bewertungen

- Davit With ElbowDokument2 SeitenDavit With Elbownitin400Noch keine Bewertungen

- Base Ring Fillet Size CalculationDokument4 SeitenBase Ring Fillet Size Calculationmiteshpatel191Noch keine Bewertungen

- Calculations For: Calculations No. Asme Viii Div 1 Ed 2019Dokument21 SeitenCalculations For: Calculations No. Asme Viii Div 1 Ed 2019David Vanegas100% (1)

- Clearance CalculationDokument12 SeitenClearance CalculationshazanNoch keine Bewertungen

- Platform Cleat CalculationDokument1 SeitePlatform Cleat Calculationmiteshpatel191Noch keine Bewertungen

- External Nozzle Loads Nozzle To Shells: Type of Loading Symbol Formula UnitDokument1 SeiteExternal Nozzle Loads Nozzle To Shells: Type of Loading Symbol Formula UnitSachinNoch keine Bewertungen

- Buffer Vessel Data SheetDokument4 SeitenBuffer Vessel Data SheetUmair A. KhanNoch keine Bewertungen

- PVElite RefDokument6 SeitenPVElite RefakhilNoch keine Bewertungen

- Tailing LugDokument3 SeitenTailing LugSajad AbdulNoch keine Bewertungen

- Flange calculation as per ASME Section VIIIDokument9 SeitenFlange calculation as per ASME Section VIIIDarshan PanchalNoch keine Bewertungen

- Design of base plate for columnDokument6 SeitenDesign of base plate for columnsoumyaNoch keine Bewertungen

- Cone To Shell ReinforcementDokument4 SeitenCone To Shell ReinforcementSajal KulshresthaNoch keine Bewertungen

- Girth Flange Load Calculation Using by FEA TechniquesDokument12 SeitenGirth Flange Load Calculation Using by FEA TechniqueskingstonNoch keine Bewertungen

- Cálculo Flange ASME VIII 1 Apendice 2Dokument5 SeitenCálculo Flange ASME VIII 1 Apendice 2Anonymous gfR3btyUNoch keine Bewertungen

- Equipment Design As Per Russian Norms - 20090218Dokument45 SeitenEquipment Design As Per Russian Norms - 20090218vikasNoch keine Bewertungen

- Sample Vessel Design (Sec - VIII Div.1)Dokument34 SeitenSample Vessel Design (Sec - VIII Div.1)Chano HanokNoch keine Bewertungen

- Tall Vertical ColumnsDokument2 SeitenTall Vertical ColumnsMas Arman TewoNoch keine Bewertungen

- Trunnion AnalysisDokument45 SeitenTrunnion AnalysisChiragJansariNoch keine Bewertungen

- Compress EvaluateDokument23 SeitenCompress EvaluateVishalDhiman100% (1)

- WRC Check List CriteriaDokument1 SeiteWRC Check List CriteriaAlvin Smith100% (1)

- New - Reinforcement of NozzleDokument24 SeitenNew - Reinforcement of NozzleVaniya GoelNoch keine Bewertungen

- Studding Flange Calculations Gasket SelectionDokument6 SeitenStudding Flange Calculations Gasket SelectionDarshan PanchalNoch keine Bewertungen

- Hinge Calculation FormulasDokument2 SeitenHinge Calculation FormulasamaNoch keine Bewertungen

- Heat Treatment Requirement Heat Treatment Requirement: o o o oDokument2 SeitenHeat Treatment Requirement Heat Treatment Requirement: o o o ofizanlaminNoch keine Bewertungen

- Flat HeadsDokument11 SeitenFlat HeadsToniNoch keine Bewertungen

- Stillwell Pipe ArrangementDokument1 SeiteStillwell Pipe ArrangementVishalDhiman100% (1)

- Documents - Tips - Pressure Vessel Design Calc Asme VIII Div 1Dokument35 SeitenDocuments - Tips - Pressure Vessel Design Calc Asme VIII Div 1bainNoch keine Bewertungen

- Waste Water Equalising Tank Anchor Chair DetailsDokument4 SeitenWaste Water Equalising Tank Anchor Chair DetailsShaheed HossainNoch keine Bewertungen

- Liting Lug Calculation VesselsDokument11 SeitenLiting Lug Calculation VesselsSudar Mysha0% (1)

- Design of Tooth Locked Quick Open Die Pressure VesselDokument4 SeitenDesign of Tooth Locked Quick Open Die Pressure VesselSEP-PublisherNoch keine Bewertungen

- Tailing LugDokument2 SeitenTailing Lugjagannadha varmaNoch keine Bewertungen

- PV Elite ResultDokument239 SeitenPV Elite ResultChaitanya Sai TNoch keine Bewertungen

- Support RingDokument13 SeitenSupport RingvamsiNoch keine Bewertungen

- Mozzle Repad Design ToolDokument2 SeitenMozzle Repad Design ToolSiddiqui Muhammad AshfaqueNoch keine Bewertungen

- Platform - Bracing SupportDokument12 SeitenPlatform - Bracing Supportpandiangv100% (1)

- MD PV ASME v0.1Dokument34 SeitenMD PV ASME v0.1nileshNoch keine Bewertungen

- Internal Pipe Distributor Design ProcedureDokument5 SeitenInternal Pipe Distributor Design Proceduresenthil kumarNoch keine Bewertungen

- Design by AnalysisDokument22 SeitenDesign by AnalysisJEELE77Noch keine Bewertungen

- Stiffening Ring Design On PV Elite For External Pressure Acting On Thin Walled Cylindrical Mounded VesselDokument4 SeitenStiffening Ring Design On PV Elite For External Pressure Acting On Thin Walled Cylindrical Mounded VesselEstuardo Javier Gan RodríguezNoch keine Bewertungen

- Max Allowable Nozzle LoadDokument1 SeiteMax Allowable Nozzle Loaddskr fkshNoch keine Bewertungen

- Davit Cal 2251B Davit Arm CalculationDokument4 SeitenDavit Cal 2251B Davit Arm Calculationnitin400Noch keine Bewertungen

- 7-12-0024 Rev 7Dokument1 Seite7-12-0024 Rev 7cynideNoch keine Bewertungen

- Platform Cleat Calculations for No. 1 at El. 47700Dokument4 SeitenPlatform Cleat Calculations for No. 1 at El. 47700shaishavNoch keine Bewertungen

- Pvelite OutputDokument44 SeitenPvelite OutputRam MurtyNoch keine Bewertungen

- Modification Thickness of A FlangeDokument3 SeitenModification Thickness of A FlangePeter PerezNoch keine Bewertungen

- 17 Asmeviii A-2 Reverse Integral FlangeDokument1 Seite17 Asmeviii A-2 Reverse Integral FlangepastylNoch keine Bewertungen

- 5 Asme Viii A-24 Clamp ConnectionDokument6 Seiten5 Asme Viii A-24 Clamp ConnectionpastylNoch keine Bewertungen

- Nozzle TempDokument2 SeitenNozzle TempRakeshNoch keine Bewertungen

- Loose Reverse Flange Design ASME VIII Div. 1 A-2Dokument1 SeiteLoose Reverse Flange Design ASME VIII Div. 1 A-2pastylNoch keine Bewertungen

- 15.1 Isa20 50 Control ValveDokument2 Seiten15.1 Isa20 50 Control Valvepastyl100% (1)

- Rectangular Vessel Stress CalculationDokument2 SeitenRectangular Vessel Stress Calculationpastyl100% (1)

- ASME VIII A-14 ExampleDokument2 SeitenASME VIII A-14 ExamplepastylNoch keine Bewertungen

- 9.1 Asmeviii Uhx U-Type IntegraltubesheetDokument3 Seiten9.1 Asmeviii Uhx U-Type IntegraltubesheetpastylNoch keine Bewertungen

- Rectangular Vessel Stress CalculationDokument2 SeitenRectangular Vessel Stress Calculationpastyl100% (1)

- 15.1 Isa20 50 Control ValveDokument2 Seiten15.1 Isa20 50 Control Valvepastyl100% (1)

- Loose Reverse Flange Design ASME VIII Div. 1 A-2Dokument1 SeiteLoose Reverse Flange Design ASME VIII Div. 1 A-2pastylNoch keine Bewertungen

- 17 Asmeviii A-2 Reverse Integral FlangeDokument1 Seite17 Asmeviii A-2 Reverse Integral FlangepastylNoch keine Bewertungen

- 5 Asme Viii A-24 Clamp ConnectionDokument6 Seiten5 Asme Viii A-24 Clamp ConnectionpastylNoch keine Bewertungen

- 7 Asmeviii A-1-6 Bolted Head ConnectionDokument1 Seite7 Asmeviii A-1-6 Bolted Head ConnectionpastylNoch keine Bewertungen

- 5 Asmeviii A-24 Clamp ConnectionDokument6 Seiten5 Asmeviii A-24 Clamp ConnectionpastylNoch keine Bewertungen

- 9 Asmeviii Ug & A-1-7 Large Radial OpeningDokument5 Seiten9 Asmeviii Ug & A-1-7 Large Radial OpeningpastylNoch keine Bewertungen

- 6 Asmeviii A-2 Bolted Flange ConnectionDokument1 Seite6 Asmeviii A-2 Bolted Flange ConnectionpastylNoch keine Bewertungen

- Asme Viii Uhx Tubesheet CalcsDokument3 SeitenAsme Viii Uhx Tubesheet CalcsjdfdfererNoch keine Bewertungen

- Explosive Ordnance DisposalDokument13 SeitenExplosive Ordnance DisposalZelwisNoch keine Bewertungen

- Adiabatic Production of Acetic AnhydrideDokument7 SeitenAdiabatic Production of Acetic AnhydrideSunilParjapatiNoch keine Bewertungen

- GbiDokument14 SeitenGbimaurice86Noch keine Bewertungen

- Smarter Washing Solutions: Modular Wash RangeDokument5 SeitenSmarter Washing Solutions: Modular Wash RangeSujesh AnNoch keine Bewertungen

- RMC Case StudyDokument2 SeitenRMC Case StudyAmer RahmahNoch keine Bewertungen

- 1729Dokument52 Seiten1729praj24083302Noch keine Bewertungen

- Report Card of Army Public School StudentDokument2 SeitenReport Card of Army Public School StudentRama KrishnaNoch keine Bewertungen

- Be Circular Fibre Reinforced ConcreteDokument4 SeitenBe Circular Fibre Reinforced ConcreteLim Kang HaiNoch keine Bewertungen

- Azura Amid (Eds.) - Recombinant Enzymes - From Basic Science To Commercialization-Springer International Publishing (2015) PDFDokument191 SeitenAzura Amid (Eds.) - Recombinant Enzymes - From Basic Science To Commercialization-Springer International Publishing (2015) PDFnurul qNoch keine Bewertungen

- Audi A3 Injeção DiretaDokument109 SeitenAudi A3 Injeção Diretawesley candido100% (1)

- Manhattan Project SummaryDokument5 SeitenManhattan Project Summaryapi-302406762Noch keine Bewertungen

- Finimpianti Power EngDokument2 SeitenFinimpianti Power EngJosip GrlicaNoch keine Bewertungen

- Curriculum Vitae: Name: Mobile: EmailDokument3 SeitenCurriculum Vitae: Name: Mobile: EmailRākesh RakhiNoch keine Bewertungen

- Caring Seedlings TLE Weekly PlanDokument3 SeitenCaring Seedlings TLE Weekly PlanMarjorie RaymundoNoch keine Bewertungen

- CS 704 Socio-Emotional and Moral Development in Middle ChildhoodDokument25 SeitenCS 704 Socio-Emotional and Moral Development in Middle ChildhoodPatricia PamintuanNoch keine Bewertungen

- 3.0 Wrap Up and SummaryDokument4 Seiten3.0 Wrap Up and SummaryGian SanchezNoch keine Bewertungen

- AI Berkeley Solution PDFDokument9 SeitenAI Berkeley Solution PDFPrathamGuptaNoch keine Bewertungen

- Data Sheet: High-Speed DiodesDokument7 SeitenData Sheet: High-Speed DiodesZoltán ÁgostonNoch keine Bewertungen

- Ucc 900 Sor em Wpi 0001 - B01Dokument73 SeitenUcc 900 Sor em Wpi 0001 - B01JonesNoch keine Bewertungen

- Sigmund Freud and His Main TheoriesDokument5 SeitenSigmund Freud and His Main TheoriesNguyen HarryNoch keine Bewertungen

- P2-1 - NME1106 - Gas Turbine LabworkDokument23 SeitenP2-1 - NME1106 - Gas Turbine LabworkKoh JovenNoch keine Bewertungen

- Advances in X-Ray Analysis - Volume 33 - 1989Dokument685 SeitenAdvances in X-Ray Analysis - Volume 33 - 1989CVNoch keine Bewertungen

- A Study To Assess The Effectiveness of PDokument9 SeitenA Study To Assess The Effectiveness of PKamal JindalNoch keine Bewertungen

- Evolution of The Fire SprinklerDokument11 SeitenEvolution of The Fire SprinklerPedro DudesonNoch keine Bewertungen

- 5R Invention Activity: Science LabDokument12 Seiten5R Invention Activity: Science LabricardoNoch keine Bewertungen

- Mid SemDokument1 SeiteMid SemvidulaNoch keine Bewertungen

- Application of EbwDokument11 SeitenApplication of Ebwsuman kumarNoch keine Bewertungen

- ETEC 520 - Assignment 2 Group ProjectDokument19 SeitenETEC 520 - Assignment 2 Group ProjectjennbosNoch keine Bewertungen

- 8602 BookDokument240 Seiten8602 BookSohail100% (2)

- BS (English) Dept of English University of SargodhaDokument36 SeitenBS (English) Dept of English University of SargodhaFEROZ KHANNoch keine Bewertungen