Beruflich Dokumente

Kultur Dokumente

The Way Kitchens Work The Science Behind Kitchen Utensils.28-32

Hochgeladen von

bhansalianiket96Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

The Way Kitchens Work The Science Behind Kitchen Utensils.28-32

Hochgeladen von

bhansalianiket96Copyright:

Verfügbare Formate

DEMO : Purchase from www.A-PDF.

com to remove the watermark

B READ M ACHINE

History of the Bread Machine

The first U.S. patent for a bread machine (patent number 383,938) was issued in the late 19th centurybefore electricity was even available. The modern home bread machine was invented in Japan and patented in the United States in 1985 for the Hosiden Electronics Company (patent number 4,538,509). The product was a success, which surprised many experts in the kitchen appliance manufacturing field. But once sales took off, many companies developed their own models.

11

12

The Way Kitchens Work

Patent no. 383,938

Patent no. 4,538,509

The original home model included a tank so water could be added automatically and an ice box so the water could be cooled to prevent the bread temperature from rising too high. More recent models have done away with these components; thermostats are better able to control the temperature inside the machine.

How Bread Makers Work

Its ingenious that someone thought of integrating all the steps required to make bread mixing the ingredients, kneading the dough, letting the yeast rise in a warm environment, and then baking the breadinto one tabletop device. One motor, a heating element, a timer, some switches, and a sensor are basically all thats needed to make a bread machine.

Most machines make loaves of either 1.0 or 1.5 pounds. You measure out the ingredients (flour, water, yeast, sugar, a pinch of salt) and drop them into the pan. You set the timer, and the machine takes over. A mixing paddle mixes the ingredients for a certain amount of time. Then the dough is allowed to rise: With the heating element on, the motor stops to give the yeast time to convert sugar into carbon dioxide and alcohol. The flour/water mixture becomes elastic enough to capture the carbon dioxide and form tiny bubbles throughout the bread. Next, the motor kicks on to knead the dough, letting excess gas escape. Finally, the heating element comes on to bake the bread, which also removes most of the alcohol. After the programmed baking time has elapsed, the beeper tells you its ready.

Inside the Bread Machine

Removing a few screws allows the bread machines metal outer cover to come off. The front control panel lifts out with its circuit board. Beneath another metal cylinder is the motor and the spindle that the mixing paddle rides on. The motor turns a large plastic geared wheel that turns the spindle above it. A rubber belt connects the motor, which sits off to one side, to the wheel. Inside the spindle is a temperature probe called a thermistor. It has a resistor (an electronics component that resists the flow of electricity) with a special property: its resistance changes with the temperature. It sits inside the spindle so it can get an

spindle

drive belt

thermistor

Heating element

Bread Machine

13

accurate reading of the temperature inside the baking loaf of bread and signal when the heating element should turn on and off. The heating element itself is a coil of high resistance wire. (For more information on how heating elements work, see the introduction, p. xiii.) A circuit board located near the motor connects to two thermal switches. They monitor the temperature of the machines inner

14

The Way Kitchens Work

thermal switch

speaker

metal cylinder to ensure that it doesnt overheat. The circuit board also includes the piezo speaker that bleeps at you when the bread has finished baking. (A piezo speaker contains a crystal that vibrates and makes sound when it receives a changing electrical voltage.) At the bottom of the bread maker is a second motor. It directly drives a centrifugal fan that draws air in from beneath the centrifugal fan bread maker and pushes it out between the machines inner cylinder and outer cover. This is one more precaution designed to prevent the user from getting burned. Not all machines have this second motor. Bread machines seem to do best with wheat ourour that contains gluten.

C AN O PENER

History of the Can Opener

Consider this curious historical fact: tin cans were in use for nearly half a century before the can opener was invented. Based on the existing technique of preserving food in glass bottles, Peter Durand invented tin cans in 1810. The first U.S. patent for tin cans was awarded in 1825 to Thomas Kensett. The cans used then were made of thick metal. By mid-century metallurgy had improved so cans could be made of more lightweight metals. At this point, inventors turned their attention to how to better open these cans.

15

Das könnte Ihnen auch gefallen

- Life Perespective 1Dokument18 SeitenLife Perespective 1bhansalianiket96Noch keine Bewertungen

- Life Perespective 2Dokument14 SeitenLife Perespective 2bhansalianiket96Noch keine Bewertungen

- Vadodara: Isolation Advised For High Risk Persons From June 1 To July 31Dokument12 SeitenVadodara: Isolation Advised For High Risk Persons From June 1 To July 31bhansalianiket96Noch keine Bewertungen

- A Timeline of Human EvolutionDokument2 SeitenA Timeline of Human Evolutionbhansalianiket96Noch keine Bewertungen

- 08jul201512075019 Aarti Nagpal Revised 72-75Dokument4 Seiten08jul201512075019 Aarti Nagpal Revised 72-75YeshiUlinaUtamiGintingNoch keine Bewertungen

- Art of Film MakingDokument15 SeitenArt of Film Makingbhansalianiket96Noch keine Bewertungen

- Cyclone ExpertiseDokument37 SeitenCyclone Expertisebhansalianiket96Noch keine Bewertungen

- Daylighting c2Dokument20 SeitenDaylighting c2mairaxeroNoch keine Bewertungen

- Langmuir Circulation - NoteDokument2 SeitenLangmuir Circulation - Notebhansalianiket96Noch keine Bewertungen

- 2 Thin Film Solar Cell-BtDokument6 Seiten2 Thin Film Solar Cell-Btbhansalianiket96Noch keine Bewertungen

- A Day in The Life of A Research ScientistDokument2 SeitenA Day in The Life of A Research Scientistbhansalianiket96Noch keine Bewertungen

- 1 Silicon Solar Cell-BtDokument12 Seiten1 Silicon Solar Cell-Btbhansalianiket96Noch keine Bewertungen

- 3 Waaree Series Ws 230-Ws 400Dokument1 Seite3 Waaree Series Ws 230-Ws 400bhansalianiket96Noch keine Bewertungen

- Sun, Wind, & Light: Architectural Design Strategies 3rd EditionDokument17 SeitenSun, Wind, & Light: Architectural Design Strategies 3rd EditionNabeeha0725% (4)

- Life - Death Poems - 0036-0037Dokument2 SeitenLife - Death Poems - 0036-0037bhansalianiket96Noch keine Bewertungen

- Life - Death Poems - 0034-0035Dokument2 SeitenLife - Death Poems - 0034-0035bhansalianiket96Noch keine Bewertungen

- Life - Death Poems - 0010-0011Dokument2 SeitenLife - Death Poems - 0010-0011bhansalianiket96Noch keine Bewertungen

- قائمة أساليب مواجهة الضغوطDokument3 Seitenقائمة أساليب مواجهة الضغوطFakher KhaliliNoch keine Bewertungen

- Life - Death Poems - 0032-0033Dokument2 SeitenLife - Death Poems - 0032-0033bhansalianiket96Noch keine Bewertungen

- Life - Death Poems - 0028-0030Dokument3 SeitenLife - Death Poems - 0028-0030bhansalianiket96Noch keine Bewertungen

- Audio Wiring Guide - 0091-0095Dokument5 SeitenAudio Wiring Guide - 0091-0095bhansalianiket96Noch keine Bewertungen

- Life - Death Poems - 0022-0023Dokument2 SeitenLife - Death Poems - 0022-0023bhansalianiket96Noch keine Bewertungen

- Life - Death Poems - 0019-0021Dokument3 SeitenLife - Death Poems - 0019-0021bhansalianiket96Noch keine Bewertungen

- Life - Death Poems - 0034-0035Dokument2 SeitenLife - Death Poems - 0034-0035bhansalianiket96Noch keine Bewertungen

- Life - Death Poems - 0024-0026Dokument3 SeitenLife - Death Poems - 0024-0026bhansalianiket96Noch keine Bewertungen

- Life - Death Poems - 0012-0013Dokument2 SeitenLife - Death Poems - 0012-0013bhansalianiket96Noch keine Bewertungen

- Audio Wiring Guide - 0106-0110Dokument5 SeitenAudio Wiring Guide - 0106-0110bhansalianiket96Noch keine Bewertungen

- Audio Wiring Guide 92: Twenty-Foot Cable ResistanceDokument5 SeitenAudio Wiring Guide 92: Twenty-Foot Cable Resistancebhansalianiket96Noch keine Bewertungen

- Life - Death Poems - 0014-0018Dokument5 SeitenLife - Death Poems - 0014-0018bhansalianiket96Noch keine Bewertungen

- Life - Death Poems - 0008-0009Dokument2 SeitenLife - Death Poems - 0008-0009bhansalianiket96Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Micropolar Fluid Flow Near The Stagnation On A Vertical Plate With Prescribed Wall Heat Flux in Presence of Magnetic FieldDokument8 SeitenMicropolar Fluid Flow Near The Stagnation On A Vertical Plate With Prescribed Wall Heat Flux in Presence of Magnetic FieldIJBSS,ISSN:2319-2968Noch keine Bewertungen

- Translation EquivalenceDokument6 SeitenTranslation EquivalenceJamal Anwar TahaNoch keine Bewertungen

- Vidura College Marketing AnalysisDokument24 SeitenVidura College Marketing Analysiskingcoconut kingcoconutNoch keine Bewertungen

- CGV 18cs67 Lab ManualDokument45 SeitenCGV 18cs67 Lab ManualNagamani DNoch keine Bewertungen

- Tender34 MSSDSDokument76 SeitenTender34 MSSDSAjay SinghNoch keine Bewertungen

- B. Ing Kls 6Dokument5 SeitenB. Ing Kls 6siskaNoch keine Bewertungen

- Colour Ring Labels for Wireless BTS IdentificationDokument3 SeitenColour Ring Labels for Wireless BTS Identificationehab-engNoch keine Bewertungen

- Ca. Rajani Mathur: 09718286332, EmailDokument2 SeitenCa. Rajani Mathur: 09718286332, EmailSanket KohliNoch keine Bewertungen

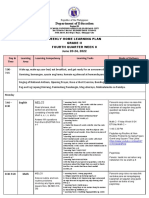

- Department of Education: Weekly Home Learning Plan Grade Ii Fourth Quarter Week 8Dokument8 SeitenDepartment of Education: Weekly Home Learning Plan Grade Ii Fourth Quarter Week 8Evelyn DEL ROSARIONoch keine Bewertungen

- Scharlau Chemie: Material Safety Data Sheet - MsdsDokument4 SeitenScharlau Chemie: Material Safety Data Sheet - MsdsTapioriusNoch keine Bewertungen

- Sieve Shaker: Instruction ManualDokument4 SeitenSieve Shaker: Instruction ManualinstrutechNoch keine Bewertungen

- MMW FinalsDokument4 SeitenMMW FinalsAsh LiwanagNoch keine Bewertungen

- Amana PLE8317W2 Service ManualDokument113 SeitenAmana PLE8317W2 Service ManualSchneksNoch keine Bewertungen

- Give Five Examples Each of Nature Having Reflection Symmetry and Radial Symmetry Reflection Symmetry Radial Symmetry Butterfly StarfishDokument12 SeitenGive Five Examples Each of Nature Having Reflection Symmetry and Radial Symmetry Reflection Symmetry Radial Symmetry Butterfly StarfishANNA MARY GINTORONoch keine Bewertungen

- HistoryDokument144 SeitenHistoryranju.lakkidiNoch keine Bewertungen

- Biomotor Development For Speed-Power Athletes: Mike Young, PHD Whitecaps FC - Vancouver, BC Athletic Lab - Cary, NCDokument125 SeitenBiomotor Development For Speed-Power Athletes: Mike Young, PHD Whitecaps FC - Vancouver, BC Athletic Lab - Cary, NCAlpesh Jadhav100% (1)

- Optimization of The Spray-Drying Process For Developing Guava Powder Using Response Surface MethodologyDokument7 SeitenOptimization of The Spray-Drying Process For Developing Guava Powder Using Response Surface MethodologyDr-Paras PorwalNoch keine Bewertungen

- Amar Sonar BanglaDokument4 SeitenAmar Sonar BanglaAliNoch keine Bewertungen

- Ground Water Resources of Chennai DistrictDokument29 SeitenGround Water Resources of Chennai Districtgireesh NivethanNoch keine Bewertungen

- EE290 Practice 3Dokument4 SeitenEE290 Practice 3olgaNoch keine Bewertungen

- The Online Medical Booking Store Project ReportDokument4 SeitenThe Online Medical Booking Store Project Reportharshal chogle100% (2)

- Feasibility StudyDokument47 SeitenFeasibility StudyCyril Fragata100% (1)

- Calibration Motion Control System-Part2 PDFDokument6 SeitenCalibration Motion Control System-Part2 PDFnurhazwaniNoch keine Bewertungen

- Failure Analysis Case Study PDFDokument2 SeitenFailure Analysis Case Study PDFScott50% (2)

- 10 Slides For A Perfect Startup Pitch DeckDokument6 Seiten10 Slides For A Perfect Startup Pitch DeckZakky AzhariNoch keine Bewertungen

- Time Table For Winter 2023 Theory ExaminationDokument1 SeiteTime Table For Winter 2023 Theory ExaminationSushant kakadeNoch keine Bewertungen

- LON-Company-ENG 07 11 16Dokument28 SeitenLON-Company-ENG 07 11 16Zarko DramicaninNoch keine Bewertungen

- ĐỀ SỐ 3Dokument5 SeitenĐỀ SỐ 3Thanhh TrúcNoch keine Bewertungen

- Computer Portfolio (Aashi Singh)Dokument18 SeitenComputer Portfolio (Aashi Singh)aashisingh9315Noch keine Bewertungen

- Exor EPF-1032 DatasheetDokument2 SeitenExor EPF-1032 DatasheetElectromateNoch keine Bewertungen