Beruflich Dokumente

Kultur Dokumente

Camara de Espuma

Hochgeladen von

guzmanitaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Camara de Espuma

Hochgeladen von

guzmanitaCopyright:

Verfügbare Formate

January 15, 2010

Foam 191a

TECHNICAL DATA

Foam chambers Model FC

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058 Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

1. DESCRIPTION

The Chemguard Model FC 2.5, 3.0, 4.0 & 6.0 Foam Chambers consist of a foam expansion chamber and an integral foam maker. The foam chamber is installed on a flammable liquid storage tank just below the roof joint. The foam solution is piped to the chamber from outside the hazard area. Upon entering the chamber, the foam solution is expanded and then discharged against a deflector inside the storage tank. The deflector directs the foam against the inside wall of the storage tank. This reduces the submergence of the foam and agitation of the fuel surface. (NFPA Type II Application)

Features

(4) models available to cover all flow requirements Top of chamber has handle, which simplifies inspection access to the vapor seal Frangible glass vapor seal is provided. The glass is scored on one side and designed to break at a minimum 10 psi but not greater than 20 psi. Chamber manufactured in ASTM A36 carbon steel with a 304 stainless steel screen covering the foam maker air inlets All foam chamber inlets and outlets are flat faced and drilled to ANSI 150 lb. standard. Flange gaskets are provided. Choice of two styles of deflector is available (split or solid) Finished with durable red epoxy paint A stainless steel inlet orifice is supplied. Chemguard sizes the orifice based on the foam solution flow requirements and the foam solution inlet pressure available at the base of the foam chamber.

2. LISTINGS AND APPROVALS

UL Listed

3. technical data

Specifications:

See Table 1

Material Standards:

Chamber - ASTM A36 Carbon Steel Screen - 304 stainless steel Inlet Orifice - Stainless Steel

Viking Technical Data may be found on The Viking Corporations Web site at http://www.vikinggroupinc.com. The Web site may include a more recent edition of this Technical Data Page.

Ordering Information :

Size 2-1/2 3 4 6 Flow: 58-177 GPM 101-292 GPM 180-642 GPM 540-1090 GPM

Table 1: Foam Chamber Specifications Part No. F15065 F15070 F15075 F15080 Weight 60 lbs. 100 lbs. 145 lbs. 270 lbs. When placing a Foam Chamber Order, you must provide the Starting Pressure and desired Flow Rate. A properly sized orifice will be made to order and installed in the Foam Chamber.

4. Installation

Foam chambers are compatible with all types of foam concentrate; protein, fluoroprotein, AFFF, and AR-AFFF. They are generally installed on the side wall of vertical storage tanks above the maximum product level. Piping coupled to the unit can be linked to a fixed foam proportioning system, or terminated a safe distance from the tank, where foam solution can be delivered via mobile fire apparatus or portable foam proportioning equipment.

Determining Orifice Size

After determining the required foam flow rate and available pressure, the orifice must be sized using the following formula:

d=

Form No. F_012201

Q 29.836 kP

1/2

1/2

Where: d = orifice (in.) Q = Solution Flow Rate (GPM) P = Pressure at orifice inlet (PSI) k = Orifice Coefficient = 0.61 Revised page replaces page 191a-d dated December 12, 2008. (Revised Figure 2.)

Foam 191b

January 15, 2010

TECHNICAL DATA

Foam chambers Model FC

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058 Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

Table 2: Accessories Size Flow: Part No. F15066 2-1/2 58-177 GPM F15067 F15068 F15069 F15071 3 101-292 GPM F15072 F15073 F15074 F15076 4 180-642 GPM F15077 F15078 F15079 F15081 6 540-1090 GPM F15082 F15083 F15084 Description Solid Deflector Split Deflector Mounting Pad Spare Vapor Seal Assembly Solid Deflector Split Deflector Mounting Pad Spare Vapor Seal Assembly Solid Deflector Split Deflector Mounting Pad Spare Vapor Seal Assembly Solid Deflector Split Deflector Mounting Pad Spare Vapor Seal Assembly Weight 5 lbs. 5 lbs. 15 lbs. 1 lbs. 10 lbs. 10 lbs. 20 lbs. 1 lbs. 20 lbs. 20 lbs. 35 lbs. 1 lbs. 30 lbs. 30 lbs. 50 lbs. 2 lbs.

5. OPERATION

The Model FC Foam Chambers produce foam by introducing air into the foam solution stream. Foam solution can be delivered to the foam chamber in a variety of ways as previously noted. Air is drawn into the foam maker through a series of annular holes located around the integral foam maker. To prevent obstruction, the air inlet holes are protected by a stainless steel screen selected with a perforation size designed to exclude most known nesting birds and insects. The open area of the screen is designed to be not less than the total area of the foam maker air inlet holes. NOTICE: The owner is responsible for maintaining the fire protection system and devices in proper operating condition. For minimum maintenance and inspection requirements, refer to recognized standards such as those produced by NFPA, LPC, and VdS which describe care and maintenance of sprinkler systems. In addition, the Authority Having Jurisdiction may have additional maintenance, testing and inspection requirements which must be followed. WARNING: Any system maintenance or testing which involves placing a control valve or detection system out of service may eliminate the Fire Protection of that system. Prior to proceeding, notify all Authorities Having Jurisdiction. Consideration should be given to employment of a Fire Patrol in the affected area. Viking Foam Products are available through a network of domestic and international distributors. See the Viking web site for closest distributor or contact The Viking Corporation. For details of warranty, refer to Vikings current list price schedule or contact Viking directly.

6. inspections, tests and maintenance

7. Availability

8. guarantee

January 15, 2010

Foam 191c

TECHNICAL DATA

Foam chambers Model FC

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058 Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

FC2.5 A B C D E F G H I J K L M N O P Q 29" 17.5" 10.625" 7" 2.5" 3.25" 6.5" 8" 4" 2.875" 5.5" 0.75" 4.5" 7.5" 0.75" 8" 12"

FC 3 34.75" 22.25" 12.75" 9" 3" 4.25" 8.5" 9.5" 6" 3.5" 6" 0.75" 6.625" 9.5" 0.75" 12" 18"

FC 4 38.5" 23.5" 14.75" 10" 4" 5.375" 10.5" 11" 8" 4.5" 7.5" 0.75" 8.625" 11.75" 0.875" 16" 24"

FC 6 44.75" 27.5" 18" 12" 6" 6.375" 12.5" 12" 10" 6.625" 9.5" 0.875" 10.75" 14.25" 1" 20" 30"

Figure 1 - Dimensions

Foam 191d

January 15, 2010

TECHNICAL DATA

Foam chambers Model FC

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058 Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

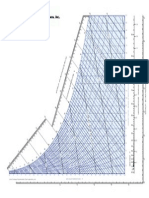

Figure 2 - Flow Range Charts

Form No. F_012201 Revised page replaces page 191a-d dated December 12, 2008. (Revised Figure 2.)

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- U BolsDokument1 SeiteU BolsguzmanitaNoch keine Bewertungen

- Design Features: SL-KZ-004 Rev. ADokument2 SeitenDesign Features: SL-KZ-004 Rev. AguzmanitaNoch keine Bewertungen

- Verbs UsosDokument43 SeitenVerbs UsosguzmanitaNoch keine Bewertungen

- Guardian 407 Vent: Guard Your Product. Guard Your Drivers. Guard Your BusinessDokument2 SeitenGuardian 407 Vent: Guard Your Product. Guard Your Drivers. Guard Your BusinessguzmanitaNoch keine Bewertungen

- Camara de EspumaDokument4 SeitenCamara de EspumaguzmanitaNoch keine Bewertungen

- Guardian 407 Vent: Guard Your Product. Guard Your Drivers. Guard Your BusinessDokument2 SeitenGuardian 407 Vent: Guard Your Product. Guard Your Drivers. Guard Your BusinessguzmanitaNoch keine Bewertungen

- Psychrometric Sist. INGLESDokument1 SeitePsychrometric Sist. INGLESguzmanitaNoch keine Bewertungen

- 1210 Valvulas CheckDokument24 Seiten1210 Valvulas CheckguzmanitaNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)