Beruflich Dokumente

Kultur Dokumente

Single Stage Air Compressor

Hochgeladen von

Izzul HazimCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Single Stage Air Compressor

Hochgeladen von

Izzul HazimCopyright:

Verfügbare Formate

1.0 ABSTRACT A vital part of many commercial, manufacturing, industrial, and automotive applications is an air compressor.

Air compressors are versatile mechanical tools that use one or numerous pistons to pump compressed air into a defined space. There are three basic types of air compressors: reciprocating, rotary, and centrifugal. These general types of air compressors can be further categorized into single or multi stage, packaged or non-packaged, air cooled or water cooled, and lubricated or nonlubricated. There are two types of piston-like air compressors: single-stage, and two-stage. These piston-like air compressors will keep the storage tank at a predetermined PSI (Pounds per Square Inch). The air compressors motor will turn off and turn on as needed to insure the proper PSI. Single-stage air compressors have one or more cylinders that pump air directly into the storage tank. Two-stage air compressors use two or more cylinders to pump air into another cylinder before pumping the air into the storage tank. Most singlestage air compressors are sufficient for normal use. Two-stage air compressors are used primarily by industries that have applications that require high-pressure. Compact air compressors are popular for easy around-the-home projects. These small air compressors do not have a storage tank; therefore they must always be running to supply the air needed for a project. Many glue guns, caulking guns, and painting guns use compact air compressors. Air compressors require the proper size hoses for optimal performance. Purchasing the right size and length of hose will keep PSI loss to a minimal. Check the hose for cracks, sun damage, or cuts often. If any of these are found, replace your hose immediately. Any leaks that may be caused by a faulty hose will add to an air compressors operating cost. Air compressors should be approached with caution. Secure the hose to guarantee minimal damage should your hose break free from the air compressor. Aftercoolers are heat exchangers that cool the heated compressed air. Once the compressed air has been condensed, the removal of the excess moisture can follow. Keeping the compressed air free from moisture is essential to most applications requiring air compressors. Air compressors will last much longer, and be more efficient, if they remain free from moisture.

Air compressors range in horse power, performance, price, operating cost, and ease of use. Always check hoses, values, bearings, and the electrical outlet of all air compressors. This will not only add to the longevity of the air compressor, but keep the operator safe.

2.0 OBJECTIVE 2.1 EXPERIMENT 1 To investigate the motor output power. 2.2 EXPERIMENT 2 To investigate the air flow rate and volume discharge of compressor cylinder. 2.3 EXPERIMENT 3 To investigate the compressor indicated power and mechanical efficiency of compressor. 2.4 EXPERIMENT 4 To investigate the compressor isothermal power and isothermal efficiency. 2.5 EXPERIMENT 5 To investigate the time taken to fully occupied the compressor receiver tank.

3.0 PROCEDURE 3.1 EXPERIMENT 1 1. Connect plug to 1 phase 240V AC power supply 2. Switch on ELCB and main switch on the control panel. 3. Make sure all the meters is showing zero before experiment except temperature meter. If the meter initial value is not zero set it by press the up button. 4. Adjust the compressor to desirable speed by the speed controller on the inverter. 5. Push the run button on the inverter operation panel and ensure that the run key is light. 6. Record down motor speed (RPM), power (Watt),and torque (Nm) each 30s time interval 7. The data continuous mark down until the pressure is automatically cut off. 8. Release air in receiver tank before next experiment. 9. Repeat step 3 to 7 by changing the speed of compressor to next desirable speed.

10. Plot graph of the pressure against temperature, indicated power against compressor speed and efficiency of compressor against compressor speed.

3.2 EXPERIMENT 2 1. Connect plug to 1 phase 240V AC power supply 2. Switch on ELCB and main switch on the control panel. 3. Make sure all the meters is showing zero before experiment except temperature meter. If the meter initial value is not zero set it by press the up button. 4. Adjust the compressor to desirable speed by the speed controller on the inverter. 5. Push the run button on the inverter operation panel and ensure that the run key is light. 6. Record down motor speed (RPM), power (Watt), and torque (Nm) each 30s time interval 7. The data continuous mark down until the pressure is automatically cut off. 8. Release air in receiver tank before next experiment. 9. Repeat step 3 to 7 by changing the speed of compressor to next desirable speed. 10. Plot graph of the pressure against temperature, indicated power against compressor speed and efficiency of compressor against compressor speed.

3.3 EXPERIMENT 3 1. Connect plug to 1 phase 240V AC power supply 2. Switch on ELCB and main switch on the control panel. 3. Make sure all the meters is showing zero before experiment except temperature meter. If the meter initial value is not zero set it by press the up button.

4. Adjust the compressor to desirable speed by the speed controller on the inverter. 5. Push the run button on the inverter operation panel and ensure that the run key is light. 6. Record down the pressure (P1, P2) motor speed (RPM), power (Watt),and torque (Nm) each 30s time interval 7. The data continuous mark down until the pressure is automatically cut off. 8. Release air in receiver tank before next experiment. 9. Repeat step 3 to 7 by changing the speed of compressor to next desirable speed. 10. Plot graph of the pressure against temperature, indicated power against compressor speed and efficiency of compressor against compressor speed.

3.4 EXPERIMENT 4 1. Connect plug to 1 phase 240V AC power supply 2. Switch on ELCB and main switch on the control panel. 3. Make sure all the meters is showing zero before experiment except temperature meter. If the meter initial value is not zero set it by press the up button. 4. Adjust the compressor to desirable speed by the speed controller on the inverter. 5. Push the run button on the inverter operation panel and ensure that the run key is light. 6. Record down the pressure (P1,P2)each 30s time interval 7. The data continuous mark down until the pressure is automatically cut off. 8. Release air in receiver tank before next experiment. 9. Repeat step 3 to 7 by changing the speed of compressor to next desirable speed. 10. Plot graph of the pressure against temperature, indicated power against compressor speed and efficiency of compressor against compressor speed.

3.5 EXPERIMENT 5 1. Connect plug to 1 phase 240V AC power supply 2. Switch on ELCB and main switch on the control panel.

3. Make sure all the meters is showing zero before experiment except temperature meter. If the meter initial value is not zero set it by press the up button. 4. Adjust the compressor to desirable speed by the speed controller on the inverter. 5. Push the run button on the inverter operation panel and ensure that the run key is light. 6. Record down the tank pressure (P1) each 30s time interval 7. The data continuous mark down until the pressure is automatically cut off. 8. Release air in receiver tank before next experiment. 9. Repeat step 3 to 7 by changing the speed of compressor to next desirable speed. 10. Plot graph of the tank pressure against time (s).

4.0 RESULTS AND DISCUSSION Experiment 1 Motor Speed Controller = 10Hz Time Data RPM Torque (NM) Motor Input Power (kW) Motor Output Power (kW) Motor Efficiency (%) 0 18.501 15.510 13.486 11.590 5.375 4.327 2.357 1.239 0 0.108 0.114 0.110 0.112 0.074 0.057 0.034 0.017 0 0.588 0.735 0.818 0.969 1.389 1.322 1.457 1.437

0 0 0

30s 464 2.1

60s 442 2.35

90s 418 2.52

120s 366 2.93

150s 218 3.27

180s 139 3.93

210s 80 4.1

240s 40 4.25

Motor Speed Controller = 20Hz Time Data RPM Torque (NM) Motor Input Power (kW) Motor Output Power (kW) Motor Efficiency (%) 0 41.08 12.11 35.51 35.88 29.92 28.58 26.31 27.63 0 0.33 0.11 0.36 0.40 0.35 0.37 0.38 0.39 0 0.815 0.941 1.021 1.101 1.183 1.295 1.434 1.394

0 0 0

30s 987 3.06

60s 916 3.49

90s 872 3.97

120s 898 4.2

150s 763 4.43

180s 752 4.7

210s 749 4.81

240s 743 4.95

Motor Speed Controller = 30Hz Time Data RPM Torque (NM) Motor Input Power (kW) Motor Output Power (kW) Motor Efficiency (%) 0 67.95 9.96 56.94 54.68 52.70 51.00 46.53 39.05 0 0.68 0.11 0.71 0.73 0.74 0.75 0.74 0.62 0 0.999 1.145 1.244 1.332 1.404 1.466 1.589 1.593

0 0 0

30s 1507 3.92

60s 1450 4.47

90s 1406 4.81

120s 1361 5.11

150s 1323 5.34

180s 1277 5.59

210s 1232 5.73

240s 1200 4.95

Motor Speed Controller = 40Hz Time Data RPM Torque (NM) Motor Input Power (kW) Motor Output Power (kW) Motor Efficiency (%) 0 86.03 8.53 73.95 71.04 67.94 65.61 0 1.03 0.11 1.07 1.10 1.10 1.10 0 1.199 1.336 1.447 1.542 1.619 1.681

0 0 0

30s 1998 4.61

60s 1935 5.09

90s 1878 5.44

120s 1819 5.75

150s 1765 5.95

180s 1718 6.13

210s -

240s -

Motor Speed Controller = 50Hz Time Data RPM Torque (NM) Motor Input Power

0 0 0 0

30s 2636 4.22 1.065

60s 2583 4.7 1.345

90s 2514 5.21 1.307

120s 2453 5.59 1.416

150s 2395 5.9 1.426

180s 2332 6.07 1.506

210s -

240s -

(kW) Motor Output Power (kW) Motor Efficiency (%) 0 119.39 8.48 104.96 101.42 103.78 98.44 0 1.27 0.11 1.37 1.44 1.48 1.48 -

Output Power vs Time

1.6 1.4 1.2 1 0.8 0.6 0.4 0.2 0 0 30 60 90 Time 120 150 180 210 10Hz 20Hz 30Hz 40Hz 50Hz

As we can see from the graph, the output power increases over time. The output power for 50Hz is higher than the others because of the compressor need lot of energy for running at speed.

Experiment 2 Motor Speed Controller = 10Hz Time Data RPM (motor) RPM (compressor) Air Flow Indicated

Output Power

0 0.00 0.00 0.00

30s

60s

90s

120s

150s

180s

210s 80.00 30.48 8.53

240s 40.00 15.24 4.27

464.00 442.00 418.00 366.00 218.00 139.00 176.78 168.40 159.26 139.45 49.50 47.15 44.59 39.04 83.06 23.26 52.96 14.83

Motor Speed Controller = 20Hz Time Data RPM (motor) RPM (compressor) Air Flow Indicated

0 0 0.00 0.00

30s 987

60s 916

90s 872

120s 898

150s 763

180s 752

210s 749

240s 743

376.05 349.00 332.23 342.14 290.70 286.51 285.37 283.08 105.29 97.72 93.02 95.80 81.40 80.22 79.90 79.26

Motor Speed Controller = 30Hz Time Data RPM (motor) RPM (compressor) Air Flow Indicated

0 0 0.00 0.00

30s 1507

60s 1450

90s 1406

120s 1361

150s 1323

180s 1277

210s 1232

240s 1200

574.17 552.45 535.69 518.54 504.06 486.54 469.39 457.20 160.77 154.69 149.99 145.19 141.14 136.23 131.43 128.02

Motor Speed Controller = 40Hz Time Data RPM (motor) RPM (compressor) Air Flow Indicated

0 0 0.00 0.00

30s 1998

60s 1935

90s 1878

120s 1819

150s 1765

180s 1718

210s 0 0.00 0.00

240s 1998 761.24 213.15

761.24 737.24 715.52 693.04 672.47 654.56 213.15 206.43 200.35 194.05 188.29 183.28

Motor Speed Controller = 50Hz Time Data RPM (motor) RPM (compressor) Air Flow Indicated

0 0

30s 2636

60s 2583

90s 2514

120s 2453

150s 2395 912.50 255.50

180s 2332 888.49 248.78

210s -

240s -

0.00 1004.32 984.12 957.83 934.59 0.00 281.21 275.55 268.19 261.69

Air Flow Indicated vs Time

300 Air Flow Indicated 250 200 150 100 50 0 0 30 60 90 Time 120 150 180 210 10Hz 20Hz 30Hz 40Hz 50Hz

The pattern of air flow indicator for 10Hz, 20Hz, 30Hz, 40Hz and 50Hz are increasing at the beginning and slowly decreasing at the end. This is because the compressor need a lot of air at the beginning to full the tank and when tank are filled the air intake to the compressor reduce.

Experiment 3 Motor Speed Controller = 10Hz Time Data P1 (bar) P2 (bar) RPM Torque (Nm) Power (kW) Indicated Power

0 0 0 0 0 0 0

30s -0.09 0.4 464 2.1 0.108 3.192

60s -0.08 0.6 442 2.35 0.114 7.307

90s -0.06 0.8 418 2.52 0.110

120s -0.01 0.8 366 2.93 0.112

150s -0.01 0.9 218 3.27 0.074

180s -0.01 1.0 139 3.93 0.057 9.100

210s -0.01 0.8 80 4.1 0.034 2.753

240s -0.01 0.6 40 4.25 0.017 0.662

14.393 17.542 10.451

Motor Speed Controller = 20Hz Time Data P1 (bar) P2 (bar) RPM Torque (Nm) Power (kW) Indicated Power

0 0 0 0 0 0 0.00

30s -0.4 0.9 987 3.06 0.33 47.31

60s -0.33 1.5 916 3.49 0.11

90s -0.31 2.0 872 3.97 0.36

120s -0.2 2.5 898 4.2 0.40 1,687. 09

150s -0.21 2.9 763 4.43 0.35 2,738. 45

180s -0.17 3.3 752 4.7 0.37 4,839. 93

210s -0.16 3.7 749 4.81 0.38 8,208. 08

240s -0.13 4.0 743 4.95 0.39 11,791 .35

229.73 651.47

Motor Speed Controller = 30Hz Time Data P1 (bar) P2 (bar) RPM Torque (Nm) Power (kW) Indicated Power

0 0 0 0.00 0 0 0.00

30s -0.71 1.5

60s -0.64 2.3

90s -0.54 3.0

120s -0.52 3.7

150s -0.43 4.4

180s -0.46 5.0

210s 0.41 5.6

240s 0.37 6.1

574.17 552.45 535.69 518.54 504.06 486.54 469.39 457.20 1507 1450 1406 1361 1323 1277 1232 1200 3.92 247.53 4.47 1,210. 35 4.81 3,641. 09 5.11 9,841. 47 5.34 5.59 5.73 4.95 19,194 35,544 62,644 96,232 .94 .53 .81 .12

Motor Speed Controller = 40Hz Time Data P1 (bar) P2 (bar) RPM Torque (Nm) Power (kW) Indicated Power

0 0 0 0 0 0 0.00

30s -0.104 2.5 1998 4.61 1.03 1,854. 21

60s -0.097 3.4 1935 5.09 0.11 6,765. 13

90s -0.086 4.3 1878 5.44

120s -0.080 5.2 1819 5.75

150s -0.068 6.0 1765 5.95

180s -0.065 6.7 1718 6.13

210s -

240s -

1.07 1.10 1.10 1.10 19,613 51,655 90,781 158,33 .14 .70 .27 3.64

Motor Speed Controller = 50Hz Time Data P1 (bar) P2 (bar) RPM Torque (Nm) Power (kW) Indicated Power

0 0 0 0 0 0 0.00

30s -0.154 1.6 2636 4.22 1.27 313.11

60s -0.141 2.4 2583 4.7 0.11 1,446. 96

90s -0.130 3.6 2514 5.21 1.37 8,401. 97

120s -0.120 4.6 2453 5.59

150s -0.112 5.6 2395 5.9

180s -0.108 6.6 2332 6.07

210s -

240s -

1.44 1.48 1.48 28,084 63,820 146,40 .94 .87 9.08

Indicated Power vs Time

180000 160000 140000 120000 100000 80000 60000 40000 20000 0 0 50 100 Time 150 200

Indicated Power

10 Hz 20Hz 30Hz 40Hz 50Hz

For experiment 3 its show that power consumption increasing with time increase. Its because single air compressor need high power to generate the compress air inside the tank. The higher the Hz the higher power need.

Experiment 4 Motor Speed Controller = 10Hz Time Data T1 (C) P1 (bar) P2 (bar) RPM Torque (Nm)

0 0 0 0 0 0

30s 38.0 -0.09 0.4 464 2.1

60s 38.7 -0.08 0.6 442 2.35

90s 39.2 -0.06 0.8 418 2.52

120s 39.4 -0.01 0.8 366 2.93

150s 38.7 -0.01 0.9 218 3.27

180s 37.6 -0.01 1.0 139 3.93

210s 37.3 -0.01 0.8 80 4.1

240s 37.2 -0.01 0.6 40 4.25

Motor Speed Controller = 20Hz Time Data T1 (C) P1 (bar) P2 (bar) RPM Torque (Nm)

0 0 0 0 0 0

30s 44.2 -0.09 0.4 448 1.70

60s 47.2 -0.08 0.6 428 2.10

90s 49.6 -0.06 0.8 378 2.47

120s 51.7 -0.01 0.8 244 3.49

150s 53.7 -0.01 0.9 54 3.50

180s 55.6 -0.01 1.0 164 3.57

210s 57.2 -0.01 0.8 170 3.58

240s 58.7 -0.01 0.6 25 3.71

Motor Speed Controller = 30Hz Time Data T1 (C) P1 (bar) P2 (bar) RPM Torque (Nm)

0 0 0 0 0 0

30s 63.6 -0.76 1.2 1538 3.51

60s 68.6 -0.67 2.0 1468 4.11

90s 73.2 -0.61 2.8 1420 4.50

120s 77.2 -0.52 3.5 1370 4.85

150s 80.6 -0.52 4.1 1326 5.06

180s 83.6 -0.41 4.8 1280 5.30

210s 86.3 -0.44 5.3 1235 5.52

240s 88.4 -0.39 5.9 1185 5.66

Motor Speed Controller = 40Hz Time Data T1 (C) P1 (bar) P2 (bar) RPM Torque (Nm)

0 0 0 0 0 0

30s 90.4 -0.76 1.2 1538 3.51

60s 95.9 -0.67 2.0 1468 4.11

90s 100.3 -0.61 2.8 1420 4.50

120s 104.3 -0.52 3.5 1370 4.85

150s 107.9 -0.52 4.1 1326 5.06

180s 110.9 -0.41 4.8 1280 5.30

210s -

240s -

Motor Speed Controller = 50Hz Time Data T1 (C) P1 (bar) P2 (bar) RPM Torque (Nm)

0 0 0 0 0 0

30s 91.1 -1.51 1.61 2625 4.17

60s 97.1 -1.37 2.70 2552 4.83

90s 104.2 -1.29 3.80 2487 5.26

120s 110.5 -1.19 4.90 2430 5.62

150s 116.0 -1.11 5.80 2368 5.86

180s 121.4 -1.00 6.80 2306 6.05

210s -

240s -

Torque vs Time

7 6 5 Torque 4 3 2 1 0 0 50 100 Time 150 200 10Hz 20Hz 30Hz 40Hz 50Hz

Experiment 5 show that torque increase when time increase. As rotational motion increases, the amount of friction and constraints on the materials. If torque were to increases linearly,

the amount of the friction would also increase, and depending on the amount of friction/heat the materials could take, would eventually cause a breakdown.

Experiment 5 Motor Speed Controller = 10Hz Time Data Pt (bar)

0 0

30s 0.10

60s 0.40

90s 0.80

120s 1.00

150s 1.10

180s 1.18

210s 1.19

240s 1.20

Motor Speed Controller = 20Hz Time Data Pt (bar)

0 0

30s 0.85

60s 1.55

90s 1.90

120s 2.70

150s 3.40

180s 4.00

210s 4.60

240s 5.25

Motor Speed Controller = 30Hz Time Data Pt (bar)

0 0

30s 1.15

60s 2.05

90s 2.80

120s 3.60

150s 4.40

180s 5.00

210s 5.60

240s 6.25

Motor Speed Controller = 40Hz Time Data Pt (bar)

0 0

30s 1.30

60s 2.55

90s 3.50

120s 4.60

150s 5.30

180s 6.30

210s -

240s -

Motor Speed Controller = 50Hz Time Data

30s

60s

90s

120s

150s

180s

210s

240s

Pt (bar)

1.60

2.90

4.10

5.20

6.20

7.30

Tank Pressure vs Time

8 Tank Pressure 6 4 2 0 0 50 100 Time 150 200 10Hz 20Hz 30Hz 40Hz 50Hz

For experiment 5 the pressure increase with increase of time. To compress air inside the tank need pressure so to achieve desire amount of air compressor pressure will increase until its full fill the quantity its need.

5.0 CONCLUSION In this experiment we learn that the relationship between the RPM, motor output power, air flow rate and volume discharge of compressor cylinder, mechanical efficiency of compressor, compressor isothermal power and isothermal efficiency and time taken to fully occupied the compressor receiver tank. We also learn how to operate the compressor and its safety and precaution steps.

Das könnte Ihnen auch gefallen

- Separating and Throttling CalorimeterDokument11 SeitenSeparating and Throttling CalorimeterSims Gift Shiba67% (3)

- Fmcpra2 Lab Report PDFDokument20 SeitenFmcpra2 Lab Report PDFNzeza Carine100% (1)

- Scotch Yolk Mechanism Lab Report 2010-ME-206Dokument7 SeitenScotch Yolk Mechanism Lab Report 2010-ME-206Syed Imtinan Ahmed0% (1)

- Series and Parallel PumpsDokument8 SeitenSeries and Parallel PumpsLanyoong67% (3)

- Trial On Reciprocating CompressorDokument3 SeitenTrial On Reciprocating CompressorHardik S. Borse100% (1)

- Air Compressor Performance TestDokument7 SeitenAir Compressor Performance TestRajneeshKrNoch keine Bewertungen

- Experiment 3 Air Compressor PDFDokument9 SeitenExperiment 3 Air Compressor PDFah qian100% (1)

- U4526113 Rankine Cycle Lab ReportDokument7 SeitenU4526113 Rankine Cycle Lab ReportTegan Doblinger100% (1)

- Two-Stage Air Compressor Lab ReportDokument11 SeitenTwo-Stage Air Compressor Lab ReportWill Haynes83% (6)

- Experiment No.:-8: Study The Working and Construction of The Reciprocating Air CompressorDokument6 SeitenExperiment No.:-8: Study The Working and Construction of The Reciprocating Air Compressordhirendra singhNoch keine Bewertungen

- Experiment No. 2 Steam Quality Determination: GradeDokument22 SeitenExperiment No. 2 Steam Quality Determination: GradeAli Requiso Mahmud100% (1)

- Experiment 2 Single Stage CompressorDokument16 SeitenExperiment 2 Single Stage CompressorTshepo Moloto100% (1)

- Dryness Fraction of Steam LabDokument17 SeitenDryness Fraction of Steam LabRoneil Napier100% (3)

- Lab Report 1Dokument26 SeitenLab Report 1ParvinNoch keine Bewertungen

- Calibration of Bourdon Pressure Gage PDFDokument3 SeitenCalibration of Bourdon Pressure Gage PDFMohammed Cardoza100% (1)

- Pitot Tube Exper.Dokument4 SeitenPitot Tube Exper.AbdulrazzaqAL-Maliky100% (1)

- Experiment 4, 5, 6 (Single, Series and Parallel Centrifugal Pumps)Dokument11 SeitenExperiment 4, 5, 6 (Single, Series and Parallel Centrifugal Pumps)Safi Ullah WarraichNoch keine Bewertungen

- Lab Report For Venturi MeterDokument9 SeitenLab Report For Venturi MeterRichard Puni89% (44)

- Full Report Bernoulli Experiment TiqaDokument19 SeitenFull Report Bernoulli Experiment TiqaAtiqah Samad100% (5)

- Lab3E6 - Series and Parallel Pump PDFDokument13 SeitenLab3E6 - Series and Parallel Pump PDFShimal De Silva50% (2)

- Energy Losses in BendsDokument8 SeitenEnergy Losses in BendsVikramSingh0% (3)

- Experiment No. 1 Hydraulic RamDokument13 SeitenExperiment No. 1 Hydraulic RamAlex Luminarias67% (6)

- Experiment 2 - Calibration of Pressure Gauge2Dokument8 SeitenExperiment 2 - Calibration of Pressure Gauge2Śūpęr MòÐó60% (5)

- Bernoulli S Principle Demonstration Lab ReportDokument18 SeitenBernoulli S Principle Demonstration Lab ReportHasan RabyNoch keine Bewertungen

- Two Stage Air CompressorDokument5 SeitenTwo Stage Air Compressorkhalijahjamal0% (1)

- Experiment 1 Bare and Lagged PipesDokument23 SeitenExperiment 1 Bare and Lagged PipesTJ ArciagaNoch keine Bewertungen

- Fluid Mechanics ReportDokument13 SeitenFluid Mechanics ReportChan Jiun Haur100% (3)

- Experiment 3 Reaction TurbineDokument20 SeitenExperiment 3 Reaction TurbineAnonymous T7vjZG4ot100% (1)

- Report 7Dokument9 SeitenReport 7Muizzuddin Saleh100% (4)

- Experiment 6 (Calibration of Temperature Measuring Devices - A4)Dokument16 SeitenExperiment 6 (Calibration of Temperature Measuring Devices - A4)Jamiel CatapangNoch keine Bewertungen

- Demonstration On Bernoulli's TheoremDokument22 SeitenDemonstration On Bernoulli's TheoremMahe RukhNoch keine Bewertungen

- Experiment To Determine The Centre of Pressure On A Partially Submerged Plane SurfaceDokument3 SeitenExperiment To Determine The Centre of Pressure On A Partially Submerged Plane SurfaceUditha Wedage50% (2)

- Pipe Surge and Water HammerDokument10 SeitenPipe Surge and Water HammerDominic Kipkemoi100% (3)

- Fluid Lab - Pump in Parallel and SeriesDokument8 SeitenFluid Lab - Pump in Parallel and SeriesYukiYukina100% (2)

- Centrifugal Pump Lab ReportDokument16 SeitenCentrifugal Pump Lab Reportapi-31051928380% (5)

- Bernoulli Theorem DemonstrationDokument27 SeitenBernoulli Theorem DemonstrationmanzahuhuNoch keine Bewertungen

- Lab Report Performance Characteristics of Centrifugal PumpDokument10 SeitenLab Report Performance Characteristics of Centrifugal PumpRam Krishna Singh85% (33)

- Change of State of Gases ExperimentDokument6 SeitenChange of State of Gases ExperimentRetriana Maharani Retri100% (1)

- Series & Parallel Pump TestDokument22 SeitenSeries & Parallel Pump TestIkhwan Z.100% (23)

- Fluid Lab 2 - Bernoulli ExpDokument19 SeitenFluid Lab 2 - Bernoulli ExpCik Tiem Ngagiman89% (65)

- Centrifugal Pump Report CompletedDokument24 SeitenCentrifugal Pump Report CompletedMohamad Fareez Roslan100% (1)

- Refrigeration PracticalDokument15 SeitenRefrigeration PracticalRichardt Loots100% (2)

- Bare and LaggedDokument20 SeitenBare and Laggedchimikoxd25% (4)

- University Thermodynamics Laboratory Report (Ratio of Volume)Dokument5 SeitenUniversity Thermodynamics Laboratory Report (Ratio of Volume)Jackson KcNoch keine Bewertungen

- Energy Losses in Bends and FittingsDokument11 SeitenEnergy Losses in Bends and FittingsQuenneBelocura100% (1)

- Orifice & Free Jet FlowDokument6 SeitenOrifice & Free Jet FlowMohamedElkikiNoch keine Bewertungen

- Exp3 Single Stage Piston CompressorDokument11 SeitenExp3 Single Stage Piston Compressortayseer sarhanNoch keine Bewertungen

- AtlasDokument5 SeitenAtlasSunil KumarNoch keine Bewertungen

- Exp #10Dokument19 SeitenExp #10Eng TariqNoch keine Bewertungen

- DTC P1283 ADokument12 SeitenDTC P1283 AInternal88Noch keine Bewertungen

- Pressure Pulse Sensor OsciloscopioDokument9 SeitenPressure Pulse Sensor OsciloscopioJoao Silva Lopes100% (2)

- Practical 7: Introduction To Axial Flow Gas Turbine Operations ObjectiveDokument11 SeitenPractical 7: Introduction To Axial Flow Gas Turbine Operations ObjectiveMuhammad Arslan AfzalNoch keine Bewertungen

- SH 09 12 BPH X Service ManualDokument52 SeitenSH 09 12 BPH X Service ManualBobi GorgievskiNoch keine Bewertungen

- Speed Info 002/02/em LSS: Product: Servoventilator 300/300A & 300/300A+No )Dokument3 SeitenSpeed Info 002/02/em LSS: Product: Servoventilator 300/300A & 300/300A+No )GABRIELNoch keine Bewertungen

- SsangYong Korando / New Actyon - Engine Control SystemDokument172 SeitenSsangYong Korando / New Actyon - Engine Control Systemtroublezaur80% (5)

- Gilian 5000 Quick Start ManualDokument4 SeitenGilian 5000 Quick Start ManualElio HerreraNoch keine Bewertungen

- Acson Service Guide Book 2010Dokument90 SeitenAcson Service Guide Book 2010afnc777100% (1)

- 3 Two Stage Air Compressor ManualDokument20 Seiten3 Two Stage Air Compressor ManualMansoob BukhariNoch keine Bewertungen

- Exp 4 Centrifugal CompressorDokument11 SeitenExp 4 Centrifugal CompressorFaris HamirNoch keine Bewertungen

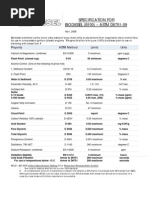

- Specification For BIODIESEL (B100) - ASTM D6751-09: Property ASTM Method Limits UnitsDokument1 SeiteSpecification For BIODIESEL (B100) - ASTM D6751-09: Property ASTM Method Limits UnitsIzzul HazimNoch keine Bewertungen

- Literature Review Data On Permeability and Selectivity: Appendix BDokument1 SeiteLiterature Review Data On Permeability and Selectivity: Appendix BIzzul HazimNoch keine Bewertungen

- ReticulationDokument118 SeitenReticulationIzzul Hazim100% (1)

- Turbine Lab ReportDokument11 SeitenTurbine Lab ReportIzzul Hazim75% (8)

- How To Adjust Rough Idle and Camshaft Timing On VW and Audi TDI Pumpe Duse EngineDokument5 SeitenHow To Adjust Rough Idle and Camshaft Timing On VW and Audi TDI Pumpe Duse EngineALP1981100% (2)

- Baselec q1 QuestionsDokument5 SeitenBaselec q1 QuestionsroiNoch keine Bewertungen

- 3178ux L TrevnewDokument75 Seiten3178ux L TrevnewOmar PerezNoch keine Bewertungen

- Unit ConversionDokument2 SeitenUnit ConversionharoldNoch keine Bewertungen

- Sample Project Report Format of 2020 Passout.Dokument84 SeitenSample Project Report Format of 2020 Passout.Prem sharmaNoch keine Bewertungen

- Harsh Environment Series Connection Systems 2014-05-05 PDFDokument8 SeitenHarsh Environment Series Connection Systems 2014-05-05 PDFSicein SasNoch keine Bewertungen

- Sir. Abdul-Kareem: Stereoisomerism - Geometric IsomerismDokument8 SeitenSir. Abdul-Kareem: Stereoisomerism - Geometric IsomerismsaudNoch keine Bewertungen

- Modeling of Power System in PSCAD/EMTDC ProgramDokument22 SeitenModeling of Power System in PSCAD/EMTDC ProgramboopelectraNoch keine Bewertungen

- Detailed Comparative Case Study On Environmentally Sustainable BuildingDokument8 SeitenDetailed Comparative Case Study On Environmentally Sustainable BuildingEditor IJTSRDNoch keine Bewertungen

- SNJB's Late Sau. Kantabai Bhavarlalji Jain College of Engineering, ChandwadDokument10 SeitenSNJB's Late Sau. Kantabai Bhavarlalji Jain College of Engineering, ChandwadAkash JadhavNoch keine Bewertungen

- Setting Calculation of Oc and Ef RealyDokument1 SeiteSetting Calculation of Oc and Ef RealyManishPandya67% (3)

- N42EH Grade Neodymium Magnets DataDokument1 SeiteN42EH Grade Neodymium Magnets DataSteve HsuNoch keine Bewertungen

- FY B.Sc. Light Reactions IDokument5 SeitenFY B.Sc. Light Reactions IVijendraNoch keine Bewertungen

- Dmart Supply Chain Management 0 Inventory Management ModuleDokument13 SeitenDmart Supply Chain Management 0 Inventory Management Moduleaarushisoral1Noch keine Bewertungen

- 2013 04Dokument110 Seiten2013 04Jose Emmanuel Martinez CordovaNoch keine Bewertungen

- FMC-FCC Single-Layer Roller Kilns FMC-FCCDokument12 SeitenFMC-FCC Single-Layer Roller Kilns FMC-FCCCeramic TilesNoch keine Bewertungen

- Recovery PDFDokument164 SeitenRecovery PDFAzizi AbdullahNoch keine Bewertungen

- ShipRight - Design Code For Unmanned Marine Systems - 2017Dokument39 SeitenShipRight - Design Code For Unmanned Marine Systems - 2017RISHABH JAMBHULKARNoch keine Bewertungen

- Transmission Lines and NetworksDokument18 SeitenTransmission Lines and NetworkszgxfsbjbnNoch keine Bewertungen

- GU-611 - PDO Engineering Standands PDFDokument1 SeiteGU-611 - PDO Engineering Standands PDFSheik Ali (QA/QC Manager Coastal)Noch keine Bewertungen

- Service Manual: (Gasoline & L.P. Gas)Dokument86 SeitenService Manual: (Gasoline & L.P. Gas)julianmata67% (3)

- Foot MouswitchDokument11 SeitenFoot MouswitchnewbeatleeNoch keine Bewertungen

- PIP-Vessel S and T Heat Exchanger Design Criteria ASME Code Section VIII, Div 1 and 2Dokument74 SeitenPIP-Vessel S and T Heat Exchanger Design Criteria ASME Code Section VIII, Div 1 and 2rizaNoch keine Bewertungen

- Jlhhvalue Based Questions Class-12Dokument16 SeitenJlhhvalue Based Questions Class-12jitender8Noch keine Bewertungen

- Pressure-Compensated Flow Control Valves - Hydraulic ValveDokument3 SeitenPressure-Compensated Flow Control Valves - Hydraulic ValveAlamin SiddiqueNoch keine Bewertungen

- Standard and Actual Vapor Compression CycleDokument19 SeitenStandard and Actual Vapor Compression CycleJB LabraNoch keine Bewertungen

- A Guide To Photovoltaic (PV) System Design and Installation: California Energy CommissionDokument40 SeitenA Guide To Photovoltaic (PV) System Design and Installation: California Energy CommissionKuroko TetsuyaNoch keine Bewertungen

- 6.1 Mastering IELTS Writing Task 1 (PDFeBook) PDFDokument228 Seiten6.1 Mastering IELTS Writing Task 1 (PDFeBook) PDFHarsh Patel100% (6)

- Tesla CoilDokument23 SeitenTesla CoilredfordNoch keine Bewertungen

- Cheniere Energy LNG TerminalDokument8 SeitenCheniere Energy LNG TerminalKong LingweiNoch keine Bewertungen