Beruflich Dokumente

Kultur Dokumente

Natural Glue

Hochgeladen von

big johnCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Natural Glue

Hochgeladen von

big johnCopyright:

Verfügbare Formate

88.

PROFILE ON PRODUCTION OF NATURAL GLUE

88-2 TABLE OF CONTENTS

PAGE

I.

SUMMARY

88-3

II.

PRODUCT DESCRIPTION & APPLICATION

88-3

III.

MARKET STUDY AND PLANT CAPACITY A. MARKET STUDY B. PLANT CAPACITY & PRODUCTION PROGRAMME

88-4 88-4 88-7

IV.

MATERIALS AND INPUTS A. RAW MATERIALS B. UTILITIES

88-7 88-7 88-8

V.

TECHNOLOGY & ENGINEERING A. TECHNOLOGY B. ENGINEERING

88-8 88-8 88-9

VI.

MANPOWER & TRAINING REQUIREMENT A. MANPOWER REQUIREMENT B. TRAINING REQUIREMENT

88-10 88-10 88-10

VII.

FINANCIAL ANALYSIS A. TOTAL INITIAL INVESTMENT COST B. PRODUCTION COST C. FINANCIAL EVALUATION D. ECONOMIC BENEFITS

88-11 88-11 88-12 88-13 88-14

88-3

I.

SUMMARY

This profile envisages the establishment of a plant for the production of natural glue with a capacity of 100 tonnes per annum.

The present demand for the proposed product is estimated at 4,720 tonnes per annum. The demand is expected to reach at 14,659 tonnes by the year 2017.

The plant will create employment opportunities for 29 persons.

The total investment requirement is estimated at Birr 2.19 million, out of which Birr 850,000 is required for plant and machinery.

The project is financially viable with an internal rate of return (IRR) of 14% and a net present value (NPV) of Birr 400,880 discounted at 8.5%.

II.

PRODUCT DESCRIPTION AND APPLICATION

Adhesives are gluing materials which are directly extracted either from natural source like bone, gums and starches or synthetically derived from chemicals like urea-formaldehyde. Adhesive have major applications in the furniture, leather articles, shoes, printing and textile industries. They serve to fix, bind or attach solid things together

There are different types of adhesives according to their application. Production of bone-based glue is recommended for the envisaged plant.

88-4 III. MARKET STUDY AND PLANT CAPACITY

A.

MARKET STUDY

1.

Past Supply and Present Demand

Adhesives serve variety of purposes by bonding two or more surfaces together. They resist moisture and corrosion and are economical. Although synthetic adhesives replace natural adhesives extensively, animal glues continue to be used in large volumes. Except the limited domestic production of animal glue by Addis Ababa Abattoirs and syntactic adhesive by Kadisko, the supply of adhesives is mainly met through import. The latest five years import data is given Table 3.1. The Table veals that import of adhesives the past five years has been in

increasing consistently. The imported quantity which was

1497 tonnes in the year /2002 has increased to about 2,311 tonnes and 3.920 tonnes by the year 2004 and 2006, respectively. The yearly average growth rate was more than 25%.

The large volume of import together with the high growth rate attained in the last five years indicates an import substitution opportunity for domestically produced adhesives. Although official statistics on the domestic production of adhesives is not available, according to retailers of construction materials, the estimated coverage by domestic production is about 20%. Hence, domestic production is estimated at about 800 tonnes.

The current effective demand for adhesives is estimated based on the import of 8 years 2008 and the estimated domestic production. Accordingly, current effective demand is estimated at 4,720 tones.

88-5 Table 3.1 IMPORT OF ADHESIVES (TONNES)

Year 2002 2003 2004 2005 2006

Quantity 1,497.0 2,115.2 2,310.8 4,540.9 3.920.5

Source:- Compiled From Customs Authority.

2.

Projected Demand

Adhesive is principally used in the woodwork, plywood industry, textiles, leather, glass, metal, bookbinding, construction and the packaging industry. The growth in the

manufacturing sector and construction sector, particularly the present housing construction activities underway to build residential houses will give rise to the growth in demand for adhesives significantly. However, he demand projection for adhesives is made conservatively on the 12% growth rate which is such lower than the import growth rate achieved during 2002-2006. The projected demand for adhesives is presented in Table 3.2.

88-6 Table 3.2 PROJECTED DEMAND FRO ADHESIVES (TONNES)

Year 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017

Project Demand 5286 5921 6631 7427 8318 9316 10434 11687 13089 14659

Domestic production 800 800 800 800 800 800 800 800 800 800

Unsatisfied Demand 4486 5721 5831 6627 7518 8516 9634 10887 12289 13859

Of the total unsatisfied demand, about 10-15% market share can be targeted for the envisaged project.

3.

Pricing and Distribution

The average CIF price of adhesives in the recent past three years i.e 2004-2006 and allowing 30% for duty and other clearing charges a factory gate price of Birr 19,000 per tonne is recommended.

The product can be directly sold to bulk purchasers. For small consumers it can be distributed through the existing building materials distributing enterprises.

88-7 B. PLANT CAPACITY AND PRODUCTION PROGRAMME

1.

Production Capacity

Considering the scarcity of animal bone, which is the main raw material for the envisaged plant, an annual plant capacity of 100 tonnes was selected for the plant.

The envisaged plant will have a capacity to produce 100 tonnes of adhesive by working one shift per day and 300 working days is a year. The working days are set by assuming provisions for maintenance and repair works.

2.

Production Programme

The plant would start operation by utilization 75%, 85% and 100% of its capacity during the first, second and third years of operation respectively. Gradual capacity build up is envisaged considering the time required for skill development in operational and market penetration.

IV.

MATERIAL AND INPUTS

A.

RAW MATERIAL

The major raw material for the production of bone glue is animal bones (with the exception of horse bones). Butcheries are considered as a source of bone supply.

The annual animal bone requirement to produce 100 tonnes of glue is estimated to be 800 tonnes. A kilo of bone is estimated to cost Birr 1.00.

The cost of raw material is estimated to be Birr 800,000. Phenol or other disinfectants, benzyl and light petroleum are used as intermediate inputs. The annual cost of these chemicals is estimated to be Birr 35,000.

88-8 B. UTILITIES

The annual electrical energy consumption of the plant is estimated to be 72,000 kWh which costs birr 34,626. The annual water consumption of the plant is estimated to be 6,000 m3, which costs birr 33,000. The annual heavy fuel oil consumption is estimated to be 34 m3 and its costs is birr 183,940.

V.

TECHNOLOGY AND ENGINEERING

A.

TECHNOLOGY

1.

Production Process

At the initial stage bones are stored in free space and need to be sprayed with phenol or other disinfectants to delay decomposition and to lower stretch. Bones are then selected, and unwanted qualities as well as foreign materials (stones, woods, etc) are manually separated. The selected bones are introduced in to a rotating drum to be washed with water. The washed bones are, later on, crushed and filled into the solvent extraction column. At this stage, bone grease is separated from the bones.

In the next step, bones are unloaded and mechanically cleaned in order to separate the fines from bigger ones. The bigger bones are forwarded to the glue extraction unit, which makes use of counter current flow of steam at 1060 c. The result of this sub-process is a colloidal solution containing 85% water. The solution needs further concentration. A multi-stage concentrator is employed for this purpose. The final concentrate is further let to sediment and is shaped in to tables. The final product is dried and made in the form of tablet. Degreased and glue free bone is also produced simultaneously as a by-product.

88-9 2. Source of Technology

The technical data and information are compiled from the survey of the chemical sector in Ethiopia conducted by Baldo of Italy vol. III.

B.

ENGINEERING

1.

Machinery and Equipment

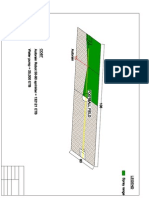

The major machinery and equipment to be installed in the envisaged plant are listed in Table 5.1. The total cost of machinery and equipment is estimated at about Birr one million out of which about Birr 850,000 will be required in foreign currency. 2. Land, Building and Civil Works

The total land requirement for the plant would be around 3000m2 out of which 300 m2 will be built up area for offices, store and production buildings. The cost of construction is estimated to be Birr 750,000. The annual land rent will be Birr 1,500. 3. Proposed Location

The envisaged plant shall be located in Jinka town in Bakogazer Woreda of South Omo Zone. Table 5.1 LIST OF MACHINERY AND EQUIPMENT Sr. No 1 2 3 4 5 6 Description Washer Solvent extraction unit Steam extraction unit Storage tank Concentrator Boiler Others Qty 2 2 2 2 2 1 -

88-10 VI. MANPOWER AND TRAINING REQUIREMENT

A.

MAN POWER REQUIREMENT

The total manpower requirement is 29. The annual and monthly salaries and wages are summarized in Table 6.1.

B.

TRAINING REQUIREMENT

No special training is needed for workers, since the production process is simple. Only a few weeks of familiarization is recommended for production workers during start up phase. Table 6.1 MAN POWER REQUIREMENT AND LABOUR COST (BIRR) No Position No. of Personnel 1 2 3 4 5 6 7 8 9 10 11 Manager Secretary Administration head Commercial Section head Production Head Technical Head Production Supervisor Production Workers Mechanics and electricians Messenger, cleaner, guard Clerks 12 Workers Benefit (15%) Total 29 19,700 35460 271,860 and finance 1 1 1 1 1 1 1 12 4 3 3 Monthly Salary 3000 800 2000 2000 1500 1500 1000 3600 2800 600 900 36000 9600 24000 24000 18000 18000 12000 43200 33600 7200 10800 Annual Salary

88-11

VII.

FINANCIAL ANALYSIS

The financial analysis of the natural glue project is based on the data presented in the previous chapters and the following assumptions:-

Construction period Source of finance

1 year 30 % equity 70 % loan

Tax holidays Bank interest Discount cash flow Accounts receivable Raw material local Work in progress Finished products Cash in hand Accounts payable

3 years 8% 8.5% 30 days 30 days 3 days 30 days 5 days 30 days

A.

TOTAL INITIAL INVESTMENT COST

The total investment cost of the project including working capital is estimated at Birr 2.19 million, of which 37 per cent will be required in foreign currency.

The major breakdown of the total initial investment cost is shown in Table 7.1.

88-12

Table 7.1 INITIAL INVESTMENT COST

Sr. No. 1 2 3 Cost Items Land lease value Building and Civil Work Plant Machinery and Equipment 4 Office Furniture and Equipment 5 6 Vehicle Pre-production Expenditure* 7 Working Capital Total Investment cost Foreign Share

Total Cost (000 Birr) 120.0 750.0 850.0

75.0

229.3

172.9 2,197.3 37

* N.B Pre-production expenditure includes interest during construction ( Birr Birr

154.34 thousand ) and

75 thousand costs of registration, licensing and formation of the company including legal fees,

commissioning expenses, etc.

B.

PRODUCTION COST

The annual production cost at full operation capacity is estimated at Birr 1.75 million (see Table 7.2). The material and utility cost accounts for 61.88 per cent, while repair and maintenance take 4.27 per cent of the production cost.

88-13 Table 7.2 ANNUAL PRODUCTION COST AT FULL CAPACITY ('000 BIRR)

Items Raw Material and Inputs Utilities Maintenance and repair Labour direct Factory overheads Administration Costs Total Operating Costs Depreciation Cost of Finance Total Production Cost

Cost 835.00 251.57 75 163.12 54.37 108.74 1,487.80 145 123.13 1,755.93

% 47.55 14.33 4.27 9.29 3.10 6.19 84.73 8.26 7.01 100

C.

FINANCIAL EVALUATION

1.

Profitability

According to the projected income statement, the project will start generating profit in the first year of operation. Important ratios such as profit to total sales, net profit to

equity (Return on equity) and net profit plus interest on total investment (return on total investment) show an increasing trend during the life-time of the project.

The income statement and the other indicators of profitability show that the project is viable.

88-14 2. Break-even Analysis

The break-even point of the project including cost of finance when it starts to operate at full capacity ( year 3) is estimated by using income statement projection.

BE =

Fixed Cost Sales Variable Cost

67 %

3.

Pay Back Period

The investment cost and income statement projection are used to project the pay-back period. The projects initial investment will be fully recovered within 6 years.

4.

Internal Rate of Return and Net Present Value

Based on the cash flow statement, the calculated IRR of the project is 14% and the net present value at 8.5% discount rate is Birr 400,880.

D.

ECONOMIC BENEFITS

The project can create employment for 29 needs, the project will generate Birr

persons.

In addition to supply of the domestic

454.330 in terms of tax revenue. The establishment of

such factory will have a foreign exchange saving effect to the country by substituting the current imports.

Das könnte Ihnen auch gefallen

- Nursery Manual For Native Plants PDFDokument309 SeitenNursery Manual For Native Plants PDFbig john100% (1)

- The Date Palm Journal PDFDokument240 SeitenThe Date Palm Journal PDFbig johnNoch keine Bewertungen

- Tea and IrrigationDokument14 SeitenTea and Irrigationbig johnNoch keine Bewertungen

- Jam and JellyDokument28 SeitenJam and Jellybig johnNoch keine Bewertungen

- Chewaka Store ModelDokument1 SeiteChewaka Store Modelbig johnNoch keine Bewertungen

- Lowland OilcropsDokument14 SeitenLowland Oilcropsbig johnNoch keine Bewertungen

- Co-Op Bulk Spice List in Order by Alphabetic Spice NameDokument3 SeitenCo-Op Bulk Spice List in Order by Alphabetic Spice Namebig johnNoch keine Bewertungen

- Tea and IrrigationDokument14 SeitenTea and Irrigationbig johnNoch keine Bewertungen

- Herb Production OrganicDokument20 SeitenHerb Production OrganicShoshannah33% (3)

- Football Field Layout1Dokument1 SeiteFootball Field Layout1big johnNoch keine Bewertungen

- PomegranatesDokument5 SeitenPomegranatesbig johnNoch keine Bewertungen

- OrangeDokument23 SeitenOrangebig john100% (1)

- FCKupload File FAO Syria Crisis Report enDokument106 SeitenFCKupload File FAO Syria Crisis Report enbig johnNoch keine Bewertungen

- BS Year1 No14 - Apr.02 1925Dokument4 SeitenBS Year1 No14 - Apr.02 1925big johnNoch keine Bewertungen

- Grape JuiceDokument16 SeitenGrape Juicebig johnNoch keine Bewertungen

- Tomato Paste and JuiceDokument14 SeitenTomato Paste and JuiceRamanathan Meyyappan100% (1)

- Horticulture Report FinalDokument57 SeitenHorticulture Report Finalbig john100% (1)

- Commodity TeaDokument4 SeitenCommodity Teabig johnNoch keine Bewertungen

- 36 Tomato Sauce, Ketchup and PureesDokument9 Seiten36 Tomato Sauce, Ketchup and Pureesbig johnNoch keine Bewertungen

- CIB, ContractDokument89 SeitenCIB, Contractbig johnNoch keine Bewertungen

- Final EgyptDokument258 SeitenFinal Egyptbig johnNoch keine Bewertungen

- CIB, ContractDokument89 SeitenCIB, Contractbig johnNoch keine Bewertungen

- Tuta AbsolutaDokument25 SeitenTuta Absolutabig johnNoch keine Bewertungen

- Participatory Irrigation Management in AlbaniaDokument25 SeitenParticipatory Irrigation Management in Albaniabig johnNoch keine Bewertungen

- Tomato MarketingDokument8 SeitenTomato Marketingbig johnNoch keine Bewertungen

- Dried Spray FruitDokument130 SeitenDried Spray Fruitbig john100% (2)

- Ethiopia Irrigation Diagnostic July 2010 2Dokument59 SeitenEthiopia Irrigation Diagnostic July 2010 2big john100% (1)

- Agribusiness Organization and Management SeminarDokument24 SeitenAgribusiness Organization and Management Seminarbig john100% (2)

- Unu Strategic Plan 2011-2014 enDokument20 SeitenUnu Strategic Plan 2011-2014 enbig johnNoch keine Bewertungen

- 101 Iced Tea RecipesDokument109 Seiten101 Iced Tea RecipesNessa Santiago100% (3)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Solar Thermal Report Highlights India, Europe MarketsDokument27 SeitenSolar Thermal Report Highlights India, Europe MarketsVikas SinghNoch keine Bewertungen

- Manufacturing Plant Cash FlowDokument9 SeitenManufacturing Plant Cash FlowKuralay TilegenNoch keine Bewertungen

- Cost-Plus Contracts: Issues and OversightDokument2 SeitenCost-Plus Contracts: Issues and OversightChinthaka AbeygunawardanaNoch keine Bewertungen

- Worksheet No 1 Bond Pricing - 2016Dokument2 SeitenWorksheet No 1 Bond Pricing - 2016z_k_j_vNoch keine Bewertungen

- FeasibDokument5 SeitenFeasibEnna Jane VillarinaNoch keine Bewertungen

- Estimating Costs For Mining Prefeasibility StudiesDokument5 SeitenEstimating Costs For Mining Prefeasibility Studiesdghfhh444t5566gfg0% (1)

- Forex Systems Research Company - Forex Trading With CandlestDokument49 SeitenForex Systems Research Company - Forex Trading With CandlestHeather CopelandNoch keine Bewertungen

- FAR Pre-Week Part 1Dokument24 SeitenFAR Pre-Week Part 1John DoeNoch keine Bewertungen

- Contract To SellDokument3 SeitenContract To SellEduardNoch keine Bewertungen

- Chapter 8 MowenDokument25 SeitenChapter 8 MowenRosamae PialaneNoch keine Bewertungen

- PWC Banking Industry Reform PDFDokument24 SeitenPWC Banking Industry Reform PDFcontactbarathNoch keine Bewertungen

- Martel Law OfficeDokument6 SeitenMartel Law Officechrisguamos69% (16)

- Ch3 LifeCycleDokument14 SeitenCh3 LifeCycleadamNoch keine Bewertungen

- Power Crisis in The PhilippinesDokument4 SeitenPower Crisis in The PhilippinesRenz Anthony EspinoNoch keine Bewertungen

- Henry FordDokument18 SeitenHenry Fordsonabeta07Noch keine Bewertungen

- Merrill Lynch Pricing Analysis for Integrated Choice StrategyDokument15 SeitenMerrill Lynch Pricing Analysis for Integrated Choice StrategyHealth & WellnessNoch keine Bewertungen

- Understanding Cost: Why It Exists and Its Importance in BusinessDokument27 SeitenUnderstanding Cost: Why It Exists and Its Importance in BusinessDARSHANA SNoch keine Bewertungen

- ECO 561 MART Teaching Effectively Eco561martdotcomDokument27 SeitenECO 561 MART Teaching Effectively Eco561martdotcomaadam456Noch keine Bewertungen

- Chapter 13 - Standard Costing - PROBLEMSDokument4 SeitenChapter 13 - Standard Costing - PROBLEMSKristina De GuzmanNoch keine Bewertungen

- Advanced Lean Training Manual Band 4Dokument106 SeitenAdvanced Lean Training Manual Band 4EXDE601E100% (39)

- PMG HouseholdBudget1Dokument1 SeitePMG HouseholdBudget1Fred AlmaNoch keine Bewertungen

- Foundations of Financial Management Canadian 8Th Edition Block Test Bank Full Chapter PDFDokument67 SeitenFoundations of Financial Management Canadian 8Th Edition Block Test Bank Full Chapter PDFweickumralphie100% (9)

- Distribution Channels: Understanding and Managing Channels To Markets Business ModelDokument63 SeitenDistribution Channels: Understanding and Managing Channels To Markets Business ModelSalma El SayedNoch keine Bewertungen

- SCM Assignment Activity Sept 20 2020 Answer Key PDF FreeDokument5 SeitenSCM Assignment Activity Sept 20 2020 Answer Key PDF FreeChizu ChizuNoch keine Bewertungen

- International Business - 0Dokument109 SeitenInternational Business - 0Madhu kumarNoch keine Bewertungen

- 1%20 %20introductionDokument85 Seiten1%20 %20introductionthrowaway1609Noch keine Bewertungen

- GLO BUS Forecast Sheet Template 2020 06 16 1Dokument114 SeitenGLO BUS Forecast Sheet Template 2020 06 16 1Rose20100% (1)

- NPV Capital Budgeting GuideDokument8 SeitenNPV Capital Budgeting GuideAnastasiaNoch keine Bewertungen

- Solution For Nike, Inc. From BaiduDokument4 SeitenSolution For Nike, Inc. From BaiduNur 'Atiqah100% (1)

- Foreword by The Presidential CandidateDokument67 SeitenForeword by The Presidential Candidatecijoe2006Noch keine Bewertungen