Beruflich Dokumente

Kultur Dokumente

Hw3 Aggregate Planning

Hochgeladen von

Modather SalahOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Hw3 Aggregate Planning

Hochgeladen von

Modather SalahCopyright:

Verfügbare Formate

Cairo University Faculty of Engineering Mechanical Design & Production Dept.

t. Production & Operations Management (MDP408b) Fall 2010 Tutorial #3: Aggregate planning

Problems to be solved by students in class: --Problems to be solved by the TA in class: 1, 2 and 4(a) Problems to be solved by students and submitted next week: 3 and 4(b)

1) A toy manufacturing company produces six types of toys. All components and parts are manufactured elsewhere, while the final assembly is conducted in house. The assembly times needed per unit for each type of toys are listed in the following table. Toy KoKi Habibi Winni Kitti Barbi Chevi Assembly time (min.) 3 8 6 4 8 10

The forecasted demand requirements over the next four quarters are given in the following table. Toy KoKi Habibi Winni Kitti Barbi Chevi 1 400 80 900 50 1200 90 Quarter 2 3 200 300 120 130 800 700 60 80 1300 1300 120 110

4 500 150 800 90 1500 100

Based on the assembly time data, evaluate the aggregate demand for the four quarters. What is the assembly time needed for an aggregate unit?

2) Suppose in problem 1, the company manager decided to use the unit selling price in determining the aggregate units. That is, the aggregate product will be measured in terms of the equivalent monetary value evaluated using the unit selling price of each product. The following table lists the selling price per unit for each product. Toy KoKi Habibi Winni Kitti Barbi Chevi Selling price (LE/unit) 10 40 20 20 60 80

Evaluate the aggregate demand and the assembly time needed for an aggregate unit.

3) A steel manufacturing company produces three types of steel sheet metal, labeled S1, S2 and S3, with different thicknesses and widths. It also produces two types of steel wire rods, labeled R1 and R2, with different diameters for industrial and construction projects. Both sheet metal and wire rods are produced in the form of coils. The production time and coil weight for each product are listed in the following table. Product type S1 S2 S3 R1 R2 Coil weight (ton) 5 8 12 1.5 2 Production time (hrs) 2.6 2.3 1.8 1.5 1.2

The forecasted demand (in number of coils) for the next six months for each product type is listed below. Product S1 S2 S3 R1 R2 1 1000 1200 1300 2400 1500 2 800 1000 900 2500 1600 3 800 900 800 2300 1700 Month 4 700 1000 800 2200 2000 5 850 1100 900 2300 1900 6 900 1200 1000 2400 1800

Based on the products weights, evaluate the aggregate demand and the assembly time needed for an aggregate unit.

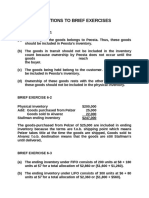

4) Given below the forecasted demand and available work time for 12 months. Two different sets of forecasted demand of two different aggregate units are provided. Forecasted demand Set A Set B 50 50 60 60 55 70 55 65 50 55 45 80 40 250 70 240 95 110 260 100 240 80 200 60

Month 1 2 3 4 5 6 7 8 9 10 11 12

The following are other necessary information:

Initial inventory Initial workforce Regular-time production rate Cost of regular-time production Cost to carry inventory Cost of stockout Cost of hiring new people Cost of laying off people

20 units 20 people 3 unit/worker/month LE 500/unit LE 25/unit/month LE 100/unit/month LE 900/person LE 800/person

a) For data set A only, use the tabular/graphical approach to find a suitable production plan with as minimal total cost as you can.

b) For data set B only, use the tabular/graphical approach to find a suitable production plan with as minimal total cost as you can.

Das könnte Ihnen auch gefallen

- Energy Efficient Manufacturing: Theory and ApplicationsVon EverandEnergy Efficient Manufacturing: Theory and ApplicationsNoch keine Bewertungen

- Fabricated Steel Plate Work World Summary: Market Values & Financials by CountryVon EverandFabricated Steel Plate Work World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- hw6 MRPDokument2 Seitenhw6 MRPModather SalahNoch keine Bewertungen

- Production Planning and ControlDokument8 SeitenProduction Planning and ControlKamal ChaitanyaNoch keine Bewertungen

- LP-Application Operations PDFDokument14 SeitenLP-Application Operations PDFAnand DharunNoch keine Bewertungen

- Quan 2204Dokument6 SeitenQuan 2204Sanjay VaryaniNoch keine Bewertungen

- Operation MGMT 15 JUNEDokument5 SeitenOperation MGMT 15 JUNErajNoch keine Bewertungen

- B.E (1E) MBA - Second Year UIE 405: Production Planning and ControlDokument2 SeitenB.E (1E) MBA - Second Year UIE 405: Production Planning and ControlgenowNoch keine Bewertungen

- Management PricipalDokument7 SeitenManagement PricipalmdivyalakshmiNoch keine Bewertungen

- ACCACAT Paper T4 Accounting For Costs INT Topicwise Past PapersDokument40 SeitenACCACAT Paper T4 Accounting For Costs INT Topicwise Past PapersGT Boss AvyLara50% (4)

- IGNOU BCA Assignment Semester - IVDokument21 SeitenIGNOU BCA Assignment Semester - IVAnonNoch keine Bewertungen

- Question Bank Operations Management MGA 602Dokument6 SeitenQuestion Bank Operations Management MGA 602Jennifer JosephNoch keine Bewertungen

- (2015 Onwards) : M.Sc. Software Systems Degree Examin Tions, April 2018Dokument6 Seiten(2015 Onwards) : M.Sc. Software Systems Degree Examin Tions, April 2018Aravind KumarNoch keine Bewertungen

- Operation Management and Information SystemDokument32 SeitenOperation Management and Information SystemaanandlNoch keine Bewertungen

- Capacity and Demand in Units Period Regular Time Overtime Subcontract DemandDokument3 SeitenCapacity and Demand in Units Period Regular Time Overtime Subcontract DemandVinay Kumar0% (1)

- Assignment IDokument4 SeitenAssignment IChristina SparksNoch keine Bewertungen

- Pom Sol 10Dokument5 SeitenPom Sol 10amritranjan123_34249Noch keine Bewertungen

- Management: Forecasting, App, MPS, MRPDokument40 SeitenManagement: Forecasting, App, MPS, MRPMukul SuryawanshiNoch keine Bewertungen

- PM QBDokument7 SeitenPM QBmayur_mechNoch keine Bewertungen

- 2724610Dokument2 Seiten2724610alpeshrptlNoch keine Bewertungen

- A2 QMTDokument3 SeitenA2 QMTaskerman100% (1)

- IEOR 162 Group Project (Fall 2013)Dokument4 SeitenIEOR 162 Group Project (Fall 2013)DracoAndruw0% (2)

- Design Handbook MAchine DesignDokument5 SeitenDesign Handbook MAchine DesignsouravNoch keine Bewertungen

- Material Requirement PlanningDokument5 SeitenMaterial Requirement Planningshwa_jn889Noch keine Bewertungen

- ORDokument5 SeitenORDeepankar RawatNoch keine Bewertungen

- Seventh Semester B.Tech. Degree Examination, June 2009 03.705 Elective - V: OPERATIONS RESEARCH (H) (2003 Admission)Dokument6 SeitenSeventh Semester B.Tech. Degree Examination, June 2009 03.705 Elective - V: OPERATIONS RESEARCH (H) (2003 Admission)loopycrowNoch keine Bewertungen

- Questions 2021Dokument7 SeitenQuestions 2021Bridgett BeeNoch keine Bewertungen

- Assignment 5 MRP PDFDokument7 SeitenAssignment 5 MRP PDFNegashNoch keine Bewertungen

- OM - I-III Chaptetrs Question BankDokument5 SeitenOM - I-III Chaptetrs Question Bankchandrarao chNoch keine Bewertungen

- Production Planning Control AssignmentDokument13 SeitenProduction Planning Control AssignmentKulmohan116Noch keine Bewertungen

- D10-CAC Spring 2013Dokument4 SeitenD10-CAC Spring 2013Mudassir HaiderNoch keine Bewertungen

- As 462Dokument6 SeitenAs 462ziabuttNoch keine Bewertungen

- ABC TutotialDokument6 SeitenABC TutotialChandran PachapanNoch keine Bewertungen

- Problems in PPCDokument4 SeitenProblems in PPCrajya lakshmiNoch keine Bewertungen

- Attempt All Questions: Summer Exam-2009 Performance Measurement Duration: 3 Hrs. Marks-100Dokument15 SeitenAttempt All Questions: Summer Exam-2009 Performance Measurement Duration: 3 Hrs. Marks-100GENIUS1507Noch keine Bewertungen

- Module Code: PMC Module Name: Performance Measurement & Control Programme: MSC FinanceDokument9 SeitenModule Code: PMC Module Name: Performance Measurement & Control Programme: MSC FinanceRenato WilsonNoch keine Bewertungen

- Alagappa University Collaborative Institution B.com (4th Semester) - Internal 1 - Cost and Management AccountingDokument3 SeitenAlagappa University Collaborative Institution B.com (4th Semester) - Internal 1 - Cost and Management AccountingSREENAVIN PNoch keine Bewertungen

- ACCA F 2 Managment Accountant Topic Wise Q A PDFDokument44 SeitenACCA F 2 Managment Accountant Topic Wise Q A PDFSaurabh KaushikNoch keine Bewertungen

- Exercises 1.1: The of Which Are More Consistent From The Point of View of ?Dokument3 SeitenExercises 1.1: The of Which Are More Consistent From The Point of View of ?Abd El-Razek AhmedNoch keine Bewertungen

- Production Engineering V SEM SET-1Dokument3 SeitenProduction Engineering V SEM SET-1Shathish GunasekaranNoch keine Bewertungen

- ACCT 321-Magerial AccountingDokument6 SeitenACCT 321-Magerial AccountingNodeh Deh SpartaNoch keine Bewertungen

- Standard Cost (RS.)Dokument13 SeitenStandard Cost (RS.)Anushree GuptaNoch keine Bewertungen

- (BUSINESS ADMINISTRATION) Company Law and Secretarial PracticeDokument5 Seiten(BUSINESS ADMINISTRATION) Company Law and Secretarial PracticeGuruKPONoch keine Bewertungen

- Cost Assignment IDokument5 SeitenCost Assignment Ifitsum100% (1)

- PAT0084 ExamFinalQDokument6 SeitenPAT0084 ExamFinalQJasmine TanNoch keine Bewertungen

- MaterialDokument8 SeitenMaterialPrasanna SharmaNoch keine Bewertungen

- Linear Programming AssignmentDokument5 SeitenLinear Programming AssignmentLakshya GargNoch keine Bewertungen

- Test 1 F5 QDokument2 SeitenTest 1 F5 QMd Enamul BasharNoch keine Bewertungen

- 30784rtpfinalnov2013 5Dokument0 Seiten30784rtpfinalnov2013 5kamlesh1714Noch keine Bewertungen

- Exam 2007 (Memo Incl)Dokument15 SeitenExam 2007 (Memo Incl)Dantè ChiapperiniNoch keine Bewertungen

- Review QsDokument92 SeitenReview Qsfaiztheme67% (3)

- POM 1 Exam 2014 FinalDokument17 SeitenPOM 1 Exam 2014 FinalBi11y 1eeNoch keine Bewertungen

- Acca f2 Management Accountant Topicwise Past PapersDokument44 SeitenAcca f2 Management Accountant Topicwise Past PapersIkram Naguib100% (2)

- HomeworkDokument3 SeitenHomeworkxandercageNoch keine Bewertungen

- 97 ZaDokument7 Seiten97 ZaMeow Meow HuiNoch keine Bewertungen

- Industrial Process Plant Construction Estimating and Man-Hour AnalysisVon EverandIndustrial Process Plant Construction Estimating and Man-Hour AnalysisBewertung: 5 von 5 Sternen5/5 (1)

- Industrial Objectives and Industrial Performance: Concepts and Fuzzy HandlingVon EverandIndustrial Objectives and Industrial Performance: Concepts and Fuzzy HandlingNoch keine Bewertungen

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIIVon EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIITatsuki OhjiNoch keine Bewertungen

- Machine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryVon EverandMachine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- Ring Test DataDokument5 SeitenRing Test DataModather SalahNoch keine Bewertungen

- Die Sets For ExtrusionDokument2 SeitenDie Sets For ExtrusionModather SalahNoch keine Bewertungen

- ExtrusionDokument2 SeitenExtrusionModather SalahNoch keine Bewertungen

- Graphs and TableDokument9 SeitenGraphs and TableModather SalahNoch keine Bewertungen

- hw4 EOQDokument2 Seitenhw4 EOQModather SalahNoch keine Bewertungen

- Materials Requirements Planning: ERP SystemsDokument5 SeitenMaterials Requirements Planning: ERP SystemsModather SalahNoch keine Bewertungen

- 6 - Operations Schedulin1Dokument4 Seiten6 - Operations Schedulin1Modather SalahNoch keine Bewertungen

- Tutorial #7Dokument1 SeiteTutorial #7Modather SalahNoch keine Bewertungen

- 1 - ForecastingDokument2 Seiten1 - ForecastingModather SalahNoch keine Bewertungen

- MRP (Chapter 7 in Textbook)Dokument2 SeitenMRP (Chapter 7 in Textbook)Modather SalahNoch keine Bewertungen

- Levels of Planning in Manufacturing Systems: Forecasting (Chapter 2)Dokument6 SeitenLevels of Planning in Manufacturing Systems: Forecasting (Chapter 2)Modather SalahNoch keine Bewertungen

- Operations SchedulingDokument4 SeitenOperations SchedulingModather SalahNoch keine Bewertungen

- Just in Time (JIT) System: 1) Toyota Production System (TPS)Dokument1 SeiteJust in Time (JIT) System: 1) Toyota Production System (TPS)Modather SalahNoch keine Bewertungen

- Production & Operation Management: Assignment #Dokument1 SeiteProduction & Operation Management: Assignment #Modather SalahNoch keine Bewertungen

- Handbook of German IdiomsDokument112 SeitenHandbook of German IdiomsModather Salah100% (4)

- Bode Plots ImportantDokument7 SeitenBode Plots ImportantModather SalahNoch keine Bewertungen

- Sistem PelumasanDokument23 SeitenSistem PelumasanVatur RahmanNoch keine Bewertungen

- Inventory Management: Russell and Taylor Operations Management, 8th EditionDokument54 SeitenInventory Management: Russell and Taylor Operations Management, 8th EditionLie Jasen100% (1)

- Cost Reduction StrategiesDokument10 SeitenCost Reduction StrategiesmeetsarkarNoch keine Bewertungen

- US Stroller AnsDokument4 SeitenUS Stroller AnsBrayan Jimenez Barba0% (1)

- Given:: Problem 6 - 21: Prepare & Reconcile Variable Costing StatementsDokument13 SeitenGiven:: Problem 6 - 21: Prepare & Reconcile Variable Costing StatementsimjiyaNoch keine Bewertungen

- Case Study Just in Time at Eicher TractorsDokument31 SeitenCase Study Just in Time at Eicher TractorsDiwakar Pasricha100% (1)

- Chapter 7 Inventory ManagementDokument12 SeitenChapter 7 Inventory ManagementPooja PatnaikNoch keine Bewertungen

- Cost and Management AccountDokument7 SeitenCost and Management AccountMsKhan0078Noch keine Bewertungen

- Supply Chain Management (Assignment 2)Dokument3 SeitenSupply Chain Management (Assignment 2)Muhammad Waqas HanifNoch keine Bewertungen

- Chapter 6 - Brief Exercises - SolutionsDokument4 SeitenChapter 6 - Brief Exercises - SolutionsQuynh Nguyen HuongNoch keine Bewertungen

- POM Aggregate PlanningDokument17 SeitenPOM Aggregate PlanningAhel Patrick VitsuNoch keine Bewertungen

- What Is Oracle ManufacturingDokument3 SeitenWhat Is Oracle ManufacturingtsurendarNoch keine Bewertungen

- ConCentric IIPC NMIMS Case StudyDokument3 SeitenConCentric IIPC NMIMS Case StudySagar GuptaNoch keine Bewertungen

- OM - (Forecasting) - M & L ManufacturingDokument3 SeitenOM - (Forecasting) - M & L ManufacturingNeelNoch keine Bewertungen

- As Per The Recommendations of Tandon CommitteeDokument2 SeitenAs Per The Recommendations of Tandon CommitteeAnkita SharmaNoch keine Bewertungen

- Bcss & Faa Que - PaperDokument3 SeitenBcss & Faa Que - PaperNaresh GuduruNoch keine Bewertungen

- Module 2 INVENTORYDokument5 SeitenModule 2 INVENTORYFatima Mae NadangaNoch keine Bewertungen

- CH006 - ReviewDokument38 SeitenCH006 - Reviewquangtoan19Noch keine Bewertungen

- Intercompany TransactionDokument3 SeitenIntercompany TransactionErjohn PapaNoch keine Bewertungen

- Vendor Managed Inventory 1008Dokument16 SeitenVendor Managed Inventory 1008mohantymamaliNoch keine Bewertungen

- MGT 49 Chapter 2 Logistics by Bowersox Prepared by LVReyesDokument14 SeitenMGT 49 Chapter 2 Logistics by Bowersox Prepared by LVReyesJeshe Balsomo100% (2)

- Exercise 4Dokument3 SeitenExercise 4rasyid_hasanNoch keine Bewertungen

- Navi Star Supplier GuidelinesDokument104 SeitenNavi Star Supplier GuidelinesEduardo UscangaNoch keine Bewertungen

- Cost Accounting Part 1 (University of Cebu) Cost Accounting Part 1 (University of Cebu)Dokument6 SeitenCost Accounting Part 1 (University of Cebu) Cost Accounting Part 1 (University of Cebu)Shane TorrieNoch keine Bewertungen

- Cost Accounting Chapter 11 QuizDokument3 SeitenCost Accounting Chapter 11 Quizzeel801Noch keine Bewertungen

- KaizenDokument21 SeitenKaizenRyan Llaneta100% (1)

- Date Details of Transaction Capital Acc. Payable Notes PayableDokument3 SeitenDate Details of Transaction Capital Acc. Payable Notes PayablerudypatilNoch keine Bewertungen

- Inventory HowjekDokument7 SeitenInventory Howjeksilent spritsNoch keine Bewertungen

- Warehousing Management: Gaurav Narkhede - Josue Servalis - Mike Macas - Praneetha BodaDokument31 SeitenWarehousing Management: Gaurav Narkhede - Josue Servalis - Mike Macas - Praneetha Bodahr chemtek100% (1)

- Is Chennai (Real Estate Stat)Dokument4 SeitenIs Chennai (Real Estate Stat)Yazhini PrabaNoch keine Bewertungen

- Lean ProductionDokument19 SeitenLean ProductionGurpreet VilkhooNoch keine Bewertungen