Beruflich Dokumente

Kultur Dokumente

BOILER Dossier

Hochgeladen von

Kiran DasCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

BOILER Dossier

Hochgeladen von

Kiran DasCopyright:

Verfügbare Formate

KUMAR ORGANIC PRODUCTS LIMITED

SOLID FUEL BOILER DOSSIER

Objective: Energy Conservation

Confidential

Page 1

KUMAR ORGANIC PRODUCTS LIMITED

TABLE OF CONTENT Sl. No. 1 2 3 4 5 6 7 8 8.1 8.2 9 10 11 12 13 14 14.1 14.2 14.3 15 Content General Information about Utilities at KOPL Steam Requirement of KOPL Specification of Reactors at Shaureya Block Specification of Reactors at Jigani Unit Specification of Reactors at Pilot Plant Fuel Consumption at KOPL Calculation: -Fuel consumption of Steam Boiler at Jigani & Shaureya Calculation: -New Solid Fuel Boiler Conclusion: Expected Savings Payback calculation Land requirement & Selection Layout plan for new 3T steam Boiler Quotations for 3T steam boiler Comparison report of received quotations Schematic diagram of 3 T Solid Fuel Boiler Other details of new 3 T Steam Boiler Feed Water details Layout & Sizing of pipe line Chimney dismantling & Fixing Piping Layout for Jigani & Shaureya Block 10 11 12 12 13 14 15 16 17 17 17 18 18 Page No. 3 3 4 5 6 7 8

Confidential

Page 2

KUMAR ORGANIC PRODUCTS LIMITED

1. General Information about Utilities at KOPL: At present KOPL are having three manufacturing facilities two of them at Jigani industrial area & third at Harpanhalli. Products manufactured at KOPL are at Jigani unit Triclosan, at Shaureya block Triclosan & Kopirox and at Harpanhalli Zinc Pyrithione. Jigani Industrial area is having two facilities Jigani plant & Shaureya block. Both the units are having separate utilities like: 1. Steam (LP & HP), 2. Cooling tower, 3. Chilling plant & 4. Thermo Fluid heating system. 2. Steam Requirement of KOPL: For steam requirement at both the units we are having non IBR boilers. In Jigani plant we have two 850 Kg/hr Furnace oil fired boilers are under operation & apart from that one more diesel fired boiler of capacity 600 Kg/hr is used in case of any breakdown or as per the requirement. On other side in Shaureya Block we have two 850 Kg/hr Furnace oil fired boilers. Steam is used at both units for process requirement & vaccum application. 1. Low Pressure (3-3.5 Kg/cm2) 2. High Pressure steam (8-10 Kg/cm2) Usage of steam: Main consumption of steam is in form of Low pressure. Low pressure steam is used for process requirement like heating of reaction mass, solvent recovery, drying of product etc., High pressure steam is required for generation of fine vacuum at distillation setup by using two stage steam jet ejector system. Detail lists of equipments of both plants where steam consumed are given below:

Confidential

Page 3

KUMAR ORGANIC PRODUCTS LIMITED

Confidential

Page 4

KUMAR ORGANIC PRODUCTS LIMITED

Confidential

Page 5

KUMAR ORGANIC PRODUCTS LIMITED

5.

Unit operations where steam consumption required are Solvent recovery by Distillation, Drying (Fluid bed drier, Tray drier), Vacuum (By using steam jet ejectors). Apart from that Reactions temperature maintain & raw material melting like -2, 4 Di Chloro Phenol. From above mention operations Distillation is consuming more then 50% of steam. For Jigani & Shaureya Block two II-stage steam jet ejectors are there to generate the vacuum, for High Vaccum distillation unit by using steam @ 10 Kg/cm2. Steam consumption for each vacuum system is approximately 150 Kg/hr which is nearly 15-20% of total steam load. Apart from this remaining 30-35% steam is used for other operations in the plant.

Confidential

Page 6

KUMAR ORGANIC PRODUCTS LIMITED

6. Fuel Consumption at KOPL: Furnace Oil is used as a fuel in Steam boilers & Thermo fluid heating system at KOPL (Jigani Unit, Shaureya Block & Harpanhalli unit). For Jigani unit High Speed Diesel is also used for Steam boilers & Thermo fluid heating system. FO & HSD consumption for Jigani unit & Shaureya Block is given in the below table on average basis. Table: Daily Furnace Oil consumption for Steam boilers in Jigani & Shaureya Sl. 1. 2. Manufacturing Total Average F.O. Consumption (Liter) 2000 1300 Jigani Unit Shaureya Block For Steam Boiler (Liter) 1700 1100 For Thermo Fluid (Liter) 300 200

No. Facility

Table: Daily HSD consumption for Steam boilers in Jigani & Shaureya Sl. 1. 2. Manufacturing Average HSD Consumption (Liter) 150 Jigani Unit Shaureya Block For Steam Boiler (Liter) 75 For Thermo Fluid (Liter) 75 -

No. Facility

From above table the average FO consumption for steam boilers at Jigani & Shaureya are 1700/1100 liters. For Jigani unit extra fuel i.e. HSD consumption for steam Boiler is 75 liters in case of any breakdown. Steam consumption of both units can be calculated on the basis of fuel consumed at boilers. Detailed steam calculation is given below.

Confidential

Page 7

KUMAR ORGANIC PRODUCTS LIMITED

7. Calculation: -Fuel consumption of Steam Boiler at Jigani & Shaureya Data: 1. Bulk density of Furnace Oil = 900 Kg/m3 2. Gross calorific value = 10200 Kcal/Kg 3. Bulk density of Furnace Oil = 900 Kg/m3 4. Gross calorific value = 9500 Kcal/Kg 5. Cost of Furnace Oil = 31.5 Rs/Kg 6. Cost of High Speed diesel = 32 Rs/Kg 7. Efficiency of boiler = 70% 8. Latent heat of steam = 540 Kcal/hr 9. Average consumption of FO for Jigani & Shaureya= (1700 & 1100) liters/day 10. Average consumption of HSD for Jigani = 75 liters/day 1. Consumption of Steam by FO & Diesel per hr for Jigani Unit Average FO consumption/hr for Jigani unit = 1700/20 = 85 Liters/hr Or 85 x 0.9 = 76.5 Kg/hr Energy produced per hr = 76.5 x 10200 = 780300 Kcal/hr Steam produce per hr = (Energy x Boiler efficiency)/latent heat of steam Steam produce per hr = (780300 x 0.7)/540 = 1011.5 Kg/hr of Steam Say = 1015 Kg/hr of Steam Average HSD consumption/hr for Jigani unit = 75/20 = 3.75 Liters/hr Or 3.75 x 0.88 = 3.33 Kg/hr Energy produced per hr = 3.33 x 9500 = 31635 Kcal/hr Steam produce per hr = (Energy x Boiler efficiency)/latent heat of steam Steam produce per hr = (31635 x 0.7)/540 = 41.5 Kg/hr of Steam Say = 42 Kg/hr of Steam

Confidential

Page 8

KUMAR ORGANIC PRODUCTS LIMITED

Total Average steam consumption for Jigani unit = 1015+42 =1057 Kg/hr Maximum load for Jigani unit can be taken @ 20% extra of average load = 1057 x 1.20 Maximum load for Jigani unit = 1268 Kg/hr or Say =1275 Kg/hr 2. Consumption of Steam by FO per hr for Shaureya Block Average FO consumption/hr for Shaureya Block = 1100/20 = 55 Liters/hr Or 55 x 0.9 = 49.5 Kg/hr Energy produced per hr = 49.5 x 10200 = 504900 Kcal/hr Steam produce per hr = (Energy x Boiler efficiency)/latent heat of steam Steam produce per hr = (504900 x 0.7)/540 = 654.5 Kg/hr of Steam Say = 655 Kg/hr of Steam for Shaureya Block Maximum load for Shaureya can be taken @ 20% extra of average load = 655 x 1.20 Maximum load for Jigani unit = 786 Kg/hr or Say = 800 Kg/hr Total max load steam for both the units = 2075 Kg or Say = 2100 Kg/hr 3. Steam Cost Total average steam consumption for both the unit is = 1057+655= 1712 Kg/hr Total Fuel consumption for both the unit is FO = 76.5+49.5= 126 Kg/hr HSD = 3.33 Kg/hr Steam Cost = Cost of fuel (FO+HSD) / kg of steam = ((126 x 31.5) + (3.33 x 32.5)) / 1712 Kg = 4077.25 Rs/1712 Kg of steam = 2.38 Rs /Kg Assuming cost of power = 0.1 Rs/kg Manpower cost = 0.02 Rs/Kg Total cost of steam = 2.38 + 0.1 + 0.02 = 2.5 Rs/Kg Say- 2.5 Rs/Kg

Confidential

Page 9

KUMAR ORGANIC PRODUCTS LIMITED

8. Calculation: -New Solid Fuel Boiler As maximum combined steam load for both units is = 2075 Kg/hr Say = 2100 Kg/hr is the maximum load of steam for the both units Assuming 20% extra capacity for future expansion so capacity of new boiler = 2100 x 1.2 = 2520 Kg/hr As per above calculations it will safer to go for boiler of capacity =3000Kg/hr Basis: Boiler Capacity 3000 Kg/hr Data: 1. Bulk density of wood = 700 Kg/m3 2. Gross calorific value of briquette = 3700 Kcal 3. Cost of wood = 3.5 Rs/Kg 4. Efficiency of boiler = 68% 1. Consumption of wood per hr M x = G.C.V x Mass of briquette Mass of Wood = (M x ) / G.C.V = (3000 x 540) / 3700 = 437.8 Kg/hr But Efficiency is 68% Actual Wood consumption per hr = 437.8 / 0.68 = 643.8 Kg/hr Say 650 Kg/hr 2. Space requirement for wood storage Basis: 24 hrs operations and 4 days of storage Volume required for 4 days storage = (24 x 4 x 650) / 700 = 89.14 m3 Say = 90 m3 Assuming stacking height as 2 meter maximum Dimension of the storage room required is 15 X 3 X 2 meter

Confidential

Page 10

KUMAR ORGANIC PRODUCTS LIMITED

3. Steam Cost The cost of fuel / kg of steam = 3.5 / ((3700 / 540) X 0.68) = 0.76 Rs/Kg of steam Assuming cost of power = 0.1 Rs/kg Manpower cost = 0.03 Rs/Kg Total cost of steam = 0.76 + 0.1 + 0.03 = 0.89 Rs/Kg Say= 0.9 Rs/Kg 08.1 Conclusion: Expected Savings From above calculations it is clear that cost of steam by solid fuel boiler will be much cheaper then FO fired non IBR boilers. Minimum 50% savings can be achieved by replacing four 850 Kg/hr FO fired non IBR boiler by one single 3 T/hr solid fuel IBR steam boiler. It will be beneficial to go for 1 IBR boiler instead of running 4 non IBR boilers. Present Steam cost = 2.5 Rs/ Kg of steam Expected Steam Cost = 0.9 Rs / Kg of steam Savings on per Kg steam = 2.5 0.9 =1.6 Rs Or Say minimum 1.25Rs/kg Average Steam consumption of both the plants = 1700 Kg/hr Or 1700 x 20hr x 30days = 10,20,000Kg / month Average minimum savings will be = 1.25 x 10,20,000 = 12,75,000 Rs / month Or = 12 x 12,75,000 = 1,53,00,000 / Annum.

Say

= 1,50,00,000 / Annum.

Confidential

Page 11

KUMAR ORGANIC PRODUCTS LIMITED

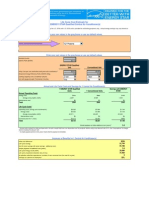

08.2 Payback calculation: Investment on new soild fuel boiler is given below in table; Sl No. 1 2 3 4 5 6 7 Description Boiler Turnkey Project Civil Work (Shed & Foundation) Soft water Piping & Pump Soft Water storage tank Contingencies SubTotal-01 Interest @ 12% Depreciation 10% SubTotal-02 Grand Total Payback = 44.34 / 150 = 0.3 Year = 3.6 months Cost (Lacs) 26.75 5 2.5 0.6 1.5 36.35 4.36 3.63 7.99 44.34 Remark

= Say 4 months

09. Land requirement & Selection: Requirement of land including solid fuel storage area, Chimney, MDC, Boiler, air preheater unit, ID fan, FD fan, blow down pit, soft water storage tank and feed water tank will be near about 400 M2. Land should be far from process area as a safety point of view. To cope-up with above requirement only suitable place is Shashank Block which is in the middle of the both process units. Free land area behind maintenance workshop is near about 768 M2 (32 Mtr x 24 Mtr), which can be utilized very effectively for above requirement. 10. Layout plan for new 3T steam Boiler: Layout plan for new boiler is given below:

Confidential

Page 12

KUMAR ORGANIC PRODUCTS LIMITED

Propsed layout Plan of 3 T Steam Boiler at Shashank Block

14.4 9.3 Vaccant Space 9.3 X 1.5 APH: 1.5 X 1.5 MDC: 1.5 X 1.5 IDF: 0.8 X 1.5 Chimeny Foundation N

Unit- Mtr

2.4 2.7

7.3

Column: 2X 0.4 Column: 2X 0.4

Vaccant Space: 1.5 X 9.0

Furnace : 2.9 X 3.0

Shell : 4.0 X 1.6

Side Space: 2.7 X 11.0

Pathway to Storage :2.4 X 13.4

Firing 3.7 Office Space: 2.0 X 2.0

Column -0.3 x 0.3 Boiler House: 10.30 X 9.30 Pathway to Storage :2.4 X 11.7 23.8

13.4 11.7

Soft Water Storage Tank-10 KL

1x0.4

Pump

Fuel Storage :2.7 X 16.5

Green Area 11.7 X 10.4

Future Ezpansion for Fuel storage : 2.80 X 10.40

PED/AAD/RAM/18.07.08

Confidential

Page 13

KUMAR ORGANIC PRODUCTS LIMITED

Quotations for 3T steam boiler: For new 3T solid fuel steam boiler weve got three different quotations from three parties M/s Forbes Marshall, M/s Thermax and M/s Micro Tech Boilers. Here M/s Thermax has submitted their quote for conversion of existing 4 T FO fired boiler to solid fuel boiler at Harpanhalli unit, while others have given their quote for new 3 T solid fuel steam boilers. The amounts theyve quoted are 70 Lacs for M/s Forbes Marshall, 34 Lac s for M/s Thermax and 29 Lacs for M/s Micro Tech Boilers. Most effective quote for 3T boiler is from M/s Forbes Marshall because of benefit of their Energy audit at KOPL & detailed study report submitted by them.

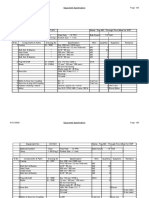

11. Comparison report for 3T Steam Boiler:

Three quotations are received for 3T steam boiler, a brief comparison report for them are given below

Confidential

Page 14

KUMAR ORGANIC PRODUCTS LIMITED

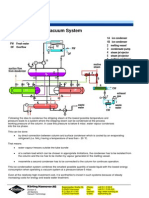

13. Schematic diagram of 3 T Solid Fuel Boiler

Confidential

Page 15

KUMAR ORGANIC PRODUCTS LIMITED

As its clear from above comparison among three parties that M/s Micro tech Boilers have given the most competitive quote as point of price. After discussions with their existing customers like Mr. Gautam Chaudhary (MD M/s Santosh Maize & India Ltd), boiler performance report is found satisfactory. Finally the order for new 3 T Steam boiler is given to M/s Microtech Boilers. A schematic diagram of the solid fuel boiler is given below Finally whole Turn-Key project is given to M/s Micro tech Boilers for 26.75 Lacs inclusive of all taxes. 13. Schematic diagram of 3 T Solid Fuel Boiler

Confidential

Page 16

KUMAR ORGANIC PRODUCTS LIMITED

14. Other details of new 3 T Steam Boiler: Following points to be consider for new boiler. 14.1 Feed Water details:

a. Feed water requirement for the boiler is 3m3/hr and it will be process at same

existing Soft water & RO plant at Shaureya block.

b. Capacity of RO plant Shaureya Block is 4.5 M3/hr. c. As distance between new boiler house to soft water plane will be 200-225 mtr. d. Specification of final discharge pumps at Soft water plant is Head-35 Mtr &

Flow- 4 M3/hr which is sufficient to pump the feed water to the boiler house.

e. For supply of feed water combination of two storage tanks of capacity 5 KL

& 10 KL will be utilized.

f. One 10 KL storage tank will be kept at boiler house on the ground which will

be flooded by soft water plant. From this 10 KL storage tank water will be pumped to 5 KL storage tank.

g. Existing 5 KL storage tank of soft water plant will be kept on the top of the

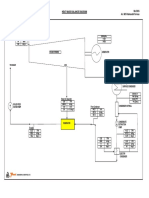

proposed boiler house (existing Building) for Boiler feeding. 14.2 Layout & Sizing of pipe line: a. In boiler house two headers shall be made i.e. High Pressure & Low Pressure. b. From HP header to LP header steam will be supplied through one PRS station. c. From HP header two lines will go to Jigani Unit & Shaureya Block (Jappro unit) of 65NB/50NB. d. For Jigani plant after Jappro unit line will be converted to 80NB LP line by using one PRS station. e. From LP header two lines of 40NB/80NB will go to pilot plant & Shaureya block.

Confidential

Page 17

KUMAR ORGANIC PRODUCTS LIMITED

Jigani & Shaureya Plant New Boiler piping Layout

Scale 01mm = 01 Mtr Jigani Unit

LP

26

HP

40 20

Pilot Plant

2 8 50 26

03MT Boiler

Shashank Block

60

N

Solvent Tanks

24

Shaureya Block

64

LP

HP

18.07.08/AAD/RAM

Process Engineering Department

14.3

Chimney dismantling & Fixing: a. Chimney dismantling from Harpanhalli unit, shifting & fixing for new 3T Steam boiler. b. Chimney dismantling from Shaureya Block incinerator, shifting & fixing at Harpanhalli boiler.

Confidential

Page 18

Das könnte Ihnen auch gefallen

- Electric Boilers: Learning OutcomeDokument8 SeitenElectric Boilers: Learning OutcomeKaustabha DasNoch keine Bewertungen

- Cooling Tower ComparisonDokument4 SeitenCooling Tower ComparisonKiran DasNoch keine Bewertungen

- Impact of Heating Rates On The Vibrated Bulk Density of CPCDokument23 SeitenImpact of Heating Rates On The Vibrated Bulk Density of CPCVinodh KumarNoch keine Bewertungen

- 00-83T0040-220 - Balance of Plant - Material BalanceDokument17 Seiten00-83T0040-220 - Balance of Plant - Material BalanceNguyễn Tiến ĐạtNoch keine Bewertungen

- Energy BalanceDokument6 SeitenEnergy BalanceAnissa MuniraNoch keine Bewertungen

- Energy and Process Optimization for the Process IndustriesVon EverandEnergy and Process Optimization for the Process IndustriesNoch keine Bewertungen

- Note - All Yellow Cells Are Manditory To Be FilledDokument2 SeitenNote - All Yellow Cells Are Manditory To Be FilledPrashant SinghNoch keine Bewertungen

- Design Calc - Cooling Tower Sizing - R1 - 15.10.2011Dokument1 SeiteDesign Calc - Cooling Tower Sizing - R1 - 15.10.2011AliAliNoch keine Bewertungen

- Energy Efficiency ImprovementDokument34 SeitenEnergy Efficiency Improvementkingcobra008Noch keine Bewertungen

- Boiler CalculationDokument4 SeitenBoiler Calculationmohsin husen BargirNoch keine Bewertungen

- Boiler Fuel Consumption CalcuyaltionDokument4 SeitenBoiler Fuel Consumption CalcuyaltionNewaz Kabir50% (2)

- ECAT Analysis GuideDokument12 SeitenECAT Analysis GuideElder RuizNoch keine Bewertungen

- BOILER - General OverviewDokument73 SeitenBOILER - General OverviewFahrul FauziNoch keine Bewertungen

- Generating Pump System Resistance CurveDokument4 SeitenGenerating Pump System Resistance CurveKiran DasNoch keine Bewertungen

- Generating Pump System Resistance CurveDokument4 SeitenGenerating Pump System Resistance CurveKiran DasNoch keine Bewertungen

- Vacuum SystemsDokument1 SeiteVacuum Systemslkumar4454Noch keine Bewertungen

- Boiler SpecificationDokument62 SeitenBoiler SpecificationamitjpNoch keine Bewertungen

- WHRB (HRSG) Performance CalculationsDokument9 SeitenWHRB (HRSG) Performance CalculationsLiam MoylanNoch keine Bewertungen

- HMBD IndicativeDokument1 SeiteHMBD Indicativeponmanikandan1Noch keine Bewertungen

- Boiler DataDokument72 SeitenBoiler DataAnirudh MeshramNoch keine Bewertungen

- Design Parameters Steam TurbineDokument25 SeitenDesign Parameters Steam TurbineeshanrastogiNoch keine Bewertungen

- BOILER DossierDokument18 SeitenBOILER DossierKiran DasNoch keine Bewertungen

- Final Ventury Working For Wet Alkaline ScrubberDokument11 SeitenFinal Ventury Working For Wet Alkaline ScrubberNanasaheb JagtapNoch keine Bewertungen

- Technical Specifications For Sugauli CogenDokument558 SeitenTechnical Specifications For Sugauli Cogenchaitanya_kumar_13Noch keine Bewertungen

- Hydrogen Generation PlantDokument11 SeitenHydrogen Generation PlantNageswar Makala100% (1)

- Jet Venturi Fume ScrubbersDokument7 SeitenJet Venturi Fume ScrubbersihllhmNoch keine Bewertungen

- Synopsis by WambeckDokument671 SeitenSynopsis by WambeckSteve Ubiam100% (3)

- 4.hydrogen Generator System and FunctionsDokument4 Seiten4.hydrogen Generator System and FunctionsAnonymous ffje1rpaNoch keine Bewertungen

- Performance Analysis and Optimization of Double-Flash Geothermal Power Plants PDFDokument9 SeitenPerformance Analysis and Optimization of Double-Flash Geothermal Power Plants PDFManahan SinagaNoch keine Bewertungen

- Ebook BoilerDokument99 SeitenEbook BoilerDari YantoNoch keine Bewertungen

- Clearer View of CrystilizerDokument5 SeitenClearer View of CrystilizerChem.EnggNoch keine Bewertungen

- Basic Design Equations For Multiphase ReactorsDokument32 SeitenBasic Design Equations For Multiphase ReactorsKiran DasNoch keine Bewertungen

- Calculation of Boiler EfficiencyDokument43 SeitenCalculation of Boiler EfficiencyTamer Abd ElrasoulNoch keine Bewertungen

- Table 1 Suggested Water Quality Limits: Source: The American Society of Mechanical EngineersDokument5 SeitenTable 1 Suggested Water Quality Limits: Source: The American Society of Mechanical EngineersGabriella LemanNoch keine Bewertungen

- Specs For NG - MFO Fired Thermal Oil HeaterDokument52 SeitenSpecs For NG - MFO Fired Thermal Oil HeaterRakapradiftaNoch keine Bewertungen

- DLT 5054-1996Dokument245 SeitenDLT 5054-1996ecsuperalNoch keine Bewertungen

- Study of Vapour Absorption System Using Waste Heat-F0283439Dokument6 SeitenStudy of Vapour Absorption System Using Waste Heat-F0283439Anonymous NGXdt2BxNoch keine Bewertungen

- How Much Coal Required To Produce 1 MW Power?: What Is The TPH of A Boiler?Dokument5 SeitenHow Much Coal Required To Produce 1 MW Power?: What Is The TPH of A Boiler?coconut borneoNoch keine Bewertungen

- Circulating Fluidized Bed BoilersDokument86 SeitenCirculating Fluidized Bed BoilersNguyen Quyet ThangNoch keine Bewertungen

- Pug MillDokument4 SeitenPug Millprashant mishraNoch keine Bewertungen

- Evaluation of Minimum Wall Thickness Calculation On Pipe/Tube CDGT KM 125, Duri HRSG # 02Dokument1 SeiteEvaluation of Minimum Wall Thickness Calculation On Pipe/Tube CDGT KM 125, Duri HRSG # 02Muhammad RezaNoch keine Bewertungen

- Kopp Rules Heat Capacity Solid PDFDokument134 SeitenKopp Rules Heat Capacity Solid PDFMouad ArradNoch keine Bewertungen

- ME6701-Power Plant EngineeringDokument16 SeitenME6701-Power Plant EngineeringNizam MANoch keine Bewertungen

- TEWI AnalysisDokument63 SeitenTEWI Analysismirali74Noch keine Bewertungen

- Air Monitoring Combustion Air Power BoilersDokument189 SeitenAir Monitoring Combustion Air Power BoilersAnonymous zdCUbW8HfNoch keine Bewertungen

- FGD Comparison - Wet Vs Semi Dry Vs DryDokument6 SeitenFGD Comparison - Wet Vs Semi Dry Vs DryAnonymous wIPMQ5rhNoch keine Bewertungen

- Boiler Types and ClassificationsDokument26 SeitenBoiler Types and ClassificationshardikNoch keine Bewertungen

- Coal ChemicalsDokument76 SeitenCoal ChemicalsNaag RajNoch keine Bewertungen

- Boiler Water TreatmentDokument1 SeiteBoiler Water TreatmentRommel Cena NepalarNoch keine Bewertungen

- Cryogenic Air Separation Unit, Oxy-CombustionDokument15 SeitenCryogenic Air Separation Unit, Oxy-CombustionHWANG INBUMNoch keine Bewertungen

- Thermal Efficiency of Turbine in A Thermal Power PlantDokument6 SeitenThermal Efficiency of Turbine in A Thermal Power PlantRavishankarNoch keine Bewertungen

- Rancang Bangun Degumming Pengolahan Cpo (Crude Palm Oil) AllDokument61 SeitenRancang Bangun Degumming Pengolahan Cpo (Crude Palm Oil) AllNovianti NoviNoch keine Bewertungen

- HEI Standards For Air Cooled Condensers - Dave Sanderlin SPIG USADokument8 SeitenHEI Standards For Air Cooled Condensers - Dave Sanderlin SPIG USASyed HafeezNoch keine Bewertungen

- Gacl-Dahej Captive Co-Generation Power Plant Corrected Gas Turbines Output Calculation On Site ConditionDokument8 SeitenGacl-Dahej Captive Co-Generation Power Plant Corrected Gas Turbines Output Calculation On Site Conditionakulahtu78Noch keine Bewertungen

- Energy Balanc HHV GPHR Asme PTCDokument2 SeitenEnergy Balanc HHV GPHR Asme PTCramli123Noch keine Bewertungen

- Test for Half of Condenser Operation冷凝器半面运行试验Dokument2 SeitenTest for Half of Condenser Operation冷凝器半面运行试验erwin5sambas5aryanaNoch keine Bewertungen

- Thermodynamic 2-Topic 5: RefrigerantDokument32 SeitenThermodynamic 2-Topic 5: RefrigerantAhmad Yusof SoapNoch keine Bewertungen

- RideDokument8 SeitenRidewahyuNoch keine Bewertungen

- Simple ORC Model SQ110918Dokument9 SeitenSimple ORC Model SQ110918radanpetricaNoch keine Bewertungen

- Name Plate Water ChillerDokument1 SeiteName Plate Water ChillerRizky Adi FirdausNoch keine Bewertungen

- Steam TablesDokument16 SeitenSteam TablesDanu MamlukatNoch keine Bewertungen

- 1 - Transmittal No. R0051734-CTCDokument7 Seiten1 - Transmittal No. R0051734-CTCNanang Cesc UttaNoch keine Bewertungen

- Zhang Yie Zien. High-Rate Mesophilic Anaerobic Digestion of Palm Oil Mill Effluent (POME) PDFDokument6 SeitenZhang Yie Zien. High-Rate Mesophilic Anaerobic Digestion of Palm Oil Mill Effluent (POME) PDFZainul Fikri TampengNoch keine Bewertungen

- Co-Generation in Textile Industries: Sandeep KumarDokument4 SeitenCo-Generation in Textile Industries: Sandeep KumartheijesNoch keine Bewertungen

- 04-2007!08!04-Comparison-500MW SC & SubC Plants in IndiaDokument4 Seiten04-2007!08!04-Comparison-500MW SC & SubC Plants in IndiaSovan NandyNoch keine Bewertungen

- MinitabHelp Regression EN PDFDokument1 SeiteMinitabHelp Regression EN PDFKiran DasNoch keine Bewertungen

- Calc CACDokument5 SeitenCalc CACKiran DasNoch keine Bewertungen

- Topic: Co-Current Gas-Liquid Flow in Slightly Inclined Pipes Presented By: John Lioumbas, Ph.D. Chemical Engineering, Thessaloniki, GreeceDokument1 SeiteTopic: Co-Current Gas-Liquid Flow in Slightly Inclined Pipes Presented By: John Lioumbas, Ph.D. Chemical Engineering, Thessaloniki, GreeceKiran DasNoch keine Bewertungen

- Me1202 - Fluid Mechanics MachineriesDokument15 SeitenMe1202 - Fluid Mechanics MachineriesKiran DasNoch keine Bewertungen

- HCufkjDokument84 SeitenHCufkjKiran DasNoch keine Bewertungen

- NetSentinel Security ServerDokument9 SeitenNetSentinel Security ServerKiran DasNoch keine Bewertungen