Beruflich Dokumente

Kultur Dokumente

209 Topcem Pronto GB NoRestriction

Hochgeladen von

FloorkitOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

209 Topcem Pronto GB NoRestriction

Hochgeladen von

FloorkitCopyright:

Verfügbare Formate

m o e t c n p o o r T P

EMICODE

EN 13813

GEV

Ready-to-use, normal setting, controlled-shrinkage mortar for quick-drying screeds (4 days)

CLASSIFICATION ACCORDING TO EN 13813 Screeds prepared with Topcem Pronto in accordance with the specifications described in this technical data sheet are classified as CT - C30 - F6 - A1fl in compliance with the European Norm EN 13813. WHERE TO USE For forming unbonded and bonded screeds on new and existing slabs in interiors and exteriors prior to installing wood,PVC, linoleum, ceramic tile, natural stone, carpet, or other floor coverings in areas where fast-drying screeds are required in order to lay floorings in a short time. Some application examples Forming screeds that are trafficable in 12 hours and completely dry in 4 days, for installing wood parquet and resilient flooring such as rubber, PVC, linoleum, etc. Screeds that are ready to receive ceramic tiles after 24 hours and natural stone flooring after 2 days. Repairing screeds in areas where it is required to lay floorings in a short time (e.g. supermarkets, shops, residences, offices, etc.). Forming heated screeds without the need for polymer additives. TECHNICAL CHARACTERISTICS Topcem Pronto is a pre-blended ready-to-use mortar with normal setting and controlled shrinkage based on a special hydraulic binder and graded aggregate. Topcem Pronto is extremely easy to use: just mix with water. This prevents mistakes from being made in adding the correct amount of binder and properly graded aggregate, which could compromise the final performance characteristics of the screed when cured. Topcem Pronto is the ideal solution where good quality graded aggregate is hard to find or for job sites such as those in city centres where the logistics involved in mixing conventional binders can be difficult. Topcem Pronto is workable for the same length of time as conventional cement based mortars but cures much faster. RECOMMENDATIONS Do not use Topcem Pronto on substrates subject to rising damp (place a vapour barrier in between). Do not mix Topcem Pronto with other binders (e.g. Mapecem, Topcem, cement, lime, gypsum, etc.) or aggregate. Mix Topcem Pronto with the correct amount of water. Do not add water to the Topcem Pronto mix once it has begun to set. Do not wet the surface of the Topcem Pronto screed.

209_topcem pronto_gb (28.01.2012 - 3 Bozza/Ciano/PDF)

emto c p ron o T P

APPLICATION PROCEDURE Preparing the substrate Topcem Pronto can be used on any substrate as long as it is not subject to rising damp. If so, use a waterproof membrane. For screeds from 10 to 35 mm thick, that require anchoring, the substrate must be dry, without cracks, free of dust and loose particles, varnish, wax, oil, and gypsum residue. Preparing the mix Topcem Pronto can be mixed in: rotating mixers; normal job site mixers; centrifugal mixers; truck mixers; automatic pressure pumps. Mix one 25-kg bag of Topcem Pronto with 1.7 l of water for at least 5 minutes. Never vary the amount of water because this will weaken the mortars final performance. The mix should have a semi-dry consistency. Tamp and float the mix until a dense, smooth surface is obtained without bleeding. UNBONDED SCREEDS (35 to 60 mm thick) The Topcem Pronto mix must be laid on an isolating layer, made up of a polyethylene sheet barrier, or similar, to allow for movement between the screed and the existing substrate. In case of rising damp use a waterproof membrane to form a vapour barrier underneath the screed. Areas of Topcem Pronto screeds containing pipes must be reinforced with light steel reinforcement such as a hexagonal mesh. Spread the Topcem Pronto mix just like any other cement based screed mix: use screed guides, then spread the mix, and tamp thoroughly before floating to obtain a better surface finish. Place isolating material (such as cardboard, polystyrene foam, cork, etc.) about 1 cm thick around the sides of the area and around columns before casting. If work is interrupted, place steel rods 20 to 30 cm long and 3 to 6 mm in diameter, spaced 20 to 30 cm apart, into the screed (which has been cut perpendicular to the substrate) to ensure a perfect connection between the new and the old pours and to prevent uneven joins and cracks. The Topcem Pronto mix is usually workable for a greater length of time than a conventional screed mix. Ambient temperatures may influence the setting and drying times.

BONDED SCREEDS (from 10 to 40 mm thick) Thin screeds must be laid directly in contact with the substrate, which may be cementitious material or made up of an old ceramic or stone floor. For other substrates, consult the MAPEI Technical Service. Once the substrate has been prepared sufficiently, and immediately before spreading on the Topcem Pronto mix, prepare bonding slurry with Planicrete according to the ratio in the table below. Apply a continuous, even 2-3 mm layer using a large flat brush, a scrubbing brush or a trowel. To get perfect adhesion, spread the Topcem Pronto on the slurry while it is still fresh (fresh on fresh technique). If the floor is subjected to high mechanical stresses, the construction joint must be made by replacing the Planicrete cementitious bonding slurry with Eporip. Spread on the Topcem Pronto using the same method described above. Mixing ratio for Planicrete cementitious slurry Planicrete: 1 part in weight; Water: Topcem: 1 part in weight; 3 parts in weight.

MEASURING MOISTURE CONTENT Normal electric hygrometers give values that are not reliable for Topcem Pronto screeds. It is therefore absolutely necessary that a carbide hygrometer is used to measure the level of residual humidity; this instrument shows the absolute value of humidity by weight. CONSUMPTION 18-20 kg/m per cm of thickness, depending on compaction. Cleaning Clean tools with water. PACKAGING Topcem Pronto is available in 25 kg bags. STORAGE Topcem Pronto is stable for at least 12 months when stored in a dry place. The product complies with the conditions of Annex XVII to Regulation (EC) N 1907/2006 (REACH), item 47. SAFETY INSTRUCTIONS FOR PREPARATION AND INSTALLATION Topcem Pronto contains cement that, when in contact with sweat or other bodily fluids, produces an irritant alkaline reaction. Wear protective clothing, gloves and eye/face protection. For further and complete information about the safe use of our product please refer to our latest version of the Material Safety Data Sheet. PRODUCT FOR PROFESSIONAL USE.

TECHNICAL DATA (typical values)

Conformity with: European EN 13813 CT - C30 - F6 - A1fl

PRODUCT IDENTITY Consistency: Colour: Bulk density (kg/m): Dry solids content (%): Hazard classification according to EC 1999/45: powder grey 1,500 100 irritant. Before using refer to the Safety instructions for preparation and application paragraph and the information on the packaging and Safety Data Sheet EC1 R Plus - extremely low emission level

EMICODE: APPLICATION DATA (at +23C - 50% R.H.) Mix ratio: Density of the mix (kg/m): Mixing time: Workability of the mix: Application temperature range: Set to light foot traffic: Waiting time before application of levelling compounds: FINAL PERFORMANCE DATA Resistance to moisture: Resistance to ageing: Resistance to solvents and oils: Resistance to acids and alkalis: Resistance to temperature: Flexibility:

1.7 l of water per 25 kg of Topcem Pronto 2,100 depending on compaction 5 to 10 mins 60 mins from +5C to +35C after 12 hours 1 to 4 days, depending on the type of flooring to be laid

excellent excellent excellent poor from -30C to +90C no

Compressive and flexural strength, and resistance to residual moisture

after 1 day: after 4 days: after 7 days: after 28 days:

Compressive strength (N/mm)

> 8 > 15 > 22 > 30

Flexural strength (N/mm)

>3 >4 >5 >6

Residual moisture (%)

< 3.5 < 2.0

emto c p ron o T P

WARNING Although the technical details and recommendations contained in this product data sheet correspond to the best of our knowledge and experience, all the above information must, in every case, be taken as merely indicative and subject to confirmation after long-term practical application: for this reason, anyone who intends to use the product must ensure beforehand that it is suitable for the envisaged application: in every case, the user alone is fully responsible for any consequences deriving from the use of the product. Please refer to the current version of the Technical Data Sheet, available from our website www.mapei.com

This symbol is used to identify Mapei products which give off a low level of volatile organic compounds (VOC) as certified by GEV (Gemeinschaft Emissionskontrollierte Verlegewerkstoffe, Klebstoffe und Bauprodukte e.V.), an international organisation for controlling the level of emissions from products used for floors.

Our Commitment To The Environment More than 150 MAPEI products assist Project Designers and Contractors create innovative LEED (The Leadership in Energy and Environmental Design) certified projects, in compliance with the U.S. Green Building Council.

All relevant references for the product are available upon request and from www.mapei.com

BUILDING THE FUTURE

209-1-2012

Any reproduction of texts, photos and illustrations published here is prohibited and subject to prosecution

(GB) A.G. BETA

Das könnte Ihnen auch gefallen

- Lenovo S340-15iwl Compal LA-H101P SchematicDokument53 SeitenLenovo S340-15iwl Compal LA-H101P SchematicYetawa Guaviare100% (4)

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringVon EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringBewertung: 4 von 5 Sternen4/5 (5)

- Altro Sample Card Altro PVC Weld RodDokument1 SeiteAltro Sample Card Altro PVC Weld RodFloorkitNoch keine Bewertungen

- LhiannanDokument6 SeitenLhiannanGreybornNoch keine Bewertungen

- Information Security Master PlanDokument6 SeitenInformation Security Master PlanMarubadi Rudra Shylesh Kumar100% (2)

- Mapecem Pronto Data - BakDokument4 SeitenMapecem Pronto Data - BakFloorkitNoch keine Bewertungen

- 2608 Planitop Fast 330 Uk NoRestrictionDokument4 Seiten2608 Planitop Fast 330 Uk NoRestrictionFloorkitNoch keine Bewertungen

- 2069 Mapelastic Foundation GB NoRestrictionDokument4 Seiten2069 Mapelastic Foundation GB NoRestrictionFloorkitNoch keine Bewertungen

- A Solvent-Free Non-Staining Acrylic-Adhesive in Water DispersionDokument4 SeitenA Solvent-Free Non-Staining Acrylic-Adhesive in Water DispersionFloorkitNoch keine Bewertungen

- 2504 Ultrabond Eco s945 1k GBDokument4 Seiten2504 Ultrabond Eco s945 1k GBFloorkitNoch keine Bewertungen

- Rapid Set Tds - NoRestrictionDokument4 SeitenRapid Set Tds - NoRestrictionFloorkitNoch keine Bewertungen

- Cemtop 400SD: Cement Based, Self Levelling, Industrial Floor Surfacing System - 6mm To 12mmDokument4 SeitenCemtop 400SD: Cement Based, Self Levelling, Industrial Floor Surfacing System - 6mm To 12mmBalasubramanian AnanthNoch keine Bewertungen

- List of Icons: Product InfoDokument11 SeitenList of Icons: Product InfoniroNoch keine Bewertungen

- Technical Data SheetDokument5 SeitenTechnical Data SheetPEng. Tech. Alvince KoreroNoch keine Bewertungen

- Mapei FibreplanDokument4 SeitenMapei FibreplanFloorkitNoch keine Bewertungen

- Cemtop 400SD PDFDokument4 SeitenCemtop 400SD PDFriverwilliamsNoch keine Bewertungen

- Latexplan Trade NoRestrictionDokument4 SeitenLatexplan Trade NoRestrictionFloorkitNoch keine Bewertungen

- Planicrete NoRestrictionDokument4 SeitenPlanicrete NoRestrictionFloorkitNoch keine Bewertungen

- 1 MF enDokument5 Seiten1 MF enachmad rizalNoch keine Bewertungen

- Epoxy Flooring TDSDokument7 SeitenEpoxy Flooring TDSMohamed MagdiNoch keine Bewertungen

- TDS en Tecnocoat CP 2049Dokument7 SeitenTDS en Tecnocoat CP 2049recep kablanNoch keine Bewertungen

- Ultrabond P902 2K Ultrabond P902 2K: Two-Component Epoxy-Polyurethane Adhesive For Wooden FlooringDokument4 SeitenUltrabond P902 2K Ultrabond P902 2K: Two-Component Epoxy-Polyurethane Adhesive For Wooden FlooringFloorkitNoch keine Bewertungen

- 2918 Mapeproof 1k Turbo UkDokument4 Seiten2918 Mapeproof 1k Turbo UkFloorkitNoch keine Bewertungen

- Tds - Emaco Cp10h - Emaco Cp10vDokument3 SeitenTds - Emaco Cp10h - Emaco Cp10vVenkata RaoNoch keine Bewertungen

- Euco TopDokument2 SeitenEuco Toppravi3434Noch keine Bewertungen

- 270 Ultrabondecos9551k GBDokument4 Seiten270 Ultrabondecos9551k GBFloorkitNoch keine Bewertungen

- Waterproofing MethodologyDokument16 SeitenWaterproofing MethodologyGaurav Nijhawan100% (1)

- FloArm Screed Eco Ver7Dokument4 SeitenFloArm Screed Eco Ver7imsNoch keine Bewertungen

- Proposal - Ayush ParkDokument25 SeitenProposal - Ayush ParkAvinash PhaseNoch keine Bewertungen

- Eco Pim TDokument4 SeitenEco Pim TFloorkitNoch keine Bewertungen

- Conbextra GP TDSDokument4 SeitenConbextra GP TDSMoataz MedhatNoch keine Bewertungen

- Tovcol T.A.: Chemical-Physical Characteristics (20ºC - 60% R.H.)Dokument2 SeitenTovcol T.A.: Chemical-Physical Characteristics (20ºC - 60% R.H.)jowicvNoch keine Bewertungen

- Amiantit. Field Installation ProcedureDokument37 SeitenAmiantit. Field Installation ProcedureABAID ULLAHNoch keine Bewertungen

- Sikafloor 81 EpocemDokument6 SeitenSikafloor 81 Epocemthe pilotNoch keine Bewertungen

- 4005 Ultraplan Eco 20 UaeDokument0 Seiten4005 Ultraplan Eco 20 UaeJohn SarthouNoch keine Bewertungen

- Jotun Epoxy Filler: Technical Data Sheet Application GuideDokument5 SeitenJotun Epoxy Filler: Technical Data Sheet Application GuidekajaqcNoch keine Bewertungen

- Florgard SLDokument3 SeitenFlorgard SLcharibackupNoch keine Bewertungen

- 5.thomsit DX Self Levelling - 3-Aug-10Dokument2 Seiten5.thomsit DX Self Levelling - 3-Aug-10adchem123Noch keine Bewertungen

- Eco Application GuideDokument8 SeitenEco Application GuidemsbaupartnerNoch keine Bewertungen

- Sikafloor 82 EpocemDokument6 SeitenSikafloor 82 Epocemthe pilotNoch keine Bewertungen

- Penguard Clear Sealer: Technical Data Sheet Application GuideDokument7 SeitenPenguard Clear Sealer: Technical Data Sheet Application GuideAnonymous 4SFfEmcHmDNoch keine Bewertungen

- Mapefloor Installation Manual-EN PDFDokument24 SeitenMapefloor Installation Manual-EN PDFYatsen Jepthe Maldonado SotoNoch keine Bewertungen

- FlotopDokument2 SeitenFlotoppravi3434Noch keine Bewertungen

- Thorolastic: Water-Based, 100% Acrylic, Elastomeric, Waterproof CoatingDokument6 SeitenThorolastic: Water-Based, 100% Acrylic, Elastomeric, Waterproof CoatingmrafigNoch keine Bewertungen

- 4007 Ultraplan Renovation Screed Uk NoRestrictionDokument2 Seiten4007 Ultraplan Renovation Screed Uk NoRestrictionFloorkitNoch keine Bewertungen

- Floor Tech SP PrimerDokument2 SeitenFloor Tech SP PrimerHatem JafouraNoch keine Bewertungen

- Betakril: Decorative Water-Based Exterior Product GroupDokument2 SeitenBetakril: Decorative Water-Based Exterior Product Groupmaga2292Noch keine Bewertungen

- FT Rimano Uni Eng 2013-08-01Dokument1 SeiteFT Rimano Uni Eng 2013-08-01Vladimir StojanovicNoch keine Bewertungen

- Mastertop 1210 Pds Asean 020811Dokument2 SeitenMastertop 1210 Pds Asean 020811hemajsuryaNoch keine Bewertungen

- Tds - Emaco Cp20Dokument3 SeitenTds - Emaco Cp20Venkata RaoNoch keine Bewertungen

- Nitowrap Method StatementDokument10 SeitenNitowrap Method StatementBalasubramanian AnanthNoch keine Bewertungen

- Application of Pentron ProdDokument3 SeitenApplication of Pentron ProdBabar AkbarNoch keine Bewertungen

- Ceresit Global Ce40 Aquastatic TdsDokument3 SeitenCeresit Global Ce40 Aquastatic TdsSurush ZikrilobekovNoch keine Bewertungen

- Planitop HPCDokument4 SeitenPlanitop HPCdraganugNoch keine Bewertungen

- CRYOGENIC MORTAR C-1 - PRODUCT DATA SHEET Ed. 2Dokument4 SeitenCRYOGENIC MORTAR C-1 - PRODUCT DATA SHEET Ed. 2ANIBAL LOPEZNoch keine Bewertungen

- 22 03 22 Methodology Purtop 400m Roofs Decks GuttersDokument6 Seiten22 03 22 Methodology Purtop 400m Roofs Decks GuttersLOGITHASAN KRISHNANNoch keine Bewertungen

- 2801 Ultracolor Plus GB NoRestrictionDokument6 Seiten2801 Ultracolor Plus GB NoRestrictionFloorkitNoch keine Bewertungen

- Sikafloor 161Dokument6 SeitenSikafloor 161Ajit Singh RathoreNoch keine Bewertungen

- Cmci Cmci: High Performance Epoxy Grout SystemDokument2 SeitenCmci Cmci: High Performance Epoxy Grout Systempravi3434Noch keine Bewertungen

- 31 Ultralite Rapid Flex s1 Uk NoRestrictionDokument4 Seiten31 Ultralite Rapid Flex s1 Uk NoRestrictionFloorkitNoch keine Bewertungen

- CSR - Roofseal Ultra - BOQDokument3 SeitenCSR - Roofseal Ultra - BOQCSR Consultant and AssociatesNoch keine Bewertungen

- Plasteroc MPRDokument2 SeitenPlasteroc MPRTori SmallNoch keine Bewertungen

- Techno XT TechnicalDokument4 SeitenTechno XT TechnicalniroNoch keine Bewertungen

- Camaro Loc BrochureDokument25 SeitenCamaro Loc BrochureFloorkitNoch keine Bewertungen

- Mastic Sample BoardDokument1 SeiteMastic Sample BoardFloorkitNoch keine Bewertungen

- No. 110 Inside Cove Corner KitDokument1 SeiteNo. 110 Inside Cove Corner KitFloorkitNoch keine Bewertungen

- Leoline Installation and MaintenanceDokument8 SeitenLeoline Installation and MaintenanceFloorkitNoch keine Bewertungen

- Invisiweld Installation GuidelinesDokument2 SeitenInvisiweld Installation GuidelinesFloorkitNoch keine Bewertungen

- Crain 247 Multi Purpose Wall TrimmerDokument2 SeitenCrain 247 Multi Purpose Wall TrimmerFloorkitNoch keine Bewertungen

- Avenue Installation and MaintenanceDokument8 SeitenAvenue Installation and MaintenanceFloorkitNoch keine Bewertungen

- Uzin L 3 Gold: Product Data SheetDokument2 SeitenUzin L 3 Gold: Product Data SheetFloorkitNoch keine Bewertungen

- L3 Gold System Primer GB 01Dokument2 SeitenL3 Gold System Primer GB 01FloorkitNoch keine Bewertungen

- Itec Installation GuidelinesDokument3 SeitenItec Installation GuidelinesFloorkitNoch keine Bewertungen

- Recommended Adhesives GuideDokument1 SeiteRecommended Adhesives GuideFloorkitNoch keine Bewertungen

- Uzin PE 260Dokument2 SeitenUzin PE 260FloorkitNoch keine Bewertungen

- Uzin PE 360Dokument2 SeitenUzin PE 360FloorkitNoch keine Bewertungen

- Uzin NC 152Dokument2 SeitenUzin NC 152FloorkitNoch keine Bewertungen

- Uzin NC 150 New: Product Data SheetDokument2 SeitenUzin NC 150 New: Product Data SheetFloorkitNoch keine Bewertungen

- Uzin Ke 2000 S: Product Data SheetDokument4 SeitenUzin Ke 2000 S: Product Data SheetFloorkitNoch keine Bewertungen

- Uzin KE 2428Dokument2 SeitenUzin KE 2428FloorkitNoch keine Bewertungen

- Uzin KE 603Dokument2 SeitenUzin KE 603FloorkitNoch keine Bewertungen

- Uzin NC 110Dokument4 SeitenUzin NC 110FloorkitNoch keine Bewertungen

- Ultrabond P902 2K Ultrabond P902 2K: Two-Component Epoxy-Polyurethane Adhesive For Wooden FlooringDokument4 SeitenUltrabond P902 2K Ultrabond P902 2K: Two-Component Epoxy-Polyurethane Adhesive For Wooden FlooringFloorkitNoch keine Bewertungen

- Uzin NC 150 New: Product Data SheetDokument2 SeitenUzin NC 150 New: Product Data SheetFloorkitNoch keine Bewertungen

- Uzin NC 145: Product Data SheetDokument2 SeitenUzin NC 145: Product Data SheetFloorkitNoch keine Bewertungen

- 231 Ultrabond Eco Vs90 UkDokument4 Seiten231 Ultrabond Eco Vs90 UkFloorkitNoch keine Bewertungen

- Uzin L 3 Gold: Product Data SheetDokument2 SeitenUzin L 3 Gold: Product Data SheetFloorkitNoch keine Bewertungen

- 270 Ultrabondecos9551k GBDokument4 Seiten270 Ultrabondecos9551k GBFloorkitNoch keine Bewertungen

- 219 Ultrabond Eco Fix UkDokument4 Seiten219 Ultrabond Eco Fix UkFloorkitNoch keine Bewertungen

- 268 Ultrabond Eco 520 UkDokument4 Seiten268 Ultrabond Eco 520 UkFloorkitNoch keine Bewertungen

- Buku BaruDokument51 SeitenBuku BaruFirdaus HoNoch keine Bewertungen

- BQ - Structural Works - CompressedDokument163 SeitenBQ - Structural Works - CompressedLee YuxuanNoch keine Bewertungen

- Standalone Financial Results, Limited Review Report For December 31, 2016 (Result)Dokument4 SeitenStandalone Financial Results, Limited Review Report For December 31, 2016 (Result)Shyam SunderNoch keine Bewertungen

- Deictics and Stylistic Function in J.P. Clark-Bekederemo's PoetryDokument11 SeitenDeictics and Stylistic Function in J.P. Clark-Bekederemo's Poetryym_hNoch keine Bewertungen

- MultiZone Limitations and HintsDokument2 SeitenMultiZone Limitations and HintsRubén Darío Becerra GalindoNoch keine Bewertungen

- Design and Analysis of DC-DC Boost Converter: September 2016Dokument5 SeitenDesign and Analysis of DC-DC Boost Converter: September 2016Anonymous Vfp0ztNoch keine Bewertungen

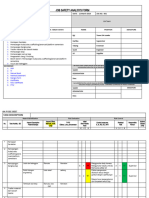

- JSA FormDokument4 SeitenJSA Formfinjho839Noch keine Bewertungen

- GSM Based Prepaid Electricity System With Theft Detection Using Arduino For The Domestic UserDokument13 SeitenGSM Based Prepaid Electricity System With Theft Detection Using Arduino For The Domestic UserSanatana RoutNoch keine Bewertungen

- Evolution of Management AccountingDokument35 SeitenEvolution of Management AccountingNuqiah Fathiah Seri100% (1)

- Datasheet of STS 6000K H1 GCADokument1 SeiteDatasheet of STS 6000K H1 GCAHome AutomatingNoch keine Bewertungen

- CMS156Dokument64 SeitenCMS156Andres RaymondNoch keine Bewertungen

- SeaTrust HullScan UserGuide Consolidated Rev01Dokument203 SeitenSeaTrust HullScan UserGuide Consolidated Rev01bong2rmNoch keine Bewertungen

- Nodal Analysis Collection 2Dokument21 SeitenNodal Analysis Collection 2Manoj ManmathanNoch keine Bewertungen

- 8A L31 Phiếu BTDokument7 Seiten8A L31 Phiếu BTviennhuNoch keine Bewertungen

- Lab Activity 5Dokument5 SeitenLab Activity 5Jasmin CeciliaNoch keine Bewertungen

- A List of 142 Adjectives To Learn For Success in The TOEFLDokument4 SeitenA List of 142 Adjectives To Learn For Success in The TOEFLchintyaNoch keine Bewertungen

- Exam Ref 70 483 Programming in C by Wouter de Kort PDFDokument2 SeitenExam Ref 70 483 Programming in C by Wouter de Kort PDFPhilNoch keine Bewertungen

- Ethics FinalsDokument22 SeitenEthics FinalsEll VNoch keine Bewertungen

- The Story of An Hour QuestionpoolDokument5 SeitenThe Story of An Hour QuestionpoolAKM pro player 2019Noch keine Bewertungen

- MBA 2nd Sem SyllabusDokument6 SeitenMBA 2nd Sem SyllabusMohammad Ameen Ul HaqNoch keine Bewertungen

- Industry GeneralDokument24 SeitenIndustry GeneralilieoniciucNoch keine Bewertungen

- Boeing SWOT AnalysisDokument3 SeitenBoeing SWOT AnalysisAlexandra ApostolNoch keine Bewertungen

- Tushnet - An Essay On RightsDokument43 SeitenTushnet - An Essay On RightslarisamannNoch keine Bewertungen

- Appsc Aee Mains 2019 Electrical Engineering Paper III 1fcbb2c9Dokument12 SeitenAppsc Aee Mains 2019 Electrical Engineering Paper III 1fcbb2c9SURYA PRAKASHNoch keine Bewertungen

- Dr. Babasaheb Ambedkar Technological UniversityDokument3 SeitenDr. Babasaheb Ambedkar Technological UniversityalfajNoch keine Bewertungen

- High Intermediate 2 Workbook AnswerDokument23 SeitenHigh Intermediate 2 Workbook AnswernikwNoch keine Bewertungen

- IPMI Intelligent Chassis Management Bus Bridge Specification v1.0Dokument83 SeitenIPMI Intelligent Chassis Management Bus Bridge Specification v1.0alexchuahNoch keine Bewertungen