Beruflich Dokumente

Kultur Dokumente

Ec9 Ex91 Tension Bending Interaction

Hochgeladen von

imotalpOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ec9 Ex91 Tension Bending Interaction

Hochgeladen von

imotalpCopyright:

Verfügbare Formate

Ec9_ex91_Interaction_Tension

Tension force and bending moment

Page 1 of 4

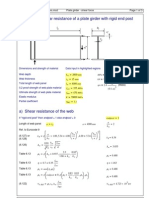

Example 9.1. Tension force and bending moment

Under the load at the centre of the beam there is a transverse web stiffener which means that there are cross welds on both the flanges and the web. The beam is restrained laterally at the load application point.

Dimensions and material properties

Flange height: Flange depth: Web thickness: h := 200 mm b := 140 mm tw := 12 mm

bf

tw z bw h y

Flange thickness: tf := 16 mm Length: Width of web plate: b w := h 2 tf b w = 168 mm L := 2 m

[1] Table 3.2b Alloy: EN AW-6082 T6 EP/O t > 5 mm fo := 260 MPa Buckling class E := 70000 MPa Partial safety factors: fu := 310 MPa BC := "A" G := 27000 MPa

FEd NEd L L

tf

Bending moment

M1 1.10 M2 1.25

Lateral buckling

Moment and force

Axial tension force and eccentricity Bending moment S.I. units kN 1000 newton NEd := 300 kN My.Ed := 40 kNm kNm kN m MPa 1000000 Pa

Classification of the cross section in bending. Effective thickness

Web

w := 0.40

bw tw

w = 5.6

:=

250 MPa fo

= 0.981

The cross welds at the centre of the beam does not influence the buckling class (see 6.1.4.4 (3)) [1] Table 6.2 BC = "A" [1] 6.1.5 (2)

1w := 11

2w := 16

3w := 22

classw := if w > 1w , if w > 2w , if w > 3w , 4 , 3 , 2 , 1

) ) ) ( )

classw = 1

Local buckling: cw := if

22 , 1.0 ,

32

220

w

aluMATTER

tw.ef := if classw 4 , tw cw , tw

cw = 1

tw.ef = 12.0 mm

T Hglund

2007-07-19

Ec9_ex91_Interaction_Tension

Tension force and bending moment

Page 2 of 4

Flanges

[1] 6.1.4.3 [1] Table 6.2 [1] 6.1.5 (2)

f :=

b tw tf

1f := 3

2f := 4.5

3f := 6

f = 8

classf = 4

classf := if f > 1f , if f > 2f , if f > 3f , 4 , 3 , 2 , 1

) ) )

Local buckling: cf := if

6 , 1.0 ,

10

tf.ef := if classf 4 , tf cf , tf

2 f

24

cf = 0.865

tf.ef = 13.84 mm

Classification of the total cross-section: class := if ( classf > classw , classf , classw) class = 4

Net section at the cross weld

[1] Table 6.2 HAZ softening factor

u.haz := 0.60

tf.haz := u.haz tf tw.haz := u.haz tw tf.haz = 9.6 mm tw.haz = 7.2 mm t1 = 14.652 mm b haz = 35 mm tf = 16 mm

[1] 6.2.5.1 (2) Effective thickness, flange Effective thickness, web

[1] 6.1.6.3 (3) Extent of HAZ i web (MIG-weld) t1 := 0.333 ( tw + 2 tf )

b haz := if ( t1 > 6 mm , if ( t1 > 12 mm , if ( t1 > 25 mm , 40 mm , 35 mm) , 30 mm) , 20 mm)

Bending moment resistance

[1] 6.2.5.1 Elastic modulus of gross cross section Wel: Agr := 2 b tf + ( h 2 tf ) tw Igr := Wel := 1 12 b h ( b tw) ( h 2 tf )

3 3

Agr = 6.496 10 mm

7 4 Igr = 4.276 10 mm

Igr 2 h 1 4 b h ( b tw) ( h 2 tf )

2 2

Wel = 4.276 10 mm

Plastic modulus Wple :=

5 3 Wple = 4.968 10 mm

Elastic modulus of the effective cross section Weffe: tf = 16 mm tf.ef = 13.842 mm tw = 12 mm tw.ef = 12 mm

Allowing for local buckling: Aeffe := Agr b ( tf tf.ef ) b haz ( tw tw.ef ) Shift of gravity centre: eef := b ( tf tf.ef ) Aeffe = 6.194 10 mm

3 2

b haz 1 h tf h + b haz ( tw tw.ef ) tf 2 Aeffe 2 2 2

eef = 4.487 mm

Second moment of area with respect to centre of gross cross section:

T Hglund

tf

b haz

te,f

b haz

2 2007-07-19

te,w

aluMATTER

bhaz

Ec9_ex91_Interaction_Tension

Tension force and bending moment Page 3 of 4 h f haz h haz Ieffe := Igr b ( tf tf.ef ) ( tw tw.ef ) b haz ( tw tw.ef ) tf 12 2 2 2 2

Ieffe = 4.02 10 mm

7 7 4 4 3

Second moment of area with respect to centre of effective cross section: Ieffe := Ieffe eef Aeffe Weffe := Ieffe h 2 [1] Tab. 5.3 + eef

2

Ieffe = 4.007 10 mm

5

Weffe = 3.835 10 mm

Shape factor for welded, class 4 cross-section

:=

Weffe Wel

= 0.897

Design moment and axial force resistance of the cross section ( My,Rd and NRd) [1] (5.14) My.Rd := fo Wel NRd := fo Aeffe My.Rd = 90.7 kNm NRd = 1.5 10 kN

3

M1

M1

Net section with HAZ softening

Anet := 2 b tf.haz + tw.haz b w Inet := 0.5 b tf.haz ( h tf ) + tw.haz b w

2 3 1

Anet = 3.898 10 mm 12 Inet = 2.56 10 mm

5 7 4

Wnet :=

Inet 2 h

Wnet = 2.56 10 mm

Design moment and axial force resistance of the net section ( My,Rd.net and NRd.ner) [1] (5.14) My.Rd.net := fu Wnet NRd.net := fu Anet My.Rd.net = 63.5 kNm NRd.net = 966.6 kN

M2

M2

Bending and axial force At effective section

[1] 6.2.9.1

[1] 6.2.9

Class 4 cross section:

0 := 1

= 0.646

0 := 1

0 := 1

[1] (5.40)

NEd N Rd

My.Ed + My.Rd

in section without weld

At net section

0 := 1

[1] (5.40)

0 := 1

0

0 := 1

0

NEd N Rd.net

My.Ed + My.Rd.net

= 0.94

in section with weld

T Hglund

aluMATTER

2007-07-19

Ec9_ex91_Interaction_Tension

Tension force and bending moment

[1] 6.3.2 2 b tf 12

3

Page 4 of 4

Lateral-torsional buckling

Lateral stiffness constant

Iz := Iw := It :=

h tw 12

Iz = 7.346 10 mm Iw = 6.218 10

10

[1] Figure J.2 Varping constant:

(h tf )2 Iz

4 2 b tf + h tw 3

3 3

mm

4

Torsional constant: Length [1] I.1.2 Moment relation and Support conditions [1] I.1.2 (6) C1 - constant Mono symmetry parameter Load application parameter Shear modulus [1] I.1.2 kwt :=

It = 4.975 10 mm L = 2m

:= 0

ky := 1 kz := 1 kw := 1

2

C1 := 0.310 + 0.428 + 0.262 zj := 0 zg := 0

0.5

C1 = 1.796

G = 2.7 10 MPa kwt = 0.894

2

kw L C1 kz

E Iw G It

[1] (I.3)

cr :=

1 + kwt

cr = 2.409

Wy := Wel

Mcr := cr

E Iz G It L

[1] 6.3.2.3 (1) LT :=

Wy fo

Mcr

LT = 0.563 LT = 0.2 0LT = 0.4

[1] 6.3.2.2 (2) LT := if ( class > 2 , 0.2 , 0.1)

0LT := if ( class > 2 , 0.4 , 0.6)

[1] 6.3.2.1 (1) LT := 0.5 1 + LT LT 0LT + LT

LT = 0.675 LT = 0.955

LT := LT +

LT LT

Design moment and axial force resistance of the cross section (no HAZ) [1] (5.14) Mb.Rd := LT fo Wel NRd := fo Agr Mb.Rd = 96.5 kNm NRd = 1.5 10 kN

3

M1

M1

Lateral-torsional buckling check with influence of axial tensile force

In combination with bending moment, reduce axial tension force with a factor My.Ed Mb.Rd

T Hglund

vec := 0.8

vec

NEd NRd

= 0.258

aluMATTER

2007-07-19

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Recitation 5ADokument14 SeitenRecitation 5AShaminda AmbaheraNoch keine Bewertungen

- Pharmaceutical Mushrooms - Cordyceps SinensisDokument4 SeitenPharmaceutical Mushrooms - Cordyceps SinensisimotalpNoch keine Bewertungen

- Wind Load Design of Photovoltaic Power Plants by Comparison of Design Codes and Wind Tunnel TestsDokument15 SeitenWind Load Design of Photovoltaic Power Plants by Comparison of Design Codes and Wind Tunnel TestsLuis FajardoNoch keine Bewertungen

- Lecture 1 Design of StaircaseDokument68 SeitenLecture 1 Design of Staircaseilyas100% (2)

- Ec9 Ex93 Beam Column No WeldDokument4 SeitenEc9 Ex93 Beam Column No WeldimotalpNoch keine Bewertungen

- Strut and TieDokument55 SeitenStrut and Tiesukrit_ghorai75% (4)

- Di Carluccio Rischio Sismico PDFDokument272 SeitenDi Carluccio Rischio Sismico PDFJosé Miguel BarataNoch keine Bewertungen

- RoofDek ManualDokument76 SeitenRoofDek Manualpedlopes100% (1)

- Part 3 Diaphragm Design ExamplesDokument76 SeitenPart 3 Diaphragm Design Examplesmlamour100% (1)

- Strut and Tie Sample 03Dokument5 SeitenStrut and Tie Sample 03Oliver AtomNoch keine Bewertungen

- Structure Calculation Sheet For SiloDokument174 SeitenStructure Calculation Sheet For Silojohn12345Noch keine Bewertungen

- Ec9 Ex92 Beam Column RHSDokument3 SeitenEc9 Ex92 Beam Column RHSimotalpNoch keine Bewertungen

- Structure Calculation Sheet For SiloDokument1 SeiteStructure Calculation Sheet For SiloimotalpNoch keine Bewertungen

- Strut & Tie ModelDokument67 SeitenStrut & Tie Modelahmed adel100% (9)

- Cordy IJMM Hybrid ArticleDokument14 SeitenCordy IJMM Hybrid ArticleimotalpNoch keine Bewertungen

- Method For Growing Cordyceps Sinensis On A Substrate and Novel Method For HyDokument9 SeitenMethod For Growing Cordyceps Sinensis On A Substrate and Novel Method For HyimotalpNoch keine Bewertungen

- Torsion Open Cross Section ConstantsDokument5 SeitenTorsion Open Cross Section ConstantsimotalpNoch keine Bewertungen

- Ec9 Ex84 Thin WalledDokument9 SeitenEc9 Ex84 Thin WalledimotalpNoch keine Bewertungen

- Torsion constants for hollow cross sectionsDokument2 SeitenTorsion constants for hollow cross sectionsimotalpNoch keine Bewertungen

- Ec9 Ex95 Beam Column CantileverDokument3 SeitenEc9 Ex95 Beam Column CantileverimotalpNoch keine Bewertungen

- Ec9 Ex94 Beam Column HAZDokument5 SeitenEc9 Ex94 Beam Column HAZimotalpNoch keine Bewertungen

- Ec9 Ex83 Torsion Double SkinDokument2 SeitenEc9 Ex83 Torsion Double SkinimotalpNoch keine Bewertungen

- Ec9 Ex56 Compression OrthotropicDokument6 SeitenEc9 Ex56 Compression OrthotropicimotalpNoch keine Bewertungen

- Ec9 Ex61 Shear No StiffenersDokument3 SeitenEc9 Ex61 Shear No StiffenersimotalpNoch keine Bewertungen

- Example 5.1. Axial Force Resistance of Member With Square Hollow SectionDokument1 SeiteExample 5.1. Axial Force Resistance of Member With Square Hollow SectionimotalpNoch keine Bewertungen

- Ec9 Ex44 Bending Trapez Class 4Dokument7 SeitenEc9 Ex44 Bending Trapez Class 4imotalpNoch keine Bewertungen

- Ec9 Ex43 Bending Trapez Class 2Dokument7 SeitenEc9 Ex43 Bending Trapez Class 2imotalpNoch keine Bewertungen

- Bending moment resistance cross section calculationDokument5 SeitenBending moment resistance cross section calculationimotalpNoch keine Bewertungen

- Ec9 Ex42 Bending O SectionDokument6 SeitenEc9 Ex42 Bending O SectionimotalpNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Saes H 201Dokument9 SeitenSaes H 201heartbreakkid132Noch keine Bewertungen

- READING 4.1 - Language and The Perception of Space, Motion, and TimeDokument10 SeitenREADING 4.1 - Language and The Perception of Space, Motion, and TimeBan MaiNoch keine Bewertungen

- WORK ORDER TITLEDokument2 SeitenWORK ORDER TITLEDesign V-Tork ControlsNoch keine Bewertungen

- E 74 - 06 - For Force Measuring InstrumentsDokument12 SeitenE 74 - 06 - For Force Measuring InstrumentsSarvesh MishraNoch keine Bewertungen

- Running Head:: Describe The Uses of Waiting Line AnalysesDokument6 SeitenRunning Head:: Describe The Uses of Waiting Line AnalysesHenry AnubiNoch keine Bewertungen

- RB450G Trouble ShootingDokument9 SeitenRB450G Trouble Shootingjocimar1000Noch keine Bewertungen

- DLP Din8Dokument2 SeitenDLP Din8KOUDJIL MohamedNoch keine Bewertungen

- Coating Inspector Program Level 1 Studen 1Dokument20 SeitenCoating Inspector Program Level 1 Studen 1AhmedBalaoutaNoch keine Bewertungen

- HR MasterlistDokument6 SeitenHR MasterlistLeychelle AnnNoch keine Bewertungen

- Seminar - Review 2 FinalDokument12 SeitenSeminar - Review 2 FinalBhaskaruni Sai TarunNoch keine Bewertungen

- A Hirshfeld Surface Analysis and Crystal StructureDokument8 SeitenA Hirshfeld Surface Analysis and Crystal StructureLidiane MicheliniNoch keine Bewertungen

- Ziva RWW ManuscriptDokument3 SeitenZiva RWW ManuscriptroderunnersdNoch keine Bewertungen

- Shop SupervisionDokument38 SeitenShop SupervisionSakura Yuno Gozai80% (5)

- EtomDokument1 SeiteEtomarthryxNoch keine Bewertungen

- I2E: Embedding Innovation as Organizational StrategyDokument11 SeitenI2E: Embedding Innovation as Organizational StrategyDeepak PanditNoch keine Bewertungen

- Mohammad Abu-Radi ResumeDokument4 SeitenMohammad Abu-Radi ResumeMohammad Abu-RadiNoch keine Bewertungen

- PrEN 12271-10 - Factory Production ControlDokument17 SeitenPrEN 12271-10 - Factory Production ControlPedjaNoch keine Bewertungen

- The Influence of Teleworking On Performance and Employees Counterproductive BehaviourDokument20 SeitenThe Influence of Teleworking On Performance and Employees Counterproductive BehaviourCHIZELUNoch keine Bewertungen

- Influence of Oxygen in Copper - 2010Dokument1 SeiteInfluence of Oxygen in Copper - 2010brunoNoch keine Bewertungen

- Silicon ManufacturingDokument132 SeitenSilicon ManufacturingAndrea SottocornolaNoch keine Bewertungen

- Gentle Classical Nature Sample - Units1 and 2Dokument129 SeitenGentle Classical Nature Sample - Units1 and 2Carita HemsleyNoch keine Bewertungen

- Technology and Livelihood Education: Agri - Fishery Arts (Agricultural Crops Production) Marketing Agricultural ProductsDokument14 SeitenTechnology and Livelihood Education: Agri - Fishery Arts (Agricultural Crops Production) Marketing Agricultural Productslana del rey100% (1)

- Mayan Calendar End Date Sparks Doomsday SpeculationDokument16 SeitenMayan Calendar End Date Sparks Doomsday SpeculationElfen RoxanneNoch keine Bewertungen

- 7 C's of Business LetterDokument3 Seiten7 C's of Business LetterGladys Forte100% (2)

- Sinavy Pem Fuel CellDokument12 SeitenSinavy Pem Fuel CellArielDanieli100% (1)

- Hackathon Statements V1Dokument10 SeitenHackathon Statements V1AayushNoch keine Bewertungen

- MA4850 Supply Chain & Logistics ManagementDokument21 SeitenMA4850 Supply Chain & Logistics ManagementQy LeeNoch keine Bewertungen

- Tithi PRAVESHADokument38 SeitenTithi PRAVESHAdbbircs100% (1)

- Rúbrica de composición escritaDokument2 SeitenRúbrica de composición escritafrancisco alonsoNoch keine Bewertungen

- Events of National Importance 2016Dokument345 SeitenEvents of National Importance 2016TapasKumarDashNoch keine Bewertungen