Beruflich Dokumente

Kultur Dokumente

Ec9 Ex94 Beam Column HAZ

Hochgeladen von

imotalpOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ec9 Ex94 Beam Column HAZ

Hochgeladen von

imotalpCopyright:

Verfügbare Formate

Ec9_ex94_Beam column HAZ.

mcd

Axial force and bending moment

Page 1 of 5

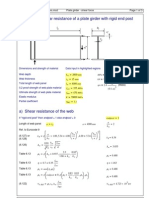

Example 9.4. Beam-column with cross weld

The beam-column is subject to an eccentric axial force with same eccentricity at both ends. The beam is prevented from warping at the ends by rigid rectangular hollow beams. These beams are simply supported at the load points A and D. The structure is a text beam [2]. There is a welded joint at a section x sw from the support A.

tf

C bb

h bw

y z tw

rb

h := 100 mm b := 49.9 mm tw := 4.88 mm tf := 4.97 mm lbeam := 1201 mm b b := 140 mm rb := 30 mm exc := 200 mm xsw := 170 mm r := 0 mm b w := h 2 tf 2 r BC := "A" b w = 90 mm [1] Table 3.2b) G := 27000 MPa

Dimensions and material properties

Section height: Flange depth: Web thickness: Flange thickness: Overall length: Cross beams: Support Eccentricity Location of cross weld Inner radius: Web height: Alloy: EN AW-6082 T6 Strength according to test in [2] fo := 311 MPa

Cross weld

xsw B bb A e N rb

(buckling class, E := 70000 MPa

fu.haz := 253 MPa

Partial safety factors: To compare with the test, all factors are set to 1.0

M1 := 1.0

M2 := 1.0

Moment and force

Axial force (compression) Bending moment at the ends S.I. units: kN 1000 newton My.Ed := NEd exc kNm kN m NEd := 17 kN My.Ed = 3.4 kNm MPa 1000000 Pa

References

[1] [2] EN 1999-1-1 Edlund, S. Eurocode 9 - Design of aluminium structures - Part 1-1: General rules. 2007 Buckling of T-Section Beam-Columns in Aluminium with or without Transverse Welds. Strustural Engineering, Royal Institute of technology, Stockholm.

aluMATTER 2007-08-10

T Hglund

lbeam

Ec9_ex94_Beam column HAZ.mcd

Axial force and bending moment

Page 2 of 5

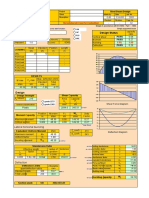

Classification of the cross section

(Detail calculations omitted) y-y-axis bending z-z-axis bending axial force classy := 3 classz := 3 classc := 3

Cross weld

[1] 5.5 [1] Table 6.2 [1] (6.64) HAZ softening at a section xsw = 170 mm from the column end In this example use value from tests fu.haz = 253 MPa which means

0 :=

fu.haz M1

M2 fo

0 = 0.814

Design resistance, y-y-axis bending

[1] 6.2.5 Elastic modulus of the gross cross section Wel: Ag := 2 b tf + ( h 2 tf ) tw Ig := 1 12 b h ( b tw) ( h 2 tf )

3 3

b

2

Ag = 935.5 mm

h bw

6 4 Ig = 1.418 10 mm

y z tw

Wel := [1] Table 6.4 [1] (6.26) [1] (6.25)

Ig 2 h

Wel = 2.836 10 mm

Shape factor for class 3 cross-section, say Design moment of resistance of the cross section Mc,Rd

y := 1

My.Rd := fo y Wel

M1

My.Rd = 8.82 kNm

Design resistance, z-z-axis bending

Iz := Wz := [1] (6.26) [1] (6.25) 2 tf b 12 Iz 2 b

3

Iz = 1.029 10 mm

3

4 3

Wz = 4.125 10 mm

Shape factor for class 3 cross-section, say Design moment of resistance Mz.Rd := fo z Wz

z := 1 M1

Mz.Rd = 1.283 kNm

Axial force resistance, y-y buckling

[1] 6.3.1 Cross section area of gross cross section A gr Agr := b h ( b tw) ( h 2 tf ) Cross section area of class 3 cross section Second moment of area of gross cross section: Iy :=

T Hglund 2

Agr = 935.5 mm Aeff := Agr

2 12

b tf + 2 b tf

h tf 1 3 + ( h 2 tf ) tw 12 2

aluMATTER

Iy = 1.418 10 mm

2007-08-10

tf

Ec9_ex94_Beam column HAZ.mcd

[1] Table 6.8

Axial force and bending moment

lyc := lbeam + 2 rb Ncr :=

3

Page 3 of 5

lyc = 1.261 10 mm Ncr = 616.044 kN

Effective buckling length

Buckling load

E Iy

lyc

2

[1] 6.3.1.2 [1] Table 6.6

Slenderness parameter

y :=

Agr fo Ncr

y = 0.687 = 0.2 o = 0.1

:= if ( BC = "A" , 0.2 , 0.32) o := if ( BC = "A" , 0.1 , 0 )

:= 0.5 1 + ( y o) + y

2

= 0.795 y = 0.837

y := min

1

2 y 2

, 1

fo

[1] Table 6.5

No longitudinal welds Axial force resistance Ny.Rd := y

:= 1 M1

Aeff Ny.Rd = 243.6 kN

Axial force resistance, z-z axis buckling

Effective buckling length Buckling load Iz := 2 tf b 12

3

lzc := lbeam + rb Ncr :=

lzc = 1.231 m Ncr = 46.9 kN

E Iz

lzc

2

[1] 6.3.1.2 [1] 6.3.1.2

Slenderness parameter

2 := 0.5 1 + ( z o) + z

z :=

Agr fo Ncr

z = 2.49 = 3.839 z = 0.148

z := min

1

2 2

+ z

, 1

Nz.Rd := z NRd := fo fo

[1] 6.3.1.1

Axial load resistance

M1

Aeff

Nz.Rd = 43 kN NRd = 290.9 kN

and without column buckling

M1

Aeff

Flexural buckling of beam-column

[1] 6.3.3.3 [1] (6.67) Cross weld from column end HAZ reduction factors, see above xsw = 170 mm lyc = 1261 mm xsw lyc = 0.135

0 = 0.814 x = 0.9

[1] (6.65)

x := min

0 , 1 xsw + 1 sin ( ) y y lyc

T Hglund

aluMATTER

2007-08-10

Ec9_ex94_Beam column HAZ.mcd

Axial force and bending moment

Page 4 of 5

Exponents in interaction formulae [1] (6.42c) [1] (6.61c)

0 := y

0 := if ( 0 < 1 , 1 , 0) yc := if ( yc < 0.8 , 0.8 , yc)

NEd = 17 kN

0 = 1 yc = 0.837

My.Ed = 3.4 kNm Uy = 0.591

yc := 0 y

Flexural buckling check

[1] (6.59)

NEd Uy := y x NRd

yc

My.Ed

0 My.Rd

Lateral-torsional buckling

[1] Annex J Figure J.2 Warping constant: Iw := It :=

(h tf )2 Iz

4 2 b tf + h tw 3 Wy := Wel

3 3

Iw = 2.324 10 mm It = 7.958 10 mm

4 3

Torsional constant: Lateral buckling length

4 3

L := lbeam 2 b b

Wy = 2.836 10 mm

Constant bending moment, warping prevented at the ends [1] I.1.2 C, k , and k w constants C1 := 1 kz := 1 kw := 0.5

[1] I.1.2

wt := cr :=

Mcr :=

kw L C1 kz

E Iw G It

2

wt = 1.877 cr = 2.127

L = 921 mm Mcr = 9.03 kNm

[1] (I.7)

1 + wt

[1] (I.2)

cr

L

E Iz G It

[1] 6.3.2.(1)

LT :=

y Wy fo

Mcr

LT = 0.988 LT = 0.2 0LT = 0.4 LT = 1.047 LT = 0.718

[1] 6.3.2.2 (2) LT := if ( classz > 2 , 0.2 , 0.1)

0LT := if ( classz > 2 , 0.4 , 0.6)

[1] (6.57) [1] (6.56)

2 LT := 0.5 1 + LT ( LT 0LT ) + LT

LT := LT +

LT LT

Lateral-tortional buckling checks

Check three sections

lzc := lbeam + 2 rb i := 1 .. 3 xs := 0 mm

1

xs := xsw 2

xs :=

3

lbeam 2

+ rb

xs lzc

= ( 0 0.135 0.5 )

T Hglund

aluMATTER

2007-08-10

Ec9_ex94_Beam column HAZ.mcd

HAZ reduction factors [1] (5.51)

Axial force and bending moment

(0 = 1 except at xs ) 2

Page 5 of 5

e D C bb N rb

0 := 0 i

Weld at section i = 2

( ) 0 := if ( i = 2 , 0 , 1 )

0 := if 0 > 1 , 1 , 0 i i i

i i

0 = ( 1 0.814 1 )

lbeam xsw B e N

[1] (6.65) or (6.69)

x :=

3 Cross weld 2

bb

xs z + ( 1 z) sin lzc

x = ( 6.76 1.63 1.00 )

[1] (6.66) or (6.70)

xLT :=

LT + ( 1 LT ) sin

xs lzc

xLT = ( 1.39 0.98 1.00 )

[1] (6.42a) [1] (6.42b) [1] (6.42c) [1] 6.3.3.2)

0 := z y 0 := z

2 2

0 := if ( 0 < 1 , 1 , if ( 0 > 2 , 2 , 0) ) 0 := if ( 0 < 1 , 1 , if ( 0 > 2 , 2 , 0) ) 0 := if ( 0 < 1 , 1 , 0) c := if ( c < 0.8 , 0.8 , c) y = 0.837 z = 0.148 zc := if ( zc < 0.8 , 0.8 , zc)

Mz.Ed := 0 kNm

0 = 1 0 = 1 0 = 1 c = 0.8 c = 1 zc = 0.8

0 := y

c := 0 z c := 0 zc := 0 z

Lateral-torsional buckling of beam-column

[1] (6.63) c c zc My.Ed NEd Mz.Ed ULT := + + z x NRd LT xLT My.Rd 0 Mz.Rd Max utilisation, lateral-torsional buckling Max utilisation, flexural buckling

ULT = ( 0.489 0.872 1.013 ) Uz.max = 1.013 Uy = 0.591

Uz.max := max( ULT )

Comment: Uz.max = 1.013 mean that the test failure load exceeded the characteristic strength with 1.3%

T Hglund

aluMATTER

2007-08-10

rb

Das könnte Ihnen auch gefallen

- 5.15 Swing Barrier v.1.0Dokument190 Seiten5.15 Swing Barrier v.1.0rfvz6sNoch keine Bewertungen

- Ec9 Ex61 Shear No StiffenersDokument3 SeitenEc9 Ex61 Shear No StiffenersimotalpNoch keine Bewertungen

- Staircase Design: 8.28kN/m 15.57kN/mDokument3 SeitenStaircase Design: 8.28kN/m 15.57kN/mBikki CyamaNoch keine Bewertungen

- Design of Section According To Eurocode 2Dokument2 SeitenDesign of Section According To Eurocode 23cesNoch keine Bewertungen

- Base Plate Design BS CodeDokument3 SeitenBase Plate Design BS CodeFodor ZoltanNoch keine Bewertungen

- Bearing CheckDokument6 SeitenBearing CheckdhanushkaNoch keine Bewertungen

- AngleDokument7 SeitenAngleNguyễnTúSơnNoch keine Bewertungen

- Anchor Design for 219mm Pole SupportDokument1 SeiteAnchor Design for 219mm Pole SupportS A K ClostreNoch keine Bewertungen

- COMPARISON OF COMPOSITE BEAM DESIGNDokument8 SeitenCOMPARISON OF COMPOSITE BEAM DESIGNMohamed Abo-ZaidNoch keine Bewertungen

- Sfex Pad Eyes Calculations 35T - 32MMDokument1 SeiteSfex Pad Eyes Calculations 35T - 32MMJohn Rom CabadonggaNoch keine Bewertungen

- Rafter design calculations for common rafter span of 3.1mDokument8 SeitenRafter design calculations for common rafter span of 3.1mstarsplesh100% (1)

- Purlin DesignDokument10 SeitenPurlin Designitissa INGENIERIANoch keine Bewertungen

- 3 5mDokument8 Seiten3 5mSanjay sharmaNoch keine Bewertungen

- Knee ConnectionsDokument13 SeitenKnee ConnectionsNag RajNoch keine Bewertungen

- 1 Input Data: Hilti PROFIS Engineering 3.1.1Dokument10 Seiten1 Input Data: Hilti PROFIS Engineering 3.1.1Zaido Al HalabiNoch keine Bewertungen

- Corbel and NibDokument17 SeitenCorbel and NibCatherine Mohanji GeraNoch keine Bewertungen

- ACI 318 Footing Design CalculationsDokument4 SeitenACI 318 Footing Design CalculationsBoubakeur FerkousNoch keine Bewertungen

- 41-Pile FoundationDokument56 Seiten41-Pile Foundationsharif uddinNoch keine Bewertungen

- Beam - Deflection CheckDokument8 SeitenBeam - Deflection CheckChhour CENoch keine Bewertungen

- Design of Z Purlins ReportDokument18 SeitenDesign of Z Purlins ReportAgarwal MittalNoch keine Bewertungen

- Corbel BS8110Dokument3 SeitenCorbel BS8110Nugraha BintangNoch keine Bewertungen

- Joist Girder DesignDokument42 SeitenJoist Girder DesignsravanNoch keine Bewertungen

- 1 Design ដៃរណែងមុំ 35Dokument1 Seite1 Design ដៃរណែងមុំ 35Ce Win100% (1)

- SLAB AND WALL DESIGN CALCULATIONSDokument7 SeitenSLAB AND WALL DESIGN CALCULATIONSRameez Ahmed AbbasiNoch keine Bewertungen

- BEAMDokument3 SeitenBEAMTano BahabobaNoch keine Bewertungen

- Web Tapered Frame Design Based On AISC-ASD 9th, Appendix F Input Data & Design SummaryDokument3 SeitenWeb Tapered Frame Design Based On AISC-ASD 9th, Appendix F Input Data & Design SummaryLivian TeddyNoch keine Bewertungen

- Design of Stairs Design of Stairs From Ground To Landing Material PropertiesDokument3 SeitenDesign of Stairs Design of Stairs From Ground To Landing Material PropertiesJohn Paul Hilary EspejoNoch keine Bewertungen

- Connessione A Taglio EC3 IngleseDokument15 SeitenConnessione A Taglio EC3 Inglesemihai_serban13Noch keine Bewertungen

- Sheet1 A-B Bay CM: Properties of Gantry SectionDokument2 SeitenSheet1 A-B Bay CM: Properties of Gantry SectionadihindNoch keine Bewertungen

- Reference: Sheet 0: Preliminary Design of Plate GirderDokument13 SeitenReference: Sheet 0: Preliminary Design of Plate GirderFranklyn Genove100% (1)

- For Battened Columns For Strength Cal 10% Increase in The KL/RDokument4 SeitenFor Battened Columns For Strength Cal 10% Increase in The KL/RvineetukNoch keine Bewertungen

- Brace Compression and Tension Capacity Design Charts As Per CSA S16 09 Rev1.5Dokument44 SeitenBrace Compression and Tension Capacity Design Charts As Per CSA S16 09 Rev1.5Antonio LópezNoch keine Bewertungen

- Purlin DesignDokument6 SeitenPurlin DesignAnonymous mcHqIfbnV1Noch keine Bewertungen

- Base Plate Design SummaryDokument3 SeitenBase Plate Design SummarySơn Nguyễn-LêNoch keine Bewertungen

- Design - of - Steel - Structure-I PDFDokument54 SeitenDesign - of - Steel - Structure-I PDFNi Mesh100% (1)

- X Y and Partners: Steel Beam DesignDokument35 SeitenX Y and Partners: Steel Beam DesignAndré SantosNoch keine Bewertungen

- RC Beam - CantileverDokument2 SeitenRC Beam - CantilevermayphyoNoch keine Bewertungen

- CSA Bolted Connection FatigueDokument3 SeitenCSA Bolted Connection FatiguejurieskNoch keine Bewertungen

- Project Job Ref.: V B T, y T, R CDokument3 SeitenProject Job Ref.: V B T, y T, R CM IQbalNoch keine Bewertungen

- Column DesignDokument56 SeitenColumn DesignSakar ShresthaNoch keine Bewertungen

- Hollow Sections PropertiesDokument20 SeitenHollow Sections PropertiesHorace Prophetic DavisNoch keine Bewertungen

- Beam DesignDokument7 SeitenBeam DesignKasi ViswanathanNoch keine Bewertungen

- Stair Stringer DesignDokument2 SeitenStair Stringer DesignTerry CheukNoch keine Bewertungen

- Diagram Drawing Design Forces and DetailsDokument6 SeitenDiagram Drawing Design Forces and Detailswaweng22Noch keine Bewertungen

- Crane Runway Beam Design - Crane Load CalculationDokument6 SeitenCrane Runway Beam Design - Crane Load CalculationAlex MolinaNoch keine Bewertungen

- Purlin DesignDokument9 SeitenPurlin DesignAjayvidyanand SharmaNoch keine Bewertungen

- Splice 03Dokument15 SeitenSplice 03LexNoch keine Bewertungen

- Hilti Bolt Connection-6 anchor-HSTDokument5 SeitenHilti Bolt Connection-6 anchor-HSTTuấnThanhNoch keine Bewertungen

- Design Slip-Critical Steel ConnectionDokument9 SeitenDesign Slip-Critical Steel ConnectionKURONoch keine Bewertungen

- Bolt Capacity2Dokument2 SeitenBolt Capacity2abdul kareeNoch keine Bewertungen

- Bolt capacity and bending checks as per BS EN-1993-1-8Dokument2 SeitenBolt capacity and bending checks as per BS EN-1993-1-8waweng22Noch keine Bewertungen

- SABP Q 008 Concrete Masonry WallsDokument22 SeitenSABP Q 008 Concrete Masonry Wallsaseptman1Noch keine Bewertungen

- Retaining Wall DesignDokument2 SeitenRetaining Wall Design3cesNoch keine Bewertungen

- Thiet Ke Cot Composite - EC4. V1.0 (MS03)Dokument5 SeitenThiet Ke Cot Composite - EC4. V1.0 (MS03)luuvandong48xf396Noch keine Bewertungen

- Concrete Corbel Design SummaryDokument14 SeitenConcrete Corbel Design Summarynavneet3bawaNoch keine Bewertungen

- 5span Contineous BeamDokument22 Seiten5span Contineous BeamBilal Ahmed Barbhuiya100% (1)

- Design Parameters For Corbel:1: B D D D 450Dokument3 SeitenDesign Parameters For Corbel:1: B D D D 450Living LifeNoch keine Bewertungen

- Analysis Report Tensile Canopy - HOCKEY STADIUM - R0 - ADokument23 SeitenAnalysis Report Tensile Canopy - HOCKEY STADIUM - R0 - ANeeraj KumarNoch keine Bewertungen

- GIRT DESIGN C140x60x20x4 BEAMDokument2 SeitenGIRT DESIGN C140x60x20x4 BEAMYaşarUğurNoch keine Bewertungen

- Ec9 Ex56 Compression OrthotropicDokument6 SeitenEc9 Ex56 Compression OrthotropicimotalpNoch keine Bewertungen

- Wind Load Design of Photovoltaic Power Plants by Comparison of Design Codes and Wind Tunnel TestsDokument15 SeitenWind Load Design of Photovoltaic Power Plants by Comparison of Design Codes and Wind Tunnel TestsLuis FajardoNoch keine Bewertungen

- Lecture 1 Design of StaircaseDokument68 SeitenLecture 1 Design of Staircaseilyas100% (2)

- Structure Calculation Sheet For SiloDokument174 SeitenStructure Calculation Sheet For Silojohn12345Noch keine Bewertungen

- Strut and Tie Sample 03Dokument5 SeitenStrut and Tie Sample 03Oliver AtomNoch keine Bewertungen

- RoofDek ManualDokument76 SeitenRoofDek Manualpedlopes100% (1)

- Cordy IJMM Hybrid ArticleDokument14 SeitenCordy IJMM Hybrid ArticleimotalpNoch keine Bewertungen

- Di Carluccio Rischio Sismico PDFDokument272 SeitenDi Carluccio Rischio Sismico PDFJosé Miguel BarataNoch keine Bewertungen

- Recitation 5ADokument14 SeitenRecitation 5AShaminda AmbaheraNoch keine Bewertungen

- Part 3 Diaphragm Design ExamplesDokument76 SeitenPart 3 Diaphragm Design Examplesmlamour100% (1)

- Structure Calculation Sheet For SiloDokument1 SeiteStructure Calculation Sheet For SiloimotalpNoch keine Bewertungen

- Strut and TieDokument55 SeitenStrut and Tiesukrit_ghorai75% (4)

- Strut & Tie ModelDokument67 SeitenStrut & Tie Modelahmed adel100% (9)

- Pharmaceutical Mushrooms - Cordyceps SinensisDokument4 SeitenPharmaceutical Mushrooms - Cordyceps SinensisimotalpNoch keine Bewertungen

- Method For Growing Cordyceps Sinensis On A Substrate and Novel Method For HyDokument9 SeitenMethod For Growing Cordyceps Sinensis On A Substrate and Novel Method For HyimotalpNoch keine Bewertungen

- Ec9 Ex91 Tension Bending InteractionDokument4 SeitenEc9 Ex91 Tension Bending InteractionimotalpNoch keine Bewertungen

- Ec9 Ex92 Beam Column RHSDokument3 SeitenEc9 Ex92 Beam Column RHSimotalpNoch keine Bewertungen

- Ec9 Ex84 Thin WalledDokument9 SeitenEc9 Ex84 Thin WalledimotalpNoch keine Bewertungen

- Ec9 Ex93 Beam Column No WeldDokument4 SeitenEc9 Ex93 Beam Column No WeldimotalpNoch keine Bewertungen

- Ec9 Ex83 Torsion Double SkinDokument2 SeitenEc9 Ex83 Torsion Double SkinimotalpNoch keine Bewertungen

- Torsion constants for hollow cross sectionsDokument2 SeitenTorsion constants for hollow cross sectionsimotalpNoch keine Bewertungen

- Torsion Open Cross Section ConstantsDokument5 SeitenTorsion Open Cross Section ConstantsimotalpNoch keine Bewertungen

- Ec9 Ex44 Bending Trapez Class 4Dokument7 SeitenEc9 Ex44 Bending Trapez Class 4imotalpNoch keine Bewertungen

- Ec9 Ex95 Beam Column CantileverDokument3 SeitenEc9 Ex95 Beam Column CantileverimotalpNoch keine Bewertungen

- Example 5.1. Axial Force Resistance of Member With Square Hollow SectionDokument1 SeiteExample 5.1. Axial Force Resistance of Member With Square Hollow SectionimotalpNoch keine Bewertungen

- Bending moment resistance cross section calculationDokument5 SeitenBending moment resistance cross section calculationimotalpNoch keine Bewertungen

- Ec9 Ex56 Compression OrthotropicDokument6 SeitenEc9 Ex56 Compression OrthotropicimotalpNoch keine Bewertungen

- Ec9 Ex43 Bending Trapez Class 2Dokument7 SeitenEc9 Ex43 Bending Trapez Class 2imotalpNoch keine Bewertungen

- Ec9 Ex42 Bending O SectionDokument6 SeitenEc9 Ex42 Bending O SectionimotalpNoch keine Bewertungen

- Hoist and Winch CatalogDokument69 SeitenHoist and Winch Catalogbaptista5989Noch keine Bewertungen

- Jingbo Lin: First Officer/Airline PilotDokument1 SeiteJingbo Lin: First Officer/Airline PilotAssignment GuruNoch keine Bewertungen

- Honeycomb StructureDokument8 SeitenHoneycomb StructureGunaseelan VNoch keine Bewertungen

- Vortex Induced VibrationsDokument7 SeitenVortex Induced VibrationsKevin Paredes GutierrezNoch keine Bewertungen

- pc-6 Tcds f56-107Dokument27 Seitenpc-6 Tcds f56-107Charles Francesc XavierNoch keine Bewertungen

- MPD A350v1 - R01 - I00Dokument341 SeitenMPD A350v1 - R01 - I00budiaero100% (4)

- M50-AL QuestionsDokument2 SeitenM50-AL QuestionsOwen Chieng OCNoch keine Bewertungen

- Turning A Precision WasherDokument7 SeitenTurning A Precision WasherkokiskoNoch keine Bewertungen

- Hungarian Aeronautical Industry 2014Dokument44 SeitenHungarian Aeronautical Industry 2014Anonymous KaoLHAktNoch keine Bewertungen

- Brillantes - The Apollo CentennialDokument4 SeitenBrillantes - The Apollo CentennialicaicaicarusNoch keine Bewertungen

- Quality Provisions for Aeronautical and Space System ContractorsDokument49 SeitenQuality Provisions for Aeronautical and Space System ContractorsPaulNoch keine Bewertungen

- Flexural Analysis of Balsa Core Sandwich Composite - Failure MechaDokument104 SeitenFlexural Analysis of Balsa Core Sandwich Composite - Failure MechaManjinderSinghNoch keine Bewertungen

- AE-May-2015-04-BS-7Dokument15 SeitenAE-May-2015-04-BS-7umchem2Noch keine Bewertungen

- Flow Measuring DevicesDokument39 SeitenFlow Measuring DevicesAbdul Moeed Kalson100% (1)

- Unit 15 Aircraft Propulsion AssignmentDokument18 SeitenUnit 15 Aircraft Propulsion AssignmentTerrence Owens50% (2)

- TR.TECH interview questions on aircraft systemsDokument2 SeitenTR.TECH interview questions on aircraft systemsKshitiz RastogiNoch keine Bewertungen

- 350PCDokument1.244 Seiten350PCBlueSkyMasterNoch keine Bewertungen

- Upper and Lower FinsDokument12 SeitenUpper and Lower FinsmahdicoincheNoch keine Bewertungen

- 1400Dokument2 Seiten1400Yonathan GomezNoch keine Bewertungen

- Needles Restrictor Hk66k102Dokument16 SeitenNeedles Restrictor Hk66k102seaqu3stNoch keine Bewertungen

- Audio Switch and DC Volume Control For TVDokument5 SeitenAudio Switch and DC Volume Control For TVbaczonifNoch keine Bewertungen

- Docwise For AircraftDokument143 SeitenDocwise For Aircraftdarrow doriNoch keine Bewertungen

- Vintage Airplane - Apr 1985Dokument32 SeitenVintage Airplane - Apr 1985Aviation/Space History LibraryNoch keine Bewertungen

- Army CH-47D Operators Manual PDFDokument717 SeitenArmy CH-47D Operators Manual PDFDave91Noch keine Bewertungen

- Diab Sandwich HandbookDokument51 SeitenDiab Sandwich HandbookmijobitoNoch keine Bewertungen

- QDB 15 PofDokument142 SeitenQDB 15 Pofant100% (1)

- WingtraDokument4 SeitenWingtraHernan Cuyubamba LazoNoch keine Bewertungen

- Piper Archer II Checklist GuideDokument8 SeitenPiper Archer II Checklist GuideJosías GenemNoch keine Bewertungen

- Manual EngineDokument273 SeitenManual EngineabmelegariNoch keine Bewertungen

- Design of Wing Spar Cross Section For Optimum Fatigue Life Design of Wing Spar Cross Section For Optimum Fatigue LifeDokument6 SeitenDesign of Wing Spar Cross Section For Optimum Fatigue Life Design of Wing Spar Cross Section For Optimum Fatigue LifeAwan AJaNoch keine Bewertungen