Beruflich Dokumente

Kultur Dokumente

Production Chemicals

Hochgeladen von

Anonymous QM0NLqZOCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Production Chemicals

Hochgeladen von

Anonymous QM0NLqZOCopyright:

Verfügbare Formate

http://www.scribd.

com/doc/43726118/The-Chemistry-and-Technology-of-Petroleum#logout

Contact Chemicals has developed a range of Demulsifiers designed to enhance the removal of water and solids from the oil and gas as it passes through the various processes of the production systems. Demulsifiers are applied both by continuous injection or batch treatment application. Your representative will test to determine the most effective product for your application Demulsifiers-BatchTreating Batch treating or Knockout demulsifiers are designed to work on a broad range of oils and a wide spectrum of treating ranges. These demulsifiers are designed to break up interfacial pads in treaters by destabilizing the iron products or byproducts, clays, solids or precipitated paraffins. Demulsifiers Continuous Injection

These products are designed and formulated to the specific oil and production systems at each location. The Demulsifier must remove the water and solids from the oil and obtain clean water in the time determined by the treating system. To evaluate the products currently in our product line or to formulate a new product, fresh produced fluids must be obtained with testing normally done on site. Biocide and Water Clarifiers The presence of bacteria in oil and gas production can cause corrosion in all areas of the production equipment. Treating problems due to slime pads in treaters or free water knockouts is also common if bacterial contamination goes untreated. Contact Chemicals have a REGISTERED Cocodiamine based biocide that is effective in controlling aerobic, anerobic and acid producing bacteria. This product can be applied down

hole, into production tanks and equipment and for water floods. It is effectively applied by the batch treatment method or by continuously injected. A kill study is done prior to treatment to determine the treatment dosage. Other products such as Sodium Hypochlorite (Bleach), Gluteraldehydes Quaternary Amines or Diamines can be used to control bacteria if it is found that the bacteria have grown resistant to the Cocodiamine based product. Water clarifiers Are used in oil and gas treating systems if the water is contaminated with solids. These solids may include formation clays, sands, precipitated scales or iron sulfides. Normally sequestering agents or flocculants are applied to the produced water to clean or floc (increase particle size) to aid in settling the particles to the bottom of the water tanks.

Corrosion Inhibitors Contact Chemicals have developed a variety of Corrosion Inhibitors designed to protect facilities from all types of corrosive environments. Corrosion can occur through out a production system from the wellbore to the gas or oil sales lines. The most common types of corrosion found in the Oil and Gas industry are caused by salt water (brine), hydrogen sulfide, carbon dioxide and organic acids.

Corrosion / Scale Inhibitors This type of combination products can be utilized if both corrosion and scale problems are occurring in a system. This normally occurs downhole. Depending on the dynamics of the production, we have both

oil and water soluble products available to effectively protect from corrosion as well as scaling caused by carbonate, sulfide and sulfate deposition. Both the water and oil based types are most effective if applied by continuous injection. They also provide protection if applied by frequent batch application. Products can be applied in both sweet and sour environments. Corrosion Inhibitors - Continuous Injection Continuous injection type Corrosion Inhibitors are primarily designed to prevent corrosion in water systems, mainly in vessels, water injection systems, flowlines and pipelines. These products are normally blends of quaternary amines or quaternary ammonium compounds and low foaming surfactants. These inhibitors are very effective in both sweet and sour producing systems. Methanol Corrosion Inhibitors These products are specifically formulated to be used either as a Methanol inhibitor or to be injected into flowlines or gathering systems that contain large amounts of Methanol. These products are very effective protecting metal from corrosion due to acid gases and salt brines. Corrosion Inhibitors - Batch Application Batch type corrosion inhibitors are formulated to spread evenly on the exposed metal and to provide a tenacious film, protecting the metal from its corrosive environment. Normally these products are oil soluble and are composed of dimmer acids, imidazolines and surfactant type demulsifiers. By batching down a well this corrosion inhibitor can protect the casing, tubing, pump and flowlines. When batched into flowlines it is normally diluted with hydrocarbon based oils or fuels and placed between two pigs.

Annular Corrosion Inhibitors These corrosion inhibitors are designed to protect exposed metal from oxygen, hydrogen sulfide, carbon dioxide and organic acids. Contact Chemicals also has available a nonregulated Environmentally friendly packer fluid inhibitor.

Hydrogen Sulfide Scavengers Hydrogen Sulfide Scavengers are available for use in bubble towers or for continuous injection application. These products are designed with scavenging surfactants, made to react quickly with the hydrogen sulfide gas and to form a water soluble byproduct that can be disposed of into any registered water disposal system. oxygen Scavengers Oxygen scavengers are used in the oilfield industry at any location where any dissolved oxygen is detected. Dissolved oxygen can be highly corrosive and can cause severe corrosive damage in production equipment. Oxygen can be introduced into produced fluids in many ways but the most common would be by the introduction of source water, recycle pumps or trucked in fluids.

Paraffin & Ashphaltene Paraffin and Asphaltene, when precipitated out from produced liquids will accumulate and deposit on downhole tubing or in flowlines. Extreme deposition will cause flow restriction or total plugging. Contact Chemicals carry Paraffin and Asphaltene treatment chemicals including Solvents, Dispersants and Inhibitors or Pour Point Depressants. Testing

will be done to ensure the most effective product will be applied for your application Paraffin Asphaltene Solvents Paraffin and Asphaltene solvents are a unique blend of Aromatic and Aliphatic solvents. Solvents are normally applied by a batch application to dissolve precipitated paraffin and Asphaltene from accumulations in downhole equipment, flowlines, or tanks in both oil and gas systems. Paraffin Asphaltene Dispersants The unique formulas are designed to attack and penetrate deep into the precipitated particle as well as to destroy the binding property between the particles allowing the particulate to be dispersed back into the fluid production. Dispersants are blended in aromatic solvents and are designed to be applied by continuous injection. Contact Chemicals have a variety of products that are effective in both oil and gas processes. . Paraffin Asphaltene Inhibitors Paraffin and Asphaltene Inhibitors or crystal modifiers are products that are designed to prevent the particles from binding together, attaining such weight where they would precipitate out of the produced fluids. The application of Inhibitors are normally the most cost effective method of mitigating paraffin or asphaltene problems in oil and gas systems. Scale Inhibitors Scale Inhibitors are necessary to prevent the precipitation and deposition of various scales in or on production equipment. Scales form when the physical condition of the water containing the ions change, therefore lowering the solubility. Physical changes may include pressure changes, temperature change or a change in pH. The most common types of scale found in the oil and gas industry are composed of calcium, strontium,

barium and iron compounds. Phosphate Esters, Phosphonates or Acrylic Polymers are commonly used to prevent scale deposition. These inhibitors can be applied throughout a production system and can be formulated to be applied in high temperature environments. Scale Inhibitors must be present at all times in the produced fluids in order to prevent deposition. Contact Chemicals offer products that can be applied by continuous injection, batch and by squeeze. Scale Corrosion Inhibitors Combination Scale/Corrosion Inhibitors can be used when both corrosion and scaling are a problem and the dynamics of the well only allow for one injection point. Contact Chemicals provides both oil and water soluble products. The oil soluble products provide corrosion protection by filming the exposed metal and by inhibiting the water to provide protection from carbonate, sulfate and sulfide scale deposition. These products can be applied by continuous injection or by batching. The water soluble products inhibit the water as well as provide protection from carbonate and sulfate scales. Both products can be applied to sour and sweet oil and gas systems.

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Sedimentary Basins of IndiaDokument90 SeitenSedimentary Basins of Indiasidharth100% (1)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Corrosion (Piles)Dokument8 SeitenCorrosion (Piles)JavierNoch keine Bewertungen

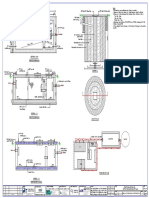

- Truck Lay Bye Toilet Block - 04 PDFDokument1 SeiteTruck Lay Bye Toilet Block - 04 PDFSanjeev KumarNoch keine Bewertungen

- Lec 1 - Highway LocationDokument28 SeitenLec 1 - Highway LocationJalal Habib KhanNoch keine Bewertungen

- Bacoor 320 PDRDokument39 SeitenBacoor 320 PDRLian Spurgeon Las Pinas100% (1)

- Syllabus On The General Objectives For IMO STCW-F Basic Safety Training For All Fishing Vessel PersonnelDokument21 SeitenSyllabus On The General Objectives For IMO STCW-F Basic Safety Training For All Fishing Vessel PersonnelSapriyun SNoch keine Bewertungen

- Dao 2007 20 - 182 PDFDokument12 SeitenDao 2007 20 - 182 PDFTreborSelasor100% (3)

- Properties of Water 5Dokument3 SeitenProperties of Water 5Anonymous QM0NLqZONoch keine Bewertungen

- WaterDokument1 SeiteWaterAlizay AamirNoch keine Bewertungen

- Properties of Water 4Dokument2 SeitenProperties of Water 4Anonymous QM0NLqZONoch keine Bewertungen

- Properties of Water 3Dokument2 SeitenProperties of Water 3Anonymous QM0NLqZONoch keine Bewertungen

- WaterDokument1 SeiteWaterAlizay AamirNoch keine Bewertungen

- Ground Floor ConstructionDokument3 SeitenGround Floor ConstructionAnonymous QM0NLqZONoch keine Bewertungen

- Properties of Water 2Dokument1 SeiteProperties of Water 2Anonymous QM0NLqZONoch keine Bewertungen

- Chemical and Physical Properties: StatesDokument3 SeitenChemical and Physical Properties: StatesAnonymous QM0NLqZONoch keine Bewertungen

- Earth Is The Third Planet From The Sun and The Only Astronomical Object Known To Harbor LifeDokument6 SeitenEarth Is The Third Planet From The Sun and The Only Astronomical Object Known To Harbor LifeAnonymous QM0NLqZONoch keine Bewertungen

- Physical CharacteristicsDokument13 SeitenPhysical CharacteristicsAnonymous QM0NLqZONoch keine Bewertungen

- Special Floor Structures: StoreyDokument1 SeiteSpecial Floor Structures: StoreyAnonymous QM0NLqZONoch keine Bewertungen

- Floor Covering: FlooringDokument2 SeitenFloor Covering: FlooringAnonymous QM0NLqZONoch keine Bewertungen

- Earth Is The ThirdDokument1 SeiteEarth Is The ThirdrobertoNoch keine Bewertungen

- Earth Is The Third Planet From The Sun and The Only Astronomical Object Known To Harbor LifeDokument6 SeitenEarth Is The Third Planet From The Sun and The Only Astronomical Object Known To Harbor LifeAnonymous QM0NLqZONoch keine Bewertungen

- CauveryDokument13 SeitenCauveryAnonymous QM0NLqZONoch keine Bewertungen

- Meaning of Sedimentary RocksDokument19 SeitenMeaning of Sedimentary RocksAnonymous QM0NLqZONoch keine Bewertungen

- S.No Month/Year 0ffice Ram Srini P.Samy Mami Tahsildhar Total MaintenaDokument4 SeitenS.No Month/Year 0ffice Ram Srini P.Samy Mami Tahsildhar Total MaintenaAnonymous QM0NLqZONoch keine Bewertungen

- While Conventional Natural Gas Streams From The Earth Relatively EasilyDokument3 SeitenWhile Conventional Natural Gas Streams From The Earth Relatively EasilyAnonymous QM0NLqZONoch keine Bewertungen

- The Importance of Natural Fractures in A Tight Reservoir For PotentialDokument21 SeitenThe Importance of Natural Fractures in A Tight Reservoir For PotentialAnonymous QM0NLqZONoch keine Bewertungen

- Hydraulic Fracturing (Also Fracking, Fraccing, Frac'ing, Hydrofracturing or Hydr Ofracking) Is ADokument2 SeitenHydraulic Fracturing (Also Fracking, Fraccing, Frac'ing, Hydrofracturing or Hydr Ofracking) Is AAnonymous QM0NLqZONoch keine Bewertungen

- Using Orthorhombic Depth Imaging To Image Fractures in Tight Reservoirs of The RDG FieldDokument18 SeitenUsing Orthorhombic Depth Imaging To Image Fractures in Tight Reservoirs of The RDG FieldAnonymous QM0NLqZONoch keine Bewertungen

- Enhancement of The Imbibition Recovery by Surfactants in Tight OilDokument11 SeitenEnhancement of The Imbibition Recovery by Surfactants in Tight OilAnonymous QM0NLqZONoch keine Bewertungen

- Tight ReservoirDokument11 SeitenTight ReservoirAnonymous QM0NLqZONoch keine Bewertungen

- Basin NotesDokument3 SeitenBasin NotesAnonymous QM0NLqZONoch keine Bewertungen

- Coal Bed MethaneDokument6 SeitenCoal Bed MethaneAnonymous QM0NLqZONoch keine Bewertungen

- Basin NotesDokument3 SeitenBasin NotesAnonymous QM0NLqZONoch keine Bewertungen

- Water Resources in IndiaDokument4 SeitenWater Resources in IndiaAnonymous QM0NLqZONoch keine Bewertungen

- Basin NotesDokument3 SeitenBasin NotesAnonymous QM0NLqZONoch keine Bewertungen

- Water Resources in IndiaDokument4 SeitenWater Resources in IndiaAnonymous QM0NLqZONoch keine Bewertungen

- Reverse Osmosis FixedDokument18 SeitenReverse Osmosis FixedBenNoch keine Bewertungen

- DENR News Alerts 06 July 2021 Tuesday PDFDokument84 SeitenDENR News Alerts 06 July 2021 Tuesday PDFVENCHIE VIC FABREONoch keine Bewertungen

- Skigo PulverDokument1 SeiteSkigo PulverchbergNoch keine Bewertungen

- Canal and Drainage Act 1873Dokument37 SeitenCanal and Drainage Act 1873Naeem Ul HussnainNoch keine Bewertungen

- Teh 2016Dokument102 SeitenTeh 2016Gabriel GodoyNoch keine Bewertungen

- JEE-Advance Chemistry 2015 Paper 1Dokument6 SeitenJEE-Advance Chemistry 2015 Paper 1Soumodip ChakrabortyNoch keine Bewertungen

- ENVI-PUR Operating Instructions BC 51-200Dokument72 SeitenENVI-PUR Operating Instructions BC 51-200Merzouq IngNoch keine Bewertungen

- Top Entry Mixers: HM Top-Entry Mixer Is A Configured Unit EngineeredDokument2 SeitenTop Entry Mixers: HM Top-Entry Mixer Is A Configured Unit EngineeredSudjono BroNoch keine Bewertungen

- Zambia Chapter 4 DDokument26 SeitenZambia Chapter 4 Dsouvik5000Noch keine Bewertungen

- Paper-1-Questions Geo 2021Dokument40 SeitenPaper-1-Questions Geo 2021chaku spikyNoch keine Bewertungen

- AP9100+ Installation InstructionsDokument4 SeitenAP9100+ Installation InstructionssimonNoch keine Bewertungen

- Solubility Product NotesDokument21 SeitenSolubility Product Notesgtdombo100% (1)

- SPM Bio Perlis 2009 Serta SkemaDokument96 SeitenSPM Bio Perlis 2009 Serta Skemahilmi72100% (1)

- Antimussol UDF LiqDokument10 SeitenAntimussol UDF Liqraju_hosssenNoch keine Bewertungen

- Making Weather Observations: Observing - Whatever The WeatherDokument8 SeitenMaking Weather Observations: Observing - Whatever The WeatherankaradanNoch keine Bewertungen

- TK 60275-4-MM Magnum Plus Maintenance Manual Rev 0 09-08Dokument152 SeitenTK 60275-4-MM Magnum Plus Maintenance Manual Rev 0 09-08MironIoanNoch keine Bewertungen

- Moisture Vapor Transfer Theory: Fabric Objective Measurement Assignment - 3Dokument19 SeitenMoisture Vapor Transfer Theory: Fabric Objective Measurement Assignment - 3NiveditaKumariNoch keine Bewertungen

- FuMaTech FumasepmembranesDokument6 SeitenFuMaTech FumasepmembranesAnisa Tri HutamiNoch keine Bewertungen

- Hydro WAX CX MSDSDokument5 SeitenHydro WAX CX MSDSMohammed Tanjil Morshed remonNoch keine Bewertungen

- Pig Farming: by Mr. Olorunlagba YomiDokument22 SeitenPig Farming: by Mr. Olorunlagba YomiAbe AkinolaNoch keine Bewertungen

- Bộ Đề 02 - Tham Khảo Avdv Ute 2023Dokument6 SeitenBộ Đề 02 - Tham Khảo Avdv Ute 2023Trân TrầnNoch keine Bewertungen

- Normal OperationDokument15 SeitenNormal OperationRaiAsifnawazNoch keine Bewertungen

- Gianniny FactsheetDokument6 SeitenGianniny Factsheetapi-240177035Noch keine Bewertungen

- 02 - Establishing Background Levels - EPA - 1995Dokument7 Seiten02 - Establishing Background Levels - EPA - 1995JessikaNoch keine Bewertungen