Beruflich Dokumente

Kultur Dokumente

Anti Frtion Bearings

Hochgeladen von

Sachin TirurCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Anti Frtion Bearings

Hochgeladen von

Sachin TirurCopyright:

Verfügbare Formate

Anti Friction Bearing

Antifriction bearings minimize friction by removing any possible sliding between bearing surfaces and replacing all contacts with rolling interfaces. They substitute balls or rollers for a hydrodynamic or hydrostatic fluid film to carry loads with reduced friction. They utilize a separator to space the hardened rolling elements apart. The Anti-Friction Bearing Manufacturers Association Standards (AFBMA) provides standardized dimensions, tolerances and fits of ball and roller bearings. Antifriction bearings can be categorized to three different configurations: axial ball, roller and thrust bearings. They are more desirable than plain bearing due to their lower friction and reduced lubrication requirement. However, the life of antifriction bearing is limited by the fatigue life of the material they are made of and the type of lubricant being used. The types of antifriction bearing are group by the shape of the rolling element and they are ball bearings, cylindrical roller bearings, tapered roller bearings, and needle roller bearings. There are variations within each type of bearings and only the most commonly used ones are discussed below.

Taper Roller Bearings Taper roller bearings consists of two main units, a cup and a cone. The cup is on the outer race whereas the cone consists of inner race, the separator and compliment of taper rollers. The taper rollers are guided by the high load on the inner race. The taper roller bearings are manufactured with interchangeable cups and cone on the shaft separately. These bearings are capable of carrying both the radial and axial loads and permit fine adjustment for end play. Greater care is required to ensure the proper alignment of bearings and maintenance of proper axial clearance is essential to avoid bearing failure. Due to more development in the design of the taper roller bearings, these are also available with 2 rows and 4 rows.

Cylindrical Roller Bearings In this type of bearings, the rollers race tracks are essentially cylindrical, however they may be ground slightly curved in order to achieve thereby small degree of flexibility. The rollers are guided between two lips on either the inner race or the outer race. Other types provided with either no lip, one lip or two lips, according to the function which the bearing has to perform. Ball Bearings have a point contact on the races whereas all types of cylindrical roller bearings have a line contact. Due to line contact the cylindrical roller bearings have a very high radial load carrying capacity as compared to ball bearings of the same size. Due to their separable design, cylindrical roller bearings are more convenient for mountings than ball bearings.

Self Aligning Spherical Roller Bearings This type of bearing consists of spherical outer race and inner race with two tracks, a cage, and a complement of spherical shaped rollers. Just like double row self aligning ball bearings too are not sensitive to misalignment and they can adjust themselves to shaft deflections. Due to the principle, sizes and shaft of rollers and accuracy with which they are guided these bearings have un axial capacity. The design of this bearing permits radial load and heavy thrust load in either direction.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Y Motor Planet GearDokument4 SeitenY Motor Planet GearFabian FragosoNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- ABB Distribution Transformer Handbook (Step7)Dokument92 SeitenABB Distribution Transformer Handbook (Step7)salmanejaz78675% (4)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Prof DR Ismail Omar Uthm: Rentice For TNBDokument16 SeitenProf DR Ismail Omar Uthm: Rentice For TNBmadzrulNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Integral Concrete Bridge EC2 - 2010Dokument98 SeitenIntegral Concrete Bridge EC2 - 2010paramsandhu100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- NNM Release Notes 9.00Dokument22 SeitenNNM Release Notes 9.00Mohan RajNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Raised Face Flange Ball ValvesDokument28 SeitenRaised Face Flange Ball Valvesrudy_423522658Noch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

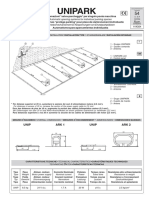

- Unipark SchémaDokument4 SeitenUnipark SchémaIMEN DHIBINoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Solenoid Coils: Data SheetDokument23 SeitenSolenoid Coils: Data SheetJohn BarrowNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- KEPServer Enterprise v5.30 and v4.50 Release NotesDokument8 SeitenKEPServer Enterprise v5.30 and v4.50 Release NotesZaaCk AranoNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Asme Sec V Art 6 Ed 2004Dokument10 SeitenAsme Sec V Art 6 Ed 2004Anonymous fnVTzv9XlNoch keine Bewertungen

- 03 - Introduction To TrixboxDokument25 Seiten03 - Introduction To TrixboxduyluanNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- MANUAL IG - RS20 - RS30 - RS40 - Managed - 14 - 1209 - enDokument62 SeitenMANUAL IG - RS20 - RS30 - RS40 - Managed - 14 - 1209 - enrickduzziNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Cracking in Asphalt Pavements PDFDokument30 SeitenCracking in Asphalt Pavements PDFKreen132100% (1)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- E633-13 Standard Guide For Use of Thermocouples in Creep and Stress-Rupture Testing To 1800 - F (1000 - C) in AirDokument8 SeitenE633-13 Standard Guide For Use of Thermocouples in Creep and Stress-Rupture Testing To 1800 - F (1000 - C) in AirislamakthamNoch keine Bewertungen

- Check-Mate: Ram and Uni-Drum Package Selection GuideDokument11 SeitenCheck-Mate: Ram and Uni-Drum Package Selection Guidevasuraj002Noch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Bsbhrm613 Task 1Dokument7 SeitenBsbhrm613 Task 1Fasih ur Rehman AbidNoch keine Bewertungen

- Avaya Call Recording: Graphical User InterfaceDokument4 SeitenAvaya Call Recording: Graphical User InterfacejyotikothariNoch keine Bewertungen

- Wireless Headphones PresentationDokument35 SeitenWireless Headphones PresentationYu100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Iso 11171 2020Dokument15 SeitenIso 11171 2020Saul GomezNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Report JCBDokument18 SeitenReport JCBAshok KumarNoch keine Bewertungen

- RCI510 Setup PDFDokument10 SeitenRCI510 Setup PDFDaniel Castillo PeñaNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- MGT613 Quiz 1Dokument11 SeitenMGT613 Quiz 1Himansu Sekhar KisanNoch keine Bewertungen

- CN 04 Coduri HandoutDokument19 SeitenCN 04 Coduri HandoutTeoMiuNoch keine Bewertungen

- Junior EngineerDokument4 SeitenJunior EngineerRinchen DorjiNoch keine Bewertungen

- Full Syllabus of ICAB (Certificate Level, Professional Level & Advanced Level)Dokument96 SeitenFull Syllabus of ICAB (Certificate Level, Professional Level & Advanced Level)Monirul Islam MoniirrNoch keine Bewertungen

- 0144 MNEC CommunicationsDokument4 Seiten0144 MNEC CommunicationsVagelis AntoniouNoch keine Bewertungen

- 70-411 R2 Test Bank Lesson 15Dokument11 Seiten70-411 R2 Test Bank Lesson 15Mazaher MohamedaliNoch keine Bewertungen

- SSL PT Manual 2011 ExternalDokument11 SeitenSSL PT Manual 2011 ExternalkmabdNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Excellesson 10Dokument38 SeitenExcellesson 10api-302374740Noch keine Bewertungen

- Aps 31253 CDL 20Dokument7 SeitenAps 31253 CDL 20M H Khan RonyNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)