Beruflich Dokumente

Kultur Dokumente

EZ Pilot RSS Brochure Halliburton

Hochgeladen von

nstl0101Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

EZ Pilot RSS Brochure Halliburton

Hochgeladen von

nstl0101Copyright:

Verfügbare Formate

DIRECTIONAL DRILLING

Pilot Fleet of Automated Drilling Systems

EZ-Pilot Rotary Steerable System

Reliable, cost-effective rotary steering

Sperry Drilling services EZ-Pilot system delivers cost-eective rotary steering services to the greater drilling market. Rotary steering is no longer the domain of high-cost operations, such as deepwater oshore drilling. With the EZ-Pilot system, land and shallow-water operators can take advantage of all the benets of rotary steering at an aordable price. The EZ-Pilot system provides accurate directional drilling control while allowing continuous rotation of the drillstring. The tool employs the natural forces of gravity combined with simple, infrequent geometric changes, forcing the bit o-center, thus changing the trajectory of the well. EZ-Pilot System Operation The EZ-Pilot system is an instrumented, near-bit stabilizer with three main components, including a rotating mandrel, an eccentric inner sleeve, and a weighted, nonrotating outer housing. The tool works by controlling the orientation of the eccentric cam system, which osets the mandrel and the bit in the desired direction. Rotation of the cam system to change toolface orientation is accomplished by controlling an ultrahigh-torque DC motor powered by lithium batteries. The position of the outer housing is constantly monitored, and the tool automatically corrects the eccentric cam system setting as required to maintain proper toolface orientation. The target toolface is set through simple rotary speed commands, or on-the-y downlinking commands, sent from the surface when coupled with either Geo-Span software/PWD or electromagnetic telemetry. Capabilities and Features Suitable for drilling vertical, directional, and horizontal applications Capable of kicking o from vertical Simple and cost-eective, with fewer than 130 components Flow rate, rotary speed, weight-on-bit, or lost circulation materials restrictions are consistent with MWD limitations Easily recongurable for dierent hole sizes

Borehole wall Weighted outer housing Inner sleeve/ offset cam Rotating mandrel

This cutaway shows the main components of the tool with a 90 right deflection. The EZ-Pilot system has fewer than 130 total components.

Benets Zero sliding time for more eective ROP Helps reduce drillstring buckling in long horizontals, greatly extending reach Continuous rotation helps improve hole cleaning and reduces risk of getting stuck Low pressure-drop design helps reduce hydraulics requirements, critical on smaller rigs Helps increase ability to drill with more aggressive bits Smoother wellbore curvature helps reduce torque and drag Helps lower operating and lost-in-hole costs

HAL17051

DIRECTIONAL DRILLING

EZ-Pilot Rotary Steerable System Specications

Nominal Tool OD Maximum Housing OD Hole Size Range Length Weight Connections and Recommended Make-up Torque - Top - Bottom Mimimum Kickoff Angle Design Performance (Build/Drop/Turn) Max Dog Leg Severity While Reaming - Rotating - Sliding Maximum Shaft Rotary Torque RPM Range Maximum Operating Temperature Maximum Operating Pressure Maximum Mass Flow Rate Typical Pressure Loss Through Tool Maximum Sand Content Maximum Lost Circulation Material Maximum Weight-on-Bit Vibration Mud Type Ultimate Body Overpull Not Operating (No Continued Operation Replace EZ-Pilot Tool) Uplink Surface Software Inclinometer Accuracy and Span Survey Measure Point (Average) ** ABI At-Bit Inclination Measure Point Power Supply Maximum Run Duration*** Internal Diameter Tool Diagram A EZ-Pilot Btm Box to Blade Distance B EZ-Pilot Btm Box to Inclination Pt 850 System 6-3/4 in. / 171.5 mm 8.1 in. / 205.7 mm 8-1/2 in., 8-3/4 in., 9-7/8 in. / 216 mm, 222 mm, 251 mm 13.0 ft / 3.96 m 1,800 lbm / 816.5 kg 4 1/2-in. IF box 32,000 lbf.ft / 4,339 daN.m 4 1/2-in. REG box 22,000 lbf.ft / 2,983 daN.m 0 8 per 100 ft / 8 per 30 m 8 per 100 ft / 8 per 30 m 17 per 100 ft / 17 per 30 m 13,800 lbf.ft/ 1,871 daN.m 30 to 280 302F / 150C 20,000 psi / 138 MPa 20,000 lbm/min to 9,071 kgm/min 15 psi with 12 ppg mud and 800 gpm / 0.1 MPa with 1.44 gr/cc mud and 3,028 l/min 3% by volume 100 lbm/bbl (285 kgm/m3) nutplug or fibrous 42,500 lbf / 18,905 daN As per Sperrys LWD specifications (available upon request) Compatible with majority; successfully run with WBM, OBM, SBM, and silicate muds 322,400 lbf / 143,411 daN Sperry DWD / FE / EM Compatible with the InSite service 0.1 @ 2s, 0 to 110 28 ft / 8.53 m 7 ft 6 in. / 2.29 m Lithium Batteries Variable, up to 7 days 2 in. / 50.8 mm 2 ft 8 in. / 0.81 m 7 ft 6 in. / 2.29 m 1/8-inch undergauge

MWD

1/16-inch undergauge control stabilizer

Full gauge

B A

* Certain hole sizes are special order; contact your Sperry Drilling representative for more information. ** Survey point will vary dependent on BHA design. *** Battery life is a function of directional profile and hole conditions; average run is 5 days.

2012 Halliburton. All rights reserved. Sales of Halliburton products and services will be in accord solely with the terms and conditions contained in the contract between Halliburton and the customer that is applicable to the sale. H04622-A4 8/12 www.halliburton.com

HAL17808

For more information, contact us at sperry@halliburton.com

Das könnte Ihnen auch gefallen

- Examples of - BOP EspecificationsDokument22 SeitenExamples of - BOP EspecificationsDiego AraqueNoch keine Bewertungen

- Teknik Sondaj Rig#4 BrochureDokument10 SeitenTeknik Sondaj Rig#4 BrochureBaris UnalNoch keine Bewertungen

- Mug Pump Technical InfoDokument5 SeitenMug Pump Technical InfoEmmanuel Soberano HernandezNoch keine Bewertungen

- ChokesBrochure ENG v01Dokument12 SeitenChokesBrochure ENG v01ermaiezNoch keine Bewertungen

- 43 DST Packer Test ToolDokument2 Seiten43 DST Packer Test ToolKim MissonNoch keine Bewertungen

- Daihatsu PartDokument1 SeiteDaihatsu PartLeonard Capriant100% (1)

- Tesco 213 30000e Casing DrillingDokument12 SeitenTesco 213 30000e Casing Drillingelianacolme100% (4)

- 05 - 3 ProtectorsDokument35 Seiten05 - 3 ProtectorsAndre Damara100% (1)

- Gas Lift EditedDokument20 SeitenGas Lift Edited56962645Noch keine Bewertungen

- PolarProp ApplicationDokument4 SeitenPolarProp ApplicationCristian BarbuceanuNoch keine Bewertungen

- 30-Top-Drive Casing Running Tool enDokument2 Seiten30-Top-Drive Casing Running Tool enluis alberto franco rodriguezNoch keine Bewertungen

- Optimization of Drilling Parameters With The Performance of Multilobe Positive Displacement Motor (PDM)Dokument8 SeitenOptimization of Drilling Parameters With The Performance of Multilobe Positive Displacement Motor (PDM)drilling moneytree100% (1)

- Underreamer - WikipediaDokument2 SeitenUnderreamer - WikipediaHistory MatchingNoch keine Bewertungen

- Slim Hole Drilling TechnologyDokument11 SeitenSlim Hole Drilling TechnologyMuhammad MohtashimNoch keine Bewertungen

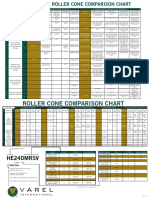

- VAREL RC Comparison Chart Final 2012Dokument2 SeitenVAREL RC Comparison Chart Final 2012Baitaw WanwarangNoch keine Bewertungen

- H03729Dokument4 SeitenH03729AQUILES CARRERANoch keine Bewertungen

- Smith Nozzles PDFDokument2 SeitenSmith Nozzles PDFrangga1000Noch keine Bewertungen

- Drillmec Hydraulic Drilling Rig Package Model Hh220 Fa: Technical DataDokument2 SeitenDrillmec Hydraulic Drilling Rig Package Model Hh220 Fa: Technical DataFernando OstoichNoch keine Bewertungen

- Catalogue 2018: Magnetic Thickness Detector (MTD)Dokument2 SeitenCatalogue 2018: Magnetic Thickness Detector (MTD)wesam tetouhaNoch keine Bewertungen

- Trip Sheet (RIH) : Presented by "Petroleum Capsules" ChannelDokument5 SeitenTrip Sheet (RIH) : Presented by "Petroleum Capsules" ChannelAhmed AjeebNoch keine Bewertungen

- Well Completion and Its TypesDokument14 SeitenWell Completion and Its TypesJagdish annayaNoch keine Bewertungen

- Technical Manual Mecanical Bumper SubDokument6 SeitenTechnical Manual Mecanical Bumper SubYeisson Rubio100% (1)

- Cup Type TesterDokument1 SeiteCup Type TesterJohnsNoch keine Bewertungen

- 9 1/2" Autotrak RCLS: Technical Data SheetDokument2 Seiten9 1/2" Autotrak RCLS: Technical Data SheetTamer Hesham AhmedNoch keine Bewertungen

- Diametros de Pozo y Trepanos Perf IIDokument1 SeiteDiametros de Pozo y Trepanos Perf IImiguelNoch keine Bewertungen

- Oil Well DesigningDokument15 SeitenOil Well DesigningShashank SacamuriNoch keine Bewertungen

- Registered Data Sheet Perforating System Evaluation, Api RP 19B Section 1Dokument1 SeiteRegistered Data Sheet Perforating System Evaluation, Api RP 19B Section 1Devia Suswodijoyo100% (1)

- Nation 16 3 Hour On: Pet-A, Oil Gas Well Drillin Ompletion For 016Dokument7 SeitenNation 16 3 Hour On: Pet-A, Oil Gas Well Drillin Ompletion For 016سالم العيساويNoch keine Bewertungen

- 3 - Arenas Curables y ActivadoresDokument52 Seiten3 - Arenas Curables y ActivadoresPablo SotoNoch keine Bewertungen

- Multi-Lobe Torque (MLT) Rings: Rigtelligence For The FutureDokument2 SeitenMulti-Lobe Torque (MLT) Rings: Rigtelligence For The FutureNawawi YusronNoch keine Bewertungen

- Drilling Process BasicsDokument18 SeitenDrilling Process BasicsBudiman50% (2)

- The Pressure's On Innovations in Gas Lift, Maharon Bin JadidDokument10 SeitenThe Pressure's On Innovations in Gas Lift, Maharon Bin JadidjoreliNoch keine Bewertungen

- Reservoir SimulationDokument3 SeitenReservoir SimulationEuler MendozaNoch keine Bewertungen

- Casing Design SheetDokument2 SeitenCasing Design SheetHammad KhalidNoch keine Bewertungen

- Chap EDokument44 SeitenChap ERANJITH K PNoch keine Bewertungen

- Section08 - Drilling Deviated HoleDokument28 SeitenSection08 - Drilling Deviated HoleMohamed ElshoraNoch keine Bewertungen

- Pathfinder HDS-1 MWD Gamma ToolDokument2 SeitenPathfinder HDS-1 MWD Gamma Toolcheeeky_monkeyNoch keine Bewertungen

- Spe 31656 MS PDFDokument99 SeitenSpe 31656 MS PDFVíctor Eduardo Salas OlguínNoch keine Bewertungen

- Kudu PCP SpecificationsDokument1 SeiteKudu PCP SpecificationsBledarNoch keine Bewertungen

- Hole Conditioning Before Running Casing or LinerDokument1 SeiteHole Conditioning Before Running Casing or LinerYougchu LuanNoch keine Bewertungen

- New Criteria For Gravel and Screen Selection For Sand Control PDFDokument14 SeitenNew Criteria For Gravel and Screen Selection For Sand Control PDFCharles DesmazuresNoch keine Bewertungen

- Formulas Average Angle PDFDokument5 SeitenFormulas Average Angle PDFJ.J. CVNoch keine Bewertungen

- BKDokument1 SeiteBKmbloexNoch keine Bewertungen

- MPD Brochure BeyondDokument10 SeitenMPD Brochure BeyondIRLANDA100% (1)

- The Saturn Probe Applications in The Makakam DeltaDokument4 SeitenThe Saturn Probe Applications in The Makakam DeltaNgwe Min TheinNoch keine Bewertungen

- UniDokument21 SeitenUnisparda94Noch keine Bewertungen

- Casing While Drilling PPT (2) - 1Dokument33 SeitenCasing While Drilling PPT (2) - 1Sangam ShiralNoch keine Bewertungen

- SCA2016-098 - Paper - D Whitby - NOV - Offshore Wireline Coring PDFDokument6 SeitenSCA2016-098 - Paper - D Whitby - NOV - Offshore Wireline Coring PDFdave_whitbyNoch keine Bewertungen

- Drilling Engineering: PETE 203Dokument48 SeitenDrilling Engineering: PETE 203AbdullahNoch keine Bewertungen

- MWD Failure Report in RUN9 of RZ-08 Well PDFDokument12 SeitenMWD Failure Report in RUN9 of RZ-08 Well PDFJorgeNoch keine Bewertungen

- Managed Pressure Drilling & Underbalanced Operations: Platinum SponsorsDokument4 SeitenManaged Pressure Drilling & Underbalanced Operations: Platinum SponsorsSyed IrtazaNoch keine Bewertungen

- Petrophysics Logging Tools PDFDokument5 SeitenPetrophysics Logging Tools PDFsdb158Noch keine Bewertungen

- BOP BoltsDokument5 SeitenBOP BoltsHadirah DunglahNoch keine Bewertungen

- CDAMnemonicsDokument18 SeitenCDAMnemonicsvanthodcNoch keine Bewertungen

- Directional Drilling TD PDFDokument10 SeitenDirectional Drilling TD PDFmissaoui100% (1)

- Lecture #2 Pee3321 Rig Systems Wellbore Elements and VolumesDokument25 SeitenLecture #2 Pee3321 Rig Systems Wellbore Elements and Volumesحيدر بادي - Haider Badi100% (1)

- GeoPilot Workbook - Final PDFDokument21 SeitenGeoPilot Workbook - Final PDFjhonathan tovarNoch keine Bewertungen

- How To Run and Cement Liners Part 4Dokument5 SeitenHow To Run and Cement Liners Part 4Blanche NeigeNoch keine Bewertungen

- Rotary Steerable DataDokument6 SeitenRotary Steerable DataOse EbhohimenNoch keine Bewertungen

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.Von EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.Noch keine Bewertungen

- The Endless Pursuit of Truth: Subalternity and Marginalization in Post-Neorealist Italian FilmDokument206 SeitenThe Endless Pursuit of Truth: Subalternity and Marginalization in Post-Neorealist Italian FilmPaul MathewNoch keine Bewertungen

- Sally Mann Hold Still - A Memoir With Photographs (PDFDrive)Dokument470 SeitenSally Mann Hold Still - A Memoir With Photographs (PDFDrive)danitawea100% (1)

- Bragg Waveguide and Its DescriptionDokument22 SeitenBragg Waveguide and Its DescriptionPratibha Karki RawatNoch keine Bewertungen

- Roman Catholic of Aklan Vs Mun of Aklan FULL TEXTDokument33 SeitenRoman Catholic of Aklan Vs Mun of Aklan FULL TEXTDessa Ruth ReyesNoch keine Bewertungen

- Your ManDokument5 SeitenYour ManPaulino JoaquimNoch keine Bewertungen

- Potato Lab ReportDokument10 SeitenPotato Lab ReportsimplylailaNoch keine Bewertungen

- Linear Arrangement 3rdDokument30 SeitenLinear Arrangement 3rdSonu BishtNoch keine Bewertungen

- "International Finance": A Project Submitted ToDokument6 Seiten"International Finance": A Project Submitted ToAkshay HarekarNoch keine Bewertungen

- Isolasi Dan Karakterisasi Runutan Senyawa Metabolit Sekunder Fraksi Etil Asetat Dari Umbi Binahong Cord F L A Steen S)Dokument12 SeitenIsolasi Dan Karakterisasi Runutan Senyawa Metabolit Sekunder Fraksi Etil Asetat Dari Umbi Binahong Cord F L A Steen S)Fajar ManikNoch keine Bewertungen

- Invoice Ce 2019 12 IVDokument8 SeitenInvoice Ce 2019 12 IVMoussa NdourNoch keine Bewertungen

- Teruhisa Morishige: Mazda Engineering StandardDokument9 SeitenTeruhisa Morishige: Mazda Engineering Standardmohammad yazdanpanahNoch keine Bewertungen

- FR-A800 Plus For Roll To RollDokument40 SeitenFR-A800 Plus For Roll To RollCORTOCIRCUITANTENoch keine Bewertungen

- Physics Waves MCQDokument6 SeitenPhysics Waves MCQAyan GhoshNoch keine Bewertungen

- Adult Consensual SpankingDokument21 SeitenAdult Consensual Spankingswl156% (9)

- Proff Ethi PDFDokument12 SeitenProff Ethi PDFgeethammani100% (1)

- 1574 PDFDokument1 Seite1574 PDFAnonymous APW3d6gfd100% (1)

- Chapter 2teeth and Its Care: Worksheet - 1Dokument11 SeitenChapter 2teeth and Its Care: Worksheet - 1RPJNoch keine Bewertungen

- Boxnhl MBS (Design-D) Check SheetDokument13 SeitenBoxnhl MBS (Design-D) Check SheetKumari SanayaNoch keine Bewertungen

- ECON2100 CO Abdool W21Dokument5 SeitenECON2100 CO Abdool W21Imran AbdoolNoch keine Bewertungen

- Unit 5 - Simulation of HVDC SystemDokument24 SeitenUnit 5 - Simulation of HVDC Systemkarthik60% (10)

- Design & Evaluation in The Real World: Communicators & Advisory SystemsDokument13 SeitenDesign & Evaluation in The Real World: Communicators & Advisory Systemsdivya kalyaniNoch keine Bewertungen

- Dispeller of Obstacles PDFDokument276 SeitenDispeller of Obstacles PDFLie Christin Wijaya100% (4)

- Sindhudurg Kokan All Tourism Spot Information WWW - Marathimann.inDokument54 SeitenSindhudurg Kokan All Tourism Spot Information WWW - Marathimann.inMarathi Mann92% (12)

- ART 6 LEARNING PACKET Week2-3Dokument10 SeitenART 6 LEARNING PACKET Week2-3Eljohn CabantacNoch keine Bewertungen

- Oral Abstract PresentationDokument16 SeitenOral Abstract Presentationapi-537063152Noch keine Bewertungen

- Anecdotal Records For Piano Methods and Piano BooksDokument5 SeitenAnecdotal Records For Piano Methods and Piano BooksCes Disini-PitogoNoch keine Bewertungen

- ABC of Effective WritingDokument4 SeitenABC of Effective Writingprada85Noch keine Bewertungen

- Adjective Clauses: Relative Pronouns & Relative ClausesDokument4 SeitenAdjective Clauses: Relative Pronouns & Relative ClausesJaypee MelendezNoch keine Bewertungen

- Henry FayolDokument4 SeitenHenry FayolFaryal MughalNoch keine Bewertungen

- Indicator For Meridian Diagnosis AGNIS BAT 02 (User's Manual) AGNISDokument5 SeitenIndicator For Meridian Diagnosis AGNIS BAT 02 (User's Manual) AGNISssmaddiNoch keine Bewertungen