Beruflich Dokumente

Kultur Dokumente

Fossil-Fuel Power Plants: Prime Mover

Hochgeladen von

mannuOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fossil-Fuel Power Plants: Prime Mover

Hochgeladen von

mannuCopyright:

Verfügbare Formate

Thermal power plant A thermal power station is a power plant in which the prime mover is steam driven.

Water is heated, turns into steam and spins a steam turbine which drives an electrical generator. After it passes through the turbine, the steam is condensed in a condenserand recycled to where it was heated; this is known as a Rankine cycle. The greatest variation in the design of thermal power stations is due to the different fossil fuel resources generally used to heat the water. Some prefer to use the term energy center because such facilities convert forms of heat energy into electrical energy.[1] Certain thermal power plants also are designed to produce heat energy for industrial purposes of district heating, or desalination of water, in addition to generating electrical power. Globally, fossil fueled thermal power plants produce a large part of man-made CO2 emissions to the atmosphere, and efforts to reduce these are many, varied and widespread. Introductory overview [edit] Almost all coal, nuclear, geothermal, solar thermal electric, and waste incineration plants, as well as many natural gas power plants are thermal. Natural gas is frequently combusted in gas turbines as well as boilers. The waste heat from a gas turbine can be used to raise steam, in a combined cycleplant that improves overall efficiency. Power plants burning coal, fuel oil, or natural gas are often calledfossil-fuel power plants. Some biomass-fueled thermal power plants have appeared also. Non-nuclear thermal power plants, particularly fossil-fueled plants, which do not use co-generation are sometimes referred to as conventional power plants.

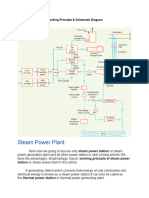

Typical coal thermal power station [edit]

1. Cooling tower 2. Cooling water pump 3. transmission line (3-phase) 4. Step-up transformer (3-phase) 5. Electrical generator (3-phase) 6. Low pressure steam turbine 7. Condensate pump 8. Surface condenser 9. Intermediate pressure steam turbine

10. Steam Control valve 11. High pressure steam turbine 12. Deaerator 13. Feedwater heater 14. Coal conveyor 15. Coal hopper 16. Coal pulverizer 17. Boiler steam drum 18. Bottom ash hopper

19. Superheater 20. Forced draught (draft) fan 21. Reheater 22. Combustion air intake 23. Economiser 24. Air preheater 25. Precipitator 26. Induced draught (draft) fan 27. Flue gas stack

Transport of coal fuel to site and to storage [edit] Most thermal stations use coal as the main fuel. Raw coal is transported from coal mines to a power station site by trucks, barges, bulk cargo ships or railway cars. Generally, when shipped by railways, the coal cars are sent as a full train of cars. The coal received at site may be of different sizes. The railway cars are unloaded at site by rotary dumpers or side tilt dumpers to tip over onto conveyor belts below. The coal is generally conveyed to crushers which crush the coal to about 34 inches (19 mm) size. The crushed coal is then sent by belt conveyors to a storage pile. Normally, the crushed coal is compacted by bulldozers, as compacting of highly volatile coal avoids spontaneous ignition. The crushed coal is conveyed from the storage pile to silos or hoppers at the boilers by another belt conveyor system.

Das könnte Ihnen auch gefallen

- How To Make An Effective PowerPoint PresentationDokument12 SeitenHow To Make An Effective PowerPoint PresentationZach Hansen100% (1)

- Electricity for the farm Light, heat and power by inexpensive methods from the water wheel or farm engineVon EverandElectricity for the farm Light, heat and power by inexpensive methods from the water wheel or farm engineBewertung: 5 von 5 Sternen5/5 (1)

- Thermal Power PlantDokument24 SeitenThermal Power PlantRon 61Noch keine Bewertungen

- Thermal Power PlantDokument34 SeitenThermal Power PlantRama Krishna KariNoch keine Bewertungen

- Thermal Power PlantDokument27 SeitenThermal Power Plantvenki249100% (1)

- Power Plant Instrumentation: Lecture NotesDokument35 SeitenPower Plant Instrumentation: Lecture NotesmaanwarNoch keine Bewertungen

- Gajendra KumarDokument23 SeitenGajendra KumarGAJENDRA KUMARNoch keine Bewertungen

- Gics-In-India Getting Ready For The Digital WaveDokument81 SeitenGics-In-India Getting Ready For The Digital Wavevasu.gaurav75% (4)

- Industrial Training AT: Submitted By: Rishikesh (11-1-6-002) NIT, SilcharDokument26 SeitenIndustrial Training AT: Submitted By: Rishikesh (11-1-6-002) NIT, SilcharRakesh Roshan KeshriNoch keine Bewertungen

- Thermal Power Generation Full Seminar Report 74537Dokument23 SeitenThermal Power Generation Full Seminar Report 74537Umang Vyas88% (8)

- Thermal Power Plant - EeDokument20 SeitenThermal Power Plant - EePrabhat Chandra100% (1)

- Thermal Power Plant BasicsDokument79 SeitenThermal Power Plant BasicsMukundan SwamynathanNoch keine Bewertungen

- Thermal Power Plant: Gaini Zail Singh Punjab Technical University Campus (Bathinda)Dokument30 SeitenThermal Power Plant: Gaini Zail Singh Punjab Technical University Campus (Bathinda)Sriram ramsNoch keine Bewertungen

- China's Military UAV Industry - 14 June 2013Dokument21 SeitenChina's Military UAV Industry - 14 June 2013Deep Kanakia100% (1)

- Report #1: Alternating-Current Project: Steam-Electric Power PlantDokument41 SeitenReport #1: Alternating-Current Project: Steam-Electric Power PlantKian TecsonNoch keine Bewertungen

- Region: South Central State: Andhra PradeshDokument118 SeitenRegion: South Central State: Andhra PradeshpaulinNoch keine Bewertungen

- Thermodynamic analysis of geothermal heat pumps for civil air-conditioningVon EverandThermodynamic analysis of geothermal heat pumps for civil air-conditioningBewertung: 5 von 5 Sternen5/5 (2)

- Thermal Power Station: o o o o o o oDokument9 SeitenThermal Power Station: o o o o o o oMehbub BashaNoch keine Bewertungen

- 38 Thermal Power PlantDokument26 Seiten38 Thermal Power PlantSwaraj TodankarNoch keine Bewertungen

- Thermal Power StationDokument13 SeitenThermal Power StationmuthucharaNoch keine Bewertungen

- Thermal Power StationDokument21 SeitenThermal Power StationSatria WinandaNoch keine Bewertungen

- Thermal Power PlantDokument29 SeitenThermal Power PlantSiri VenniNoch keine Bewertungen

- Jaipur: Vivekananda Institute of TechnologyDokument29 SeitenJaipur: Vivekananda Institute of TechnologyAashish SangwanNoch keine Bewertungen

- Thermal Power StationDokument18 SeitenThermal Power StationGautam KumarNoch keine Bewertungen

- Thermal Power PlantDokument16 SeitenThermal Power PlanthebishtNoch keine Bewertungen

- Jaipur: Vivekananda Institute of TechnologyDokument29 SeitenJaipur: Vivekananda Institute of TechnologyAnonymous ytZsBOVNoch keine Bewertungen

- Thermal Power StationDokument17 SeitenThermal Power StationJayAr EsquilloNoch keine Bewertungen

- Lesson 1 Thermal Power PlantDokument43 SeitenLesson 1 Thermal Power Plantyasin daiNoch keine Bewertungen

- Thermal Power Plants-FinalDokument61 SeitenThermal Power Plants-FinalBhavya ShrivastwaNoch keine Bewertungen

- Abhishek Kumar Asif Ahmad Niket Rakeshan Zeeshan AliDokument21 SeitenAbhishek Kumar Asif Ahmad Niket Rakeshan Zeeshan AliTanveer AzizNoch keine Bewertungen

- Thermal Power PlantDokument5 SeitenThermal Power PlantAnudeep ChittluriNoch keine Bewertungen

- Thermal Power Plant: Shubham Thakur 13BME8149 5MEL3 Mechanical EngineeringDokument34 SeitenThermal Power Plant: Shubham Thakur 13BME8149 5MEL3 Mechanical EngineeringMos MohNoch keine Bewertungen

- TPP General InformationDokument1 SeiteTPP General InformationlokmanNoch keine Bewertungen

- Power Plant Steam Steam Turbine Electrical Generator Condensed Condenser Rankine Cycle Fossil Fuel Heat Energy District Heating Desalination Fossil-Fuel Power StationsDokument1 SeitePower Plant Steam Steam Turbine Electrical Generator Condensed Condenser Rankine Cycle Fossil Fuel Heat Energy District Heating Desalination Fossil-Fuel Power StationsNithyanandmNoch keine Bewertungen

- Thermal EngineeringDokument10 SeitenThermal Engineeringlokeshdhangar842Noch keine Bewertungen

- Thermal Power StationDokument16 SeitenThermal Power StationDinesh Karthik VithiyananthNoch keine Bewertungen

- Thermal Power - WikipediaDokument24 SeitenThermal Power - WikipediaEusebia MaedzwaNoch keine Bewertungen

- PPT4 Coal FiredDokument31 SeitenPPT4 Coal FiredWinston LibangaNoch keine Bewertungen

- Powergeneration 190508075320Dokument19 SeitenPowergeneration 190508075320SRINIVAS TNoch keine Bewertungen

- Thermal Power PlantDokument31 SeitenThermal Power PlantfefwerewNoch keine Bewertungen

- PP 9th Meeting GENERATING STATIONS Thermal Power PlantDokument5 SeitenPP 9th Meeting GENERATING STATIONS Thermal Power PlantJohn Kenneth LoricoNoch keine Bewertungen

- Report On Thermal Power PlantDokument22 SeitenReport On Thermal Power PlantNitinNoch keine Bewertungen

- Mani Report 1Dokument53 SeitenMani Report 1Mani MukatiNoch keine Bewertungen

- Thermal Power Station: From Wikipedia, The Free EncyclopediaDokument1 SeiteThermal Power Station: From Wikipedia, The Free EncyclopediaVijayakumar ChandrasekaranNoch keine Bewertungen

- Power Generation-Steam Power: Typical Diagram of A Coal-Fired Thermal Power StationDokument8 SeitenPower Generation-Steam Power: Typical Diagram of A Coal-Fired Thermal Power StationMuhammad Ramiz ZakirNoch keine Bewertungen

- Thermal Power Station: From Wikipedia, The Free EncyclopediaDokument6 SeitenThermal Power Station: From Wikipedia, The Free EncyclopediaKrunal TapodhanNoch keine Bewertungen

- Steam Power Plants: Rankine CycleDokument6 SeitenSteam Power Plants: Rankine CycleRam NathNoch keine Bewertungen

- Training ReportDokument61 SeitenTraining ReportAnkur PanchalNoch keine Bewertungen

- Table of Content: Page Number 1 3 2 Parts 6 3 Function Diagram 8 4 Function 9 5 Advantages 18 6 Disadvantages 20Dokument20 SeitenTable of Content: Page Number 1 3 2 Parts 6 3 Function Diagram 8 4 Function 9 5 Advantages 18 6 Disadvantages 20Utsav ShuklaNoch keine Bewertungen

- Introduction and Thermal Power PlantDokument27 SeitenIntroduction and Thermal Power PlantKshitij AggarwalNoch keine Bewertungen

- Industrial Training PresentationDokument25 SeitenIndustrial Training PresentationHarshit MittalNoch keine Bewertungen

- National Capital Power Station N.T.P.C: Presented by KshitijDokument25 SeitenNational Capital Power Station N.T.P.C: Presented by KshitijHarshit MittalNoch keine Bewertungen

- Introduction To CFPPDokument34 SeitenIntroduction To CFPPVenkat CherukuriNoch keine Bewertungen

- T Project ReportDokument63 SeitenT Project ReportArif AhmadNoch keine Bewertungen

- Me Lab 3Dokument27 SeitenMe Lab 3Jerome Vega AndesNoch keine Bewertungen

- Energy InfrastructureDokument34 SeitenEnergy InfrastructureRatnesh SinghNoch keine Bewertungen

- Tharmal 2Dokument48 SeitenTharmal 2Prittam Kumar JenaNoch keine Bewertungen

- Abhishek Kumar Asif Ahmad Niket Rakeshan Zeeshan AliDokument21 SeitenAbhishek Kumar Asif Ahmad Niket Rakeshan Zeeshan AliSuphi YükselNoch keine Bewertungen

- Physics 4.Dokument5 SeitenPhysics 4.SOLAIMANNoch keine Bewertungen

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesVon EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNoch keine Bewertungen

- Town PlanningDokument1 SeiteTown PlanningmannuNoch keine Bewertungen

- 634613406101378750Dokument15 Seiten634613406101378750mannuNoch keine Bewertungen

- Lord CurzonDokument4 SeitenLord CurzonmannuNoch keine Bewertungen

- AcknowledgementDokument1 SeiteAcknowledgementmannuNoch keine Bewertungen

- Core (1) SfasfaDokument24 SeitenCore (1) SfasfamannuNoch keine Bewertungen

- Cyclotron and Its Application: HistoryDokument23 SeitenCyclotron and Its Application: HistorymannuNoch keine Bewertungen

- Indian Premier LeagueDokument10 SeitenIndian Premier LeaguemannuNoch keine Bewertungen

- What Happens If You Reach A Temperature 0Dokument2 SeitenWhat Happens If You Reach A Temperature 0mannuNoch keine Bewertungen

- ResumeDokument3 SeitenResumemannuNoch keine Bewertungen

- AgricultureDokument2 SeitenAgriculturemannuNoch keine Bewertungen

- On A Hot Morning Fighting by Young Servants of The Capulet and Montague Families Is Stopped by The Prince Who Tells Them That The Next Person Who Breaks The Peace Will Be Punished With DeathDokument2 SeitenOn A Hot Morning Fighting by Young Servants of The Capulet and Montague Families Is Stopped by The Prince Who Tells Them That The Next Person Who Breaks The Peace Will Be Punished With DeathmannuNoch keine Bewertungen

- Iffco Policy FormatDokument14 SeitenIffco Policy FormatmannuNoch keine Bewertungen

- Air PollutionDokument1 SeiteAir PollutionmannuNoch keine Bewertungen

- On A Hot Morning Fighting by Young Servants of The Capulet and Montague Families Is Stopped by The Prince Who Tells Them That The Next Person Who Breaks The Peace Will Be Punished With DeathDokument2 SeitenOn A Hot Morning Fighting by Young Servants of The Capulet and Montague Families Is Stopped by The Prince Who Tells Them That The Next Person Who Breaks The Peace Will Be Punished With DeathmannuNoch keine Bewertungen

- Resume Harshdeep Singh Sachdeva House No. C-6 Shahdanacolony Model Town-Bareilly MOBILE NO.:9760620178Dokument1 SeiteResume Harshdeep Singh Sachdeva House No. C-6 Shahdanacolony Model Town-Bareilly MOBILE NO.:9760620178mannuNoch keine Bewertungen

- Leo TolstoyDokument2 SeitenLeo TolstoymannuNoch keine Bewertungen

- S.NO. Major Acitities Minor Activities Status Date of CompletionDokument4 SeitenS.NO. Major Acitities Minor Activities Status Date of CompletionmannuNoch keine Bewertungen

- Pension General Revision of Pension Pre 2006 Pensioners 14-10-08Dokument9 SeitenPension General Revision of Pension Pre 2006 Pensioners 14-10-08mannuNoch keine Bewertungen

- DRDokument7 SeitenDRmannuNoch keine Bewertungen

- Conserving Natural ResourcesDokument2 SeitenConserving Natural ResourcesmannuNoch keine Bewertungen

- Development of The ConceptDokument10 SeitenDevelopment of The ConceptmannuNoch keine Bewertungen

- About DietDokument10 SeitenAbout DietmannuNoch keine Bewertungen

- Gurdwara Dera Kar Sewa: To Whom It May ConcernDokument1 SeiteGurdwara Dera Kar Sewa: To Whom It May ConcernmannuNoch keine Bewertungen

- ConservationDokument4 SeitenConservationmannuNoch keine Bewertungen

- William WordsworthDokument10 SeitenWilliam WordsworthmannuNoch keine Bewertungen

- HonDokument4 SeitenHonManpreet SachdevaNoch keine Bewertungen

- Renewable Nonrenewable Solar Electricity Wind Geothermal Biomass HydropowerDokument18 SeitenRenewable Nonrenewable Solar Electricity Wind Geothermal Biomass HydropowermannuNoch keine Bewertungen

- Against Cce PatternDokument1 SeiteAgainst Cce PatternmannuNoch keine Bewertungen

- Hydro ElectricityDokument5 SeitenHydro ElectricitymannuNoch keine Bewertungen

- Rate If Iodine and PropanoneDokument3 SeitenRate If Iodine and Propanoneshareef1Noch keine Bewertungen

- Fall 3050 SyllabusDokument6 SeitenFall 3050 Syllabustaher91Noch keine Bewertungen

- General Characteristics of Phonemes: Aspects of Speech SoundsDokument8 SeitenGeneral Characteristics of Phonemes: Aspects of Speech SoundsElina EkimovaNoch keine Bewertungen

- E-Waste: Name: Nishant.V.Naik Class: F.Y.Btech (Civil) Div: VII SR - No: 18 Roll No: A050136Dokument11 SeitenE-Waste: Name: Nishant.V.Naik Class: F.Y.Btech (Civil) Div: VII SR - No: 18 Roll No: A050136Nishant NaikNoch keine Bewertungen

- Walton Finance Way Strategy (MO)Dokument12 SeitenWalton Finance Way Strategy (MO)AshokNoch keine Bewertungen

- Load Schedule: DescriptionDokument1 SeiteLoad Schedule: Descriptionkurt james alorroNoch keine Bewertungen

- Net Pert: Cable QualifierDokument4 SeitenNet Pert: Cable QualifierAndrés Felipe Fandiño MNoch keine Bewertungen

- Technology 6 B Matrixed Approach ToDokument12 SeitenTechnology 6 B Matrixed Approach ToNevin SunnyNoch keine Bewertungen

- DILG Opinion-Sanggunian Employees Disbursements, Sign Checks & Travel OrderDokument2 SeitenDILG Opinion-Sanggunian Employees Disbursements, Sign Checks & Travel OrderCrizalde de DiosNoch keine Bewertungen

- Newcastle University Dissertation FormatDokument6 SeitenNewcastle University Dissertation FormatWriteMyEnglishPaperForMeSterlingHeights100% (1)

- ISSA2013Ed CabinStores v100 Часть10Dokument2 SeitenISSA2013Ed CabinStores v100 Часть10AlexanderNoch keine Bewertungen

- Marine-Derived Biomaterials For Tissue Engineering ApplicationsDokument553 SeitenMarine-Derived Biomaterials For Tissue Engineering ApplicationsDobby ElfoNoch keine Bewertungen

- Understanding Culture Society, and PoliticsDokument3 SeitenUnderstanding Culture Society, and PoliticsVanito SwabeNoch keine Bewertungen

- MotorsDokument116 SeitenMotorsAmália EirezNoch keine Bewertungen

- Resa Auditing Theorydocx - CompressDokument64 SeitenResa Auditing Theorydocx - CompressMaeNoch keine Bewertungen

- Molde Soldadura TADokument1 SeiteMolde Soldadura TAMarcos Ivan Ramirez AvenaNoch keine Bewertungen

- Face Detection and Recognition Using Opencv and PythonDokument3 SeitenFace Detection and Recognition Using Opencv and PythonGeo SeptianNoch keine Bewertungen

- 2012 Conference NewsfgfghsfghsfghDokument3 Seiten2012 Conference NewsfgfghsfghsfghabdNoch keine Bewertungen

- MSDS Formic AcidDokument3 SeitenMSDS Formic AcidChirag DobariyaNoch keine Bewertungen

- TRAVEL POLICY CARLO URRIZA OLIVAR Standard Insurance Co. Inc - Travel Protect - Print CertificateDokument4 SeitenTRAVEL POLICY CARLO URRIZA OLIVAR Standard Insurance Co. Inc - Travel Protect - Print CertificateCarlo OlivarNoch keine Bewertungen

- Category (7) - Installation and Maintenance of Instrumentation and Control SystemsDokument3 SeitenCategory (7) - Installation and Maintenance of Instrumentation and Control Systemstafseerahmed86Noch keine Bewertungen

- Patricio Gerpe ResumeDokument2 SeitenPatricio Gerpe ResumeAnonymous 3ID4TBNoch keine Bewertungen

- Course Outline Cbmec StratmgtDokument2 SeitenCourse Outline Cbmec StratmgtskyieNoch keine Bewertungen

- Offshore Training Matriz Matriz de Treinamentos OffshoreDokument2 SeitenOffshore Training Matriz Matriz de Treinamentos OffshorecamiladiasmanoelNoch keine Bewertungen

- Frequently Asked Questions: Lecture 7 To 9 Hydraulic PumpsDokument5 SeitenFrequently Asked Questions: Lecture 7 To 9 Hydraulic PumpsJatadhara GSNoch keine Bewertungen

- Mini Project A-9-1Dokument12 SeitenMini Project A-9-1santhoshrao19Noch keine Bewertungen