Beruflich Dokumente

Kultur Dokumente

027

Hochgeladen von

Matias MancillaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

027

Hochgeladen von

Matias MancillaCopyright:

Verfügbare Formate

Mathematical modelling of pulverized coal furnaces

A. Berm udez

1

, J. L. Ferrn

1

, A. Li nan

2

and L. Saavedra

1

1

Departamento de Matematica Aplicada, Universidad de Santiago de Compostela

15782 Santiago de Compostela, Spain

2

E.T.S. Ingenieros Aeronauticos, Universidad Politecnica de Madrid

Pl. Cardenal Cisneros 3, 28040 Madrid, Spain

Monografas de la Real Academia de Ciencias de Zaragoza 34, 2750, (2010).

1 Introduction

The goal of this paper is to show how mathematics and computational science can

help to design not only the geometry but also the operation conditions of dierent parts

of a pulverized coal power plant as the one shown in Figure 1.

Figure 1. Sketch of a coal red power plant

27

In the last few years, the development of mathematical models and computational

tools, including high performance computers and commercial computational uid dynam-

ics (CFD) packages, has allowed introducing the numerical simulation as an important

tool to analyze the phenomena occurring in some dierent installations of a power plant.

For example, in Figure 2 the ow of secondary air dragging pulverized coal particles

has been modelled, whereas in Figure 3 some numerical results corresponding to the

simulation of erosion in the system of transport of ashes to silos are shown.

Figure 2. System of coal input to the boiler

Figure 3. Simulation of erosion

The main scope of this paper is to model and numerically solve the physico-chemical

28

processes occurring in the interior of the boiler, which is the part of the furnace where

combustion of pulverized coal particles takes place (it can be seen at the center of Figure

1). CFD simulations can help to achieve a better performance of the installation in order

to maximize the energetic eciency, to minimize the NO

x

formation, to control soiling

phenomena or to assure a stable and sustainable ignition.

2 Mathematical modelling

In this section we present the mathematical model for a turbulent reactive two-phase

ow taking place in the interior of the boiler. The two phases correspond to the gas

mixture and to the solid coal particles. They will be described in an Eulerian-Lagrangian

framework.

The gas phase model includes the conservation equations describing a steady, com-

pressible, turbulent, radiant and reactive uid. This uid will be a mixture of O

2

, CO

2

,

H

2

O, V

(g)

, CO, SO

2

, H

2

and N

2

.

The solid phase model must include the motion equation of a single particle and

expressions for the sources from the solid phase to the gas one.

2.1 Gas phase model

We consider the standard equations for mass and momentum conservation, for the

turbulence and for the thermal radiation, namely,

(v) = f

m

, (1)

(v v) +p = g + f

m

v

s

, (2)

=

e

_

v +v

t

_

2

3

e

( v)I, (3)

v k [( +

t

) k] = G

k

, (4)

v

__

+

t

1.3

_

_

= 1.44

k

G

k

1.92

2

k

, (5)

x

I + (a +

s

)I

s

4

_

S

2

(

, )I(x,

)d

= aI

b

, (6)

with

t

= 0.09

k

2

and G

k

=

t

v + (v)

t

2

.

Furthermore, we assume the low Mach number approximation, that is, we impose

=

p

RT

(7)

where p denotes the average ambient pressure which is supposed to be constant in this

state equation.

29

2.2 The combustion model

The combustion of coal particles, including devolatilization and char oxidation has

been treated extensively in the literature (see, for example, [1] or [7]). The BFL combus-

tion model introduced in Berm udez et al [2] considers a simplied kinetic model consisting

of the following physico-chemical process (reactions 1 to 5 within the porous particles and

reactions 6 to 8 in the gas phase):

1 CO

2

+ C

(s)

2 CO + (q

1

)

2

1

2

O

2

+ C

(s)

CO + (q

2

)

3 H

2

O + C

(s)

CO + H

2

+ (q

3

)

4 V

(s)

V

(g)

+ (q

4

)

5 H

2

O

(s)

H

2

O

(g)

+ (q

5

)

6 CO +

1

2

O

2

CO

2

+ (q

6

)

7 V

(g)

+

1

O

2

2

CO

2

+

3

H

2

O +

4

SO

2

+ (q

7

)

8 H

2

+

1

2

O

2

H

2

O + (q

8

)

where indices s (respectively g) refers to the solid phase (respectively, to the gas phase).

The q

i

denotes the heat released in the i-th reaction per unit of gasied mass.

Figure 4. Scheme of the combustion of a coal particle

For simplicity, in this paper we will consider the volatiles mixture represented by one

single molecule,

V

(g)

= C

1

H

2

O

3

S

4

, (8)

of molecular mass M

vol

, where coecients

1

,

2

,

3

and

4

are deduced from the ultimate

analysis of the coal.

The stoichiometric coecients

i

are calculated in terms of the volatiles composition

using the expressions:

1

= (2

1

+

2

/2 + 2

4

3

)/2,

2

=

1

,

3

=

2

/2 and

4

=

4

.

30

For char oxidation we have considered a reduced mechanism including the three overall

reactions 1, 2 and 3, of rst order with respect to the local mean concentration of CO

2

, O

2

and H

2

O, measured by the product of the local gas density,

g

, times the mass fractions.

We have considered the reactions to be of zero order with respect to the local char density,

C

. Obviously these three reaction rates must be equated to zero when the carbon of the

particle is completely consumed, and therefore a Heaviside function is also included as a

factor. More precisely, the local homogenized reaction rates per unit volume within the

particle are modelled using global Arrhenius laws of the form

w

1

= B

1

e

E

1

/RT

g

Y

CO

2

H(

C

), (9)

w

2

= B

2

e

E

2

/RT

g

Y

O

2

H(

C

), (10)

w

3

= B

3

e

E

3

/RT

g

Y

H

2

O

H(

C

), (11)

where Y

CO

2

, Y

O

2

and Y

H

2

O

are the local mass fractions of CO

2

, O

2

and H

2

O in the gas

lling the porous interstices and

C

is the density of carbon in the form of char. For the

generation of volatiles and moisture evaporation we shall use the simple laws

w

4

= B

4

e

E

4

/RT

V

, (12)

w

5

= B

5

e

E

5

/RT

H

2

O

, (13)

where

V

and

H

2

O

are the local values within the coal particle of the density of volatiles

and H

2

O remaining in condensed form. The moisture generation is, for simplicity, here

described with a kinetic model similar to the pyrolysis model of volatiles generation. We

have chosen the rates of water vapour and volatiles generation to be of rst order with

respect to

H

2

O

and

V

.

The fundamental assumption to obtain this model is the Burke-Schumann hypothesis.

Therefore, the gas phase reactions 6 to 8 are supposed to be frozen or to occur with

innitely fast velocity in a gaseous thin diusion ame that can be placed either inside the

particle, or in the gas surrounding the particle or in the gas far from the particle. The type

of combustion that will occur will depend on the temperature and local concentrations of

oxygen, carbon monoxide, volatiles and H

2

in the gas environment; the model will decide

in which situation the particle is.

The combustion model that we present in this paper consists of two coupled models:

the gas phase model including the mass and energy conservation equations and the solid

phase model. On the one hand the gas phase model determines the atmosphere in which

particles are burnt and, on the other hand, the solid phase model provides mass and

energy sources to the gas.

31

2.2.1 Gas phase Model

Let L

g

be the dierential operator dened by

L

g

(u) =

(

g

u)

t

+ (

g

uv

g

) (

g

Du), (14)

where D is a gas phase diusion coecient which, for simplicity, will be considered to be

the same for all species and equal to the thermal diusivity (Lewis number equal to one).

Then, the conservation equations of the gaseous species are given by

g

t

+ (

g

v

g

) = f

m

, (15)

L

g

(Y

g

O

2

) = f

m

O

2

4

7

w

6

32

1

M

vol

w

7

8w

8

, (16)

L

g

(Y

g

CO

2

) = f

m

CO

2

+

11

7

w

6

+

44

2

M

vol

w

7

, (17)

L

g

(Y

g

H

2

O

) = f

m

H

2

O

+

18

3

M

vol

w

7

+ 9w

8

, (18)

L

g

(Y

g

SO

2

) = f

m

SO

2

+

64

4

M

vol

w

7

, (19)

L

g

(Y

g

CO

) = f

m

CO

w

6

, (20)

L

g

(Y

g

V

) = f

m

V

w

7

, (21)

L

g

(Y

g

H

2

) = f

m

H

2

w

8

, (22)

L

g

(h

g

T

) = f

e

+ q

6

w

6

+ q

7

w

7

+ q

8

w

8

q

rg

, (23)

where w

6

, w

7

and w

8

denote, respectively, the mass consumption rates per unit volume of

the volatiles, CO and H

2

, due to the chemical reactions 6, 7 and 8, taking place in the gas

phase; h

g

T

is the gas phase specic thermal enthalpy, which we shall for simplicity write

as c

p

T

g

considering the gas phase specic heat at constant pressure, c

p

, to be constant,

and q

rg

is the radiant heat ux vector.

The local homogenized reaction rates per unit volume within the particle could be

modelled by using global Arrhenius laws of the form:

w

6

=

2

g

Y

1/2

O

2

Y

CO

Y

1/2

H

2

O

B

6

e

E

6

/RT

,

w

7

=

1+

1

g

Y

1

O

2

Y

V

B

7

e

E

7

/RT

,

w

8

=

3/2

g

Y

1/2

O

2

Y

H

2

B

8

e

E

8

/RT

.

Nevertheless, as we are considering the Burke-Schumann hypothesis of innitely fast

gas phase reactions, which implies the non coexistence of CO, V and H

2

with O

2

, we do

not need to provide expressions for the gas phase reaction rates. We can obtain equations

32

without the gas phase reaction terms considering the following conserved scalars of Shvab-

Zeldovich type:

g

1

= Y

g

O

2

4

7

Y

g

CO

32

1

M

vol

Y

g

V

8Y

g

H

2

, (24)

g

2

= Y

g

CO

2

+

11

7

Y

g

CO

+

44

2

M

vol

Y

g

V

, (25)

g

3

= Y

g

H

2

O

+

18

3

M

vol

Y

g

V

+ 9Y

g

H

2

, (26)

g

4

= Y

g

SO

2

+

64

4

M

vol

Y

g

V

, (27)

H

g

= h

g

T

+ q

6

Y

g

CO

+ q

7

Y

g

V

+ q

8

Y

g

H

2

. (28)

Then from (15)-(23) we have the equations

L

g

(

g

1

) = f

m

O

2

4

7

f

m

CO

32

1

M

vol

f

m

V

8f

m

H

2

, (29)

L

g

(

g

2

) = f

m

CO

2

+

11

7

f

m

CO

+

44

2

M

vol

f

m

V

, (30)

L

g

(

g

3

) = f

m

H

2

O

+

18

3

M

vol

f

m

V

+ 9f

m

H

2

, (31)

L

g

(

g

4

) = f

m

SO

2

+

64

4

M

vol

f

m

V

, (32)

L

g

(H

g

) = f

e

+ q

6

f

m

CO

+ q

7

f

m

V

+ q

8

f

m

H

2

q

rg

. (33)

Owing to the Burke-Schumann hypothesis we can determine two regions of the ow

eld: one region with oxygen,

O

, and another one without oxygen,

F

. The gas phase

reactions 6 to 8 take place in a diusion-controlled ame where the volatiles, CO and H

2

are burning with oxygen separating

O

from

F

. This surface is called

F

(see Figure 5

for details).

Figure 5. Diusion ame

Once we have solved (29),

g

1

will determine the regions of the domain and therefore

the way to recover the mass fractions and the enthalpy from the Shvab-Zeldovich variables:

33

1. If

g

1

> 0 we are in the domain

O

, this implies that Y

g

V

= Y

g

H

2

= Y

CO

= 0 and using

(24)-(28) we obtain Y

g

O

2

=

g

1

, Y

g

CO

2

=

g

2

, Y

g

H

2

O

=

g

3

, Y

g

SO

2

=

g

4

and h

g

T

= H

g

.

2. If

g

1

< 0 we are in the domain

F

so Y

g

O

2

= 0 and w

6

= w

7

= w

8

= 0. In this case

to determine the mass fractions and the enthalpy we need to solve two additional

equations of (21)-(23) without gas phase reaction terms.

2.2.2 Particle Gasification Model

The solid phase model is based on a Lagrangian computation of the temperature and

density of each coal particle throughout its trajectory. We assume that the particles are

spherical and its radius and its ash density remain constant during the combustion. So

the model will be valid for particles with high content of ash.

The density of a coal particle is determined by:

p

=

H

2

O

+

V

+

C

+

ash

. (34)

The evolution of

H

2

O

,

V

and

C

, with radial coordinate r and time t, will be given by

V

t

= w

4

,

H

2

O

t

= w

5

,

C

t

= w

C

, (35)

in terms of the mass rates, per unit volume and time, of generation of volatiles w

4

, water

vapour w

5

and char gasication w

C

, given by equations (9)-(13).

To write the particle temperature equation we take into account that the heat conduc-

tion time across the particle is short compared with the diusion time so we can consider

the temperature spatially uniform. This temperature is given by the equation

4

3

a

3

p

c

s

dT

p

dt

= 4a

2

(q

p

+ q

r

) +

_

a

0

_

8

i=1

q

i

w

i

_

4r

2

dr, (36)

where 4a

2

q

p

and 4a

2

q

r

are the heat ux by conduction and by radiation, respectively,

which have the following expressions

q

p

= k

dT

dr |

r=a

+

, q

r

=

p

_

1

4

_

S

2

I(x, )d T

4

p

_

, (37)

where I(x, ) is the radiation intensity in the direction at the position of the particle,

denoted by x,

p

is the particle emissivity and S

2

is the unit sphere.

Due to the assumed uniformity of the temperature within the particle and the expres-

sions (12) and (13), the rates of generation of water vapour and volatiles are spatially

uniform and known functions of T

p

and we can write the evolution with time of

V

and

H

2

O

as

d

V

dt

= B

4

e

E

4

/RTp

V

, (38)

d

H

2

O

dt

= B

5

e

E

5

/RTp

H

2

O

, (39)

34

We cannot write a similar expression for the third equation in (35) because the depen-

dence of

1

,

2

and

3

on Y

CO

, Y

O

2

and Y

H

2

O

, which are not uniform within the particle.

In fact, if we want to know the evolution of

C

, the values of Y

CO

, Y

O

2

, Y

H

2

O

have to be

calculated using mass conservation equations for the gas phase within the pores of the

particle for each given value of T

p

and the mass fractions on the surface of the particle.

In order to simplify the treatment of the eects of the gasication char reactions 1, 2

and 3, Damk ohler numbers have been dened for these reactions as

Da

i

=

a

2

D

e

B

i

e

E

i

/RTp

, i = 1, 2, 3. (40)

We consider that the activation energies of these heterogeneous reactions are large enough,

so that Da

i

are of order unity only a very short time. Damk ohler numbers will determine

the stage of char gasication:

First stage (Da

i

1, i = 1, 2, 3): kinetically-controlled reactions. Char gasication

reactions can be considered frozen (

1

=

2

=

3

= 0) and there is no production

of CO or H

2

within the particle.

So, to determine the particle density in the rst stage, we only have to solve the

equations (38) and (39). In this stage, the equation for the particle temperature

(36) which can be simplied using that the gas phase reaction 7 is assume to be

innitely fast. Thus, if we compute the value

1

at the particle surface

s

1

= Y

s

O

2

32

1

M

vol

Y

s

V

, (41)

we have two dierent cases:

If

s

1

< 0 the reaction 7 takes place in a diusion ame outside the particle and

prevents the oxygen to reach the surface. In this case equation (36) becomes

4

3

a

3

p

c

s

dT

p

dt

= 4a

2

(q

p

+ q

r

) +

_

a

0

(q

4

w

4

+ q

5

w

5

) 4r

2

dr, (42)

If

s

1

> 0 the oxygen reaches the particle and reacts with the volatiles which

cannot leave the particle. In this case the energy equation simplies to

4

3

a

3

p

c

s

dT

p

dt

= 4a

2

(q

p

+ q

r

) +

_

a

0

(q

4

+ q

7

)w

4

+ q

5

w

5

4r

2

dr, (43)

Second stage (Da

i

1, i = 1, 2, 3): diusion-controlled reactions. Char gasication

reactions are very fast and they occur in a diusion ame at r = r

c

which implies that

char and CO

2

, O

2

and H

2

O cannot coexist. This limit case leads to the shrinking

core model.

The procedure which allows us to deduce the equations to be solved to determine

1

,

2

and

3

in the second stage, as well as the expressions for the sources to the

35

gas phase, has been done in [2]. There are only two cases in which

2

= 0, one in the

limit case in which the gasication of char reactions are kinetically controlled and

the other one when the oxygen reaches the particle core surface because of the small

particle size based Damk ohler numbers. Since we consider that this two cases are not

relevant in our simulations, we will suppose, for simplicity of the implementation,

that reaction 2 never takes place. Next, they are summarized taking into account

that they are dierent depending on the domain in which the particle is and the

position of the diusion ame with respect to the particle:

1. Particle in

F

(

g

1

< 0). In this case we have to solve

11

3

=

_

Y

g

CO

2

+

11

3

_

e

D

De

(1a/rc)

,

3

2

=

_

Y

g

H

2

O

+

3

2

_

e

D

De

(1a/rc)

,

(44)

where

i

=

m

i

g

aD

, i = 1, 3, 4, 5, (45)

and D

e

is the diusion coecient of the gas mixture inside the particle pores.

The temperature equation is

4

3

a

3

p

c

s

dT

p

dt

= 4a

2

(q

p

+ q

r

) + 4

g

aD(q

1

1

+ q

3

3

+ q

4

4

+ q

5

5

), (46)

where

q

p

=

k

ac

p

(h

g

T

h

s

T

)

e

1

. (47)

2. Particle in

O

(

g

1

> 0) and Y

s

O

2

> 0. The diusion ame moves into the

particle (i.e. r

c

< r

f

a). The equations to solve are

e

D

De

(a/r

f

1)+

= + 1,

11

3

_

22

3

+

11

3

+

44

2

M

vol

_

e

D

De

(a/r

f

a/rc)

=

_

Y

g

CO

2

11

3

_

+

3

44

2

M

vol

_

e

D

De

(1a/rc)

,

3

2

_

3

2

+

18

3

M

vol

_

e

D

De

(a/r

f

a/rc)

=

_

Y

g

H

2

O

5

18

3

M

vol

_

e

D

De

(1a/rc)

,

(48)

with given by

=

Y

g

O

2

8

3

_

+

3

_

+

32

1

M

vol

. (49)

36

The temperature equation is

4

3

a

3

p

c

s

dT

p

dt

= 4a

2

(q

p

+ q

r

) + 4

g

aD(q

1

1

+ q

3

3

+ q

4

4

+ q

5

5

+

14

3

q

6

1

+

7

3

q

6

3

+ q

7

4

+

1

6

q

8

3

) (50)

where q

p

is given by (47).

3. Particle in

O

(

g

1

> 0) and Y

s

O

2

= 0. The diusion ame is surrounding the

particle (i.e. r

f

> a). In this case we have to solve

11

3

=

_

Y

g

CO

2

+

11

3

+

_

22

3

+

11

3

+

44

2

M

vol

_

e

D

De

(1a/rc)

,

3

2

=

_

Y

g

H

2

O

+

3

2

+

_

3

2

+

18

3

M

vol

_

e

D

De

(1a/rc)

.

(51)

The temperature equation is

4

3

a

3

p

c

s

dT

p

dt

= 4a

2

(q

p

+ q

r

) + 4

g

aD(q

1

1

+ q

3

3

+ q

4

4

+ q

5

5

+

14

3

q

6

1

+

7

3

q

6

3

+ q

7

4

+

1

6

q

8

3

) (52)

where

q

p

=

k

ac

p

1

_

h

g

T

h

s

T

+

_

q

6

_

14

3

+

7

3

_

+ q

7

+ q

8

1

6

_

. (53)

In all the three cases, the position of the shrinking core is given by

0

C

g

aD

r

2

c

dr

c

dt

= (

1

+

3

). (54)

2.2.3 Sources to the gas phase

The purpose of solving the solid phase model is to obtain the sources of mass and

energy to the gas phase from coal particles gasication. Once we know this sources we

can solve equations (29)-(33) and obtain the temperature and composition of the gas

mixture.

The expressions for the sources of mass of each of the species due to one single particle

are:

37

1. In

F

(Y

g

O

2

= 0):

F

m

O

2

= F

m

SO

2

= 0, (55)

F

m

CO

2

=

4ak

c

p

_

11

3

1

_

, (56)

F

m

H

2

O

=

4ak

c

p

_

3

2

3

_

, (57)

F

m

CO

=

4ak

c

p

_

14

3

1

+

7

3

3

_

, (58)

F

m

V

=

4ak

c

p

4

, (59)

F

m

H

2

=

4ak

c

p

1

6

3

. (60)

2. In

O

(Y

g

O

2

> 0):

F

m

O

2

=

4ak

c

p

_

8

3

(

1

+

3

)

32

1

M

vol

4

_

, (61)

F

m

CO

2

=

4ak

c

p

_

11

3

(

1

+

3

) +

44

2

M

vol

4

_

, (62)

F

m

H

2

O

=

4ak

c

p

_

5

+

18

3

M

vol

4

_

, (63)

F

m

SO

2

=

4ak

c

p

64

4

M

vol

4

, (64)

F

m

CO

= F

m

V

= F

m

H

2

= 0. (65)

Both in

O

and in

F

the total source of mass is

F

m

=

4ak

c

p

(66)

and the source of energy is

F

e

= 4ak

_

(

c

s

c

p

T

p

T

g

)

e

1

+ (1 )

_

q

6

c

p

_

14

3

1

+

7

3

3

_

+

q

7

c

p

4

+

q

8

c

p

1

6

3

__

c

s

T

p

dm

p

dt

,

(67)

where

=

_

_

1 when

s

1

> 0 (ame inside the particle) or

g

< 0 (there is no oxygen in the vicinity),

1

when

g

1

> 0 and

s

1

< 0 (ame outside the particle),

The homogenized sources in the gas phase per unit volume and time, at point x, are

computed adding the contributions of each single particle that at some instant t is at

point x by the expression

f

(x) =

Ne

j=1

Np

i=1

q

j

p

ij

100

_

t

ij

f

0

F

ij

(t)(x x

ij

p

(t))dt (68)

38

where F

ij

(t) is the source of mass or energy of one particle of type i introduced through

inlet j, at instant t, x

ij

p

(t) is the position occupied by this particle at instant t, (x) is the

Dirac measure at point 0, t

ij

f

is the time needed for the particle to be completely burned

or to leave the furnace, q

j

is the mass ow of coal through the inlet j, p

ij

is the percentage

of particles of the type i through inlet j, and N

e

and N

p

are the number of inlets and

types of particles, respectively.

2.3 Particle Motion Model

To solve the solid phase model we need to follow each single particle along the domain.

We will suppose that the forces aecting the particle motion are only the drag force and

the gravity. We obtain the particle velocity by solving the ordinary dierential equation:

dv

p

dt

= F

A

(v

g

v

p

) +g, (69)

v

p

(0) = v

p0

, (70)

where F

A

is the drag force per mass unit which can be written as

F

A

=

3

16

p

a

2

C

D

Re. (71)

Here v

g

is the gas mixture velocity, v

p

the particle velocity, the gas viscosity, Re is the

Reynolds number relative to the particle, namely,

Re =

g

| v

g

v

p

|

2a

, (72)

and C

D

is the drag coecient which can be deduced from

C

D

=

_

1+0.15Re

0.687

Re/24

if Re 1000,

0.44 in other case.

2.3.1 Stochastic Particle Dispersion Modelling

In the particle motion model that we propose, coal particles only respond to the mean

uid velocity. This is correct if the ow is laminar but if we consider a turbulent ow

we must take into account the eect of a random uctuating velocity. For this purpose

we have coupled the particle motion model with a discrete random walk model. This

type of models specify the velocity as the sum of the mean uid velocity and a Gaussian

distributed random velocity uctuation with zero mean and a variance related to the

turbulent velocity scale computed from the turbulence model used. The random value of

the velocity is kept constant over an interval of time given by the characteristic lifetime

of the eddies, as made by [8].

39

Since we use the k turbulence model, the instantaneous uid velocity is calculated

as

v

g

= v

g

+

_

1

_

2k

3

,

2

_

2k

3

,

3

_

2k

3

_

, (73)

where

i

, i = 1, 2, 3, are normally distributed random numbers. The eddy time scale that

we consider is

e

= 0.15

k

log(r), (74)

where r is a uniform random number between 0 and 1. The particle eddy crossing time

is given by

c

= log

_

1

L

e

v

g

v

p

_

, (75)

where = 1/F

A

is the particle relaxation time and

L

e

= 0.09

k

1.5

(76)

is the eddy length scale.

As many random walk models, this model produces reasonable behavior in ows with

homogeneous turbulence. The suitability of many random walk models and others particle

dispersion models is analyzed in [6] or in [9] to include the eect of anisotropy.

We compute the trajectory, the density, the temperature and the sources to the gas

phase for a sucient number of representative particles (number of tries) with dierent

sizes, dropped from each cell of each inlet (as seen in Figure 6).

Figure 6. Trajectories of particles from a single cell

3 Algorithm and numerical methods

In order to numerically solve the dierent equations of the coupled two-phases problem

we implement a segregated procedure, leading to the algorithm shown in Figure 7.

40

Figure 7. Global algorithm

In the next subsections we describe the numerical methods used to solve the equations

of each problem in the sequential algorithm of Figure 7.

3.1 Momentum conservation equations

For solving the steady-state Navier-Stokes equations we use a P

1

-bubble/P

1

mixed

nite element combined with the method of characteristics and proceed to the elimination

of bubbles prior to the assembly by static condensation. Thus, we have to solve the

41

following boundary-value problem:

_

3v 4v X

t

+v X

2t

2t

+p = f in

v =

f

m

1

2t

(3 ln 4 ln X

t

+ ln X

2t

) in

v = v

e

on

e

v = 0 on

p

n p

n = 0 on

s

where X

t

(x) = (x, t; 0) and X

2t

(x) = (x, 2t; 0).

For that, we propose the following algorithm:

Step 0. Input v

0

y p

0

Step 1. Given v

0

and p

0

, v

1

and p

1

are the solution of the system:

_

_

_

1

t

v

1

zdx +

_

e

(v

1

+ (v

1

)

T

) : zdx

_

p

1

zdx =

_

f

1

zdx+

+

_

1

t

v

0

X

0

zdx

_

v

1

qdx =

_

g qdx

v

1

= v

e

on

e

v

1

= 0 on

p

with

g =

f

m

1

t

(ln ln X

0

),

p = p +

2

3

e

g.

Step n (n 1). Given v

n1

, v

n

, p

n1

and p

n

, v

n+1

and p

n+1

are the solution of the

system:

_

_

_

3

2t

v

n+1

zdx +

_

e

(v

n+1

+ (v

n+1

)

T

) : zdx

_

p

n+1

zdx =

_

f

n+1

zdx+

+

_

2

t

v

n

X

n

zdx

_

1

2t

v

n1

X

n1

zdx

_

v

n+1

qdx =

_

g qdx

v

n+1

= v

e

on

e

v

n+1

= 0 on

p

42

with

g =

f

m

1

2t

(3 ln 4 ln X

n

+ 3 ln X

n1

),

p = p +

2

3

e

g.

Discretizing and eliminating the bubbles for all steps, this leads to a linear system

with the following structure:

_

_

_

_

_

_

A 0 0 B

(1)

T

0 A 0 B

(2)

T

0 0 A B

(3)

T

B

(1)

B

(2)

B

(3)

C

_

_

_

_

_

_

_

_

_

_

_

_

v

1

v

2

v

3

p

_

_

_

_

_

_

=

_

_

_

_

_

_

S

(1)

1

S

(2)

1

S

(3)

1

S

2

_

_

_

_

_

_

3.2 Radiation

For the equation of the intensity of radiation we use a six-ux method for the semidis-

cretization in and choose between a nite element method and a nite dierence method

(the latter is only valid for a structured mesh), for spatial discretization.

The equations to be solved are

_

_

x

I + (a +

s

)I

s

4

_

S

2

(

, )I(x,

)d

= aI

b

in ,

I(x) =

1

w

w

q

r

n +

T

4

w

on .

3.2.1 Six-flux method

Let

I(x, ) W :=< w

1

, . . . , w

6

> and

I

+

1

(x) =

I(x,

1

) I

1

(x) =

I(x,

2

)

I

+

2

(x) =

I(x,

3

) I

2

(x) =

I(x,

4

)

I

+

3

(x) =

I(x,

5

) I

3

(x) =

I(x,

6

)

Then

I(x, ) = I

+

1

(x)w

1

() + I

1

(x)w

2

() + + I

+

3

(x)w

5

() + I

3

(x)w

6

()

because of

w

j

(

i

) =

ij

, 1 i, j 6.

By introducing F

i

:= I

+

i

+ I

i

and q

i

:= I

+

i

I

i

, for 1 i 3, the six-ux method

for the semidiscretization in leads to the boundary-value problem,

_

x

i

_

F

i

x

i

_

+ KF

i

2

s

3

j=1

j=i

F

j

=

2aT

4

in , 1 i 3

F

i

+

n

i

|n

i

|

F

i

x

i

=

1

w

w

_

i=1

F

i

x

i

n

i

_

+ 2

T

4

w

on , 1 i 3

43

3.2.2 Finite elements

The algorithm proposed is the following:

Step 0. Input F

0

i

, 0 i 3

Step n+1. Given F

n

i

, F

n+1

i

are solution of the problems:

_

F

n+1

i

x

i

z

i

x

i

dx +

_

KF

n+1

i

z

i

dx +

_

1 + C

2

C

3

C

1

F

n+1

i

z

i

|n

i

|d

_

C

2

C

1

(

3

j=1

j=i

F

n

j

|n

j

|)z

i

|n

i

|d

1

C

1

2T

4

w

z

i

|n

i

|d

_

2

s

s(

3

j=1

j=i

F

n

j

)z

i

dx =

_

2a

g

T

4

z

i

dx +

_

2a

s

T

4

s

z

i

dx

where

C

1

= 1 +

1

w

w

_

3

j=1

|n

j

|

_

C

2

=

1

w

w

C

3

=

3

j=1

j=i

|n

j

|

3.2.3 Finite Differences

We suppose that = [0, l

x

] [0, l

y

] [0, l

z

]. Then the boundary condition above reads

w

F

i

+

F

i

x

i

n

i

=

2

w

T

4

w

on .

The proposed algorithm is the following:

Step 0. Input F

0

i

, 0 i 3

Step n+1. Given F

n

i

, we obtain F

n+1

1

as the solution to the problems dened on lines

parallel to the x axis

_

x

_

F

n+1

1

x

_

+ KF

n+1

1

= b

1n

in

x

= [0, l

x

] {y

j

} {z

l

},

F

n+1

1

x

n

1

+

w

F

n+1

1

=

2

w

(T

n

w

)

4

on

x

= {(0, y

j

, z

l

)} {(l

x

, y

j

, z

l

)},

with

b

1n

= 2

s

s

3

j=1

j=1

F

n

j

+

2a

g

(T

n

)

4

+

2a

s

(T

s

)

4

.

This leads to the simple linear system

A{F

1

} = S

44

where

A =

_

_

_

_

_

_

_

d

1

p

d

1

s

d

1

s

.

.

.

.

.

.

.

.

.

.

.

. d

nx1

s

d

nx1

s

d

nx

p

_

_

_

_

_

_

_

S =

_

_

_

_

_

_

_

_

_

_

_

_

1

2

h

1

b

1

1

+

2

w

(T

w

(x

1

, y

j

, z

l

))

4

.

.

.

1

2

(h

i1

+ h

i

)b

1

i

.

.

.

1

2

h

nx1

b

1

nx

+

2

w

(T

w

(x

nx

, y

j

, z

l

))

4

_

_

_

_

_

_

_

_

_

_

_

_

d

p

=

_

_

_

_

_

_

_

_

_

_

_

_

_

1

2

1

+

2

h

1

+

w

+

1

2

h

1

K

1

.

.

.

1

2

i1

+

i

h

i1

+

1

2

i

+

i+1

h

i

+

1

2

(h

i1

+ h

i

)K

i

.

.

.

1

2

nx1

+

nx

h

nx1

+

w

+

1

2

h

nx1

K

nx

_

_

_

_

_

_

_

_

_

_

_

_

_

d

s

=

_

_

_

_

_

_

1

2

1

+

2

h

1

.

.

.

1

2

nx1

+

nx

h

nx1

_

_

_

_

_

_

F

1

= (F

11

, . . . , F

1nx

)

T

and F

1i

= F

n+1

1

(x

i

, y

j

, x

l

), i = 1, . . . , n

x

.

In a similar way, we proceed with lines parallel to the axis y and z, giving values of

F

n+1

2

and F

n+1

3

, respectively.

3.3 Advection-diusion equations

The advection-diusion-reaction equations of the gas-phase model are of the general

form,

Du(x, t)

Dt

((x, t)D(x)u(x, t)) + c(x, t)u(x, t) = f(x, t).

More specically, the energy and mass conservation equations are of this type. In order

to solve them we use a second order semi-Lagrange-Galerkin scheme. We discretize the

convective term using the formula

Du

Dt

=

u

t

+v u

1

2t

_

3u

n+1

4u

n

n

+ u

n1

n1

_

,

where

n

(x) = (x, t

n+1

; t

n

)

is the position at time t = t

n

of the uid particle that is at point x at time t

n+1

and that

moves with velocity v. The characteristic curves (x, s; t) are the unique solution of the

ODE

d(x, s; t)

dt

= v((x, s; t), t), s, t [0, T]

(x, s; s) = x.

45

To solve this ODE we can use a fourth-order Runge-Kutta method or a third-order

xed point method with the operator T : dened by

T = t

_

1.5v

n

0.5v

n1

_

that satises Ty = y with

y = x (x, t

n+1

; t

n

).

The latter makes possible to adapt the time step.

3.4 Algorithm for the solid phase model

In order to solve the combustion model introduced in the previous sections, we have

designed an algorithm which distinguishes, at each time step, the combustion stage in

which the particle is. In Figure 3.4 we can see a scheme of this algorithm that we apply

to each single particle.

Figure 8. Algorithm for solving the combustion model

46

4 Numerical Results

4.1 Analysis of numerical diusion

Results of the study of the numerical diusion when solving a convection-diusion

equation with the nite element method introduced in the previous section can be seen

in Figure 4.1. They could be compared, for instance, with those of [5].

Figure 9. Comparison of results for a benchmark 3D test

4.2 A coal ame simulation

A detailed study of the structure of a turbulent pulverized coal ame has been done

in Hwang et al [3, 4].

Our purpose will be to do a full numerical simulation of the turbulent pulverized coal

burner, used in these articles (see Figure 10).

Figure 10. Scheme of the experiment

47

In this study, methane is supplied to ignite the two-phase jet because the coal injection

rate is very small and ame stabilization is impossible for a pure pulverized coal ame.

The methane ow rate is the minimum amount needed to form a stable ame. The

experiment is designed as follows: rst the air is supplied to the main burner port and the

methane to the annular slit burner. Next the gas ame due to the air and the methane

is formed, and nally, when the methane diusion ame becomes stable, the pulverized

coal particles are dropped.

In order to make a numerical simulation of this experiment we proceed to the following

steps:

1. We make a simulation with Fluent of the rst stage of the experiment, until the

methane ame is stable. Figure 11 shows the geometrical domain for the CFD

simulation. The data corresponding to ows are: through the coal-air inlet 1.810

4

kg/s of air and 1.49 10

4

kg/s of coal are introduced whereas 1.67 10

5

kg/s of

gas enters through the gas inlet.

Figure 11. Geometry of the burner

2. With the results of the gas phase obtained from the Fluent simulation we solve our

combustion model.

3. We solve the combustion model with Fluent (namely Discrete Phase Model) starting

at the same initial data.

4. We compare results provided by both methods.

Figures 12 and 13 show the homogenized sources of total mass and O

2

, respectively,

obtained with both models.

48

Figure 12. Source of mass (f

m

)

Figure 13. Source of O

2

(f

m

O

2

)

Furthermore, with respect to unburned coal we have obtained the following results

from the two dierent models:

Fluent:

Volume integral of mass source: 6.34664 10

5

kg/s

Mass of released volatiles: 94.54 %

Mass of gasied char: 50.50 %

BFL:

Volume integral of mass source: 7.55143 10

5

kg/s

Mass of released volatiles: 98.31 %

Mass of gasied char: 44.53 %

49

5 Conclusions

We have proposed a mathematical model for a pulverized coal furnace and subse-

quently numerical methods for solving it. For validation purposes, we have simulated an

experiment involving the combustion of pulverized coal particles in a cylindrical domain.

Results obtained have been compared with those given by Fluent.

Acknowledgment

Part of this work was supported by Ministerio de Educaci on y Ciencia through project

ENE2005-09190-C04-01: Investigacion Aplicada en Conversi on Limpia de Combustibles

Fosiles (CLCF)

References

[1] K. Annamalai and W. Ryan. Interactive processes in gasication and combustion. II Isolated

carbon, coal and porous char particles. Progr. Energy Combust. Sci., 19:383446 (1993).

[2] A. Berm udez and J.L. Ferrn and A. Li n an. The modelling of the generation of volatiles, H

2

and CO, and their simultaneous diusion controlled oxidation, in pulverised coal furnaces.

Combustion Theory and Modelling, 11:949976 (2007).

[3] S-M. Hwang, R. Kurose, F. Akamatsu, H. Tsuji, H. Makino and M. Katsuki. Observation of

detailed structure of turbulent pulverized-coal ame by optical measurement (Part 1, time-

averaged measurement of behavior of pulverised-coal particles and ame structure). JSME

International Journal, 49(4):13161327, 2006.

[4] S-M. Hwang, R. Kurose, F. Akamatsu, H. Tsuji, H. Makino and M. Katsuki. Observation

of detailed structure of turbulent pulverized-coal ame by optical measurement (Part 2, in-

stantaneous two-dimensional measurement of combustion reaction zone and pulverised coal

particles). JSME International Journal, 49(4):13281335, 2006.

[5] M.R. Kaazempur-M. and C.R. Ethier. An ecient characteristic Galerkin scheme for the

advection equation in 3-D. Comput. Methods Appl. Mech. Engrg., 191:5345-5363, 2002.

[6] J.M. Macinnes and F. V. Bracco. Stochastic particle dispersion modeling and the tracer-

particle limit Phys. Fluids, 12:28092824 (1992).

[7] F.A. Williams. Combustion Theory. The Benjamin/Cummings Publ. Co., Inc, Menlo Park,

1985.

[8] A.D. Gosman and E. Ioannides. Aspects of computer simulation of liquid-fueled combustors.

J. Energy, 7(6):482490, 1983.

[9] Q. Zhou and M.A. Leschziner. A time-correlated stochastic model for particle dispersion in

anisotropic turbulence. 8th Turbulent Shear Flows Symposium., Munich, 1991.

50

Das könnte Ihnen auch gefallen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- CA3000A Dodge BearingDokument708 SeitenCA3000A Dodge BearingSuphi YükselNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Amca Publication 11-03: Certified Ratings Program Operating ManualDokument30 SeitenAmca Publication 11-03: Certified Ratings Program Operating ManualMatias MancillaNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Catalago Resumen de ValvulasDokument21 SeitenCatalago Resumen de ValvulasMatias MancillaNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Amca Publication 11-03: Certified Ratings Program Operating ManualDokument30 SeitenAmca Publication 11-03: Certified Ratings Program Operating ManualMatias MancillaNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- p-100 Vol2 1935 Part5Dokument132 Seitenp-100 Vol2 1935 Part5Matias MancillaNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- CA3000A Dodge BearingDokument708 SeitenCA3000A Dodge BearingSuphi YükselNoch keine Bewertungen

- Chapter 21Dokument25 SeitenChapter 21Matias MancillaNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Refractories For Heat Treating: Industrial CeramicsDokument6 SeitenRefractories For Heat Treating: Industrial CeramicsMatias MancillaNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Envirenmental EngineeringDokument87 SeitenEnvirenmental Engineering4919404Noch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hamada Boiler Catalogue Page 58 Coalmac 2Dokument1 SeiteHamada Boiler Catalogue Page 58 Coalmac 2Matias MancillaNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- CA3000A Dodge BearingDokument708 SeitenCA3000A Dodge BearingSuphi YükselNoch keine Bewertungen

- Carter Variator CatDokument40 SeitenCarter Variator CatMatias MancillaNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Technical Documents of The BoilerDokument20 SeitenTechnical Documents of The BoilerMatias Mancilla0% (1)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hamada Boiler Catalogue Page 47 Rotary Furnace For AMPDokument1 SeiteHamada Boiler Catalogue Page 47 Rotary Furnace For AMPMatias MancillaNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hamada Boiler Catalogue Page 56 Heavy Duty Chain GrateDokument1 SeiteHamada Boiler Catalogue Page 56 Heavy Duty Chain GrateMatias MancillaNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Hamada Boiler Catalogue Page 22 Coal Storage and PLC ControlDokument1 SeiteHamada Boiler Catalogue Page 22 Coal Storage and PLC ControlMatias MancillaNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hamada Boiler Catalogue Page 57 Coalmac 1Dokument1 SeiteHamada Boiler Catalogue Page 57 Coalmac 1Matias MancillaNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Hamada Boiler Catalogue Page 65 Rice Husk Firing Boiler 4Dokument1 SeiteHamada Boiler Catalogue Page 65 Rice Husk Firing Boiler 4Matias MancillaNoch keine Bewertungen

- Hamada Boiler Catalogue Page 59 Coalmac 3Dokument1 SeiteHamada Boiler Catalogue Page 59 Coalmac 3Matias MancillaNoch keine Bewertungen

- Hamada Boiler Catalogue Page 60 Coalmac 4Dokument1 SeiteHamada Boiler Catalogue Page 60 Coalmac 4Matias MancillaNoch keine Bewertungen

- Hamada Boiler Catalogue Page 59 Coalmac 3Dokument1 SeiteHamada Boiler Catalogue Page 59 Coalmac 3Matias MancillaNoch keine Bewertungen

- Hamada Boiler Catalogue Page 60 Coalmac 4Dokument1 SeiteHamada Boiler Catalogue Page 60 Coalmac 4Matias MancillaNoch keine Bewertungen

- Hamada Boiler Catalogue Page 63 Rice Husk Firing Boiler 2Dokument1 SeiteHamada Boiler Catalogue Page 63 Rice Husk Firing Boiler 2Matias MancillaNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hamada Boiler Catalogue Page 61 EFB Palm Waste FiringDokument1 SeiteHamada Boiler Catalogue Page 61 EFB Palm Waste FiringMatias MancillaNoch keine Bewertungen

- Hamada Boiler Catalogue Page 64 Rice Husk Firing Boiler 3Dokument1 SeiteHamada Boiler Catalogue Page 64 Rice Husk Firing Boiler 3Matias MancillaNoch keine Bewertungen

- Hamada Boiler Catalogue Page 67 TVTB 3Dokument1 SeiteHamada Boiler Catalogue Page 67 TVTB 3Matias MancillaNoch keine Bewertungen

- Hamada Boiler Catalogue Page 62 Rice Husk Firing Boiler 1Dokument1 SeiteHamada Boiler Catalogue Page 62 Rice Husk Firing Boiler 1Matias MancillaNoch keine Bewertungen

- Solid Fuel Combustion On Water-Cooled Vibrating Grate: Plant Equipment and ComponentsDokument2 SeitenSolid Fuel Combustion On Water-Cooled Vibrating Grate: Plant Equipment and ComponentsMatias MancillaNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Hamada Boiler Catalogue Page 7 Fluidizing Fire and Biomass FuelDokument1 SeiteHamada Boiler Catalogue Page 7 Fluidizing Fire and Biomass FuelMatias MancillaNoch keine Bewertungen

- Hamada Boiler Catalogue Page 8 Model DF Series General ViewDokument1 SeiteHamada Boiler Catalogue Page 8 Model DF Series General ViewMatias MancillaNoch keine Bewertungen

- Manufacture of Synthetic RubberDokument22 SeitenManufacture of Synthetic RubberHossamKandilNoch keine Bewertungen

- CBSE Class 10science Revision Notes Chapter-01 Chemical Reaction and EquationsDokument7 SeitenCBSE Class 10science Revision Notes Chapter-01 Chemical Reaction and EquationsAmit AryaNoch keine Bewertungen

- British Patent for Orbitally Rearranged Monoatomic ElementsDokument24 SeitenBritish Patent for Orbitally Rearranged Monoatomic ElementsSean ReevesNoch keine Bewertungen

- Electron ConfigurationDokument30 SeitenElectron ConfigurationShiela Dianne Caliwanagan100% (1)

- EEI Mid-Term Exam QuestionsDokument2 SeitenEEI Mid-Term Exam QuestionsrahulNoch keine Bewertungen

- Chapter 15Dokument50 SeitenChapter 15陈希尧Noch keine Bewertungen

- Fractional Distillation ExplainedDokument6 SeitenFractional Distillation ExplainedDeny AlsanNoch keine Bewertungen

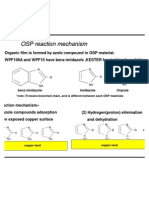

- OSP Reaction MechanismDokument2 SeitenOSP Reaction MechanismsmtdrkdNoch keine Bewertungen

- 1 AlkalinityDokument1 Seite1 AlkalinityprakashNoch keine Bewertungen

- Ssasas DSDSDDokument9 SeitenSsasas DSDSDZia RathoreNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Thesis-ZnS Nanoparticles - Synthesis, CharacterizationDokument75 SeitenThesis-ZnS Nanoparticles - Synthesis, CharacterizationDeepak Baghel100% (2)

- Solubility of Drugs-PART I - Sankalp GharatDokument48 SeitenSolubility of Drugs-PART I - Sankalp GharatSiddhant BanwatNoch keine Bewertungen

- SLES Concentration Effect On The Rheolog TraducidoDokument22 SeitenSLES Concentration Effect On The Rheolog TraducidoJose GamezNoch keine Bewertungen

- Natural Evaporative CoolingDokument5 SeitenNatural Evaporative CoolingCM SoongNoch keine Bewertungen

- 22 Metallic Glass: Aggregated Diamond or Hyper DiamondDokument3 Seiten22 Metallic Glass: Aggregated Diamond or Hyper DiamondMariam AbdulkariamNoch keine Bewertungen

- Enthalpy Calibration For Wide DSC Peaks: Thermochimica ActaDokument4 SeitenEnthalpy Calibration For Wide DSC Peaks: Thermochimica ActaLee Chee KheongNoch keine Bewertungen

- Review of Cansolv SO Scrubbing System's First Commercial Operations in The Oil Refining IndustryDokument17 SeitenReview of Cansolv SO Scrubbing System's First Commercial Operations in The Oil Refining Industryrogerh44Noch keine Bewertungen

- Elementary and Middle School Science Lesson Plan - Solid LiquidDokument5 SeitenElementary and Middle School Science Lesson Plan - Solid LiquidMaria sofia NapuaNoch keine Bewertungen

- Oil Colour ChangeDokument5 SeitenOil Colour ChangeHamid DarvishiNoch keine Bewertungen

- Chemistry College Entrance Exams Enrichment Class 2019Dokument98 SeitenChemistry College Entrance Exams Enrichment Class 2019Myra Lee Camarista EsmayaNoch keine Bewertungen

- Nalsize 7541: Emulsification AidDokument3 SeitenNalsize 7541: Emulsification Aidalakazum28Noch keine Bewertungen

- Chemistry 1.2 NotesDokument13 SeitenChemistry 1.2 NotescheeheNoch keine Bewertungen

- Energetics of Displacement Reaction (ΔH = -219 kJ/molDokument1 SeiteEnergetics of Displacement Reaction (ΔH = -219 kJ/molnewacademy234100% (2)

- Use of Phase Diagrams in Studies of Refractories CorrosionDokument19 SeitenUse of Phase Diagrams in Studies of Refractories CorrosionVictorNoch keine Bewertungen

- Defraction of LightDokument21 SeitenDefraction of LightPrakhar94% (18)

- Chap. 4.2 Desigh and Rating of Tube Bundle Heat ExchangersDokument22 SeitenChap. 4.2 Desigh and Rating of Tube Bundle Heat ExchangersMeshal Al-mutairiNoch keine Bewertungen

- Basic Production of X-Rays: Jason Matney, MS, PHDDokument39 SeitenBasic Production of X-Rays: Jason Matney, MS, PHDkrimo biomédicalNoch keine Bewertungen

- Enzymes Speed Up Chemical ReactionsDokument4 SeitenEnzymes Speed Up Chemical ReactionsAhmedNoch keine Bewertungen

- Textile Chemical Brochure 8.6.22 - 031Dokument1 SeiteTextile Chemical Brochure 8.6.22 - 031NIKESH PRAKASHNoch keine Bewertungen

- Cooling Tower Problems and Chemical DosingDokument2 SeitenCooling Tower Problems and Chemical Dosingvela vanNoch keine Bewertungen

- Quantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessVon EverandQuantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessBewertung: 4 von 5 Sternen4/5 (6)

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseVon EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseBewertung: 3.5 von 5 Sternen3.5/5 (69)

- The Physics of God: How the Deepest Theories of Science Explain Religion and How the Deepest Truths of Religion Explain ScienceVon EverandThe Physics of God: How the Deepest Theories of Science Explain Religion and How the Deepest Truths of Religion Explain ScienceBewertung: 4.5 von 5 Sternen4.5/5 (23)

- Packing for Mars: The Curious Science of Life in the VoidVon EverandPacking for Mars: The Curious Science of Life in the VoidBewertung: 4 von 5 Sternen4/5 (1395)

- Summary and Interpretation of Reality TransurfingVon EverandSummary and Interpretation of Reality TransurfingBewertung: 5 von 5 Sternen5/5 (5)