Beruflich Dokumente

Kultur Dokumente

ShaliUrethane TC STP

Hochgeladen von

dox4printCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ShaliUrethane TC STP

Hochgeladen von

dox4printCopyright:

Verfügbare Formate

ShaliUrethane TC

Two Component Aliphatic Polyurethane UV Resistant Top Coat

Description

ShaliUrethane TC (formerly known as Shaliol PU) is two component, liquid aliphatic polyurethane based UV and weather resistant coating. It is ideal protective coating for exposed surfaces as it provides excellent weather resistance and light stability. ShaliUrethane TC films are hard, tough but flexible and display good solvent and gasoline resistance. ShaliUrethane TC is available in various colours.

Characteristics

Pot Life, 30 oC Application Temp, oC Drying time @30 oC Surface Dry Hard Dry Full Cure Recoating Time, Hrs Minimum Maximum Impact resistance (cm.kg) Abrasion resistance Weathering resistance (QUV) Flash Point, oC Base Hardener 5 Hrs 10 40 Adhesion to Steel & Concrete Coverage, square meter/Kg Dry Film Thickness / coat, microns Excellent 6 to 7 @ 75 microns 60 75

30 minutes, 6 hrs 7 days 6 48

100

Finish

Glossy

~ 40 mg 1000 hrs

Hardness, sec. (Pendulum Hardness after 7 days curing) Flexibility (Conical Mandrel),mm Temperature Resistance, oC Volume Solids

195

1

Up to 120 50 60 %

> 23 > 23

Application

On shore and off shore industries. Power Plants Petrochemical and Pharmaceutical complexes Cement and steel plants, Transportation Industries Infrastructure projects Chemical plants.

Advantages

UV and weather resistance. Better adhesion and flexibility Mild Chemical resistance.

Application Methodology

Clean surface by oil free compressed air, sandblasting, wire brushes or other mechanical means to ensure removal of all rust, oil, grease, dirt, or any other loose particle prior to application of primer. ShaliUrethane TC being a Top coat, is applied over suitable anticorrosive primer or intermediate coats. Aged coatings coating should be roughened by emery paper grade 400 / 600 for better bonding. Apply only on dry surfaces. Stir the Component A and Component B separately. If settling is observed in the Component

A, loosen the settled material with the help of hand stirrer followed by power driven stirrer for quick homogenous mixing. Mix hardener gradually into the base under continuous stirring. Apply mixed homogenous mix by brush, roller, conventional or airless spray. Use suitable compatible thinner to get the desired workability. Volume of thinner generally required varies from 5 15 % depending upon the method of application i.e. brush, roller, conventional spray or airless spray. Conventional Spray Application 5 15 1.2 1.4 40 70 Airless Spray Application 5 Max 0.28 1400 - 1800

Thinner, % Nozzle Orifice, mm Nozzle Pressure, Psi

Cleaning

Clean all tools immediately after use with xylene. Do not allow material to harden.

Health & Safety

The product should not come in contact with the skin and eyes, or be swallowed. Ensure adequate ventilation and avoid inhalation of vapours as some people are sensitive to resins, hardeners and solvents. Wear suitable protective clothing, gloves and eye protection. In case of contact with skin, rinse with plenty of clean water, then cleanse with soap and water. Do not use solvent to clean the contacted area. In case of contact with eyes, rinse immediately with plenty of clean water and seek medical advice. If swallowed seek medical attention immediately - do not induce vomiting.

Packing

Available in 5 Kgs units consist of Component A and B.

Storage

Store in a cool dry place under shed away from heat.

Shelf Life

6 months in original unopened sealed conditions.

211/2011

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- NGL Fractionation Using HYSYSDokument30 SeitenNGL Fractionation Using HYSYSAhmad Deyab100% (3)

- BambooDokument52 SeitenBamboohksmallray100% (2)

- Beam Deflection FormulaeDokument2 SeitenBeam Deflection Formulae7575757575100% (6)

- Solar Accessories: U / Z Clams Aluminum Exclusion Clamps / Sections Steel Structures Cold RoleDokument5 SeitenSolar Accessories: U / Z Clams Aluminum Exclusion Clamps / Sections Steel Structures Cold Roledox4printNoch keine Bewertungen

- MR K Ramakrishnan Managing Infrastruc Proj RiskDokument22 SeitenMR K Ramakrishnan Managing Infrastruc Proj Riskdox4printNoch keine Bewertungen

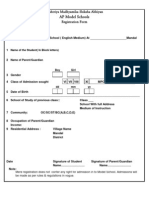

- AP Model Schools: Rashtriya Madhyamika Shiksha Abhiyan Registration FormDokument1 SeiteAP Model Schools: Rashtriya Madhyamika Shiksha Abhiyan Registration Formdox4printNoch keine Bewertungen

- Price Price: Gannon Dunkerley & Co. LTDDokument1 SeitePrice Price: Gannon Dunkerley & Co. LTDdox4printNoch keine Bewertungen

- Mail Elevation A, B, C& D A0Dokument1 SeiteMail Elevation A, B, C& D A0dox4printNoch keine Bewertungen

- M/S. Gannon Dunkerly & Co LTD., 6-3-1111/16, Nishanth Bagh, Begumpet, Hyderabad - 16Dokument1 SeiteM/S. Gannon Dunkerly & Co LTD., 6-3-1111/16, Nishanth Bagh, Begumpet, Hyderabad - 16dox4printNoch keine Bewertungen

- 06 Weekly Progress Report For Jun ' 13Dokument1 Seite06 Weekly Progress Report For Jun ' 13dox4printNoch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument14 SeitenDisclosure To Promote The Right To Informationdox4printNoch keine Bewertungen

- Bangalore: Gulshan Trading CompanyDokument1 SeiteBangalore: Gulshan Trading Companydox4printNoch keine Bewertungen

- GDCL Manglore 1Dokument3 SeitenGDCL Manglore 1dox4printNoch keine Bewertungen

- Ref: MAI / GDCL / Q: 2012 - 2013 / 600: Email: Mai@maroor - inDokument2 SeitenRef: MAI / GDCL / Q: 2012 - 2013 / 600: Email: Mai@maroor - indox4printNoch keine Bewertungen

- Microscopes: Compiled by Guided byDokument136 SeitenMicroscopes: Compiled by Guided byAmeena100% (3)

- Sensors & TransducersDokument5 SeitenSensors & TransducersSachith Praminda RupasingheNoch keine Bewertungen

- RougingDokument6 SeitenRougingmarcmanichNoch keine Bewertungen

- Mock 2-Chem SPMDokument11 SeitenMock 2-Chem SPMLyna JingomNoch keine Bewertungen

- CPCS Antidote ChartDokument1 SeiteCPCS Antidote ChartWesam Al-TawilNoch keine Bewertungen

- Concrete Mix Proportioning Using EMMA SoftwareDokument12 SeitenConcrete Mix Proportioning Using EMMA SoftwareYuliusRiefAlkhalyNoch keine Bewertungen

- Superpave Laboratory WorkshopDokument62 SeitenSuperpave Laboratory WorkshopAugusto M. ReyesNoch keine Bewertungen

- Supernova Simulation LabDokument3 SeitenSupernova Simulation LabAlli ANoch keine Bewertungen

- Rydlyme: The Solution To Your Water Scale ProblemsDokument4 SeitenRydlyme: The Solution To Your Water Scale Problemswq3erwqerwerNoch keine Bewertungen

- X RAY Residual StressDokument36 SeitenX RAY Residual StressAnonymous oTrMza100% (1)

- 87 Kerabondplus GB in PDFDokument4 Seiten87 Kerabondplus GB in PDFpankajNoch keine Bewertungen

- Summer Holiday HomeworkDokument13 SeitenSummer Holiday Homeworkneerajbro2679Noch keine Bewertungen

- D. Types of Tests On SandDokument9 SeitenD. Types of Tests On SandSandeepNoch keine Bewertungen

- PhysicsDokument396 SeitenPhysicsGreeny34Noch keine Bewertungen

- NaphtechDokument15 SeitenNaphtechIwe D'luffyNoch keine Bewertungen

- Aakash Rank Booster Test Series For NEET Aakash Rank Booster Test Series For NEET-2020 2020Dokument12 SeitenAakash Rank Booster Test Series For NEET Aakash Rank Booster Test Series For NEET-2020 2020VedNoch keine Bewertungen

- Is Alcohol in Skincare Products Bad For Your Skin in The Long TermDokument6 SeitenIs Alcohol in Skincare Products Bad For Your Skin in The Long TermgaladrielinNoch keine Bewertungen

- Corrosion Under InsulationDokument25 SeitenCorrosion Under InsulationNaqib Nordin33% (3)

- Ch3 SolutionsDokument64 SeitenCh3 Solutionsmohimran2002100% (1)

- Product Manual FFETDokument21 SeitenProduct Manual FFETAan Sarkasi Amd100% (1)

- Manual Wilden P2-METAL PDFDokument28 SeitenManual Wilden P2-METAL PDFMarco SilvaNoch keine Bewertungen

- SRM University: Part - A Answer ALL Questions (10 X 2 20 Marks)Dokument2 SeitenSRM University: Part - A Answer ALL Questions (10 X 2 20 Marks)Ruby SmithNoch keine Bewertungen

- EOCQ Ans 6Dokument2 SeitenEOCQ Ans 6harshanauoc100% (2)

- Atomic Structure BWDokument47 SeitenAtomic Structure BWShweta Saatish PandeyNoch keine Bewertungen

- Fund - Elect DE52.Dokument355 SeitenFund - Elect DE52.atashi baran mohantyNoch keine Bewertungen

- Ohe Fitting GuidelineDokument56 SeitenOhe Fitting Guidelinepretha56Noch keine Bewertungen

- Technical Document PDFDokument64 SeitenTechnical Document PDFAdamovic InesNoch keine Bewertungen

- mp1 2 PDFDokument1 Seitemp1 2 PDFAmer MehmoodNoch keine Bewertungen

- Water-Soluble Sulfate in Soil: Standard Test Method ForDokument3 SeitenWater-Soluble Sulfate in Soil: Standard Test Method ForJufer MedinaNoch keine Bewertungen