Beruflich Dokumente

Kultur Dokumente

QTN For Epoxy and ESD Flooring Dtd.28!2!2012

Hochgeladen von

dox4printOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

QTN For Epoxy and ESD Flooring Dtd.28!2!2012

Hochgeladen von

dox4printCopyright:

Verfügbare Formate

QUOTATION

Item No. Description Unit Quantity 2472 Rate 1652 Amount 4,083,744.00

sqm 26 Providing 2mm thick hard, antistatic, abrasion resistant, robust solvent free epoxy flooring (ESD flooring) with the following specifications. 1. Surface Preparation Surface Preparation of concrete substrate with proper diamond grinding /Proper Vacuum assisted shot blasting machine equipment to remove dust, laitance, other contaminants etc., and to form the required anchor profile on the floor substrate. 2. Providing and applying 2 part water dispersed epoxy resin primer Sikafloor80 Promer @ 0.3 kg/m 3. Installation of underlay Moisture barrier 2mm

Providing and applying three part, self smoothing, solvent free, moisture barrier epoxy modified cement screed Sikafloor81 EpoCem at at thickness of 2mm @ approx. 2.25 kg/m/mm having Carbon dioxide diffusion co efficient CO = 4168 as per Klopfer Engelgried method, water vapour diffusion coefficient HO=252 as per DIN 52615, Water absorption coefficient W=0.02 kg/m as per DIN 52617. When applied at minimum 2mm thickness it can be laid over high moisture content substrate and must be used when substrate moisture is more than 4%. 4. Installation of low emission, electrostatic conductive, self smoothing epoxy resin system Supply and application of Sika Electrostatic conductive Epoxy Flooring System with electrode based in the following sequence:. i Over the surface, an epoxy resin based primer Sikafloor 161 shall be applied. The primer ia s two component material consisting of Component A and Component B; the mixing ratio would be 79:21, by weight.

ii. The Earthing kit (Electrode) with copper tape shall be placed according to the specification mentioned above, The name of the earthing kit would be Sikafloor Leitset and the copper tape would be Sika Kupferleitband or equivalent iii. Over the primed surface, a conductive under of Sikafloor 220W should be applied. The conductive undercoat is a two component material, which should be mixed at the specified ratio like 83:17 (by weight) and applied using a brush or roller. This is water borne epoxy and the mixed density is 1.04kg/I.

iv. Application of low emission, electrostatic conductive, self smoothing epoxy topping of 1.5mm thickness with Sikafloor 266 ECF CR including taking the conductivity measurements of top coat as per the technical specification. The product conforms to Compressive strength is 80N/mm as per EN 138922, Resistance to ground: RG10 to 10 as per IEC 613404 1 Flexural Strength is 39N/mm as per EN 138922, Shore D Hardness is 84 as per DIN 53 505 Abrasion resistance is 45mg (CS 10/1000/1000)(14days/+23C) as DIN 53 109 Taber Abrader Test) applied @ 2.1 Kg/sqm followed by Sikadur 502 @ 0.6 Kg/sqm. All in complete as per the manufacturers specifications and directions of the engineer in charge. ESD FLOOR REQUIREMENT AND SPECIFICATION Major Specification: 1. Electrical Resistance (On conductive black Coat): Surface resistance between 104 to 106 as per DIN IEC 6134041 Standard. 2. Walkinvoltage: 100V to +100V as per DIN IEC 613405 1 Standard. 3. System Resistance: Less than 35M including floor concrete substrate etc as per DIN IEC 6134051 Standard. 4. Compressive Strength: More than 80N/mm2 as per EN 1961 Standard. 5. Flexural Strength: More than 55N/mm2 as per EN 1961 Standard. 6. Abrasion resistance: Maximum thickness reduction should not be more than 2mm as per IS 91621979/IS 12371980.

7. Hardness: Shore D hardness of floor more than 85as per DIN53505. 8. Tensile Strength: More than 15N/mm2 as per EN 1961 Standard. 9. Pull Out Strength/Bond Strength: More than 1.5N/mm2 or concrete failure as per ISO4624 Standard. 10. Gloss: 75% as per IS 1011988 Standard. 11. Chemical Resistance: Resistance to acids, caustic soda, liquid soap, IPA etc as per IS 46311968. 12. Water absorption: Less than 0.5% as per ASTM D570. 13. Slip resistance:Better than R11 as per Employers Liability Insurers Institute of safety at work (BIA). 14. Low VOC. 15. Temporary Moisture Barrier underlay screed: a. Layer thickness Min. 2mm must be applied. b. CarbonDiOxide Diffusion Coefficient (CO2) Co2~4168 acc. Carbonation Resistance for 3mm thickness R~12.5M. c. Water Absorption Coefficient W W ~ 0.02 Kg/m2 X h0.5 acc. To DIN 52 617. d. Water Vapor Diffusion Coefficient (H2O) H2O~252 acc. Equivalent air Layer Depth for 3mm Thickness SD~0.75m. e. EModulus Static: ~19.9 KN/mm2 (at +20oC) ~23.2 KN/mm2 (at 20oC). f. Compressive Strength 60 N/mm2 as per IS 9162 1979. g. Flexural Strength 18 N/ mm2 as per IS 9162 1979. h. Bond Strength 4.1 N/ mm2 according to EN 13892 8. i. Production Description A three part, Epoxy modified Cementitious, fine textured mortar for self smoothing floor screeds used as temporary barrier. 16. Particle emission Certificate according to CSM statement of Qualification ISO 146441, class3. 17. Out gassing Emission Certificate according to CSM statement of Qualification ISO 146448, class3. Construction/Configuration:

Details of construction above concrete floor are as follows, 1. Epoxy Moisture barrier to avoid any moisture related deboning/blisters of floor in future or during application. 2. Epoxy Scrape coat as per requirement depending on actual condition of concrete substrate. 3. Primary coat as binder. 4. Electrodes as per requirements to be embedded inside the floor (NO cupper strips/copper grid or external lying of electrodes are permitted). 5. Epoxy Conductive code for providing uniform conductivity of ESD flooring. 6. Epoxy load bearing top coat of required thickness and color as per our selection from RAL Shade. General Condition: 1. Warranty to be provided for blisters, de bonding and loss of ESD property due to material degradation. 2. Scratch resistance coating and preventive maintenance methodology, facility, provision to be provided. 3. After sale service to be provided immediately for full warranty period free of cost. 4. Repair, relaying charges will be paid for repair, relaying etc due damages caused by us on actual. Substrate Requirement: 1. Compressive strength of concrete should be floor more than 25N/mm2. 2. Pull out strength of concrete should be more than 1.5N/mm2. 3. Undulation of floor less than 5mm on a span of 10meter. 4. Floor surface to be free from laitance, grease, oil, inorganic/organic acids, polyurethane etc. 5. Surface should be free from voids, cracks, potholes etc. 6. High spots to be eliminated. 7. Metal panels/parts to be eliminated. 8. Expansion joints if any to be identified. 9. At least 15mm clearance to be provided from floor to door etc.

sqm 27 Providing 2mm thick hard, abrasion resistant, robust solvent free epoxy flooring (Non ESD flooring) with the following specifications. 1. Surface Preparation Prepare the dry concrete surface using proper diamond grinding equipment to remove any loose material, contaminations and laitance to provide a sound, fine gripping surface. Clean the entire floor area using a powerful industrial vacuum cleaner. 2. Providing and applying 2 part water dispersed epoxy resin primer Sikafloor80 Primer approx at the rate of 0.3 kg/sqm 3. Installation of underlay Moisture barrier 2mm

960

1320

1,267,200.00

Providing and applying three part, self smoothing, solvent free, moisture barrier epoxy modified cement screed Sikafloor 81 EpoCem at thickness of 2mm @ approx. 4.5 kg/m having Carbon dioxide diffusion coefficient CO = 4168 as per Klopfer Engelgried method, water vapour diffusion coefficient HO=252 as per DIN 52615, Water absorption coefficient W=0.02 kg/m as per DIN 52617. When applied at minimum 2mm thickness it can be laid over high moisture content substrate and must be used when substrate moisture is more than 4%. 4. Providing and applying epoxy resin based primer Sikafloor 161 shall be applied. The primer is a two component A and Component B; the mixing ration would be 79:21, by weight. 5. Installation of self laveling epoxy requirement Providing and applying four part, self smoothing solvent free, coloured, smooth glossy, epoxy resin screed Sikafloor266CR@ approx. 2.5 kg/m (including Sikadur 501) having compressive strength of N/mm EN 138922, Flexural strength of 39N/mm as per EN 138922, Shore D Hardness 84 As per DIN 53 505 abrasion resistance 45mg (CS 10/1000/100) DIN 53 109 (Taber Abrader Test). All in complete as per the manufacturers specifications and directions of the engineer in charge.

52 Providing water proofing treatment with two coats of polyurethane of approved manufacture "UNISEAL WS1" / "TECHCOAT61P" or equivalent for the sunken floors. The sunken slab and the side vertical walls should be finished smooth with cement plaster (Cement plaster will be measured and paid for separately as an item), the surface should be absolutely dry, free from dust, grease, oil and loose particles. Providing necessary scaffolding wherever required and cleaning the surface etc., complete all as per the manufacturer's specifications. NOTE: 1) The sunken floor shall be tested after the treatment for water tightness by impounding water for a period of 48 hours. 2) Performance guarantee for a period of 10 years be obtained from the contractors/manufacturers of the paint. 3) The coverage capacity for "UNISEAL WS1" or equivalent for a smooth surface should be 3.717sqm/kg (40sft/kg) for the first coat and 4.647sqm/kg (50sft/kg) for the second coat and for a roughsurface the coverage should be 2.788 sqm/kg (30 sft/kg) for the first coat and 3.717 sqm/kg (40 sft/kg) for the second coat respectively as per the manufacturer's specifications. The coverage capacity for "TECHCOAT61P" (Rubber based polyurethane) or equv, for a smooth surface should be 4.182sqm/ltr (45 sft/ltr) for the first coat and 4.647sqm/ltr (50sft/ltr) for the second coat and for a rough surface the coverage should be 3.717 sqm/ltr (40sft/ltr) for the first coat and 4.182sqm/ltr (45sft/ltr) for the second coat respectively as per the manufacturers specification at all heights.

sqm

275

450

123,750.00

53 Providing and laying water proofing treatment over RCC roof in 3 courses, as specified below, after thoroughly cleaning surface of the roof slab with wire brush, cleaning of dust and foreign matters, raking and cleaning of construction joints if any etc., complete to make the surface suitable for receiving water proofing treatment. I COURSE : The existing covering on slab to be removed and the surface of the RCC slab exposed. Construction joints if any are to be raked and cleaned. A coat of cement slurry at the rate of 4.4kg/sqm mixed with acrylic water proofing compound (as per manufacturers specification) is spreaduniformly over the RCC roof area and ensuring that the slurry penetrates into the RCC slab below and fills all micro cracks and all other porous areas. Over this a layer of 15mm thick cement mortar 1:5, mixed with acrylic water proofing compound as per manufacturers specifications shall be laid to place the II course. II COURSE : A sinle layer of brick on edge with 15mm wide gaps filled with CM 1:5 mixed with acrylic water compound is laid (i.e., bricks placed vertically on its 75x115mm side or 75x230mm side as the case may be, to suit the required thickness of course), when the bottom layer (I course) is still green and laid to slope of 1 in 60 as per roof drainage scheme using approved well burnt bricks (waer absorption not more than 20%) with minimum thickness of 65mm at outer edge including the top and bottom plastering (I & III course) to get required gradient, laying the bricks with not less than 15mm gap alround, which shall be properly filled completely and compacted with CM 1:5 mixed with acrylic water proofing compound as per manufacturer's specification using full bricks or bricks cut to required size to lay the course with single layer with gradient said above for adequate drainage.

sqm

2861 Regret

III COURSE : 20mm thick cement motar 1:4 mixed with acrylic water proofing compound with a layer of chicken mesh 12mmx26g and marked with 300mmx300mm false squares including curing etc., for not less than 7 days, complete all as per specifications at all heights and directions of Engineer in charge. The 20mm thick layershall be carried out in two layers of 10mm thick with an inter layerof chicken mesh of 12mm x 26g laid in between the two layers of cement mortar at all heights. NOTE : The acrylic water proofing compound to be used shall be; a) CHEMSEAL manufactured by M/s. Overseas Water Proofing Corporation, Mumbai. The proportion of CHEMSEAL shall be 2% by weight of cement OR CONPLAST X 421 IC integral water proofing compound manufactured by M/s. FOSROC Chemicals(India) Ltd., Bangalore. The proportion of CONPLAST X 421 IC shall be 130ml per 50kg of cement. OR ROFFE HYPROOF manufactured by M/s. ROFFE Construction Chemicals Pvt. Ltd., liquid integral water proofing compound at 140ml per 50kg of cement OR Equivalent. b) The second course of the treatment shall be laid in single course using full bricks / cut bricks as may be required for laying the course in 1 in 60 slope. c) The rate to include all labour, material and contingent coats for execution of work in a workman like manner including curing, etc., complete for respective courses. d) The plane horizontal measurements of roof slab only shall be measured for payment. e) The theoretical cement consumption required for the above work will be worked out based on coefficient for each layer of work as per specification. f) The work shall b got executed through specilised water proofing agency. g) The contractor should finish a guarantee bond in the prescribed format for satisfactory water proofing performance for 10 years.

54 Providing and laying weathering course and over deck insulation with cellular light weight concrete of density not exceeding 800 Kgs/cum obtained by mixing fly ash, sand, cement with approved foaming agent in specified proportions as per manufactures specifications laid to uniform thickness of 170 mm thick and having thermal conductivity 0.08 to 0.555 W/mk possessing a compressive strength of 150kg/sqcm. in 28 days including curing, scaffolding and executing the work at all heights etc., complete as per manufacturers specifications and direction of the EngineerinCharge at all heights. NOTE: Contractors may furnish complete specification with test reports and works etc., for the item for evaluating the specification/item and approval Terms & Condition :

cum

733 Regret

The rates quoted above is inclusive of Cost of material (inclusive of ED @ 10.3%) and application The material quoted is manufactured by M/s. APURVA INDIA LTD., Mumbai, which is equivalent to Cost of material which works out 70% of the total order is to be procured by you by placing the order For the direct supplies based on the order placed by you against our Proforma Invoice you will be Transportation charges will be charged extra. A lead time of 10 days is taken for supplies from the day of ordering to dispatch. Execution of work is Any deviation in the order is to be informed to us before procuring the material. 8 Specified colour shade shall be provided by you at least 10 days in advance. 9 Electricity, Water, Safe Storage place is to be provided at site at your cost. 10 The application charges are to be paid 50% in advance and balance on progress. 11 Any changes in the Taxes and levis is force measured.

1 2 3 4 5 6 7

Das könnte Ihnen auch gefallen

- BOQ WaterproofingDokument6 SeitenBOQ Waterproofinghareshkp100% (1)

- Insulation SpecDokument16 SeitenInsulation Specsandesh100% (1)

- Fosroc - UG Water Tank SpecsDokument1 SeiteFosroc - UG Water Tank SpecsShakil AkhterNoch keine Bewertungen

- 18R 97Dokument16 Seiten18R 97Manoj Singh100% (4)

- Beam Deflection FormulaeDokument2 SeitenBeam Deflection Formulae7575757575100% (6)

- Filipino Catholic Wedding Ceremony LiturgyDokument8 SeitenFilipino Catholic Wedding Ceremony LiturgyHoney Joy ChuaNoch keine Bewertungen

- Technical Data Speedmaster SM 102: Printing Stock Blanket CylinderDokument1 SeiteTechnical Data Speedmaster SM 102: Printing Stock Blanket CylinderAHMED MALALNoch keine Bewertungen

- Hsse S 005 - Hsse in ProjectsDokument11 SeitenHsse S 005 - Hsse in ProjectsAHMED AMIRANoch keine Bewertungen

- She Walks in BeautyDokument6 SeitenShe Walks in Beautyksdnc100% (1)

- BambooDokument52 SeitenBamboohksmallray100% (2)

- BOQ For Waterproofing Works: Modern IT Solutions, NoidaDokument4 SeitenBOQ For Waterproofing Works: Modern IT Solutions, NoidaAbhinav Saini100% (1)

- Fosroc System BOQDokument12 SeitenFosroc System BOQAsdf GhjkNoch keine Bewertungen

- Lesson Plan For DemoDokument7 SeitenLesson Plan For DemoShiela Tecson GamayonNoch keine Bewertungen

- Methodology For TERRACE Waterproofing NITOPROOF 600 PDFDokument7 SeitenMethodology For TERRACE Waterproofing NITOPROOF 600 PDF폴로 쥰 차100% (1)

- Waterproofing Techniques for Concrete StructuresDokument9 SeitenWaterproofing Techniques for Concrete StructureshemantrulzNoch keine Bewertungen

- VFTO DocumentationDokument119 SeitenVFTO DocumentationSheri Abhishek ReddyNoch keine Bewertungen

- Differential Scanning CalorimetryDokument60 SeitenDifferential Scanning CalorimetryMariyam100% (2)

- Epoxy and ESD FlooringDokument4 SeitenEpoxy and ESD Flooringdox4printNoch keine Bewertungen

- Sikafloor 82 EpocemDokument6 SeitenSikafloor 82 Epocemthe pilotNoch keine Bewertungen

- Sikafloor 81 EpocemDokument6 SeitenSikafloor 81 Epocemthe pilotNoch keine Bewertungen

- PSOW2 - MS For Waterproofing Dated 04.11.2023Dokument5 SeitenPSOW2 - MS For Waterproofing Dated 04.11.2023projectsNoch keine Bewertungen

- E 1605 SikaCor 255 277Dokument6 SeitenE 1605 SikaCor 255 277emanuelluca@yahoo.comNoch keine Bewertungen

- ITCC in Riyadh Residential Complex J10-13300 07100-1 WaterproofingDokument5 SeitenITCC in Riyadh Residential Complex J10-13300 07100-1 WaterproofinguddinnadeemNoch keine Bewertungen

- UP PWD WP Spec (1)Dokument9 SeitenUP PWD WP Spec (1)sanjay kumarNoch keine Bewertungen

- Enershield - HP: Vapor Permeable Air/Water-Resistive Barrier MembraneDokument8 SeitenEnershield - HP: Vapor Permeable Air/Water-Resistive Barrier MembranePramod V PatilNoch keine Bewertungen

- Sikafloor - 262 AS: 2-Part Epoxy Electrostatically Conductive Self-Smoothing SystemDokument6 SeitenSikafloor - 262 AS: 2-Part Epoxy Electrostatically Conductive Self-Smoothing Systemthe pilotNoch keine Bewertungen

- Water Proof SpecDokument2 SeitenWater Proof SpecdjgiumixNoch keine Bewertungen

- Specification GlassFiberDokument6 SeitenSpecification GlassFiberMukesh MaharjanNoch keine Bewertungen

- Sikafloor 155 WNDokument4 SeitenSikafloor 155 WNRobin PrayogoNoch keine Bewertungen

- Water Proofing BoqDokument4 SeitenWater Proofing Boqravi1214Noch keine Bewertungen

- Endura-Joint Treatment Products & ProcedureDokument89 SeitenEndura-Joint Treatment Products & ProcedureSrihariKyatamNoch keine Bewertungen

- Waterproofing techniques for basementDokument6 SeitenWaterproofing techniques for basementShashi Bhushan SinghNoch keine Bewertungen

- Dm-dsi-SPEC09 - Corrosion PR & Odor CNTRLDokument13 SeitenDm-dsi-SPEC09 - Corrosion PR & Odor CNTRLhardikNoch keine Bewertungen

- Built-Up Bituminous Waterproofing SpecificationDokument6 SeitenBuilt-Up Bituminous Waterproofing SpecificationMorris AlcantaraNoch keine Bewertungen

- TDs - Emaco R101Dokument3 SeitenTDs - Emaco R101Venkata RaoNoch keine Bewertungen

- BOQ SL Cond DissDokument3 SeitenBOQ SL Cond DissANAND MADHABAVINoch keine Bewertungen

- Self Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2Dokument5 SeitenSelf Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2200365530Noch keine Bewertungen

- 09875Dokument10 Seiten09875sethu1091Noch keine Bewertungen

- FRS Electrical Panel Spec EOIDokument20 SeitenFRS Electrical Panel Spec EOITravis WoodNoch keine Bewertungen

- E-Mix - Flowment 550 PDFDokument4 SeitenE-Mix - Flowment 550 PDFngNoch keine Bewertungen

- Sikafloor 220 W ConductiveDokument5 SeitenSikafloor 220 W Conductivethe pilotNoch keine Bewertungen

- Guide Specification: NeoflexDokument4 SeitenGuide Specification: NeoflexruloNoch keine Bewertungen

- ITCC in Riyadh Residential Complex J10-13300 07150-1 DampproofingDokument3 SeitenITCC in Riyadh Residential Complex J10-13300 07150-1 DampproofinguddinnadeemNoch keine Bewertungen

- Single Wall Tank Specification GuideDokument12 SeitenSingle Wall Tank Specification GuideAlonso VillaNoch keine Bewertungen

- 80080-TCH-0000-SP-003_SIGNED-Coating ProcedureDokument7 Seiten80080-TCH-0000-SP-003_SIGNED-Coating ProcedurePaul NieNoch keine Bewertungen

- Concrete Top SupremeDokument2 SeitenConcrete Top Supremepravi3434Noch keine Bewertungen

- Fosroc Conbextra EP 0211Dokument4 SeitenFosroc Conbextra EP 0211Tri SuhartantoNoch keine Bewertungen

- Epocoat 111 PDFDokument3 SeitenEpocoat 111 PDFjunaid112Noch keine Bewertungen

- High performance anti-carbonation coatingDokument4 SeitenHigh performance anti-carbonation coatingDejan MicicNoch keine Bewertungen

- A.1: Foundation Upto Plinth Level A.1: Civil WorksDokument19 SeitenA.1: Foundation Upto Plinth Level A.1: Civil WorksShohanur RahmanNoch keine Bewertungen

- Specifications for Primary SealDokument2 SeitenSpecifications for Primary SealVinayaKumarNoch keine Bewertungen

- High Strength Concrete Repair MortarDokument2 SeitenHigh Strength Concrete Repair Mortarpravi3434Noch keine Bewertungen

- 2012 Product Catalogue 2012Dokument222 Seiten2012 Product Catalogue 2012Bogdan MuresanNoch keine Bewertungen

- WEBER Kol SRK KONFOR Konsantre IngDokument2 SeitenWEBER Kol SRK KONFOR Konsantre IngGökhan PanpaNoch keine Bewertungen

- Nitoflor EPU100Dokument4 SeitenNitoflor EPU100Allan DerickNoch keine Bewertungen

- Tekncoat - Technical - Data (1) - 006Dokument1 SeiteTekncoat - Technical - Data (1) - 006aboali8686Noch keine Bewertungen

- My Con Pds Sikafloor 220 W ConductiveDokument7 SeitenMy Con Pds Sikafloor 220 W ConductivelaurenjiaNoch keine Bewertungen

- Shower Waterproofing SystemDokument2 SeitenShower Waterproofing SystemLoz101Noch keine Bewertungen

- 01 Stangard 1311 Insulkote (Class A)Dokument5 Seiten01 Stangard 1311 Insulkote (Class A)Manish CorporationNoch keine Bewertungen

- TDS Bostik BoscoSeal PU XDokument5 SeitenTDS Bostik BoscoSeal PU XJosip MedvedNoch keine Bewertungen

- Fosroc Dekguard AC: Constructive SolutionsDokument4 SeitenFosroc Dekguard AC: Constructive SolutionsVJ QatarNoch keine Bewertungen

- Fluid Roof CoatingDokument4 SeitenFluid Roof CoatingEng Victor FidelisNoch keine Bewertungen

- Tds - Emaco s88c TDokument2 SeitenTds - Emaco s88c TVenkata RaoNoch keine Bewertungen

- ITCC in Riyadh Residential Complex J10-13300 07500-1 RoofingDokument8 SeitenITCC in Riyadh Residential Complex J10-13300 07500-1 RoofinguddinnadeemNoch keine Bewertungen

- BTT EB Specification Double Wall 08-07Dokument13 SeitenBTT EB Specification Double Wall 08-07Alonso VillaNoch keine Bewertungen

- Conbextra EP 0211Dokument4 SeitenConbextra EP 0211didonkimurayahooNoch keine Bewertungen

- Euco 352 EpoxyDokument2 SeitenEuco 352 Epoxypravi3434Noch keine Bewertungen

- Euco 620 EpoxyDokument2 SeitenEuco 620 Epoxypravi3434Noch keine Bewertungen

- 105508Dokument56 Seiten105508dox4printNoch keine Bewertungen

- Organizational Behaviour & Change GuideDokument19 SeitenOrganizational Behaviour & Change GuideSureshbabu SugumaranNoch keine Bewertungen

- Differentiating Project Management From Program ManagementDokument3 SeitenDifferentiating Project Management From Program ManagementMosab BakryNoch keine Bewertungen

- Wienerberger-NZEB - May 2011Dokument7 SeitenWienerberger-NZEB - May 2011dox4printNoch keine Bewertungen

- Chakri PEBDokument8 SeitenChakri PEBdox4printNoch keine Bewertungen

- Brick Mesh and Corner Bead for Wall ConstructionDokument1 SeiteBrick Mesh and Corner Bead for Wall Constructiondox4printNoch keine Bewertungen

- JK Erectrors & FsbricatorsDokument3 SeitenJK Erectrors & FsbricatorskrmcharigdcNoch keine Bewertungen

- Epack Polymers (P) LTDDokument20 SeitenEpack Polymers (P) LTDcharibackupNoch keine Bewertungen

- Simplex Engineering&FOundary WorksDokument9 SeitenSimplex Engineering&FOundary Worksdox4printNoch keine Bewertungen

- Kirby Building Systems India LTDDokument5 SeitenKirby Building Systems India LTDdox4printNoch keine Bewertungen

- Radiant Enterprises ProfileDokument5 SeitenRadiant Enterprises Profiledox4printNoch keine Bewertungen

- Letter From RathakrishnanDokument1 SeiteLetter From Rathakrishnandox4printNoch keine Bewertungen

- L&T Buildings at FactoriesDokument36 SeitenL&T Buildings at FactoriesSreekanth PSNoch keine Bewertungen

- Navayuga Enterprises (Aerocon)Dokument2 SeitenNavayuga Enterprises (Aerocon)dox4printNoch keine Bewertungen

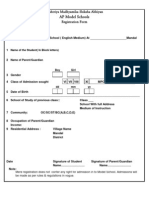

- AP Model Schools Registration FormDokument1 SeiteAP Model Schools Registration Formdox4printNoch keine Bewertungen

- TS For Civil WorkDokument43 SeitenTS For Civil WorkKinfe MehariNoch keine Bewertungen

- MR K Ramakrishnan Managing Infrastruc Proj RiskDokument22 SeitenMR K Ramakrishnan Managing Infrastruc Proj Riskdox4printNoch keine Bewertungen

- News ViewsDokument20 SeitenNews Viewsdox4printNoch keine Bewertungen

- इंटरनेट मानक और जानकारी का अधिकारDokument14 Seitenइंटरनेट मानक और जानकारी का अधिकारdox4printNoch keine Bewertungen

- State Bank of India Bike Loan For Honda ActivaDokument2 SeitenState Bank of India Bike Loan For Honda Activadox4printNoch keine Bewertungen

- Gulf Opening2009 PDFDokument6 SeitenGulf Opening2009 PDFAvijit DashNoch keine Bewertungen

- Ethical Governance in The Indian Construction Industry - A Case STDokument19 SeitenEthical Governance in The Indian Construction Industry - A Case STdox4printNoch keine Bewertungen

- Mail Elevation A, B, C& D A0Dokument1 SeiteMail Elevation A, B, C& D A0dox4printNoch keine Bewertungen

- 06 Weekly Progress Report For Jun ' 13Dokument1 Seite06 Weekly Progress Report For Jun ' 13dox4printNoch keine Bewertungen

- Metal FormsDokument6 SeitenMetal Formsdox4printNoch keine Bewertungen

- PW 371Dokument150 SeitenPW 371Patrick SilberbauerNoch keine Bewertungen

- ch13Dokument13 Seitench13asokan80Noch keine Bewertungen

- 1st Activity in ACCA104Dokument11 Seiten1st Activity in ACCA104John Rey BonitNoch keine Bewertungen

- MirazDokument1 SeiteMirazTatat PatrianiNoch keine Bewertungen

- Lesson 5 The 19th Century PhilippinesDokument5 SeitenLesson 5 The 19th Century PhilippinesJoquem PamesaNoch keine Bewertungen

- MAMALUMPONG JORDAN A. BSN-3 Literature ReviewDokument3 SeitenMAMALUMPONG JORDAN A. BSN-3 Literature ReviewJordan Abosama MamalumpongNoch keine Bewertungen

- Academic StyleDokument4 SeitenAcademic StyleHa ToNoch keine Bewertungen

- Batangas State University - Testing and Admission OfficeDokument2 SeitenBatangas State University - Testing and Admission OfficeDolly Manalo100% (1)

- VR 2200 CatalogueDokument4 SeitenVR 2200 Catalogueh.torabyNoch keine Bewertungen

- Entrepreneurship Starting and Operating A Small Business 4th Edition Mariotti Test Bank Full Chapter PDFDokument33 SeitenEntrepreneurship Starting and Operating A Small Business 4th Edition Mariotti Test Bank Full Chapter PDFmelrosecontrastbtjv1w100% (14)

- Ozone Layer EssayDokument7 SeitenOzone Layer Essayb71bpjha100% (2)

- WEEK 1 Materi-EM101-M01-The Foundation of Business 2Dokument48 SeitenWEEK 1 Materi-EM101-M01-The Foundation of Business 2ddhani299Noch keine Bewertungen

- 8th Edition of The AJCC - TNM Staging System of Thyroid Cancer - What To Expect (ITCO#2)Dokument5 Seiten8th Edition of The AJCC - TNM Staging System of Thyroid Cancer - What To Expect (ITCO#2)Valentina IndahNoch keine Bewertungen

- Jurnal Aceh MedikaDokument10 SeitenJurnal Aceh MedikaJessica SiraitNoch keine Bewertungen

- O Ring Design ParametersDokument2 SeitenO Ring Design ParametersHatim KapasiNoch keine Bewertungen

- HB Im70 QRDokument1 SeiteHB Im70 QROsamaNoch keine Bewertungen

- Guide To Program EVK1100 With AVR32studioDokument2 SeitenGuide To Program EVK1100 With AVR32studioRobert T. WursterNoch keine Bewertungen

- Galway Music Officer RoleDokument20 SeitenGalway Music Officer RoleJohanna KennyNoch keine Bewertungen

- Pressure Vessel Components and MaterialsDokument30 SeitenPressure Vessel Components and MaterialsFirst UserNoch keine Bewertungen

- Brief History of Gifted and Talented EducationDokument4 SeitenBrief History of Gifted and Talented Educationapi-336040000Noch keine Bewertungen

- Production of Carotenoids From Rhodotorula Mucilaginosa and Their Applications As Colorant Agent in Sweet CandyDokument7 SeitenProduction of Carotenoids From Rhodotorula Mucilaginosa and Their Applications As Colorant Agent in Sweet CandyEspinosa Balderas GenaroNoch keine Bewertungen

- Main Unit (M8 Connector Type) : FS-N41CDokument2 SeitenMain Unit (M8 Connector Type) : FS-N41CJulian Gabriel PerezNoch keine Bewertungen

- Text Book Development 1Dokument24 SeitenText Book Development 1Iqra MunirNoch keine Bewertungen

- Sexual ExtacyDokument18 SeitenSexual ExtacyChal JhonnyNoch keine Bewertungen

- The Spurgeon Library - Spurgeon's Secret For Raising Godly ChildrenDokument8 SeitenThe Spurgeon Library - Spurgeon's Secret For Raising Godly ChildrenGlenn VillegasNoch keine Bewertungen