Beruflich Dokumente

Kultur Dokumente

Turnbuckles

Hochgeladen von

Ronny AndalasCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Turnbuckles

Hochgeladen von

Ronny AndalasCopyright:

Verfügbare Formate

Tur nbuckles

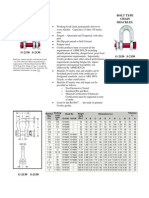

CROSBY TURNBUCKLES

HG-225 Hook &

Eye

HG-226 Eye & Eye

HG-227 Jaw & Eye

HG-228 Jaw & Jaw

Meets the performance

requirements of Federal

Specifications FF-T791b,

Type 1, Form 1 - Class

5, and ASTM F-1145,

except for those

provisions required of

the contractor.

Meets the performance

requirements of Federal

Specifications FF-T791b,

Type 1, Form 1 - Class

6, and ASTM F-1145,

except for those

provisions required of

the contractor.

Meets the performance

requirements of Federal

Specifications FF-T791b,

Type 1, Form 1 - Class

4, and ASTM F-1145,

except for those

provisions required of

the contractor.

Meets the performance

requirements of Federal

Specifications FF-T791b,

Type 1, Form 1 - Class

8, and ASTM F-1145,

except for those

provisions required of

the contractor.

Meets the performance

requirements of Federal

Specifications FF-T791b,

Type 1, Form 1 - Class

7, and ASTM F-1145,

except for those

provisions required of

the contractor.

Turnbuckle assembly combinations include: Eye and Eye, Hook and Hook, Hook and Eye,

Jaw and Jaw, Jaw and Eye.

End fittings are Quenched and Tempered, bodies heat treated by normalizing.

Crosby's Quenched and Tempered end fittings and normalized bodies have enhanced

impact properties for greater toughness at all temperatures.

Hot Dip galvanized.

Hooks are forged with a greater cross sectional area that results in a stronger hook with

better fatigue properties.

Modified UNJ thread on end fittings for improved fatigue properties. Body has UNC

threads.

Turnbuckle eyes are forged elongated, by design, to maximize easy attachment in

system and minimize stress in the eye. For turnbuckle sizes 1/4" through 2-1/2 ", a

shackle one size smaller can be reeved through eye.

Forged jaw ends are fitted with bolts and nuts on sizes 1/4" through 5/8", and pins and

cotters on sizes 3/4" through 2-3/4".

TURNBUCKLES RECOMMENDED FOR STRAIGHT OR IN-LINE PULL ONLY.

Lock Nuts available for all sizes.

Typical hardness levels, Tensile Strengths and Ductility Properties are available for all

sizes.

Turnbuckles can be furnished proof tested or magnaflux inspected with certificates if

requested at time of order.

Crosby products meet or exceed all the requirements of ASME B30.26 including

identification, ductility, design factor, proof load and temperature requirements.

Importantly, Crosby products meet other critical performance requirements including

fatigue life, impact properties and material traceability, not addressed by ASME B30.26.

RIGGING HARDWARE

HG-223 Hook &

Hook

Modified thread: Note

stress relieving radii in this

unretouched photo

enlargement of the

supabuckle.

Standard thread: Note

stress building sharp V in

this unretouched photo

enlargement.

151

Tur nbuckles

HG-223 HOOK & HOOK TURNBUCKLES

RIGGING HARDWARE

End fittings are Quenched and Tempered, bodies heat treated by normalizing.

Hot Dip galvanized steel.

Hooks are forged with a greater cross sectional area that results in a stronger hook with

better fatigue properties.

Crosby products meet or exceed all requirements of ASME B30.26 including identification,

ductility, design factor, proof load and temperature requirements. Importantly, Crosby

products meet other critical performance requirements including fatigue life, impact

properties and material traceability, not addressed by ASME B30.26.

TURNBUCKLES RECOMMENDED FOR STRAIGHT OR IN-LINE PULL ONLY.

Modified UNJ thread on end fittings for improved fatigue properties.

Body has UNC threads.

Fatigue Rated.

HG-223 Hook & Hook

Meets the performance

requirements of Federal

Specifications FF-T791b, Type

1, Form 1 - Class 5, and ASTM

F-1145, except for those

provisions required of the

contractor.

HG-223 HOOK & HOOK

THREAD

DIA. &

TAKE UP

(IN.)

HG-223

STOCK

NO.

WORKING

LOAD

LIMIT

(LBS.)*

WEIGHT

EACH

(LBS.)

E

CLOSED

DIMENSIONS (IN.)

J

K

M

OPEN

CLOSED

OPEN

N

CLOSED

BB

1/4 x 4

1030011

400

.30

.25

.45

1.59

1.27

11.12

7.12

11.94

7.94

4.00

5/16 x 4-1/2

1030039

700

.47

.31

.50

1.94

1.50

12.81

8.31

13.81

9.31

4.50

3/8 x 6

1030057

1,000

.78

.38

.56

2.30

1.77

16.50

10.50

17.72

11.72

6.00

1/2 x 6

1030075

1,500

1.60

.50

.66

2.94

2.28

18.82

11.82

20.38

13.38

6.00

1/2 x 12

1030119

1,500

2.28

.50

.66

2.94

2.28

30.82

17.82

32.38

19.38

12.00

5/8 x 6

1030137

2,250

2.75

.63

.90

3.69

2.81

20.50

13.25

22.50

15.25

6.00

5/8 x 12

1030173

2,250

3.50

.63

.90

3.69

2.81

32.50

19.25

34.50

21.25

12.00

3/4 x 6

1030191

3,000

3.89

.75

.98

4.52

3.33

22.38

14.88

24.78

17.28

6.00

3/4 x 12

1030235

3,000

5.43

.75

.98

4.52

3.33

34.38

20.88

36.78

23.28

12.00

3/4 x 18

1030253

3,000

8.12

.75

.98

4.52

3.33

46.38

26.88

48.78

29.28

18.00

7/8 x 12

1030271

4,000

8.10

.88

1.13 5.19

3.78

36.00

22.25

38.75

25.00

12.00

1 x 12

1030333

5,000

11.93

1.00

1.25 5.84

4.25

37.63

23.63

40.69

26.69

12.00

* Proof Load is 2.5 times the Working Load Limit. Ultimate Load is five times the Working Load Limit.

Mechanical Galvanized.

152

Tur nbuckles

HG-225 HOOK AND EYE TURNBUCKLES

RIGGING HARDWARE

End fittings are Quenched and Tempered, bodies heat treated by normalizing.

Hot Dip galvanized steel.

Turnbuckle eyes are forged elongated, by design, to maximize easy attachment in system

and minimize stress in the eye. For tunbuckle sizes 1/4" through 2-1/2", a shackle one

size smaller can be reeved through eye.

Turnbuckle hooks are forged with a greater cross sectional area that results in a stronger

hook with better fatigue properties.

Crosby products meet or exceed all requirements of ASME B30.26 including identification,

ductility, design factor, proof load and temperature requirements. Importantly, Crosby

products meet other critical performance requirements including fatigue life, impact

properties and material traceability, not addressed by ASME B30.26.

TURNBUCKLES RECOMMENDED FOR STRAIGHT OR IN-LINE PULL ONLY.

Modified UNJ thread on end fittings for improved fatigue properties.

Body has UNC threads.

Fatigue Rated.

HG-225 Hook & Eye

Meets the performance

requirements of Federal

Specifications FF-T791b, Type

1, Form 1 - Class 6, and

ASTM F-1145, except for

those provisions required of

the contractor.

HG-225 HOOK & EYE

THREAD

DIA. &

TAKE UP

(IN.)

HG-225

STOCK

NO.

WORKING

LOAD

WEIGHT

LIMIT

EACH

A

(LBS.)*

(LBS.)

1/4 x 4

1030636 400

.29

5/16 x 4-1/2 1030654 700

3/8 x 6

1030672 1,000

1/2 x 6

DIMENSION (IN.)

J

K

M

N

R

OPEN CLOSED OPEN CLOSED

E

CLOSED

X

CLOSED

BB

.25

.45

1.59

1.27 11.46

7.46

12.09

8.09

.78

.34

1.75

4.00

.49

.31

.50

1.94

1.50 13.19

8.69

13.47

.78

.38

.56

2.30

1.77 16.98

10.98

17.94

9.47

.94

.44

2.09

4.50

11.94

1.12

.53

2.52

6.00

1030690 1,500

1.61

.50

.66

2.94

2.28 19.45

12.45

20.67

13.67

1.44

.72

3.23

6.00

1/2 x 12

1030734 1,500

2.26

.50

.66

2.94

2.28 31.45

5/8 x 6

1030752 2,250

2.70

.63

.90

3.69

2.81 21.96

18.45

32.67

19.67

1.44

.72

3.23

12.00

13.96

22.72

15.47

1.75

.88

3.90

6.00

5/8 x 12

1030798 2,250

3.78

.63

.90

3.69

2.81 33.21

19.96

34.72

21.47

1.75

.88

3.90

12.00

3/4 x 6

1030814 3,000

3.89

.75

.98

4.52

3.33 23.13

15.63

24.95

17.45

2.09

1.00 4.69

6.00

3/4 x 12

1030850 3,000

5.83

.75

3/4 x 18

1030878 3,000

6.33

.75

.98

4.52

3.33 35.13

21.63

36.95

23.45

2.09

1.00 4.69

12.00

.98

4.52

3.33 47.13

27.63

48.95

29.45

2.09

1.00 4.69

18.00

7/8 x 12

1030896 4,000

8.10

.88

1.13 5.19

3.78 36.53

22.78

38.66

24.91

2.38

1.25 5.10

12.00

1 x 12

1030958 5,000

11.93

1.00 1.25 5.84

4.25 38.80

24.80

41.20

27.20

3.00

1.44 6.36

12.00

* Proof Load is 2.5 times the Working Load Limit. Ultimate Load is five times the Working Load Limit.

Mechanical Galvanized.

153

Tur nbuckles

HG-226 EYE AND EYE TURNBUCKLES

RIGGING HARDWARE

End fittings are Quenched and Tempered, bodies heat treated by normalizing.

Hot Dip galvanized steel.

Turnbuckle eyes are forged elongated, by design, to maximize easy attachment in system

and minimize stress in the eye. For turnbuckle sizes 1/4" through 2-1/2", a shackle one

size smaller can be reeved through eye.

Modified UNJ thread on end fittings for improved fatigue properties. Body has UNC threads.

Crosby products meet or exceed all requirements of ASME B30.26 including identification,

ductility, design factor, proof load and temperature requirements. Importantly, Crosby

products meet other critical performance requirements including fatigue life, impact

properties and material

traceability, not addressed

by ASME B30.26.

TURNBUCKLES

RECOMMENDED FOR

STRAIGHT OR IN-LINE

PULL ONLY.

Fatigue Rated.

HG-226 Eye & Eye

Meets the performance

requirements of Federal

Specifications FF-T791b, Type

1, Form 1 - Class 4, and ASTM

F-1145, except for those

provisions required of the

contractor.

HG-226 EYE & EYE

THREAD

DIAMETER

& TAKE UP

(IN.)

STOCK

NO.

GALV.

WORKING

LOAD

LIMIT *

(LBS.)

WEIGHT

EACH

(LBS.)

J

OPEN

K

CLOSED

DIMENSIONS (IN.)

M

N

R

OPEN

CLOSED

X

CLOSED

BB

1/4 x 4

1031252

500

.26

.25

11.80

7.80

12.25

8.25

.78

.34

1.75

4.00

5/16 x 4-1/2

1031270

800

.45

.31

13.56

9.06

14.12

9.62

.94

.44

2.09

4.50

3/8 x 6

1031298

1,200

.76

.38

17.47

11.47

18.16

12.16

1.12

.53

2.52

6.00

1/2 x 6

1031314

2,200

1.54

.50

20.08

13.08

20.96

13.96

1.44

.72

3.23

6.00

1/2 x 12

1031350

2,200

2.14

.50

32.08

19.08

32.96

19.96

1.44

.72

3.23

12.00

5/8 x 6

1031378

3,500

2.40

.63

21.93

14.68

22.93

15.68

1.75

.88

3.90

6.00

5/8 x 12

1031412

3,500

3.42

.63

33.93

20.68

34.93

21.68

1.75

.88

3.90

12.00

3/4 x 6

1031430

5,200

3.79

.75

23.88

16.38

25.12

17.62

2.09

1.00

4.69

6.00

3/4 x 12

1031476

5,200

5.48

.75

35.88

22.38

37.12

23.62

2.09

1.00

4.69

12.00

3/4 x 18

1031494

5,200

7.19

.75

47.88

28.38

49.12

29.62

2.09

1.00

4.69

18.00

7/8 x 12

1031519

7,200

7.22

.88

37.07

23.32

38.57

24.82

2.38

1.25

5.10

12.00

7/8 x 18

1031537

7,200

9.95

.88

49.07

29.32

50.57

30.82

2.38

1.25

5.10

18.00

1x6

1031555

10,000

9.04

1.00

27.97

19.97

29.72

21.72

3.00

1.44

6.36

6.00

1 x 12

1031573

10,000

11.50

1.00

39.97

25.97

41.97

27.72

3.00

1.44

6.36

12.00

1 x 18

1031591

10,000

14.00

1.00

51.97

31.97

53.72

33.72

3.00

1.44

6.36

18.00

1 x 24

1031617

10,000

17.25

1.00

63.97

37.97

65.72

39.72

3.00

1.44

6.36

24.00

1-1/4 x 12

1031635

15,200

19.00

1.25

42.81

28.31

45.06

30.56

3.56

1.81

7.72

12.00

1-1/4 x 18

1031653

15,200

23.00

1.25

54.81

34.31

57.06

36.56

3.56

1.81

7.72

18.00

1-1/4 x 24

1031671

15,200

27.00

1.25

66.81

40.31

69.06

42.56

3.56

1.81

7.72

24.00

1-1/2 x 12

1031699

21,400

27.50

1.50

45.50

30.50

48.00

33.00

4.06

2.12

8.62

12.00

1-1/2 x 18

1031715

21,400

31.00

1.50

57.50

36.50

60.00

39.00

4.06

2.12

8.62

18.00

1-1/2 x 24

1031733

21,400

37.50

1.50

69.50

42.50

72.00

45.00

4.06

2.12

8.62

24.00

1-3/4 x 18

1031779

28,000

52.50

1.75

57.38

39.38

60.38

42.38

4.62

2.38

10.00

18.00

1-3/4 x 24

1031797

28,000

58.00

1.75

69.38

45.38

72.38

48.38

4.62

2.38

10.00

24.00

2 x 24

1031813

37,000

85.25

2.00

75.69

51.69

79.19

55.19

5.75

2.69

13.09

24.00

2-1/2 x 24

1031831

60,000

144.25

2.50

78.62

54.62

82.62

58.62

6.50

3.12

13.78

24.00

2-3/4 x 24

1031859

75,000

194.00

2.75

81.00

57.00

85.50

61.50

7.00

3.25

15.22

24.00

* Proof Load is 2.5 times the Working Load Limit. Ultimate Load is 5 times the Working Load Limit.

Mechanical Galvanized.

154

Tur nbuckles

HG-227 JAW AND EYE TURNBUCKLES

H G - 2 2 7 J AW & E Y E

THREAD

DIA. &

TAKE UP

(IN.)

1/4 x 4

5/16 x 4-1/2

3/8 x 6

1/2 x 6

1/2 x 9

1/2 x 12

5/8 x 6

5/8 x 9

5/8 x 12

3/4 x 6

3/4 x 9

3/4 x 12

3/4 x 18

7/8 x 12

7/8 x 18

1x6

1 x 12

1 x 18

1 x 24

1-1/4 x 12

1-1/4 x 18

1-1/4 x 24

1-1/2 x 12

1-1/2 x 18

1-1/2 x 24

1-3/4 x 18

1-3/4 x 24

2 x 24

2-1/2 x 24

2-3/4 x 24

HG-227

STOCK

NO.

1031877

1031895

1031911

1031939

1031957

1031975

1031993

1032019

1032037

1032055

1032073

1032091

1032117

1032135

1032153

1032171

1032199

1032215

1032233

1032251

1032279

1032297

1032313

1032331

1032359

1032395

1032411

1032439

1032457

1032475

WORKING

LOAD

LIMIT

(LBS.*)*

500

800

1,200

2,200

2,200

2,200

3,500

3,500

3,500

5,200

5,200

5,200

5,200

7,200

7,200

10,000

10,000

10,000

10,000

15,200

15,200

15,200

21,400

21,400

21,400

28,000

28,000

37,000

60,000

75,000

WEIGHT

EACH

(LBS.)

.30

.50

.80

1.51

1.71

2.08

2.35

3.17

3.61

4.00

4.75

5.93

7.00

8.36

9.75

8.92

11.20

13.30

17.00

19.42

24.18

28.50

28.99

35.00

39.18

53.75

60.68

89.00

150.00

183.00

.25

.31

.38

.50

.50

.50

.63

.63

.63

.75

.75

.75

.75

.88

.88

1.00

1.00

1.00

1.00

1.25

1.25

1.25

1.50

1.50

1.50

1.75

1.75

2.00

2.50

2.75

.45

.50

.54

.55

.55

.55

.82

.82

.82

1.03

1.03

1.03

1.03

1.23

1.23

1.31

1.31

1.31

1.31

1.86

1.86

1.86

2.25

2.25

2.25

2.60

2.60

2.62

3.06

3.68

E

CLOSED

1.58

1.98

2.12

2.75

2.75

2.75

3.50

3.50

3.50

4.18

4.18

4.18

4.18

4.85

4.85

5.53

5.53

5.53

5.53

7.21

7.21

7.21

7.88

7.88

7.88

9.40

9.40

11.86

13.56

15.22

G

.62

.87

.87

1.06

1.06

1.06

1.31

1.31

1.31

1.50

1.50

1.50

1.50

1.75

1.75

2.06

2.06

2.06

2.06

2.81

2.81

2.81

2.81

2.81

2.81

3.38

3.38

3.69

4.44

4.19

J

OPEN

11.35

13.71

16.81

19.29

25.29

31.29

20.99

26.99

32.99

22.69

28.69

34.69

46.69

36.09

48.09

26.34

38.34

50.34

62.34

41.32

53.32

65.32

43.50

55.50

67.50

55.38

67.38

72.62

75.80

77.88

DIMENSIONS (IN.)

K

M

N

CLOSED OPEN CLOSED

7.35

12.07 8.07

8.71

14.01 9.51

10.81

17.77 11.77

12.29

20.48 13.48

15.29

26.48 16.48

18.29

32.48 19.48

13.74

22.53 15.28

16.74

28.53 18.28

19.74

34.53 21.28

15.19

24.61 17.11

18.19

30.61 20.11

21.19

36.61 23.11

27.19

48.61 29.11

22.34

38.32 24.57

28.34

50.32 30.57

18.34

28.89 20.89

24.34

40.89 26.89

30.34

52.89 32.89

36.34

64.89 38.89

26.82

44.55 30.05

32.82

56.05 36.05

38.82

68.55 42.05

28.50

47.25 32.25

34.50

59.25 38.25

40.50

71.25 44.25

37.38

59.78 41.78

43.38

71.78 47.78

48.62

77.95 53.95

51.80

82.40 58.40

53.88

85.50 61.50

RIGGING HARDWARE

End fittings are Quenched and Tempered, bodies heat treated by normalizing.

Hot Dip galvanized steel.

Turnbuckles eyes are forged and elongated, by design, to maximize easy attachment in

system and minimize stress in the eye. For turnbuckles size 1/4" through 2-1/2", a shackle

one size smaller can be reeved through eye.

Forged jaw ends are fitted with bolts and nuts for 1/4" through 5/8", and pins and cotters

on 3/4" through 2-3/4" sizes.

Modified UNJ thread on end fittings for improved fatigue properties.

Body has UNC threads.

Crosby products meet or exceed all the requirements of ASME B30.26 including identification,

ductility, design factor, proof load and temperature requirements. Importantly, Crosby products

meet other critical performance requirements including fatigue life, impact properties and material

traceability, not addressed by ASME B30.26.

TURNBUCKLES RECOMMENDED FOR

STRAIGHT OR IN-LINE PULL ONLY.

Fatigue Rated.

HG-227 Jaw & Eye

Meets the performance

requirements of Federal

Specifications FF-T791b, Type

1, Form 1 - Class 8, and ASTM

F-1145, except for those

provisions required of the

contractor.

.78

.94

1.12

1.44

1.44

1.44

1.75

1.75

1.75

2.09

2.09

2.09

2.09

2.38

2.38

3.00

3.00

3.00

3.00

3.56

3.56

3.56

4.06

4.06

4.06

4.62

4.62

5.75

6.50

7.00

.34

.44

.53

.72

.72

.72

.88

.88

.88

1.00

1.00

1.00

1.00

1.25

1.25

1.44

1.44

1.44

1.44

1.81

1.81

1.81

2.12

2.12

2.12

2.38

2.38

2.69

3.12

3.25

X

CLOSED

1.75

2.09

2.52

3.23

3.23

3.23

3.90

3.90

3.90

4.69

4.69

4.69

4.69

5.10

5.10

6.36

6.36

6.36

6.36

7.72

7.72

7.72

8.62

8.62

8.62

10.00

10.00

13.09

13.78

15.22

BB

4.00

4.50

6.00

6.00

9.00

12.00

6.00

9.00

12.00

6.00

9.00

12.00

18.00

12.00

18.00

6.00

12.00

18.00

24.00

12.00

18.00

24.00

12.00

18.00

24.00

18.00

24.00

24.00

24.00

24.00

* Proof Load is 2.5 times the Working Load Limit. Ultimate Load is 5 times the Working Load Limit.

Mechanical Galvanized.

155

Tur nbuckles

HG-228 JAW AND JAW TURNBUCKLES

RIGGING HARDWARE

End fittings are Quenched and Tempered, bodies heat treated by normalizing.

Hot Dip galvanized steel.

TURNBUCKLES RECOMMENDED FOR STRAIGHT OR IN-LINE PULL ONLY.

Forged jaw ends are fitted with bolts and nuts for 1/4" through 5/8", and pins and cotters

on 3/4" through 2-3/4" sizes.

Modified UNJ thread on end fittings for improved fatigue properties.

Body has UNC threads.

Crosby products meet or exceed all the requirements of ASME B30.26 including

identification, ductility, design factor, proof load and temperature requirements. Importantly,

Crosby products meet other

critical performance

requirements including fatigue

life, impact properties and

material traceability, not

addressed by ASME B30.26.

Fatigue Rated.

HG-228 Jaw & Jaw

Meets the performance

requirements of Federal

Specifications FF-T791b, Type

1, Form 1 - Class 7, and ASTM

F-1145, except for those

provisions required of the

contractor.

H G - 2 2 8 J AW & J AW

THREAD

DIA. &

TAKE UP

(IN.)

1/4 x 4

5/16 x 4-1/2

3/8 x 6

1/2 x 6

1/2 x 9

1/2 x 12

5/8 x 6

5/8 x 9

5/8 x 12

3/4 x 6

3/4 x 9

3/4 x 12

3/4 x 18

7/8 x 12

7/8 x 18

1x6

1 x 12

1 x 18

1 x 24

1-1/4 x 12

1-1/4 x 18

1-1/4 x 24

1-1/2 x 12

1-1/2 x 18

1-1/2 x 24

1-3/4 x 18

1-3/4 x 24

2 x 24

2-1/2 x 24

2-3/4 x 24

HG-228

STOCK

NO.

1032493

1032518

1032536

1032554

1032572

1032590

1032616

1032634

1032652

1032670

1032698

1032714

1032732

1032750

1032778

1032796

1032812

1032830

1032858

1032876

1032894

1032910

1032938

1032956

1032974

1033018

1033036

1033054

1033072

1033090

WORKING

LOAD

LIMIT

(LBS.)*

500

800

1,200

2,200

2,200

2,200

3,500

3,500

3,500

5,200

5,200

5,200

5,200

7,200

7,200

10,000

10,000

10,000

10,000

15,200

15,200

15,200

21,400

21,400

21,400

28,000

28,000

37,000

60,000

75,000

WEIGHT

EACH

(LBS.)

.36

.52

.81

1.56

1.74

2.40

2.72

3.43

3.91

4.11

5.46

6.56

8.03

8.17

10.78

10.18

13.14

15.14

18.08

20.59

24.68

28.20

30.69

36.75

41.60

54.00

63.36

94.25

165.00

198.00

.25

.31

.38

.50

.50

.50

.63

.63

.63

.75

.75

.75

.75

.88

.88

1.00

1.00

1.00

1.00

1.25

1.25

1.25

1.50

1.50

1.50

1.75

1.75

2.00

2.50

2.75

.45

.50

.54

.55

.55

.55

.82

.82

.82

1.03

1.03

1.03

1.03

1.23

1.23

1.31

1.31

1.31

1.31

1.86

1.86

1.86

2.25

2.25

2.25

2.60

2.60

2.62

3.06

3.68

E

CLOSED

1.58

1.98

2.12

2.75

2.75

2.75

3.50

3.50

3.50

4.18

4.18

4.18

4.18

4.85

4.85

5.53

5.53

5.53

5.53

7.21

7.21

7.21

7.88

7.88

7.88

9.40

9.40

11.86

13.56

15.22

G

.62

.87

.87

1.06

1.06

1.06

1.31

1.31

1.31

1.50

1.50

1.50

1.50

1.75

1.75

2.06

2.06

2.06

2.06

2.81

2.81

2.81

2.81

2.81

2.81

3.38

3.38

3.69

4.44

4.19

DIMENSIONS (IN.)

J

K

OPEN CLOSED

10.90

6.90

12.36

8.36

16.14

10.14

18.50

11.50

24.50

14.50

30.50

17.50

20.05

12.80

26.05

15.80

32.05

18.80

21.50

14.00

27.50

17.00

33.50

20.00

45.50

26.00

35.11

21.36

47.11

27.36

24.72

16.72

36.72

22.72

48.72

28.72

60.72

34.72

39.84

25.34

51.84

31.34

63.84

37.34

41.50

26.50

53.50

32.50

65.50

38.50

53.38

35.38

65.38

41.38

69.54

45.54

72.98

48.98

74.75

50.75

* Proof Load is 2.5 times the Working Load Limit. Ultimate Load is 5 times the Working Load Limit.

Mechanical Galvanized.

156

M

OPEN

11.90

13.90

17.38

20.00

26.00

32.00

22.13

28.13

34.13

24.10

30.10

36.10

48.10

38.07

50.07

28.06

40.06

52.06

64.06

44.04

56.04

68.04

46.50

58.50

70.50

59.18

71.18

76.72

82.18

85.50

N

CLOSED

7.90

9.40

11.38

13.00

16.00

19.00

14.88

17.88

20.88

16.60

19.60

22.60

28.60

24.32

30.32

20.06

26.06

32.06

38.06

29.54

35.54

41.54

31.50

37.50

43.50

41.18

47.18

52.72

58.18

61.50

BB

4.00

4.50

6.00

6.00

9.00

12.00

6.00

9.00

12.00

6.00

9.00

12.00

18.00

12.00

18.00

6.00

12.00

18.00

24.00

12.00

18.00

24.00

12.00

18.00

24.00

18.00

24.00

24.00

24.00

24.00

Das könnte Ihnen auch gefallen

- List - TBC SoftDokument1 SeiteList - TBC SoftadityadhNoch keine Bewertungen

- 82Dokument1 Seite82Drajat DarmawanNoch keine Bewertungen

- 21 ExtinguishersDokument19 Seiten21 ExtinguishersTizsa TissaNoch keine Bewertungen

- Screw Pin Anchor Shackles Screw Pin Chain ShacklesDokument1 SeiteScrew Pin Anchor Shackles Screw Pin Chain ShacklesJulius HendraNoch keine Bewertungen

- Catalogue - Crosby G-2130 Bolt Type Shackle PDFDokument1 SeiteCatalogue - Crosby G-2130 Bolt Type Shackle PDFAnindya SaputraNoch keine Bewertungen

- Crosby® TurnbucklesDokument11 SeitenCrosby® TurnbucklesMidfiild CosminNoch keine Bewertungen

- Crosby Shackles G-2130 PDFDokument2 SeitenCrosby Shackles G-2130 PDFBolarinwaNoch keine Bewertungen

- Spiral Wound Gasket CatalogDokument30 SeitenSpiral Wound Gasket Catalogmayur_lanjewarNoch keine Bewertungen

- Structural Steels Equivalent ChartDokument2 SeitenStructural Steels Equivalent ChartHamdan PkNoch keine Bewertungen

- Oilfield Hoses Fittings AccembliesDokument29 SeitenOilfield Hoses Fittings Accembliesthapa786mNoch keine Bewertungen

- Sch10 Rev01Dokument1 SeiteSch10 Rev01Fallo SusiloNoch keine Bewertungen

- Is 3063-Spring WashersDokument11 SeitenIs 3063-Spring Washerspbp2956Noch keine Bewertungen

- Anclajes Red HeadDokument8 SeitenAnclajes Red HeadLeonardo AvilaNoch keine Bewertungen

- Screw Pin Anchor ShacklesDokument1 SeiteScrew Pin Anchor Shacklesnikka2012Noch keine Bewertungen

- Series 1000 Hinged ClosureDokument3 SeitenSeries 1000 Hinged ClosureKavan PatelNoch keine Bewertungen

- Split stream dearator vessel design calculationsDokument26 SeitenSplit stream dearator vessel design calculationsArt G. EnziNoch keine Bewertungen

- Series 1000 Hinged ClosureDokument3 SeitenSeries 1000 Hinged ClosureMurli RamchandranNoch keine Bewertungen

- TurnbuckleDokument6 SeitenTurnbuckleAbi Latiful HakimNoch keine Bewertungen

- Aisc Mbma Design Aid 3d Wind Dt.08.11.2019Dokument74 SeitenAisc Mbma Design Aid 3d Wind Dt.08.11.2019Ankit BhadolaNoch keine Bewertungen

- HG 225Dokument1 SeiteHG 225Claudio Alvarado ArayaNoch keine Bewertungen

- BOQ Item No. Unit Description Length Width Height TotalDokument12 SeitenBOQ Item No. Unit Description Length Width Height Totalpdkprabhath_66619207Noch keine Bewertungen

- ButterflyDokument6 SeitenButterflysachin2010Noch keine Bewertungen

- Span Tables For Simply Supported Composite BeamsDokument8 SeitenSpan Tables For Simply Supported Composite BeamsDenise2512Noch keine Bewertungen

- TEREX Halco Hammers & BitsDokument35 SeitenTEREX Halco Hammers & BitsNelson F. Leon CarvajalNoch keine Bewertungen

- Crosby Swivels: S-1 Jaw & HookDokument1 SeiteCrosby Swivels: S-1 Jaw & HookZeckNoch keine Bewertungen

- Crosby ShacklesDokument6 SeitenCrosby Shacklessabah8800Noch keine Bewertungen

- Hydril GK Annular DataDokument2 SeitenHydril GK Annular DataAndrés Ramírez100% (3)

- Stress Relief Boreback BoxDokument3 SeitenStress Relief Boreback BoxDaisuke Numata100% (1)

- Crosby 2130 2150Dokument1 SeiteCrosby 2130 2150Sumner TingNoch keine Bewertungen

- Forged, High Pressure Valves ANSI 900-4500 1/2" - 4": Butt Weld EndsDokument2 SeitenForged, High Pressure Valves ANSI 900-4500 1/2" - 4": Butt Weld Endstri_purwadiNoch keine Bewertungen

- Rigid Pipe Covering (K450) : With Extr A Rig IDDokument6 SeitenRigid Pipe Covering (K450) : With Extr A Rig IDraguhvacind4620Noch keine Bewertungen

- Technical Information Series BVMM General Description: Ball ValvesDokument6 SeitenTechnical Information Series BVMM General Description: Ball ValvesAliArababadiNoch keine Bewertungen

- Gunnebo 2000Dokument36 SeitenGunnebo 2000Ed CalheNoch keine Bewertungen

- Cilindros Hidráulicos Parker - 2H - 1110-UkDokument42 SeitenCilindros Hidráulicos Parker - 2H - 1110-UkPeterson MagroNoch keine Bewertungen

- Unbrako Catalog FastenerDokument26 SeitenUnbrako Catalog Fastenerdesign_rajeev100% (1)

- AEC MC007 Weatherproof Outlet Boxes and CoversDokument22 SeitenAEC MC007 Weatherproof Outlet Boxes and CoversSergio TC VtmNoch keine Bewertungen

- Design No. D925: BXUV.D925 Fire-Resistance Ratings - ANSI/UL 263Dokument9 SeitenDesign No. D925: BXUV.D925 Fire-Resistance Ratings - ANSI/UL 263EngTamerNoch keine Bewertungen

- Dana Spicer End YokesDokument94 SeitenDana Spicer End YokesArpit Verma100% (1)

- Inserts Dies JawsDokument28 SeitenInserts Dies JawsHany AhmedNoch keine Bewertungen

- Cameron Gui BersonDokument63 SeitenCameron Gui BersonWahyu YanuarNoch keine Bewertungen

- Dimensions and Weights for Class 900 FlangesDokument0 SeitenDimensions and Weights for Class 900 FlangesPinto CarlosNoch keine Bewertungen

- ConduitsDokument10 SeitenConduitsSiddiqui Abdul KhaliqNoch keine Bewertungen

- Reject RBC UpgradationDokument9 SeitenReject RBC Upgradationirfan.ali0463Noch keine Bewertungen

- Catálogo Aceros Orrcon 2017Dokument80 SeitenCatálogo Aceros Orrcon 2017Manuel Esteban MercadoNoch keine Bewertungen

- Hydraulic Cylinder Parker 3lDokument48 SeitenHydraulic Cylinder Parker 3lDian Pramadi100% (2)

- Survey Steel Grades MarkenübersichtDokument12 SeitenSurvey Steel Grades MarkenübersichtLeandro AlmeidaNoch keine Bewertungen

- b3311 722-2Dokument7 Seitenb3311 722-2Arnaldo BenitezNoch keine Bewertungen

- Working Guide to Drilling Equipment and OperationsVon EverandWorking Guide to Drilling Equipment and OperationsBewertung: 5 von 5 Sternen5/5 (9)

- Drilling Fluids Processing HandbookVon EverandDrilling Fluids Processing HandbookBewertung: 4.5 von 5 Sternen4.5/5 (4)

- Machine Design Elements and AssembliesVon EverandMachine Design Elements and AssembliesBewertung: 3.5 von 5 Sternen3.5/5 (2)

- The Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreVon EverandThe Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreBewertung: 3 von 5 Sternen3/5 (2)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyVon EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyBewertung: 4 von 5 Sternen4/5 (1)

- The Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringVon EverandThe Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringS. S. GillBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataVon EverandPocket Guide to Flanges, Fittings, and Piping DataBewertung: 3.5 von 5 Sternen3.5/5 (22)

- Defectometer 2.837: Eddy Current Test Instrument DEFECTOMETER 2.837Dokument11 SeitenDefectometer 2.837: Eddy Current Test Instrument DEFECTOMETER 2.837Ronny AndalasNoch keine Bewertungen

- Germann Instruments A/S: Bond-Test, Lok-Test and Capo-TestDokument1 SeiteGermann Instruments A/S: Bond-Test, Lok-Test and Capo-TestRonny AndalasNoch keine Bewertungen

- Tube Inspection Probe CatalogDokument43 SeitenTube Inspection Probe CatalogRonny AndalasNoch keine Bewertungen

- ASCE2001Dokument13 SeitenASCE2001Ronny AndalasNoch keine Bewertungen

- Evaluation of The ConcreteDokument23 SeitenEvaluation of The ConcreteRonny AndalasNoch keine Bewertungen

- Nortec Eddy CurrentDokument40 SeitenNortec Eddy CurrentCss Sfaxien100% (2)

- RCT ComparisonDokument5 SeitenRCT ComparisonRonny AndalasNoch keine Bewertungen

- Slump Test (F - Eld) Record: TRRLNK Tirna MMDokument4 SeitenSlump Test (F - Eld) Record: TRRLNK Tirna MMRonny AndalasNoch keine Bewertungen

- DM 4 EdatasheetDokument2 SeitenDM 4 EdatasheetRonny AndalasNoch keine Bewertungen

- 3221 ConcreteDokument15 Seiten3221 Concretesada44Noch keine Bewertungen

- Evaluation of The ConcreteDokument23 SeitenEvaluation of The ConcreteRonny AndalasNoch keine Bewertungen

- DMS2 SpecificationsDokument2 SeitenDMS2 SpecificationsRonny AndalasNoch keine Bewertungen

- Fastners ManualDokument153 SeitenFastners ManualRonny Andalas100% (1)

- Lec8 ConcreteDokument13 SeitenLec8 ConcreteRonny AndalasNoch keine Bewertungen

- Corrosion & Erosion: Inspection Solutions For Detection, Sizing & MonitoringDokument15 SeitenCorrosion & Erosion: Inspection Solutions For Detection, Sizing & MonitoringMohd Azrul AzmanNoch keine Bewertungen

- MG2 enDokument6 SeitenMG2 enRonny AndalasNoch keine Bewertungen

- THRADDokument2 SeitenTHRADRonny AndalasNoch keine Bewertungen

- Geit-20214en Usm Go-Dms Go Single PageDokument12 SeitenGeit-20214en Usm Go-Dms Go Single PageRonny AndalasNoch keine Bewertungen

- MTM BrochureDokument2 SeitenMTM BrochureRonny AndalasNoch keine Bewertungen

- Efndt 2.1Dokument5 SeitenEfndt 2.1Ronny AndalasNoch keine Bewertungen

- Echo 38Dokument48 SeitenEcho 38Ronny Andalas100% (1)

- SAIPEM 3000 OFFSHORE HEAVY LIFT VESSELDokument8 SeitenSAIPEM 3000 OFFSHORE HEAVY LIFT VESSELdel3333Noch keine Bewertungen

- Usd15 BrochureDokument6 SeitenUsd15 BrochureRonny AndalasNoch keine Bewertungen

- Mfec 1Dokument14 SeitenMfec 1Ronny AndalasNoch keine Bewertungen

- New UltradocDokument2 SeitenNew UltradocRonny AndalasNoch keine Bewertungen

- Iqi'sDokument6 SeitenIqi's24inspector100% (1)

- Compact Dual Function UV and Light MeterDokument2 SeitenCompact Dual Function UV and Light MeterRonny AndalasNoch keine Bewertungen

- 12 17 Lista Standarde - 2Dokument5 Seiten12 17 Lista Standarde - 2Ronny AndalasNoch keine Bewertungen

- Mall Usiness Lean: Understanding Regulations On Solvent Cleaning EquipmentDokument2 SeitenMall Usiness Lean: Understanding Regulations On Solvent Cleaning EquipmentRonny AndalasNoch keine Bewertungen

- Coast PartIIDokument5 SeitenCoast PartIIRonny AndalasNoch keine Bewertungen

- Topic 3Dokument25 SeitenTopic 35p6zzgj4w9Noch keine Bewertungen

- Coils TransponderDokument4 SeitenCoils TransponderGuadalajara JaliscoNoch keine Bewertungen

- Louie Langas Resume 2019Dokument1 SeiteLouie Langas Resume 2019Louie LangasNoch keine Bewertungen

- Vend RegDokument49 SeitenVend RegProcaeHexdofNoch keine Bewertungen

- Corrosion Types and Prevention Methods in 40 CharactersDokument75 SeitenCorrosion Types and Prevention Methods in 40 CharactersCipri Croitor0% (1)

- Blaster's Handbook PDFDokument180 SeitenBlaster's Handbook PDFsaiful100% (1)

- Polymer PhysicsDokument9 SeitenPolymer PhysicslotannaNoch keine Bewertungen

- 131179009679888042Dokument7 Seiten131179009679888042Ali AsgharNoch keine Bewertungen

- Acer Ferrari 3400 Laptop ManualDokument113 SeitenAcer Ferrari 3400 Laptop Manualmoming1Noch keine Bewertungen

- Fire Load CalculationDokument6 SeitenFire Load CalculationGunvant Patel91% (11)

- FRL GoyenDokument12 SeitenFRL GoyenAbigael92Noch keine Bewertungen

- Slump and Compacting Factor Test Values and Uses in Concrete WorkabilityDokument2 SeitenSlump and Compacting Factor Test Values and Uses in Concrete WorkabilityNick GeneseNoch keine Bewertungen

- DF PDFDokument8 SeitenDF PDFAtif JaveadNoch keine Bewertungen

- CS153 111017Dokument29 SeitenCS153 111017Sethu RamanNoch keine Bewertungen

- 2012 JBLM MILCON Tacoma Chamber of Commerce Oct2012Dokument13 Seiten2012 JBLM MILCON Tacoma Chamber of Commerce Oct2012Brackett427Noch keine Bewertungen

- Machine Guarding LP PDFDokument4 SeitenMachine Guarding LP PDFrexivyNoch keine Bewertungen

- Nagios Enable NRPEDokument2 SeitenNagios Enable NRPEMartin RuswandaNoch keine Bewertungen

- Classical Electromagnetism and OpticsDokument159 SeitenClassical Electromagnetism and OpticsRodrigo PaludoNoch keine Bewertungen

- INNOVATIVE TRENDS - FLYER-converted-mergedDokument6 SeitenINNOVATIVE TRENDS - FLYER-converted-mergedPandimadevi MNoch keine Bewertungen

- Install bladder tanks under homesDokument4 SeitenInstall bladder tanks under homessauro100% (1)

- Main Engine Fuel Pump Drive Roller Damage: Return To TOCDokument2 SeitenMain Engine Fuel Pump Drive Roller Damage: Return To TOCTunaNoch keine Bewertungen

- N-Channel Low QG Mosfet 30V, 100A, 3.3m: MOS-TECH Semiconductor Co.,LTDDokument9 SeitenN-Channel Low QG Mosfet 30V, 100A, 3.3m: MOS-TECH Semiconductor Co.,LTDAnonymous p1ig0zX6p0Noch keine Bewertungen

- Lecture 04 Critical Path Method (CPM) PDFDokument25 SeitenLecture 04 Critical Path Method (CPM) PDFAmira HachemNoch keine Bewertungen

- UCO General BrochureDokument2 SeitenUCO General BrochureSam LamNoch keine Bewertungen

- Mastertop TC 458 PDFDokument3 SeitenMastertop TC 458 PDFFrancois-Noch keine Bewertungen

- Polyken 1600 High TempDokument2 SeitenPolyken 1600 High TempKyaw Kyaw AungNoch keine Bewertungen

- Database transactions, recovery, and concurrencyDokument30 SeitenDatabase transactions, recovery, and concurrencyIvan Jan AvigueteroNoch keine Bewertungen

- Carbon Compounds: Standard/ Class/ Grade - 10 SSC, CBSE - 8 ICSEDokument53 SeitenCarbon Compounds: Standard/ Class/ Grade - 10 SSC, CBSE - 8 ICSEsaintEmNoch keine Bewertungen