Beruflich Dokumente

Kultur Dokumente

Single Phase Liquid Flow - Water Hammer and Surge Pressure Design Guide

Hochgeladen von

Civil FriendCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Single Phase Liquid Flow - Water Hammer and Surge Pressure Design Guide

Hochgeladen von

Civil FriendCopyright:

Verfügbare Formate

PROCEDURE NO.

PAGE

OF

PTD-DGS-119

PREPARED BY DATE

12

PROCESS TECHNOLOGY PROCEDURES

DEPARTMENT: SUBJECT:

D. Ayon

APPROVED BY

22-Jan-2004

PROCESS ENGINEERING

A. Bourji

REVISION DATE REV.

SINGLE PHASE LIQUID FLOW - WATER HAMMER AND SURGE PRESSURE DESIGN GUIDE

22-Jan-2004

Table of Contents

1.0 SCOPE.........................................................................................................................1 2.0 RESPONSIBILITIES ...................................................................................................1 3.0 DEFINITIONS..............................................................................................................1 4.0 WATER HAMMER AND SURGE PRESSURE ..........................................................3 5.0 REFERENCES..........................................................................................................10

147943599.doc

PROCEDURE NO.

PAGE

OF

PTD-DGS-119

PREPARED BY DATE

12

PROCESS TECHNOLOGY PROCEDURES

DEPARTMENT: SUBJECT:

D. Ayon

APPROVED BY

22-Jan-2004

PROCESS ENGINEERING

A. Bourji

REVISION DATE REV.

SINGLE PHASE LIQUID FLOW - WATER HAMMER AND SURGE PRESSURE DESIGN GUIDE

22-Jan-2004

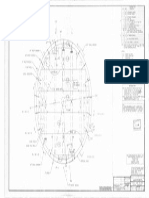

1.0 SCOPE This design guide presents the basic physical principles involved in water hammer and pressure surge. In addition, this design guide provides a method for approximating surge pressure in simple cases (see Figure 1), which can be used for preliminary design or to check the results of commercially available programs. For detailed analysis of more complex systems, SURGE2000 software is available within the Process Engineering department.

Figure 1. Surge Simple Case

2.0 RESPONSIBILITIES The process engineer is responsible for calculating water hammer pressure and for determining the means of reducing it when it exceeds the pressure capabilities of pipe and/or components in a piping system. 3.0 Definitions a b D E L p tc V = = = = = = = = = pressure wave velocity liquid bulk modulus of elasticity pipe wall thickness internal diameter of pipe = modulus of elasticity of pipe wall = the distance from the valve to the pipe inlet maximum pressure rise liquid density [slugs/ft 3 (BG Units), or kg/m3 (SI Units)] critical time valve closure time change in liquid velocity

147943599.doc

PROCEDURE NO.

REV.

DATE

PAGE OF

PTD-DGS-119 SINGLE PHASE LIQUID FLOW WATER HAMMER AND PRESSURE SURGE DESIGN GUIDE

22-Jan-04

12

Note: Consistent units must be used for all formulas. It is recommended that the process engineer, when using the formulas supplied in this text, write out the units for each variable to ensure proper cancellation of units.

147943599.doc

PROCEDURE NO.

REV.

DATE

PAGE OF

PTD-DGS-119 SINGLE PHASE LIQUID FLOW WATER HAMMER AND PRESSURE SURGE DESIGN GUIDE

22-Jan-04

12

4.0 WATER HAMMER AND SURGE PRESSURE 4.1 Potential Surge Pressure Hazards

A pressure surge is generated in a piping system whenever there is a change in flow rate of the liquid in the line. Surge pressures can cause extremely rapid changes in pressure, rapid enough to cause metallic percussions or a pounding of the line commonly known as water hammer. Potential causes of surge pressures are: 4.2 Closure of an automatic valve Rapid closure or opening of a manual or power-operated valve Slamming shut of a non-return (check) valve Starting or stopping of a pump Pressure Wave Velocity

When a fast closing valve decelerates liquid flowing in a pipe, the kinetic energy of the flowing liquid is converted to surge pressure as the liquid compresses and the pipe wall stretches. The surge pressure propagates in a wave upstream to the pipe inlet at the speed of sound in the liquid, modified by the physical characteristics of the pipe. A return negative pressure wave is reflected back to the valve from the pipe inlet. The cycle of successive reflections of the pressure wave between the pipe inlet and valve result in alternating pressure increases and decreases which are gradually attenuated by fluid friction and imperfect elasticity of the pipe. Equation 4-1 will give the velocity of the pressure wave. a=

1 + ( E )( D b) (Eq. 4-1)

Notes See Figure 2 for average bulk modulus for crude oil, fuel oil, gas oil, and gasoline See Figure 3 for average bulk modulus for lubricating oils See Figure 4 for bulk modulus of water See Table 1 for modulus of elasticity for metals

147943599.doc

PROCEDURE NO.

REV.

DATE

PAGE OF

PTD-DGS-119 SINGLE PHASE LIQUID FLOW WATER HAMMER AND PRESSURE SURGE DESIGN GUIDE Figure 2.

22-Jan-04

12

147943599.doc

PROCEDURE NO.

REV.

DATE

PAGE OF

PTD-DGS-119 SINGLE PHASE LIQUID FLOW WATER HAMMER AND PRESSURE SURGE DESIGN GUIDE Figure 3.

22-Jan-04

12

147943599.doc

PROCEDURE NO.

REV.

DATE

PAGE OF

PTD-DGS-119 SINGLE PHASE LIQUID FLOW WATER HAMMER AND PRESSURE SURGE DESIGN GUIDE Figure 4.

22-Jan-04

12

147943599.doc

PROCEDURE NO.

REV.

DATE

PAGE OF

PTD-DGS-119 SINGLE PHASE LIQUID FLOW WATER HAMMER AND PRESSURE SURGE DESIGN GUIDE

22-Jan-04

12

147943599.doc

PROCEDURE NO.

REV.

DATE

PAGE OF

PTD-DGS-119 SINGLE PHASE LIQUID FLOW WATER HAMMER AND PRESSURE SURGE DESIGN GUIDE

22-Jan-04

12

4.3

Surge Pressure Rise

The time that it takes the pressure wave to travel from the valve to the pipe inlet and back is the critical time period . The critical time can be calculated using Equation 4-2.

2L a

(Eq. 4-2)

4.3.1 Valve Closure Time < Critical Time When a valve closes faster than the critical time , the flow stoppage in the pipe is considered instantaneous. The maximum pressure rise for the instantaneous change in flow is calculated using Equation 4-3. p = aV 4.3.2 Valve Closure Time > Critical Time When the valve closure time exceeds the critical time, the pressure surge is reduced due to the cancellation between direct and reflected pressure waves. Equation 4-4 provides a rough approximation of the maximum pressure rise when the valve closure time exceeds the critical time. p = t aV c 4.4 Pressure Capability (Eq. 4-3)

(Eq. 4-4)

Pressure capability of the pipe is determined from the piping material class design pressure and design code allowance for pressure variation. For ASME B31.3-2002 design code: Subject to the owners approval, it is permissible to exceed the pressure rating or allowable stress for pressure design at the temperature of the increased condition by not more than: (a) 33% for no more than 10 hr at any one time and no more than 100 hr/yr; or (b) 20% for not more than 50 hr at any one time and no more than 500 hr/yr. For ASME B31.4 design code:

147943599.doc

PROCEDURE NO.

REV.

DATE

PAGE OF

PTD-DGS-119 SINGLE PHASE LIQUID FLOW WATER HAMMER AND PRESSURE SURGE DESIGN GUIDE

22-Jan-04

12

Pressure rise due to surges and other variations from normal operations shall not exceed the internal design pressure at any point in the piping system and equipment by more than 10%. 4.5 Allowable Surge Pressure

Equation 4-5 determines allowable surge pressure: PS=PC -PO Where: PS PC PO 4.6 = = = Allowable surge pressure Pressure capability of piping Piping operating pressure (Eq. 4-5)

Excess Surge Pressure

If the allowable surge pressure is greater than the maximum surge pressure, the piping is capable of withstanding the maximum surge pressure. If the pipe is not capable of withstanding the maximum surge pressure, the closing time of shutoff must be increased to reduce the surge pressure. Table 2 lists the minimum closing time for gate valves and permits comparison with the calculated critical time. If the valve cannot be closed slowly enough, or if a pump shutdown or startup is the reason for the water hammer, an air chamber or surge tank may be used to absorb all or most of the pressure rise. Commercial surge arrestors are available for most applications.

Table 2 - Gate Valve Minimum Closing Time

147943599.doc

PROCEDURE NO.

REV.

DATE

PAGE OF

PTD-DGS-119 SINGLE PHASE LIQUID FLOW WATER HAMMER AND PRESSURE SURGE DESIGN GUIDE

22-Jan-04

10

12

Diameter of Valve (inches) 4 6 8 10 12 14 16 18 20 22 24 or larger 5.0 REFERENCES

Number of Turns to Open (Typical) 9 13 27 32 38 45 52 58 64 76 76

Minimum Time of Closure (seconds) 9 18 42 58 69 91 205 117 158 158 158

The following publications are used as references for this design guide: 1. American Society of Mechanical Engineers, Chemical Plant and Petroleum Refinery Piping, B31.3. 2. American Society of Mechanical Engineers, Pipeline Transportation Systems For Liquid Hydrocarbons And Other Liquids, B31.4. 3. Frick, T.C., Petroleum Handbook, p. 6.59. 4. Marks, L. S., Mechanical Engineers Handbook, McGraw-Hill Book Company, New York. 5. Moody, L. F., Water Hammer Surge - Analysis and Control, "Appendix F: Simplified Derivation of Water-Hammer Formula," Philadelphia. 6. Wood, D. J., and Funk, J.E., Computer Analysis of Transient Flow in Pipe Networks Including Surge Control Devices.

147943599.doc

Das könnte Ihnen auch gefallen

- Line List Input Design GuideDokument38 SeitenLine List Input Design GuideCivil Friend86% (7)

- Flow Analysis for Hydrocarbon Pipeline EngineeringVon EverandFlow Analysis for Hydrocarbon Pipeline EngineeringNoch keine Bewertungen

- Air Dryer Atlas Copco CD 12 (01-Technical - 1154207 - 1 - 00)Dokument43 SeitenAir Dryer Atlas Copco CD 12 (01-Technical - 1154207 - 1 - 00)Leon Strantzias86% (7)

- Order To Cash Cycle Group 1Dokument4 SeitenOrder To Cash Cycle Group 1AswinAniNoch keine Bewertungen

- Computer Graphics Mini ProjectDokument25 SeitenComputer Graphics Mini ProjectGautam Singh78% (81)

- Surge Pressure (Water Hammer) Olga 5Dokument6 SeitenSurge Pressure (Water Hammer) Olga 5angry_granNoch keine Bewertungen

- Water Hammer Report 1Dokument74 SeitenWater Hammer Report 1Ah Leng LauNoch keine Bewertungen

- Line Sizing With Example PDFDokument15 SeitenLine Sizing With Example PDFAmol100% (1)

- PipelineStudio Release NotesDokument27 SeitenPipelineStudio Release NotesErdincNoch keine Bewertungen

- Line Sizing ProcedureDokument123 SeitenLine Sizing ProcedureEkundayo John100% (3)

- Surge CalculationsDokument21 SeitenSurge CalculationsJai Krishna SahithNoch keine Bewertungen

- Total Process Engineering ManualDokument260 SeitenTotal Process Engineering Manualmusabammadkhan86% (7)

- ASTM G165-99 (R2005) Standard Practice For Determining Rail-To-Earth ResistanceDokument5 SeitenASTM G165-99 (R2005) Standard Practice For Determining Rail-To-Earth Resistance曾乙申100% (1)

- Gravity Fluid Flow Design GuideDokument15 SeitenGravity Fluid Flow Design Guidec_nghiaNoch keine Bewertungen

- A Simplified Approach To Water-Hammer Analysis PDFDokument0 SeitenA Simplified Approach To Water-Hammer Analysis PDFbtjajadi100% (1)

- Hydraulic Transient Analysis Case StudyDokument30 SeitenHydraulic Transient Analysis Case StudyhutuguoNoch keine Bewertungen

- Surge TrainingDokument30 SeitenSurge TrainingSyed Ali Abdullah RizviNoch keine Bewertungen

- Example Surge AnalysisDokument68 SeitenExample Surge AnalysisJeEJyZa100% (4)

- Surge AnalysisDokument39 SeitenSurge AnalysisAneeq Sh100% (1)

- Gravity Flow Pipe Design ChartsDokument12 SeitenGravity Flow Pipe Design Chartslimin zhang100% (1)

- Hydraulic and Surge Analysis in A Pipeline Network Using PipelineStudioDokument8 SeitenHydraulic and Surge Analysis in A Pipeline Network Using PipelineStudioAnonymous WNWk1h2Noch keine Bewertungen

- Water Hammer Report (With Vacuum Air Valves)Dokument11 SeitenWater Hammer Report (With Vacuum Air Valves)Ah Leng LauNoch keine Bewertungen

- Determining The Pressure Drop To Be Used in A Control Valve Sizing CalculationDokument2 SeitenDetermining The Pressure Drop To Be Used in A Control Valve Sizing CalculationzhangamecNoch keine Bewertungen

- Faolgaexercisesjune08a4 180108170621Dokument71 SeitenFaolgaexercisesjune08a4 180108170621Aly ShahNoch keine Bewertungen

- Vent Manifold Flare Manifold DesignDokument10 SeitenVent Manifold Flare Manifold Designahsan888Noch keine Bewertungen

- Solving Liquid Hammer Problems Using Pipenet Vision and Caesar IiDokument7 SeitenSolving Liquid Hammer Problems Using Pipenet Vision and Caesar IiGopal SinghNoch keine Bewertungen

- Surge AnalysisDokument4 SeitenSurge Analysischandraprakashhh100% (2)

- Avoiding Pressure Surge Damage in PipelineDokument16 SeitenAvoiding Pressure Surge Damage in PipelineFerlie IndrapatiNoch keine Bewertungen

- Air Vessel Sizing For Water Hammer Prevention in PipelinesDokument14 SeitenAir Vessel Sizing For Water Hammer Prevention in Pipelinesab_s5036Noch keine Bewertungen

- Background: 1 Slugging Caused by PiggingDokument33 SeitenBackground: 1 Slugging Caused by PiggingGary Jones100% (1)

- Stress Analysis On Offshore PlatformsDokument45 SeitenStress Analysis On Offshore PlatformsMalarNoch keine Bewertungen

- Hydraulic TransientsDokument58 SeitenHydraulic TransientsjulianvillajosNoch keine Bewertungen

- Water Hammer 1Dokument11 SeitenWater Hammer 1shaffetiNoch keine Bewertungen

- AspenHYSYSV7 - Hydrate Formation UtilityDokument16 SeitenAspenHYSYSV7 - Hydrate Formation Utilityamms9988100% (1)

- Solve PRV and Piping Capacity Problems-Part 2Dokument7 SeitenSolve PRV and Piping Capacity Problems-Part 2roberdani12Noch keine Bewertungen

- Pipeline Hydraulic Design Proposal PDFDokument62 SeitenPipeline Hydraulic Design Proposal PDFDhia SlamaNoch keine Bewertungen

- Water Hammer Pressure CalculatorDokument1 SeiteWater Hammer Pressure CalculatormohamedfirozNoch keine Bewertungen

- Lecture On SurgeDokument42 SeitenLecture On SurgeJaspal SinghNoch keine Bewertungen

- Surge Pressure Formula PDFDokument3 SeitenSurge Pressure Formula PDFnirmal_subudhiNoch keine Bewertungen

- 1417 Pipeline Surge Analysis Studies Atmos - PSIGDokument21 Seiten1417 Pipeline Surge Analysis Studies Atmos - PSIGsmdryz100% (4)

- Computer Modelling of Hydraulic Transients in Pipe NetworksDokument8 SeitenComputer Modelling of Hydraulic Transients in Pipe Networkskhantiger100Noch keine Bewertungen

- Joule-Thomson (JT) Assembly: Oil and Gas Process and Production EquipmentDokument2 SeitenJoule-Thomson (JT) Assembly: Oil and Gas Process and Production Equipmentpedro100% (1)

- TSP0013 Steam Tracing DesignDokument23 SeitenTSP0013 Steam Tracing DesignFabio TemporiniNoch keine Bewertungen

- An Overview of Pipe Stress Engineering (Sample)Dokument34 SeitenAn Overview of Pipe Stress Engineering (Sample)Vu Truong Giang100% (1)

- User Interface - PipenetDokument47 SeitenUser Interface - Pipenetelvithaf67% (3)

- 11-3842 PSV Jump StartDokument20 Seiten11-3842 PSV Jump StartchikukotwalNoch keine Bewertungen

- HydraulicsDokument42 SeitenHydraulicsAslam ChohanNoch keine Bewertungen

- Relief Valves Sizing MethodsDokument10 SeitenRelief Valves Sizing MethodsRicardo BecNoch keine Bewertungen

- Minimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunityDokument7 SeitenMinimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunitySHINoch keine Bewertungen

- Liquid Line SizingDokument6 SeitenLiquid Line SizingManoj KumarNoch keine Bewertungen

- Advantages of Bladder Surge TanksDokument8 SeitenAdvantages of Bladder Surge TanksChrisHogbenNoch keine Bewertungen

- Calculate Flow Rate From Differential PressureDokument27 SeitenCalculate Flow Rate From Differential PressureThang Hoang Anh100% (1)

- Liquid Pipelines Surge Basic ExplainationDokument6 SeitenLiquid Pipelines Surge Basic ExplainationbryandownNoch keine Bewertungen

- Flare Piping PDFDokument1 SeiteFlare Piping PDFNilesh GohelNoch keine Bewertungen

- PDF Steam Condensate Return LinesDokument5 SeitenPDF Steam Condensate Return Linesjesus_manrique2753Noch keine Bewertungen

- Control Valve Failure Relief Rate - Liquid ServiceDokument2 SeitenControl Valve Failure Relief Rate - Liquid ServiceSaeid Rahimi MofradNoch keine Bewertungen

- Faculty of Engineering & Technology Mechanical Engineering Lab Report Fluid MechanicsDokument11 SeitenFaculty of Engineering & Technology Mechanical Engineering Lab Report Fluid MechanicsTan YikcongNoch keine Bewertungen

- Surge TankDokument26 SeitenSurge TankAmar WadoodNoch keine Bewertungen

- Control Valve - Surge Relief Valve Selection GuideDokument20 SeitenControl Valve - Surge Relief Valve Selection GuideSriya PetikiriarachchigeNoch keine Bewertungen

- WATSON Separator 1Dokument31 SeitenWATSON Separator 1Apriliana DwijayantiNoch keine Bewertungen

- Process Engineering Manual 005 IDokument81 SeitenProcess Engineering Manual 005 IzoeNoch keine Bewertungen

- Reboiler Calculations Design Guide PDF FreeDokument12 SeitenReboiler Calculations Design Guide PDF FreeSabba CabbaNoch keine Bewertungen

- Line Sizing GuidelinesDokument31 SeitenLine Sizing Guidelinesc_nghia100% (3)

- 11Dokument66 Seiten11makeencvNoch keine Bewertungen

- 7t95-P-7110ab-Vp-0009 - Mechanical Seal Dwg. (P-7110ab) - R2 - C1Dokument1 Seite7t95-P-7110ab-Vp-0009 - Mechanical Seal Dwg. (P-7110ab) - R2 - C1Civil FriendNoch keine Bewertungen

- SCG Concrete Roof Cpac Home PlanDokument24 SeitenSCG Concrete Roof Cpac Home PlanCivil FriendNoch keine Bewertungen

- Asm Foundation Model1Dokument1 SeiteAsm Foundation Model1Civil FriendNoch keine Bewertungen

- Contruction &HSE Room Layout 2Dokument1 SeiteContruction &HSE Room Layout 2Civil FriendNoch keine Bewertungen

- 7t95-P-7110ab-Vp-0004 - Sectional Dwg. (P-7110ab) - R1 - C1Dokument1 Seite7t95-P-7110ab-Vp-0004 - Sectional Dwg. (P-7110ab) - R1 - C1Civil FriendNoch keine Bewertungen

- Designing Small Shelf Layouts For Train ModelDokument49 SeitenDesigning Small Shelf Layouts For Train ModelFaizal Ngauge100% (3)

- 7t95-P-7110ab-Vp-0011 - Seal Reservoir Dwg. (P-7110ab) - R0 - C1Dokument1 Seite7t95-P-7110ab-Vp-0011 - Seal Reservoir Dwg. (P-7110ab) - R0 - C1Civil FriendNoch keine Bewertungen

- 7t95-P-7110ab-Vp-0006 - Auxiliary Piping Dwg. (2-4) (P-7110ab) - R2 - C1Dokument1 Seite7t95-P-7110ab-Vp-0006 - Auxiliary Piping Dwg. (2-4) (P-7110ab) - R2 - C1Civil FriendNoch keine Bewertungen

- 7t95-P-7110ab-Vp-0003 - Outline Drawing. (P-7110ab) - R5 - C1Dokument1 Seite7t95-P-7110ab-Vp-0003 - Outline Drawing. (P-7110ab) - R5 - C1Civil FriendNoch keine Bewertungen

- 7t95-P-7110ab-VP-0002 Pump Performance Curve (P-7110ab) r1 c1Dokument2 Seiten7t95-P-7110ab-VP-0002 Pump Performance Curve (P-7110ab) r1 c1Civil FriendNoch keine Bewertungen

- 7t95-P-7110ab-VP-0015 Motor Performance Curve (P-7110ab) Ra c3Dokument3 Seiten7t95-P-7110ab-VP-0015 Motor Performance Curve (P-7110ab) Ra c3Civil FriendNoch keine Bewertungen

- Appendix - C Sectional PropertiesDokument3 SeitenAppendix - C Sectional PropertiesCivil FriendNoch keine Bewertungen

- 7t95-P-7110ab-Vp-0012 - Coupling Dwg. (P-7110ab) - R1 - C1Dokument2 Seiten7t95-P-7110ab-Vp-0012 - Coupling Dwg. (P-7110ab) - R1 - C1Civil FriendNoch keine Bewertungen

- 7t95-P-7110ab-Vp-0005 - Auxiliary Piping Dwg. (1-4) (P-7110ab) - R0 - C1Dokument1 Seite7t95-P-7110ab-Vp-0005 - Auxiliary Piping Dwg. (1-4) (P-7110ab) - R0 - C1Civil FriendNoch keine Bewertungen

- Dwg. No. 8476-40-00Dokument1 SeiteDwg. No. 8476-40-00Civil FriendNoch keine Bewertungen

- 7t95 Po e 004 VP 0012 - Spare Part List For 2 Years Operating (Option) - r0 - c2Dokument2 Seiten7t95 Po e 004 VP 0012 - Spare Part List For 2 Years Operating (Option) - r0 - c2Civil FriendNoch keine Bewertungen

- 7t95 Po P 001 VP 0020. Utility Consumption List r0 c2Dokument2 Seiten7t95 Po P 001 VP 0020. Utility Consumption List r0 c2Civil FriendNoch keine Bewertungen

- Dwg. No. 8485-40-00Dokument1 SeiteDwg. No. 8485-40-00Civil FriendNoch keine Bewertungen

- Dwg. No. 8483-40-00Dokument1 SeiteDwg. No. 8483-40-00Civil FriendNoch keine Bewertungen

- Dwg. No. 8480-40-00Dokument1 SeiteDwg. No. 8480-40-00Civil FriendNoch keine Bewertungen

- Kmuttv23n2 3Dokument16 SeitenKmuttv23n2 3Civil FriendNoch keine Bewertungen

- DS-50-0804.02-6000-001 Rev D2 Quick CouplingDokument2 SeitenDS-50-0804.02-6000-001 Rev D2 Quick CouplingCivil FriendNoch keine Bewertungen

- Dwg. No. 8478-40-00Dokument1 SeiteDwg. No. 8478-40-00Civil FriendNoch keine Bewertungen

- 7t95 Po e 004 VP 0016 Painting Specification r1 c1Dokument2 Seiten7t95 Po e 004 VP 0016 Painting Specification r1 c1Civil FriendNoch keine Bewertungen

- Appendix - B Analysis Tables: Table B-1 Beam DiagramsDokument14 SeitenAppendix - B Analysis Tables: Table B-1 Beam DiagramsCivil FriendNoch keine Bewertungen

- Appendix A - Properties of ASTM Standard Reinforcing BarsDokument1 SeiteAppendix A - Properties of ASTM Standard Reinforcing BarsCivil FriendNoch keine Bewertungen

- D 103eDokument19 SeitenD 103eCivil FriendNoch keine Bewertungen

- Process Steam Traps Design GuideDokument8 SeitenProcess Steam Traps Design GuideCivil FriendNoch keine Bewertungen

- The Perceived Barriers and Entrepreneurial Intention of Young Technical ProfessionalsDokument6 SeitenThe Perceived Barriers and Entrepreneurial Intention of Young Technical ProfessionalsAnatta OngNoch keine Bewertungen

- Ibm v3700 Storeage PDFDokument694 SeitenIbm v3700 Storeage PDFJanakackvNoch keine Bewertungen

- University of Nottingham Department of Architecture and Built EnvironmentDokument43 SeitenUniversity of Nottingham Department of Architecture and Built EnvironmentDaniahNoch keine Bewertungen

- Visa Requirements Austrian EmbassyDokument2 SeitenVisa Requirements Austrian Embassyadalcayde2514Noch keine Bewertungen

- EE FlowchartDokument1 SeiteEE Flowchartgoogley71Noch keine Bewertungen

- Mercantile Law Zaragoza Vs Tan GR. No. 225544Dokument3 SeitenMercantile Law Zaragoza Vs Tan GR. No. 225544Ceasar Antonio100% (1)

- Reterta V MoresDokument13 SeitenReterta V MoresRam Migue SaintNoch keine Bewertungen

- Ibt - Module 2 International Trade - Theories Are: Classical and Are From The PerspectiveDokument9 SeitenIbt - Module 2 International Trade - Theories Are: Classical and Are From The PerspectiveLyca NegrosNoch keine Bewertungen

- Notes On Mass and Energy Balances For Membranes 2007 PDFDokument83 SeitenNotes On Mass and Energy Balances For Membranes 2007 PDFM TNoch keine Bewertungen

- Carpio V ValmonteDokument2 SeitenCarpio V ValmonteErvin John Reyes100% (2)

- (Ambition) Malaysia 2023 Market Insights ReportDokument46 Seiten(Ambition) Malaysia 2023 Market Insights ReportMaz Izman BudimanNoch keine Bewertungen

- Unit 8 - Week 7: Assignment 7Dokument3 SeitenUnit 8 - Week 7: Assignment 7Nitin MoreNoch keine Bewertungen

- Resume (Suyash Garg)Dokument1 SeiteResume (Suyash Garg)Suyash GargNoch keine Bewertungen

- Germany's Three-Pillar Banking SystemDokument7 SeitenGermany's Three-Pillar Banking Systemmladen_nbNoch keine Bewertungen

- God Save The Queen Score PDFDokument3 SeitenGod Save The Queen Score PDFDarion0% (2)

- Add New Question (Download - PHP? SC Mecon&id 50911)Dokument9 SeitenAdd New Question (Download - PHP? SC Mecon&id 50911)AnbarasanNoch keine Bewertungen

- Project Report EP-1Dokument9 SeitenProject Report EP-1Nikita NawleNoch keine Bewertungen

- Audit Process - Performing Substantive TestDokument49 SeitenAudit Process - Performing Substantive TestBooks and Stuffs100% (1)

- Price Action Trading Strategies - 6 Patterns That Work (Plus Free Video Tutorial)Dokument22 SeitenPrice Action Trading Strategies - 6 Patterns That Work (Plus Free Video Tutorial)kalpesh kathar100% (1)

- Factors Affecting The Rate of Chemical Reactions Notes Key 1Dokument3 SeitenFactors Affecting The Rate of Chemical Reactions Notes Key 1api-292000448Noch keine Bewertungen

- As 3789.2-1991 Textiles For Health Care Facilities and Institutions Theatre Linen and Pre-PacksDokument9 SeitenAs 3789.2-1991 Textiles For Health Care Facilities and Institutions Theatre Linen and Pre-PacksSAI Global - APACNoch keine Bewertungen

- Prestressed ConcreteDokument9 SeitenPrestressed ConcreteDiploma - CE Dept.Noch keine Bewertungen

- Dolby Atmos Specifications PDFDokument24 SeitenDolby Atmos Specifications PDFVanya ValdovinosNoch keine Bewertungen

- EC312 Object Oriented ProgrammingDokument3 SeitenEC312 Object Oriented ProgrammingJazir HameedNoch keine Bewertungen

- 02Dokument257 Seiten02shaney navoaNoch keine Bewertungen

- DBR KochiDokument22 SeitenDBR Kochipmali2Noch keine Bewertungen

- Stryker Endoscopy SDC Pro 2 DVDDokument2 SeitenStryker Endoscopy SDC Pro 2 DVDWillemNoch keine Bewertungen