Beruflich Dokumente

Kultur Dokumente

HeliCoil Tangless Gall Resistant Inserts

Hochgeladen von

Ace Industrial SuppliesCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

HeliCoil Tangless Gall Resistant Inserts

Hochgeladen von

Ace Industrial SuppliesCopyright:

Verfügbare Formate

HeliCoil Tangless Gall Resistant inserts are fabricated from a special stainless steel material which is inherently resistant

to galling. No lubrication is required with this wear resistant and gall resistant material. Gall Resistant inserts are particle free and ensure no contamination. The material provides a reduction in friction that enhances the inserts ability to provide a consistent, true clamping torque within the assembly for longer life and enhanced performance.

For electro-optical and control electronics packaging requirements that demand the utmost in FOD (foreign object debris) cleanliness, Gall Resistant inserts permit the use of Screw-Lock inserts without any coatings that may flake or migrate.

sa l

Tangless Gall Resistant inserts are ideal for aerospace, military, electronics and clean room applications where secondary operations are currently required to recover tangs during assembly.

emhartamericas.com

es Fo @ r lo ac w ei es nd t p su ric pp es lie : s. co m

Tangless Gall Resistant Inserts

The anti-gall material that eliminates the need for a secondary lubrication process

Features & Benefits: No Tangs for

Quick Installation

Set it and forget it

Corrosion Resistant

Manufactured from stainless steel

Reduced Friction

Base material eliminates the need for additional lubrication More uniform load distribution No contamination

Increased Strength Virtually Particle Free

Compatible with stainless steel screws

For use in critical, particle free applications

Tangless Gall Resistant Inserts

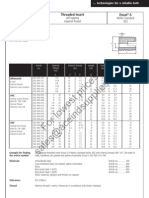

Testing was performed using #10-32 standard tapped hole blocks prepared in 316 grade stainless steel material. #10-32 STI holes were prepared to Heli-Coil specifications in aluminum material Gall Resistant inserts were installed. Tests were performed using both plain and chemically polished 316 stainless steel screws. Torque tests were conducted with the test blocks correctly aligned and mis-aligned by 2.2 and 4.4 degrees from perpendicular. The torque was recorded for 20 screws in each combination, during the 10 insertions for each screw. (Figure 1.)

Driving Torque Comparison

60

Driving Torque (N.mm)

40 30 20 10 0

sa l

es Fo @ r lo ac w ei es nd t p su ric pp es lie : s. co m

Standard Holes Gall Resistant Insert Assemblies 0 2.2 4.4 Degrees From Perpendicular

50

Torque Test Figure 1

Americas Emhart Teknologies 4 Shelter Rock Lane Danbury, CT 06810 USA Tel: (877) EMHART1 Tel: (877) 364-2781 Fax: (800) 225-5614 Canada: (514) 351-0330 Brazil: + 55 11 3871-6460 Mxico: + 52-55-5326-7100

2012 Emhart Teknologies HC1034 Rev.3 (01/12)

Based on the testing completed, Heli-Coil Gall Resistant inserts provide superior gall resisting characteristics as compared to standard tapped holes. Gall Resistant inserts also provide increased compensation for mis-alignment of both assemblies and fasteners. Because of the reduction in friction, Gall Resistant inserts provide a more consistent, true clamping torque in the fastener assembly.

emhartamericas.com

Das könnte Ihnen auch gefallen

- Weld Like a Pro: Beginning to Advanced TechniquesVon EverandWeld Like a Pro: Beginning to Advanced TechniquesBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Spot Welding Interview Success: An Introduction to Spot WeldingVon EverandSpot Welding Interview Success: An Introduction to Spot WeldingNoch keine Bewertungen

- HeliCoil Gall Resistant InsertsDokument2 SeitenHeliCoil Gall Resistant InsertsAce Industrial SuppliesNoch keine Bewertungen

- Bollhoff Armstrong HeliCoilDokument28 SeitenBollhoff Armstrong HeliCoilAce Industrial Supplies100% (1)

- Water Treatment Sight Glass FittingsDokument1 SeiteWater Treatment Sight Glass Fittingsgrincheu70Noch keine Bewertungen

- LT1061 Catalogue of RebarDokument2 SeitenLT1061 Catalogue of Rebarengage4u2020Noch keine Bewertungen

- HeliCoil Stud-Lock ApplicationsDokument2 SeitenHeliCoil Stud-Lock ApplicationsAce Industrial SuppliesNoch keine Bewertungen

- HeliCoil Tangless InsertsDokument2 SeitenHeliCoil Tangless InsertsAce Industrial SuppliesNoch keine Bewertungen

- Ex Platform Scale - PFA589Dokument5 SeitenEx Platform Scale - PFA589xinying liuNoch keine Bewertungen

- 1 - Volumen 1 - Fittings PDFDokument168 Seiten1 - Volumen 1 - Fittings PDFjuan_octoberNoch keine Bewertungen

- Mil DTL 38999 Series IIIDokument10 SeitenMil DTL 38999 Series IIIthulasi_krishnaNoch keine Bewertungen

- Technical Specification for InsulatorsDokument15 SeitenTechnical Specification for InsulatorsshahpinkalNoch keine Bewertungen

- Specification of Insulator As On January 2013Dokument11 SeitenSpecification of Insulator As On January 2013chums_23Noch keine Bewertungen

- Maryland Metrics KeensertsDokument60 SeitenMaryland Metrics KeensertsThor InternationalNoch keine Bewertungen

- Helicoil Catalog - hc2000 Rev.5Dokument36 SeitenHelicoil Catalog - hc2000 Rev.5Hugo CastroNoch keine Bewertungen

- ST-350 Strain TransducerDokument2 SeitenST-350 Strain TransducerasimovvNoch keine Bewertungen

- Bar CouplerDokument6 SeitenBar Couplerlwin_oo2435Noch keine Bewertungen

- Grinnell Mechanical Products Mechanical Outlet Coupling Installation / Assembly InstructionsDokument2 SeitenGrinnell Mechanical Products Mechanical Outlet Coupling Installation / Assembly InstructionsRay LujanNoch keine Bewertungen

- Metal Face Seals v3Dokument30 SeitenMetal Face Seals v3ntchobanov0% (1)

- Grounding Prod CatalogueDokument10 SeitenGrounding Prod CatalogueMark KrumpholzNoch keine Bewertungen

- Epcon G5 Adhesive Summary Brochure 584364Dokument2 SeitenEpcon G5 Adhesive Summary Brochure 584364William MercadoNoch keine Bewertungen

- ITW - Dynabolt Sleeve AnchorDokument3 SeitenITW - Dynabolt Sleeve AnchorBai AdiNoch keine Bewertungen

- Cofrete Polyester PLADokument88 SeitenCofrete Polyester PLATalos Sorin100% (1)

- Ficha Tecnica Trubolt RED HEADDokument6 SeitenFicha Tecnica Trubolt RED HEADCristhian Josue Cereceda BautistaNoch keine Bewertungen

- Recoil Screw Thread InsertsDokument8 SeitenRecoil Screw Thread InsertsAce Industrial SuppliesNoch keine Bewertungen

- ReCoil KeysertsDokument14 SeitenReCoil KeysertsThor InternationalNoch keine Bewertungen

- Loctite 243Dokument4 SeitenLoctite 243ablemathew173974Noch keine Bewertungen

- Plumbshield: For Use With Potable & Non-Potable Water ApplicationsDokument5 SeitenPlumbshield: For Use With Potable & Non-Potable Water ApplicationsMychloesNoch keine Bewertungen

- Design of Fit Between Die and InsertDokument4 SeitenDesign of Fit Between Die and InsertInnovative Research PublicationsNoch keine Bewertungen

- KBIIDokument13 SeitenKBIInetozx100% (1)

- Government of India Ministry of RailwaysDokument56 SeitenGovernment of India Ministry of RailwaysSalim KhanNoch keine Bewertungen

- Main Steel ConnectionsDokument40 SeitenMain Steel ConnectionsIndrayadi AbdillahNoch keine Bewertungen

- Adaptors Reducers Brochure PDFDokument20 SeitenAdaptors Reducers Brochure PDFvikkoo7Noch keine Bewertungen

- Suruburi by S.C.RewlingsDokument8 SeitenSuruburi by S.C.RewlingsMihnea OrzaNoch keine Bewertungen

- Seal-Connect: Conductor Material & DesignDokument0 SeitenSeal-Connect: Conductor Material & Designcasda73Noch keine Bewertungen

- Shear StudDokument7 SeitenShear StudcongtubatdaNoch keine Bewertungen

- DEMU 4010 Rebar Coupler System DEMUDokument24 SeitenDEMU 4010 Rebar Coupler System DEMUTonni KurniawanNoch keine Bewertungen

- X BT Brochure en W3987Dokument68 SeitenX BT Brochure en W3987Paul RobbinsNoch keine Bewertungen

- Grounding SpecificationsDokument5 SeitenGrounding SpecificationsdhineshNoch keine Bewertungen

- 245 Flux-Cored Wire Data SheetDokument2 Seiten245 Flux-Cored Wire Data Sheettoms4Noch keine Bewertungen

- AltechCorp - DIN Rail and Panel Mount Terminal BlocksDokument119 SeitenAltechCorp - DIN Rail and Panel Mount Terminal BlocksQuantumAutomationNoch keine Bewertungen

- Tuberà A EMT-IMC-RMC (Wheatland)Dokument12 SeitenTuberà A EMT-IMC-RMC (Wheatland)Carlos BozaNoch keine Bewertungen

- Clad & Weld Overlay Solutions for Oil & Gas IndustriesDokument8 SeitenClad & Weld Overlay Solutions for Oil & Gas Industrieskatchani50% (2)

- Koz Cable ClampsDokument18 SeitenKoz Cable ClampsshyamamolNoch keine Bewertungen

- Filteration TechnologyDokument4 SeitenFilteration TechnologyRajendra GuptaNoch keine Bewertungen

- Polymer Pin Insulator SpecificationDokument14 SeitenPolymer Pin Insulator SpecificationdamlanNoch keine Bewertungen

- Government of India Technical Specification for Fittings for 25 kV a.c. OHEDokument50 SeitenGovernment of India Technical Specification for Fittings for 25 kV a.c. OHEkhan11kNoch keine Bewertungen

- HeliCoil Primer Free II ApplicationsDokument2 SeitenHeliCoil Primer Free II ApplicationsAce Industrial SuppliesNoch keine Bewertungen

- Fabshield Offshore 71ni-1Dokument2 SeitenFabshield Offshore 71ni-1Anonymous ejnktktkY7Noch keine Bewertungen

- Caltech - Adhesive Tape 3359Dokument1 SeiteCaltech - Adhesive Tape 3359Mohammad AdilNoch keine Bewertungen

- DielectricUnion BXBDokument2 SeitenDielectricUnion BXBAhmed SherifNoch keine Bewertungen

- Tech in Fast Catalogue EnglishDokument42 SeitenTech in Fast Catalogue Englishsharklasers12Noch keine Bewertungen

- Chain Link Fence and Gates 32-31-13Dokument14 SeitenChain Link Fence and Gates 32-31-13melvinkorahNoch keine Bewertungen

- HeliCoil Tangless Primer Free II InsertsDokument2 SeitenHeliCoil Tangless Primer Free II InsertsAce Industrial SuppliesNoch keine Bewertungen

- ORFS fitting guideDokument7 SeitenORFS fitting guidelink2u_007Noch keine Bewertungen

- 3.2.2 General Application Fasteners (31-36) r21Dokument9 Seiten3.2.2 General Application Fasteners (31-36) r21Jonathan DouglasNoch keine Bewertungen

- Halfen Coupler Mechanical Rebar SplicingDokument33 SeitenHalfen Coupler Mechanical Rebar Splicingcarlosfilipegomes3994Noch keine Bewertungen

- Grinnell Figure 772 Grooved Rigid CouplingDokument4 SeitenGrinnell Figure 772 Grooved Rigid CouplingJuanNoch keine Bewertungen

- Loctite 243™: Technical Data SheetDokument4 SeitenLoctite 243™: Technical Data SheetRadu_ISNoch keine Bewertungen

- Gauge BlockDokument32 SeitenGauge Blocksava88100% (1)

- HeliCoil Stud-Lock InsertsDokument2 SeitenHeliCoil Stud-Lock InsertsAce Industrial SuppliesNoch keine Bewertungen

- HeliCoil NPT Inserts 8UNDokument4 SeitenHeliCoil NPT Inserts 8UNAce Industrial SuppliesNoch keine Bewertungen

- PowerCoil Screw Thread InsertsDokument103 SeitenPowerCoil Screw Thread InsertsAce Industrial SuppliesNoch keine Bewertungen

- HeliCoil Product RangeDokument40 SeitenHeliCoil Product RangeAce Industrial SuppliesNoch keine Bewertungen

- HeliCoil Aftermarket KIts Sav-A-Thread HTDokument1 SeiteHeliCoil Aftermarket KIts Sav-A-Thread HTAce Industrial SuppliesNoch keine Bewertungen

- HeliCoil Pipe Thread Inserts NPT ANPT NPSCDokument8 SeitenHeliCoil Pipe Thread Inserts NPT ANPT NPSCAce Industrial SuppliesNoch keine Bewertungen

- HeliCoil Self Tapping InsertsDokument4 SeitenHeliCoil Self Tapping InsertsAce Industrial SuppliesNoch keine Bewertungen

- HeliCoil Tangless ApplicationsDokument2 SeitenHeliCoil Tangless ApplicationsAce Industrial SuppliesNoch keine Bewertungen

- HeliCoil Insert Specs MetricDokument1 SeiteHeliCoil Insert Specs MetricAce Industrial SuppliesNoch keine Bewertungen

- HeliCoil Serrated Spark Plug InsertsDokument4 SeitenHeliCoil Serrated Spark Plug InsertsAce Industrial Supplies100% (1)

- HeliCoil NPT Inserts 8UN 2Dokument2 SeitenHeliCoil NPT Inserts 8UN 2Ace Industrial SuppliesNoch keine Bewertungen

- HeliCoil Insert Specs ImperialDokument1 SeiteHeliCoil Insert Specs ImperialAce Industrial SuppliesNoch keine Bewertungen

- HeliCoil Screw Thread InsertsDokument36 SeitenHeliCoil Screw Thread InsertsAce Industrial Supplies0% (1)

- HeliCoil Aftermarket Kits Oxygen SensorDokument1 SeiteHeliCoil Aftermarket Kits Oxygen SensorAce Industrial SuppliesNoch keine Bewertungen

- Ensat Self Tapping Inserts 307 308 SeriesDokument1 SeiteEnsat Self Tapping Inserts 307 308 SeriesAce Industrial SuppliesNoch keine Bewertungen

- HeliCoil Primer Free II ApplicationsDokument2 SeitenHeliCoil Primer Free II ApplicationsAce Industrial SuppliesNoch keine Bewertungen

- HeliCoil Primer Free II InsertsDokument2 SeitenHeliCoil Primer Free II InsertsAce Industrial SuppliesNoch keine Bewertungen

- HeliCoil Aftermarket CatalogueDokument24 SeitenHeliCoil Aftermarket CatalogueAce Industrial SuppliesNoch keine Bewertungen

- Bollhoff Rivkle RivnutsDokument52 SeitenBollhoff Rivkle RivnutsAce Industrial SuppliesNoch keine Bewertungen

- HeliCoil Aftermarket Catalogue 2Dokument24 SeitenHeliCoil Aftermarket Catalogue 2Ace Industrial SuppliesNoch keine Bewertungen

- Ripp Lock WashersDokument8 SeitenRipp Lock WashersAce Industrial SuppliesNoch keine Bewertungen

- Ensat Self Tapping Inserts 302 Series ImperialDokument1 SeiteEnsat Self Tapping Inserts 302 Series ImperialAce Industrial SuppliesNoch keine Bewertungen

- Ensat Self Tapping Inserts 302 Series MetricDokument1 SeiteEnsat Self Tapping Inserts 302 Series MetricAce Industrial SuppliesNoch keine Bewertungen

- Ensat Self Tapping Inserts 303 SeriesDokument1 SeiteEnsat Self Tapping Inserts 303 SeriesAce Industrial SuppliesNoch keine Bewertungen

- RivclinchDokument28 SeitenRivclinchAce Industrial SuppliesNoch keine Bewertungen

- Rivkle ElasticDokument12 SeitenRivkle ElasticAce Industrial SuppliesNoch keine Bewertungen

- HeliCoil Aftermarket Kits Head Bolt Thread RepairDokument1 SeiteHeliCoil Aftermarket Kits Head Bolt Thread RepairAce Industrial SuppliesNoch keine Bewertungen

- Black & Decker Advanced Home Wiring - Updated 3rd Edition - DC Circuits - Transfer Switches - Panel Upgrades PDFDokument349 SeitenBlack & Decker Advanced Home Wiring - Updated 3rd Edition - DC Circuits - Transfer Switches - Panel Upgrades PDFHector100% (1)

- PCI 6th Edition OverviewDokument36 SeitenPCI 6th Edition Overviewandrej2112Noch keine Bewertungen

- Pipe Mech Design-AWWA M45Dokument4 SeitenPipe Mech Design-AWWA M45kakoullisg100% (4)

- Dams Types and StabilityDokument141 SeitenDams Types and StabilityAdegoke samuel charlesNoch keine Bewertungen

- Spellnumber10m Bulo-NawoyDokument186 SeitenSpellnumber10m Bulo-NawoyBeverly Nicole Dugao CutiNoch keine Bewertungen

- 2018 Verity Brochure v1Dokument2 Seiten2018 Verity Brochure v1RatkoMRNoch keine Bewertungen

- Colonia eDokument20 SeitenColonia eAdhe Sri MarjukiNoch keine Bewertungen

- Rilem 2001 Connection Concrete SteelDokument1.365 SeitenRilem 2001 Connection Concrete Steelbombaikos100% (3)

- Protection Board PDFDokument2 SeitenProtection Board PDFmilanbrasinaNoch keine Bewertungen

- Reference List 1983-1995Dokument23 SeitenReference List 1983-1995Đi Để ĐếnNoch keine Bewertungen

- h06962 Chemical Injection SystemDokument1 Seiteh06962 Chemical Injection SystemkirankirkNoch keine Bewertungen

- Silt Control GuideDokument32 SeitenSilt Control GuidePcEngNoch keine Bewertungen

- 17-7ph TechsummaryDokument3 Seiten17-7ph Techsummarytahera aqeel100% (1)

- No Fines Conc SpecsDokument3 SeitenNo Fines Conc Specsway2saleemNoch keine Bewertungen

- Matrix For Augmentation of Beneficial ImpactsDokument8 SeitenMatrix For Augmentation of Beneficial ImpactsSubash DhakalNoch keine Bewertungen

- Cracking in Post-Tensioned Slabs KBondyCrackingSlabsDokument6 SeitenCracking in Post-Tensioned Slabs KBondyCrackingSlabsMark RamnarineNoch keine Bewertungen

- Useful ECBC Tables and TermsDokument17 SeitenUseful ECBC Tables and TermsAnoop SharmaNoch keine Bewertungen

- Iapmo Ues Er712Dokument10 SeitenIapmo Ues Er712Ngân NguyễnNoch keine Bewertungen

- My Central Kentucky Real Estate September 2011Dokument115 SeitenMy Central Kentucky Real Estate September 2011yourtownNoch keine Bewertungen

- ASL 9095050303-Ed01 PDFDokument82 SeitenASL 9095050303-Ed01 PDFMishra KewalNoch keine Bewertungen

- Building Services Branch Testing and Commissioning ProcedureDokument211 SeitenBuilding Services Branch Testing and Commissioning ProcedurePHYRAK100% (1)

- On Vertical Formwork: Concr Ete PressureDokument7 SeitenOn Vertical Formwork: Concr Ete PressureatiNoch keine Bewertungen

- Piping Material SelectionDokument3 SeitenPiping Material SelectionRifka AisyahNoch keine Bewertungen

- Submission: Document No Received Date Review Date NotesDokument1 SeiteSubmission: Document No Received Date Review Date NotesMahmoud AbbassNoch keine Bewertungen

- Laurie Baker Works and IdeasDokument14 SeitenLaurie Baker Works and IdeasCebo DharuNoch keine Bewertungen

- Temporary Bridge Inspection ReportDokument7 SeitenTemporary Bridge Inspection ReportNaison StanleyNoch keine Bewertungen

- Evaluation of Modified Truss Model Approach For Beam in ShearDokument10 SeitenEvaluation of Modified Truss Model Approach For Beam in ShearKinjal DaveNoch keine Bewertungen

- Bridge Structures OverviewDokument27 SeitenBridge Structures OverviewSada SivamNoch keine Bewertungen

- ITP For GlazingDokument7 SeitenITP For GlazingPratik Thakkar71% (7)

- 1pf2gf - Pgf-Int-Gp-Re10213Dokument20 Seiten1pf2gf - Pgf-Int-Gp-Re10213Johnny JessingNoch keine Bewertungen