Beruflich Dokumente

Kultur Dokumente

Smart Soot Blower System

Hochgeladen von

idigitiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Smart Soot Blower System

Hochgeladen von

idigitiCopyright:

Verfügbare Formate

Proceedings of ASME Power: ASME Power May 2 -4, 2006, Atlanta, Georgia

PWR2006-88075

TARGETED BOILER CLEANING USING SMART SOOTBLOWER

Huiying Zhuang/Clyde Bergemann Sandip Parikh/Clyde Bergemann

Sandeep Shah/ Clyde Bergemann

ABSTRACT A Smart Sootblower has been developed to meet the increasing demand for advanced boiler cleaning equipment. Utility plants are challenged to burn coals with severe slagging tendency. Slagging condition may be significantly different from pendant to pendant across the boiler. Conventional retractable sootblowers cleans superheat and reheat pendants with even intensity, resulting in over cleaning of some pendants and clinker buildup in others. Modern instrumentation such as SuperHeat Fouling Monitoring (SHFM) systems and Video Cameras is able to locate the exact spot where the slag is accumulated. With the help of these detention systems, the Smart Sootblower, a multi-mode soot blower, is able to target and adjust clean intensity based on slagging condition, thus minimizing tube leakage and clinker formation. The Smart Sootblower has two motors that independently control translation and rotation motion. This allows the sootblower to change helix for different cleaning in different sections of the boiler. Operators can select zones require aggressive cleaning and zones need less or no cleaning. Integration of SuperHeat Fouling Monitoring (SHFM) system would provide operators the knowledge of fouling condition and enable automatic control of sootblowers for optimal performance. Actual installations and data are presented. INTRODUCTION Burning coal in the power plants produces fouling and slagging on the boiler surfaces. Deposits in boilers contribute to boiler inefficiency, capacity reductions, and tube leakages. Large clinker formations on the pendants can fall and break the bottom tubes, causing millions of dollar losses. Boiler outages, many related to ash and slag, are the major causes of lost generation in the US fleet of coal-fired power plants. The cost

of these outages is in the billions of dollars per year in additional expense for replacement power and the cost of repairs. In particular, boilers switching from designed coals to low sulfur western fuels such as Power River Basin (PRB) coals often encounter severe slagging problems due to the lower ash softening temperature of PRB coals. The boiler cleanliness demands faced by todays boiler owners require a new solution for sootblowing. Operators are facing dynamic and higher slagging rates due to fuel variability, increased load and the like. Trying to control this slagging with old technology often results in over consumption of the sootblowing media and excessive erosion of boiler tube surfaces. In many plants, the experience results in a minimal improvement in heat transfer rate and a large increase in operating and maintenance costs. Slagging in the boiler has become a dynamic process. Slagging condition may be significantly different from pendant to pendant across the boiler. Large chuck of clinker may form on pendants on one side of boiler while pendants on the other side of boiler are relatively clean. Conventional retractable sootblower technology, however, assumes that slag is evenly distributed in the boiler. It cleans all the superheat and reheat pendants with equal intensity, resulting in over cleaning of some pendants and under cleaning of others. This eventually leads to tube leakage or clinker formation. Modern instrumentation such as SuperHeat Fouling Monitoring (SHFM) systems are able to locate the exact spot where the slag is accumulated. With the help of these detention systems, plant operators know which area needs to be cleaned more to eliminate the clinker, and which area require less cleaning to avoid tube erosion. Consequently, a Smart Sootblower, which is able to target and adjust cleaning intensity based on slagging condition, is developed to help power plants to optimize cleaning process, improve boiler reliability and efficiency, reduce operating cost, and increase fuel flexibility.

Copyright 2006 by ASME

OPERATIONAL THEORY Targeted cleaning is achieved by integrating two innovative technologies: Smart Sootblower and Super Heater Fouling Monitor (SHFM). With the advent of Super Heater Fouling Monitor (SHFM), real time feed back of boiler pluggage in specific areas of the boiler is available. Based on information received from the SHFM system a Smart Sootblower can be utilized to go to specific area of the boiler and focus cleaning onto the deposit. Consequently the cleaning efforts are concentrated in areas where needed most. Contrary to conventional retracts, the Smart Sootblower are being steered to areas where plugging is most severe. Conventional sootblowers only have one motor for both transverse and rotational movement. They usually run at fixed speeds and helix. As a result, the cleaning intensity is equal in the entire cleaning path. The Smart Sootblower, however, has two motors that independently control translation and rotation motion (figure 1). This allows the sootblower to change helix and speed for different cleaning zones in different sections of the boiler. With the Smart Sootblower, the jet impact time can be increased by slowing the traverse speed down and cleaning with a tighter helix. This allows operators to adjust the dwell time on a deposit in a particular area to take full advantage of cleaning capabilities that the blower offers. As a result, tenacious deposits can be aggressively cleaned to improve boiler cleaning and prevent large deposit build-ups. On the other hand in areas with little deposits, cleaning intensity can be reduced by operating with higher traversing speed and a less tight helix, thus saving steam and avoiding tube erosion. SHFM is the intelligence of the targeted cleaning system. With the slag information provided by SHFM, operators understand which zones require aggressive cleaning and which zones need less or no cleaning. By integrating with SHFM module, Smart Sootblower can also be automatically controlled and optimized. Clyde Bergemann and International Paper have pioneered the use of strain gages to measure the ash accumulation on the pendant surfaces. As described in our previous papers [1-3], SHFM utilized strain gage technology to sense slag deposits on the superheat and reheat pendants. Strain gages are installed on the hanger rods of the superheat and reheat pendants [4] (figure 2). Data from each strain gage is converted to weight using the stress strain relationship [5-6]: S = E Where, S = Stress in pounds per square inch E = Modulus of elasticity (30x106 for steel) = strain in micro inches per inch. Using the diameter of the rod a cross sectional area can be calculated, and the stress is multiplied by the area of the rod. The weight measurement can be started at any time within the process and any subsequent readings indicate the change in

weight from starting conditions. Thus it is not necessary to start from a totally unloaded rod. SYSTEM DESIGN The Targeted Boiler Cleaning system consists of two major components: Smart Sootblowers and SHFM. SHFM detects the location and quantity of slag deposit. Smart Sootlbower then adjusts the cleaning intensity for different locations on the basis of the slag information provided by SHFM. The heart of the targeted sootblowing system is its zone-based cleaning (figure 3). The cleaning intensity depends on the position of the blower and the severity of slag deposits. The operator defines zones along the path of the lance and specifies the cleaning mode and parameters in each zone (figure 4). For optimal performance, the smart sootblower can automatically adapt mode and parameter utilizing real time data from SHFM. The following modes can be selected: Variable Helix: This mode is similar to standard sootblower operation, but the traversing speed and rotational speed may both be set to define a helix the will provide approximate cleaning for the conditions in that zone. Intensive Cleaning: This mode can perform aggressive cleaning. The lance can be virtually held in place while rotation continues by selecting the number of rotations, the step distance, and the interval between cleaning points. Oscillation/ Partial Arc Cleaning: In this mode the sootblower concentrate the blowing media on the area to be cleaned by restricting its arc from a given starting angel through a specified angle of rotation. Additionally, the control system can vary the rotation speed to maintain a specified jet progression velocity (JPV) (figure 5). In addition, speed and direction control allow the operator to speed up or slow down the blower to perform "repeat" cleaning in an area without going to full retract position and starting over again. For instance, the blower can be set up via the local control panel to traverse in to the full insert position, back out for say 5 feet and go back in again to the full insert position. This method of control allows the plant to customize or "focus" cleaning in known areas of ash buildup. Operators can set up the sootblowers to clean in one direction and traverse out at a higher speed to reduce blowing media consumption and tube erosion. The SHFM system includes dozens of strain gages and data collection and processing system. The strain gages are installed on the superheat support rods. A data amplifier receives data from the strain gages and sends the data through an Ethernet cable to a personal computer in the control room, which contains the input processing and operator interface software. Graphical representations of the pendants with color-coded status as to weight loading from the gages constitute the operator interface and provide the information of slag deposit across the boiler (figure 6).

Copyright 2006 by ASME

SYSTEM OPERATON A Targeted Cleaning system was installed on a 700MW B&W boiler that has experienced several clinker falls that caused severe tube damages. Two Smart Sootblowers, one on each side, were installed in the cavity between the Platen Secondary Superheater Pendant and the Secondary Superheater Pendant, just above the nose arc of the unit. This area did not have any existing sootblowers and it was also an area of significant slag formation. SHFM are also installed for slag monitoring and Intelligent Sootblowing (ISB) control. Eight strain gages were installed on hanger rods that support the Platen Secondary Superheat Pendants, providing the location and quantity of the ash accumulation across the boiler. A performance test was conducted to evaluate the effectiveness of the Targeted Cleaning system. The test consists of two steps: baseline and Targeted Cleaning. In the baseline step, the Smart sootblowers were run in the same way as conventional sootblowers. They were operated with fixed speed and helix in the entire travel. In the Targeted Cleaning step, the clean intensity varies for different zones on the basis of information provide by the SHFM system. Zones with more weight were cleaned more intensely then zones with less weight. The cleaning intensity of light-weight zones was slightly reduced. Meanwhile, visual observation and flue gas temperatures across the boiler are used to confirm the slag information provided by strain gages. Figure 7 shows the slag weight on the superheat pendants measured by strain gages. The slag is not evenly distributed across the boiler. Among the four gages on the left side, gage L1 and L-4 have less weight than gage L-2 and L-3. Similarly, for the gages on the right side, gage R-1 and R-2 have more weight than gage R-3 and R-4. Visual observation verified that the pendants in the middle have less slag accumulation than pendants on the sides. To further confirm the slag information, temperature distribution across the boiler is also measured using a hand-held laser pyrometer through eight observation ports in the front wall. As shown in figure 8, the temperature profile is very similar with the weight profile. This indicates that the weight profile is correct because high flue gas temperature usually increases slag accumulation. Corresponding to the strain gage layout, the boiler is also divided into eight cleaning zones. Each sootblower covers 4 zones. In the Target Cleaning test, the cleaning intensity for heavy-weight zones was increased while the intensity for lightweight zones was decreased. The cleaning intensity for different zones is shown in table 1. Figure 9 compares the weight reduction by using Targeted Cleaning method with the

conventional cleaning method. It shows that by using Target Cleaning, much more slag is removed for zones that are were cleaned more intensely. The zones include zone L-2 and L-3 on the left and zone R-1 and zone R-2 on the right. In contrast, there is no significant change of weight reduction for the rest zones including R-3, R-4, L-1, and L-4 even though their intensity was slightly decreased. This result also indicates that those four heavy-weight zones are under cleaned in the conventional operation since almost twice as much of slag can be removed with an increased cleaning intensity. Those under cleaned areas could potentially cause Clinker formation. CONCLUSION By combining the SHFM and Smart Sootblower technologies, Targeted Cleaning system is able to focus on the dirty areas and skip the clean areas, thus eliminating tube leakage and clinker formation. The operational results in a 700 MW boiler have demonstrated that Targeted Cleaning cleans more effectively than conventional cleaning method by increasing cleaning intensity on dirty pendants. Installation of Targeted Cleaning system results in reduced boiler downtime, steam saving and increased boiler efficiency and fuel flexibility.

REFERENCES [1] Slag Monitoring at Georgia Power Plant Bowen IJPGC2003-40148, Charlie Breeding and Chris Bentley [2] Slag and Deposit Monitoring at TVA Cumberland PWR2004-52042, Charlie Breeding, Rabon Johnson, and Ben Zimmerman [3] Ash Measurement at NRG Huntley Using High Temperature Strain Gages, PWR2005-50203, Charlie Breeding, Joe Schmitt, and Huiying Zhuang [4] United States Patent Number 6,323,442 issued November 27, 2001 [5] An Introduction to Measurements using Strain Gages, Karl Hoffmann, 1998 [6] Strength of Materials, Ferdinand L. Songer, 1962, Harper & Roe Publishers

Copyright 2006 by ASME

Traverse and Rotation Gearbox Traverse Encoder

Lance Rotation Motor Traverse Pinion

Emergency Retract

Traverse Motor

Lance Rotation Spindle Housing

Figure 1 Smartblower Dual Motor Carriage Assembly

Figure 2 Superheat Suspension Structure and Strain Gage Location

Copyright 2006 by ASME

Figure 3 Mechanism of Zone-based Targeted Sootblowing

Figure 4 Cleaning Mode Selection for Different Zones

Copyright 2006 by ASME

Figure 5 Oscillation/ Partial Arc Cleaning with Constant JPV

Figure 6 Slag Information across the Boiler Provided by SHFM

Copyright 2006 by ASME

Figure 7 Display on the SHFM screen

2400 2300 2200 2100 2000 1900 1800 1700 1 2 3 4 5 6 7 8

Front Wall Observation Port No. (from left to right)

Temperature (F)

Figure 8 Temperature measurment across the boiler

Copyright 2006 by ASME

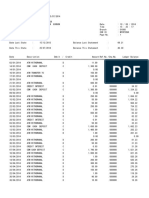

Table 1 Cleaning Intensity for Different Zones Zones Speed Conventional (fpm) Cleaning Helix (inch) Speed Targeted (fpm) Cleaning Helix (inch) L-1 79.2 6 95 6 L-2 79.2 6 62 3.8 L-3 79.2 6 62 3.8 L-4 79.2 6 95 6 R-4 79.2 6 95 6 R-3 79.2 6 95 6 R-2 79.2 6 62 3.8 R-1 79.2 6 62 3.8

600 Conventional Cleaning Targeted Cleaning 500

Weigh Reduction (lb.)

400

300

200

100

0 Zone L-1 Zone L-2 Zone L-3 Zone L-4 Zone R-4 Zone R-3 Zone R-2 Zone R-1

Figure 9 Slag removed in conventional and targeted cleaning operation

Copyright 2006 by ASME

Das könnte Ihnen auch gefallen

- Chipping and Drilling ConcreteDokument2 SeitenChipping and Drilling Concreteidigiti75% (12)

- Once Through: Steam GeneratorsDokument21 SeitenOnce Through: Steam GeneratorsrajrampallyNoch keine Bewertungen

- Economizer Recirculation For Low-Load Stability in Heat Recovery Steam GeneratorDokument10 SeitenEconomizer Recirculation For Low-Load Stability in Heat Recovery Steam GeneratorknsaravanaNoch keine Bewertungen

- History of Thermal Power PlantsDokument9 SeitenHistory of Thermal Power PlantsAnonymous gr5Pr9AVNoch keine Bewertungen

- Xviii. Soot Blowers and Furnace Temperature ProbeDokument18 SeitenXviii. Soot Blowers and Furnace Temperature Probeupt vadodaraNoch keine Bewertungen

- Training ReportPDF PDFDokument42 SeitenTraining ReportPDF PDFAman RajNoch keine Bewertungen

- SERIES 22.2: Heavy Duty Gear ReducersDokument2 SeitenSERIES 22.2: Heavy Duty Gear ReducersAmir KhanNoch keine Bewertungen

- Bhel Pipe Color Code-Aa10630 1Dokument7 SeitenBhel Pipe Color Code-Aa10630 1Vamsikrishna LakamsaniNoch keine Bewertungen

- APGENCO FlyashDokument37 SeitenAPGENCO Flyashlokesh0144Noch keine Bewertungen

- Operation Results of IHI Flue Gas Desulfurization System - Unit No.1 (1000 MW) of Hitachinaka Thermal Power Station For TEPCODokument5 SeitenOperation Results of IHI Flue Gas Desulfurization System - Unit No.1 (1000 MW) of Hitachinaka Thermal Power Station For TEPCODaniel DubeNoch keine Bewertungen

- Steam TurbinesDokument45 SeitenSteam TurbinesHaseeb Bokhari100% (1)

- An Introduction To Condensate PolishingDokument10 SeitenAn Introduction To Condensate PolishingclesncronNoch keine Bewertungen

- 57-62 1m809 - Eng72dpiDokument6 Seiten57-62 1m809 - Eng72dpiAbhinav TewariNoch keine Bewertungen

- Water QualityDokument21 SeitenWater QualityLakshmi NarayanNoch keine Bewertungen

- Boiler Afbc PDFDokument101 SeitenBoiler Afbc PDFdika wahyuNoch keine Bewertungen

- Supercritical Boiler Cleanup Cycle: Ranjan KumarDokument23 SeitenSupercritical Boiler Cleanup Cycle: Ranjan Kumarscentpcbarauni BARAUNINoch keine Bewertungen

- Engineering Declaration Unit # 2 JindalDokument16 SeitenEngineering Declaration Unit # 2 JindalVIBHAV100% (1)

- Request Letter: Sub:Requesting Experience Certificate For Applying BOE ExamDokument3 SeitenRequest Letter: Sub:Requesting Experience Certificate For Applying BOE ExammaheshNoch keine Bewertungen

- Presentation of Kawasaki FGD and SCR SystemDokument20 SeitenPresentation of Kawasaki FGD and SCR Systemjitendrashukla10836Noch keine Bewertungen

- WHRB Interlocks: S. No Boiler Equipment Logic For InterlocksDokument2 SeitenWHRB Interlocks: S. No Boiler Equipment Logic For InterlocksAmeer MeerNoch keine Bewertungen

- Boiler ConstructionDokument4 SeitenBoiler ConstructionrpshvjuNoch keine Bewertungen

- NTPC TandaDokument97 SeitenNTPC Tandamaurya1234Noch keine Bewertungen

- Heat Required in Kcal For Unit Generation of ElectricityDokument18 SeitenHeat Required in Kcal For Unit Generation of ElectricityAyan ChattarajNoch keine Bewertungen

- Proveness CriteriaDokument366 SeitenProveness CriteriaHimadri SNoch keine Bewertungen

- Consumable Selection SAILDokument50 SeitenConsumable Selection SAILSantosh CNoch keine Bewertungen

- 3 Benefites of CFB Boiler Over Pc-Fired BoilerDokument9 Seiten3 Benefites of CFB Boiler Over Pc-Fired BoilersunitbhaumikNoch keine Bewertungen

- Auxiliary BoilerDokument56 SeitenAuxiliary BoilerNirdosh AnanthNoch keine Bewertungen

- 2 Telemetry TurbineDokument12 Seiten2 Telemetry TurbineSamNoch keine Bewertungen

- HEI-IMS-CHEM-SOP05 HRSG and CCCW Chemical Dosing and PreparationDokument7 SeitenHEI-IMS-CHEM-SOP05 HRSG and CCCW Chemical Dosing and Preparationrizwan chNoch keine Bewertungen

- Requirements of Bed Material, Charcoal & Diesel. Bed MaterialDokument4 SeitenRequirements of Bed Material, Charcoal & Diesel. Bed MaterialpurvgargNoch keine Bewertungen

- 06 P F PlantDokument161 Seiten06 P F Planthirenkumar patelNoch keine Bewertungen

- 13 MW Steam Turbine 50 HZ NewDokument6 Seiten13 MW Steam Turbine 50 HZ Newteewee_cuteNoch keine Bewertungen

- Cold-Start Up of Coal Fired PowerplantsDokument6 SeitenCold-Start Up of Coal Fired PowerplantsAbdulyunus AmirNoch keine Bewertungen

- Coal Management SystemDokument12 SeitenCoal Management SystemBiswajit DuttaNoch keine Bewertungen

- NTPC (National Thermal Power Corporation) Sipat Mechanical Vocational Training Report 4-Haxxo24 I IDokument44 SeitenNTPC (National Thermal Power Corporation) Sipat Mechanical Vocational Training Report 4-Haxxo24 I Ihaxxo24Noch keine Bewertungen

- My Latest CV - EngineerDokument3 SeitenMy Latest CV - EngineersasibhushanNoch keine Bewertungen

- 500mw Checking and Setting of Hydraulic and ElectroDokument15 Seiten500mw Checking and Setting of Hydraulic and Electrothangarajm1984Noch keine Bewertungen

- Heat Rate of Thermal Power PlantDokument15 SeitenHeat Rate of Thermal Power Plantsameer betal100% (1)

- Poor Vacuum During Initial CommissioningDokument4 SeitenPoor Vacuum During Initial CommissioningCharu ChhabraNoch keine Bewertungen

- Pump Manual - Single Plunger AmbicaDokument24 SeitenPump Manual - Single Plunger AmbicaHimTex /JaswinderNoch keine Bewertungen

- Mill Reject SystemDokument22 SeitenMill Reject SystemgangatharanNoch keine Bewertungen

- CFCB Bed Ash CoolerDokument11 SeitenCFCB Bed Ash CoolerUdhayakumar VenkataramanNoch keine Bewertungen

- Technical Data For The Bhel 500 MW Steam TurbineDokument2 SeitenTechnical Data For The Bhel 500 MW Steam Turbinesai ramanaNoch keine Bewertungen

- Index: 1. Introduction To Ash and Ash Disposal System 2. Components of Ash Handling 3. Different Systems in Ash HandlingDokument11 SeitenIndex: 1. Introduction To Ash and Ash Disposal System 2. Components of Ash Handling 3. Different Systems in Ash HandlingcmcNoch keine Bewertungen

- BTLD Presentation 2Dokument23 SeitenBTLD Presentation 2Yos Wita SantosoNoch keine Bewertungen

- 3 APH PERFORMANCE in NTPC STATIONS AjaySharmaDokument15 Seiten3 APH PERFORMANCE in NTPC STATIONS AjaySharmaDSGNoch keine Bewertungen

- Presentation ON Cerc Discussion Paper On Terms & Conditions of Tariff Applicable FROM 01.04.2004Dokument74 SeitenPresentation ON Cerc Discussion Paper On Terms & Conditions of Tariff Applicable FROM 01.04.2004Mohit MalikNoch keine Bewertungen

- Bhel Recommendations On Tube FailuresDokument4 SeitenBhel Recommendations On Tube FailuresNaveen ChodagiriNoch keine Bewertungen

- Clyde Bergemann PDFDokument6 SeitenClyde Bergemann PDFenjineringNoch keine Bewertungen

- Report On Boiler Performance Audting in A Paper Plant by K.K.parthibanDokument129 SeitenReport On Boiler Performance Audting in A Paper Plant by K.K.parthibanparthi20065768Noch keine Bewertungen

- Boiler ChemistryDokument5 SeitenBoiler ChemistryChristian AganoNoch keine Bewertungen

- DR NTTPSDokument41 SeitenDR NTTPSnagasuresh100% (1)

- Dec 09Dokument35 SeitenDec 09Krishnan SanthanarajNoch keine Bewertungen

- Conference - Air Quality Control Systems in Thermal Power Plants - f1Dokument4 SeitenConference - Air Quality Control Systems in Thermal Power Plants - f1Megha ShuklaNoch keine Bewertungen

- NTPC Safety PolicyDokument15 SeitenNTPC Safety PolicySamNoch keine Bewertungen

- Bhatia Gummidipoondi WHRSG O&m Manual FinalDokument224 SeitenBhatia Gummidipoondi WHRSG O&m Manual Finalt_syamprasadNoch keine Bewertungen

- Boiler Feed PumpDokument52 SeitenBoiler Feed PumpArun Kumar100% (1)

- Clean Air Flow TestDokument4 SeitenClean Air Flow TestLakshminarayanNoch keine Bewertungen

- Soot BlowingDokument11 SeitenSoot BlowingHoncho Abhi SinhaNoch keine Bewertungen

- Catalog Steam Turbines 2013 Engl PDFDokument36 SeitenCatalog Steam Turbines 2013 Engl PDFvamsiklNoch keine Bewertungen

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasVon EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNoch keine Bewertungen

- Confined Space Rescue Plan: Description of The WorkDokument2 SeitenConfined Space Rescue Plan: Description of The Workidigiti100% (1)

- Pump NPSH Calculation: ValueDokument1 SeitePump NPSH Calculation: ValueidigitiNoch keine Bewertungen

- C700 - Basic Frame DescriptionDokument13 SeitenC700 - Basic Frame Descriptionidigiti100% (1)

- Click The Chevron To Advance.: LION (Panthera Leo)Dokument5 SeitenClick The Chevron To Advance.: LION (Panthera Leo)idigitiNoch keine Bewertungen

- Oilrefinery MINASDokument2 SeitenOilrefinery MINASidigitiNoch keine Bewertungen

- Transformer: Navigation SearchDokument18 SeitenTransformer: Navigation SearchidigitiNoch keine Bewertungen

- Energy Savings From Steam Losses On An Oil RefineryDokument11 SeitenEnergy Savings From Steam Losses On An Oil RefineryidigitiNoch keine Bewertungen

- Peter Phelps, Jr. Phelps Engineering Company Laguna Niguel, CaliforniaDokument15 SeitenPeter Phelps, Jr. Phelps Engineering Company Laguna Niguel, CaliforniaidigitiNoch keine Bewertungen

- Electromagnetic Field: Jump ToDokument9 SeitenElectromagnetic Field: Jump ToidigitiNoch keine Bewertungen

- Electrical Impedance: Electrical Impedance, or Simply Impedance, Is A Term Coined byDokument8 SeitenElectrical Impedance: Electrical Impedance, or Simply Impedance, Is A Term Coined byidigitiNoch keine Bewertungen

- CR Magnetics Sensing SolutionsDokument2 SeitenCR Magnetics Sensing SolutionsidigitiNoch keine Bewertungen

- Current Transformer MeasurementsDokument4 SeitenCurrent Transformer MeasurementsidigitiNoch keine Bewertungen

- Vertical Turbine Pumps Oil N Water Lubricated PDFDokument6 SeitenVertical Turbine Pumps Oil N Water Lubricated PDFidigitiNoch keine Bewertungen

- Onload Boiler Cleaning SystemDokument11 SeitenOnload Boiler Cleaning SystemidigitiNoch keine Bewertungen

- Oilrefinery MINASDokument2 SeitenOilrefinery MINASidigitiNoch keine Bewertungen

- PC 3 2005 Mohamadbeighy2 FinalDokument6 SeitenPC 3 2005 Mohamadbeighy2 FinalidigitiNoch keine Bewertungen

- Case Studymajor Chemical Disasters FILEminimizerDokument73 SeitenCase Studymajor Chemical Disasters FILEminimizeridigitiNoch keine Bewertungen

- (ENG) Visual Logic Robot ProgrammingDokument261 Seiten(ENG) Visual Logic Robot ProgrammingAbel Chaiña Gonzales100% (1)

- Mounting BearingDokument4 SeitenMounting Bearingoka100% (1)

- Chapter 1: Investment Landscape: Financial GoalsDokument8 SeitenChapter 1: Investment Landscape: Financial GoalsshubhamNoch keine Bewertungen

- Awais Inspector-PaintingDokument6 SeitenAwais Inspector-PaintingMohammed GaniNoch keine Bewertungen

- The "Solid Mount": Installation InstructionsDokument1 SeiteThe "Solid Mount": Installation InstructionsCraig MathenyNoch keine Bewertungen

- Data Mining - Exercise 2Dokument30 SeitenData Mining - Exercise 2Kiều Trần Nguyễn DiễmNoch keine Bewertungen

- PanasonicDokument35 SeitenPanasonicAsif Shaikh0% (1)

- Understanding Consumer and Business Buyer BehaviorDokument47 SeitenUnderstanding Consumer and Business Buyer BehaviorJia LeNoch keine Bewertungen

- Purchases + Carriage Inwards + Other Expenses Incurred On Purchase of Materials - Closing Inventory of MaterialsDokument4 SeitenPurchases + Carriage Inwards + Other Expenses Incurred On Purchase of Materials - Closing Inventory of MaterialsSiva SankariNoch keine Bewertungen

- PovidoneDokument2 SeitenPovidoneElizabeth WalshNoch keine Bewertungen

- Ver Notewin 10Dokument5 SeitenVer Notewin 10Aditya SinghNoch keine Bewertungen

- Fundamental RightsDokument55 SeitenFundamental RightsDivanshuSharmaNoch keine Bewertungen

- Research Proposal IntroductionDokument8 SeitenResearch Proposal IntroductionIsaac OmwengaNoch keine Bewertungen

- PHP IntroductionDokument113 SeitenPHP Introductionds0909@gmailNoch keine Bewertungen

- Toa Valix Vol 1Dokument451 SeitenToa Valix Vol 1Joseph Andrei BunadoNoch keine Bewertungen

- Binder 1Dokument107 SeitenBinder 1Ana Maria Gálvez Velasquez0% (1)

- DR-2100P Manual EspDokument86 SeitenDR-2100P Manual EspGustavo HolikNoch keine Bewertungen

- Ticket Udupi To MumbaiDokument2 SeitenTicket Udupi To MumbaikittushuklaNoch keine Bewertungen

- CBC Building Wiring Installation NC IIDokument72 SeitenCBC Building Wiring Installation NC IIFaysbuk KotoNoch keine Bewertungen

- Between:-Mr. Pedro Jose de Vasconcelos, of Address 14 CrombieDokument2 SeitenBetween:-Mr. Pedro Jose de Vasconcelos, of Address 14 Crombiednd offiNoch keine Bewertungen

- YeetDokument8 SeitenYeetBeLoopersNoch keine Bewertungen

- ECO 101 Assignment - Introduction To EconomicsDokument5 SeitenECO 101 Assignment - Introduction To EconomicsTabitha WatsaiNoch keine Bewertungen

- The Finley ReportDokument46 SeitenThe Finley ReportToronto StarNoch keine Bewertungen

- QuizDokument11 SeitenQuizDanica RamosNoch keine Bewertungen

- Accounting II SyllabusDokument4 SeitenAccounting II SyllabusRyan Busch100% (2)

- Pro Tools ShortcutsDokument5 SeitenPro Tools ShortcutsSteveJones100% (1)

- Prevalence of Peptic Ulcer in Patients Attending Kampala International University Teaching Hospital in Ishaka Bushenyi Municipality, UgandaDokument10 SeitenPrevalence of Peptic Ulcer in Patients Attending Kampala International University Teaching Hospital in Ishaka Bushenyi Municipality, UgandaKIU PUBLICATION AND EXTENSIONNoch keine Bewertungen

- Overcurrent CoordinationDokument93 SeitenOvercurrent CoordinationKumar100% (1)

- IP Based Fingerprint Access Control & Time Attendance: FeatureDokument2 SeitenIP Based Fingerprint Access Control & Time Attendance: FeaturenammarisNoch keine Bewertungen

- Bank Statement SampleDokument6 SeitenBank Statement SampleRovern Keith Oro CuencaNoch keine Bewertungen