Beruflich Dokumente

Kultur Dokumente

1Vol4No11 PDF

Hochgeladen von

Md Mustafa KamalOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1Vol4No11 PDF

Hochgeladen von

Md Mustafa KamalCopyright:

Verfügbare Formate

Journal of Theoretical and Applied Information Technology

2005 - 2008 JATIT. All rights reserved. www.jatit.org

OPTIMIZATION OF PD-PI CONTROLLER USING SWARM INTELLIGENCE

1 2

TUSHAR JAIN, 2M. J. NIGAM Student, Department of Electronics and Computer, IIT Roorkee, Uttarakhand, India-247667 E-mail: 1tushaar.iitr@gmail.com, 2mkndnfec@iitr.ernet.in

Assoc. Prof., Department of Electronics and Computer, IIT Roorkee, Uttarakhand, India-247667

ABSTRACT Sensitivity and Robustness is the primary issue while designing the controller for non-linear systems. One of the performance objectives for controller design is to keep the error between the controlled output and the set-point as small as possible. A comparison between Evolutionary Algorithms namely GAs (Genetic Algorithms), and Swarm Intelligence i.e. PSO (Particle Swarm Optimization) and BG (Bacterial Foraging) has been carried out on the basis of performance indices: ITAE (Integral Time Absolute Error), ISE (Integral Square Error), IAE (Integral Absolute Error) and MSE (Mean Square Error) and settling time. In this paper, the idea of model generation and optimization is explored for PD-PI controller. Most commonly known, the highly nonlinear Inverted Pendulum system is used as a test system for this approach. The simulations are tabulated in section IV to analyze which technique gives promising results for the system. Keywords: PD-PI control, Particle Swarm Optimization, Genetic Algorithms, Performance Indices, Bacterial

Foraging

1. INTRODUCTION

The interactive or series structure of PD-PI controller is shown in Fig.1:

is responsible for process stability: too low and the PV (process variable) can drift away; too high and the PV can oscillate. I (Integral): the integral of error multiplied by a gain, Ki. It is responsible for driving error to zero, but to set Ki too high is to invite oscillation or instability or integrator windup or actuator saturation. D (Derivative): the rate of change of error multiplied by a gain, Kd. Kd is responsible for system response: too high and the PV will oscillate; too slow and the PV will respond sluggishly. The signal derived is infinitely high and narrow spike.

Fig.1 PD-PI control system

The general equation of PD-PI controller is:

K U ( s ) = (1 + sK d ) K p + i s

Where,

E ( s)

(1)

Kp = Proportional Gain Ki = Integral Gain Kd = Derivative Gain

The step response of the PID controller is shown in Fig.2 and the effect of each component is discussed below [1]: P (Proportional): error multiplied by the gain, Kp. This is an adjustable amplifier. In many systems Kp 1013

Fig.2 Step response of PID controller

Journal of Theoretical and Applied Information Technology

2005 - 2008 JATIT. All rights reserved. www.jatit.org

2. NEED FOR TUNING

There are different types of objectives to be addressed by a controller; error can be minimized in different ways, as can CV (control variable) activity. Some systems have interactions and these may be of various strengths. Any interaction affects tuning of individual PD-PI. A need for a loop to be tuned if it responds slowly or if it oscillates too much or it has steady state error. 2.1. TECHNIQUES FOR CONTROLLER TUNING There are several recommendations for tuning PD-PI controller parameters and for experimental determination of process characteristics to obtain PV. These procedures can be applied when mathematical model of the process is known and also when it is unknown. In any case, these recommendations can be used for initial tuning of the controller and then user can perform fine tuning using more detail knowledge of the process [2]. The classical techniques are: Ziegler-Nichols (Z-N) Oscillation Method: Z-N tuning is used for P, PI, PID controllers. It has to be noted that controllers tuned using this procedure are tuned for control, not for tracking. Critical gain is calculated at the frequency at which system starts oscillation and the PD-PI parameters can be measured. This method fails if transfer function is not monotonous, process has astatically mode of 1st or higher order and if process is unstable. Criterion used by Z-N to tune parameters is actually IAE. A shortcoming of this method is that it requires that the plant be forced to oscillate; this can be dangerous and expensive. Reaction Based Curve Methods: With this procedure, no process model is assumed and it is based on measurements only. It can be conducted with stable and unstable processes. the procedure is valid for the system having S-shaped step response of the plant. The design objective is to achieve a particular damping in the loop response to a step reference. Cohen- Coon offers a more homogeneous response in comparison to Z-N oscillation method. These tuning methods provide the starting point for finer tuning. Modern Techniques: Another tuning method used for optimization is (EA) Evolutionary Algorithm [3] and (SI) Swarm Intelligence. EA are search

methods that take their inspiration from natural selection and survival of the fittest in the biological world and SI is originated from the study of colonies, or swarms of social organisms. The flowchart of algorithm is shown in Fig.3. One of the strengths of EAs is that they perform well on noisy functions where they may be multiple local optima. EAs tend not to get stuck on local minima and can often find a globally optimal solution. The algorithms are discussed in next sections. GAs is considered as a best tuning method for designing the PD-PI control, the main aim of this work is to analyze the other techniques such as PSO and BG for optimizing the parameters of PD-PI controller in comparison to GAs.

Fig.3 Evolutionary Algorithm

3. CASE STUDY

To investigate the impact of modern techniques on the design of PD-PI controller, a typical example of non-linear Inverted pendulum system is presented here in this section. 3.1. INVERTED PENDULUM The inverted pendulum control problem [4] is usually presented as a pole balancing task. The system to be controlled consists of a cart and a rigid pole hinged to the top of the cart. The cart can move left or right on a one-dimensional bounded track, whereas the pole can swing in the vertical plane determined by the track. The linearized

1014

Journal of Theoretical and Applied Information Technology

2005 - 2008 JATIT. All rights reserved. www.jatit.org

system equations around are:

in the state space

1 0 & x I + ml2 b & 2 & 0 x = I (M + m) + Mml & 0 0 mlb && 0 2 I (M + m) + Mml

0 m2 gl 2 I (M + m) + Mml2 0 mgl(M + m) I (M + m) + Mml2

0 x 0 & x 1 & 0

Crossover and mutation rates: Crossover and mutation rates are not fixed during evolution period. At the beginning, crossover and mutation rates are, respectively, fixed to 0.9 and 0.1, then decrease 10 percent in each generation until crossover rate is 0.5 and mutation rate is 0.01. Population size: The population size has to be an even number and is kept fixed throughout. Generally, the bigger the population size, the more design features are included. The population size should neither be too small nor too big. The procedure of optimizing will be slow when the population size is big.

0 I + ml 2 2 + + I M m Mml ( ) u + 0 ml 2 I ( M + m) + Mml

(2)

1 y= 0

0 0

0 1

x & 0 x + 0 u 0 0 &

3.3. PARTICLE SWARM OPTIMIZATION (3) Particle swarm optimization (PSO) is a population based stochastic optimization technique inspired by social behavior of bird flocking or fish schooling [6]. PSO learns from the scenario and uses it to solve the optimization problems. In PSO, each single solution is a "bird" in the search space. We call it "particle". All particles have fitness values which are evaluated by the fitness function to be optimized, and have velocities which direct the flying of the particles. The particles fly through the problem space by following the current optimum particles. PSO is initialized with a group of random particles (solutions) and then searches for optima by updating generations. In each iteration, every particle is updated by following two "best" values. The first one is the best solution (fitness) it has achieved so far. (The fitness value is also stored.) This value is called pbest. Another "best" value that is tracked by the particle swarm optimizer is the best value, obtained so far by any particle in the population. This best value is a global best and called gbest. When a particle takes part of the population as its topological neighbors, the best value is a local best and is called lbest. After finding the two best values, the particle updates its velocity and positions with following equation (4) and (5). v [] = v [] + c1 * rand () * (pbest [] - present []) + c2 * rand () * (gbest [] - present []) (4) present [] = present [] + v [] (5)

Where, M = mass of cart = 0.5 kg m = mass of pendulum = 0.2 kg b = friction of cart = 0.1 N/m/sec I = inertia of pendulum = 0.006 kgm2 l = length of pendulums center of mass = 0.3 m F = force applied to cart The state of the system is defined by values of & ) the cart position, four system variables: ( x, x &, , cart velocity, pendulum angle and angular velocity of the pendulum pole, respectively. Control force is applied to the system to prevent the pole from falling while keeping the cart within the specified limits. 3.2. GENETIC ALGORITHMS The GAs control parameters play an important role in the procedure for optimizing the parameters of the PD-PI controller. Some worthwhile discussions of the GAs parameters are made as follows [5]: Encoding form: The linear encoding form is used. The length of binary coding string for each variable is important for the GAs. There is always a compromise between complexity and accuracy in the choice of string length. Here, a 16-bit binary coding is used for each parameter.

1015

Journal of Theoretical and Applied Information Technology

2005 - 2008 JATIT. All rights reserved. www.jatit.org

v[] is the particle velocity, present[] is the current particle (solution). pbest[] and gbest[] are defined as stated before. rand () is a random number between (0, 1). c1, c2 are learning factors usually c1 = c2 = 2. 3.4. BACTERIAL FORAGING This paper considers the foraging behavior of E. coli, which is a common type of bacteria [7]. Its behavior to move comes from a set of up to six rigid 100-200 rps spinning flagella, each driven as a biological motor. An E. coli bacterium alternates between running and tumbling. Running speed is 10-20 m/sec, but they cannot swim straight. The main goal based on bacterial foraging is to apply in order to find the minimum of J ( ), R n , not in the gradient J ( ). here, when is the position of a bacterium, and J ( ) is an attractant-repellant profile. That is, it means where nutrients and noxious substances are located, so J() < 0, J ( ) = 0, J ( ) > 0 represent the presence of nutrients, a neutral medium and the presence of noxious substances, respectively can be shown by

P ( j , k , l ) = { i ( j , k , l ) | i = 1 , 2 ,...., N }

Fig.4 Step Response of pendulum angle

Fig. 5 Block diagram of PD-PI control system

(6)

Equation (6) represents the positions of each member in the population of the N bacteria at the jth chemotactic step, kth reproduction step, and lth elimination-dispersal event. Basically, chemotaxis is a foraging behavior that implements a type of optimization where bacteria tries to climb up the nutrient concentration (find lower and lower values of J ( ) ), avoid noxious substances, and search for ways out of neutral media. It implements a biased random walk. This paper describes the method in the form of an algorithm to search optimal value of PD-PI parameter. 4. RESULTS AND DISCUSSION

The performance of the PD-PI control can be judged by the values of its parameters. The algorithms as explained have been used to estimate the parameters. Empirical tuning methods cannot be applied to the system under consideration as the conditions (i.e. open loop stability, S-shaped response etc.) for applying them are not satisfied. The performance with GAs, PSO and BG is analyzed on the basis of ITAE, ISE, MSE, IAE and the settling time of the pendulum to maintain its initial position i.e. 0o for the force applied to the cart. For settling time, a band of -0.0005 rad to +0.0005 rad are considered around 0 rad. The simulated results of PD-PI control using GAs, PSO and BG for different types of errors are shown in Fig.6, Fig.7 and Fig.8 respectively.

The open loop step response of pendulum angle is shown in Fig.4.

Fig.6 Step responses (ITAE, ISE, IAE, MSE) using Gas

1016

Journal of Theoretical and Applied Information Technology

2005 - 2008 JATIT. All rights reserved. www.jatit.org

Peak angle (rad)

0.02949

0.00808 3

0.0608

Table.3 Comparison of steady state response (ISE)

Characteristic s Settling time (sec)

Fig.7 Step responses (ITAE, ISE, IAE, MSE) using PSO

GAs 3.36 0.00569

PSO 2.4 0.00127

BG 5.93 0.0158

Peak angle (rad)

Table.4 Comparison of steady state response (IAE)

Characteristic s Settling time (sec) Peak angle (rad)

GAs 2.69 0.00882 4

PSO 1.15 0.00114 6

BG 1.53 0.0302

Fig.8 Step Response (ITAE, ISE, IAE, MSE) using BG

Table.5 Comparison of steady state response (MSE)

Table.1 Comparison of Performance Indices

Performance Indices Using Genetic Algorithms Using Particle Swarm Optimizatio n Using Bacterial Foraging

ITAE 0.045 0

ISE

IAE 0.211 1

MSE 2.1e06

Characteristic s Settling time (sec) Peak angle (rad) 5.

GAs 3.33 0.00569 9

PSO 1.97 0.00116 8

BG 4.78 0.0133

0.00083

CONCLUSIONS

0.004 2

0.00002 3

0.015 3

8.24e08

0.370 3

0.0039

0.232 4

1.469e -5

Table.2 Comparison of steady state response (ITAE)

Characteristi cs Settling time (sec)

For the system under consideration, the simulation results with PSO techniques prove to be more effective than with GAs and BG. In GAs, the limits defined by the number of parameters gives the search region while in PSO, the search region is independent of the number of parameters, given by the distance between the randomly selected initial position and the position corresponding to optimal fitness value. The speed of computation is determined by the velocity initializing the PSO algorithm with which it reaches to the best solution. It is also observed that the speed of computation in PSO is very less in comparison to GAs and BG. A disadvantage of PD-PI tuning using PSO is that the values of Kp, Ki, and Kd are quite high in comparison to the values determined using GA and BG.

GAs 0.9449

PSO 0.5652

BG 1.76

1017

Journal of Theoretical and Applied Information Technology

2005 - 2008 JATIT. All rights reserved. www.jatit.org

Empirical tuning method discussed in section II cannot be applied in this case as the system considered is not open loop stable. From the step response, it can be seen that BG gives good results in terms of settling time in comparison to GAs. PSO algorithms combined with other intelligent techniques, such as neural networks, expert systems, and fuzzy logic control systems open a new way to design and construct intelligence control systems adapted to complex processes.

Tushar Jain is an M.Tech student with specialization in Control and Guidance, Department of Electronics and Computer at Indian Institute of Technology Roorkee. He received his B.Tech degree from Babu Banarsidas Institute of Technology, Ghaziabad in 2007. His research areas of interest are Fuzzy Control, Intelligent Control and Monitoring Systems and Robotics. M. J. Nigam is Associate Professor in Control & Guidance group, Department of Electronics and Computer at Indian Institute of Technology Roorkee. He received his B.Tech degree from Regional Engineering College (now National Institute of Technology), Warangal in 1976 and M.E. and Ph.D. from University of Roorkee (now Indian Institute of Technology Roorkee) with specialization in Control and Guidance in 1978 and 1992 respectively. His research areas of interest are Digital Image Processing, Robotics, and Filtering Techniques. A number of research papers in the above areas have also been published/ presented in various journals and Conferences.

REFRENCES [1] Kiam Heong Ang, Gregory Chong: PD-PI Control System Analysis, Design, and Technology IEEE TRANSACTIONS ON CONTROL SYSTEMS TECHNOLOGY, VOL.13, No.4, July 2005 PP: 559-576. [2] Graham C. Goodwin, Stefan F. Graebe, Mario E. Salgado: Control System Design, 2nd edition, January 2000. [3] Greffenstette, J. J. "Optimization of Control Parameters for Genetic Algorithms," IEEE Transactions on Systems, Man, and Cybernetics SMC-16, 1, 1986, 122-128. [4] Dadios, Elmer P.; Williams, David J., A Fuzzy-Genetic Controller for the Flexible PoleCart Balancing Problem, Proceedings of IEEE International Conference on Evolutionary Computation, pp 223, ISBN: 0 7803 2902 3, Nagoya, Japan, 1996. [5] Goldberg, D. E.: Genetic algorithms in search, optimization and machine learning (AddisonWesley, 1989). [6] James Kennedy, Russell Eberhart: Particle Swarm Optimization, IEEE Transactions, pp. 1942-1948, 1995. [7] Kevin M. Passino, Biomimicry of Bacterial Foraging for Distributed Optimization and Control, IEEE Control Systems Magazine, June 2002, p.p. 52-67

1018

Das könnte Ihnen auch gefallen

- 2012bukataphd PDFDokument200 Seiten2012bukataphd PDFMd Mustafa Kamal100% (1)

- Basic Instrumentation Measuring Devices and Basic Pid ControlDokument125 SeitenBasic Instrumentation Measuring Devices and Basic Pid ControlCuong Nguyen ChiNoch keine Bewertungen

- IJSC Vol2 Iss1 253 260 2 PDFDokument8 SeitenIJSC Vol2 Iss1 253 260 2 PDFMd Mustafa KamalNoch keine Bewertungen

- Help PDFDokument2 SeitenHelp PDFMd Mustafa KamalNoch keine Bewertungen

- 19Dokument42 Seiten19Bhavya SainiNoch keine Bewertungen

- Omega PID TunningDokument4 SeitenOmega PID TunningOwaisNoch keine Bewertungen

- Lars hagg2012PID PDFDokument6 SeitenLars hagg2012PID PDFMd Mustafa KamalNoch keine Bewertungen

- GA Speed Regulation of BLDCDokument6 SeitenGA Speed Regulation of BLDCdivinelightNoch keine Bewertungen

- Lecture15 PDFDokument34 SeitenLecture15 PDFMd Mustafa KamalNoch keine Bewertungen

- Best simple PID tuning rulesDokument27 SeitenBest simple PID tuning rulesstathiss11Noch keine Bewertungen

- Up ReportDokument26 SeitenUp ReportMaheshNoch keine Bewertungen

- OpticalDokument88 SeitenOpticalMd Mustafa KamalNoch keine Bewertungen

- 1 PDFDokument75 Seiten1 PDFMd Mustafa KamalNoch keine Bewertungen

- A PSO-Based Optimum Design of PID Controller For A Linear Brushless DC MotorDokument5 SeitenA PSO-Based Optimum Design of PID Controller For A Linear Brushless DC MotorMd Mustafa KamalNoch keine Bewertungen

- Xiachangliang 4 PDFDokument8 SeitenXiachangliang 4 PDFMd Mustafa KamalNoch keine Bewertungen

- Linux 2 Weeks Short CourseDokument2 SeitenLinux 2 Weeks Short CourseMd Mustafa KamalNoch keine Bewertungen

- TransDokument25 SeitenTransMd Mustafa KamalNoch keine Bewertungen

- Microprocessor Controlled Ac and DC DrivesDokument21 SeitenMicroprocessor Controlled Ac and DC DrivesMd Mustafa KamalNoch keine Bewertungen

- Hydro Power Plant EssentialsDokument41 SeitenHydro Power Plant EssentialsMd Mustafa Kamal100% (2)

- Microprocessor Controlled Ac and DC DrivesDokument21 SeitenMicroprocessor Controlled Ac and DC DrivesMd Mustafa KamalNoch keine Bewertungen

- Session-Animation and GraphicsDokument68 SeitenSession-Animation and GraphicsMd Mustafa KamalNoch keine Bewertungen

- Gain and Noise Figure of Erbium-Doped Fiber Amplifier (EDFADokument5 SeitenGain and Noise Figure of Erbium-Doped Fiber Amplifier (EDFAMd Mustafa KamalNoch keine Bewertungen

- Digital control of speed using SCRs and ADCDokument6 SeitenDigital control of speed using SCRs and ADCMd Mustafa KamalNoch keine Bewertungen

- The Fractional Fourier Transform and Its ApplicationsDokument26 SeitenThe Fractional Fourier Transform and Its ApplicationsCarlos Francisco HerreraNoch keine Bewertungen

- The Fractional Fourier Transform and Its ApplicationsDokument26 SeitenThe Fractional Fourier Transform and Its ApplicationsCarlos Francisco HerreraNoch keine Bewertungen

- BLDC FuzzyDokument6 SeitenBLDC FuzzyMd Mustafa KamalNoch keine Bewertungen

- Digital control of speed using SCRs and ADCDokument6 SeitenDigital control of speed using SCRs and ADCMd Mustafa KamalNoch keine Bewertungen

- Use of EDCA Access During HCF Polling: Mathilde Benveniste, Avaya LabsDokument5 SeitenUse of EDCA Access During HCF Polling: Mathilde Benveniste, Avaya LabsMd Mustafa KamalNoch keine Bewertungen

- 11 03 0293 00 000e CFB DeletionDokument3 Seiten11 03 0293 00 000e CFB DeletionMd Mustafa KamalNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Micro Shelter Product Description V5aDokument11 SeitenMicro Shelter Product Description V5aIan JaredNoch keine Bewertungen

- Lecture 1-5 Atomic and Molecular Physics by Nek M ShaikhDokument25 SeitenLecture 1-5 Atomic and Molecular Physics by Nek M Shaikh125-The Legend StarNoch keine Bewertungen

- FFA Furfural Fire and Health HazardsDokument2 SeitenFFA Furfural Fire and Health HazardsYuga Pria PungkasanNoch keine Bewertungen

- Preparation Exam API 510:N°01 QuestionsDokument3 SeitenPreparation Exam API 510:N°01 QuestionskorichiNoch keine Bewertungen

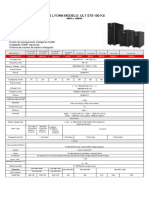

- Ups Lyonn Modelo: Ult St5-100 KS: 10KVA A 120KVADokument1 SeiteUps Lyonn Modelo: Ult St5-100 KS: 10KVA A 120KVASebastian Matias CruzNoch keine Bewertungen

- Reso Course PlannerDokument2 SeitenReso Course PlannerSnehasishGhosh100% (1)

- TR01B - Muhammad Aditya Prana Yoga - Analisa Listrik Chapter8.3Dokument3 SeitenTR01B - Muhammad Aditya Prana Yoga - Analisa Listrik Chapter8.3AzeedNoch keine Bewertungen

- AtmegaDokument22 SeitenAtmegaMUKILANNoch keine Bewertungen

- Quantitative Reasoning: Factors, HCF & LCM, FactorialsDokument2 SeitenQuantitative Reasoning: Factors, HCF & LCM, FactorialsNaman JainNoch keine Bewertungen

- Búsqueda Del Medio - RENR6305 - 994F Wheel Loader Power TrainDokument5 SeitenBúsqueda Del Medio - RENR6305 - 994F Wheel Loader Power TrainDavidCPNoch keine Bewertungen

- Citect V7.0 Error Codes PDFDokument13 SeitenCitect V7.0 Error Codes PDFWahyu PrakosoNoch keine Bewertungen

- Engineering Chemistry Lab Osmania UniversityDokument83 SeitenEngineering Chemistry Lab Osmania UniversityMujtaba khanNoch keine Bewertungen

- Bio PharmaceuticsDokument48 SeitenBio PharmaceuticsRajan Kashyap100% (2)

- Inverse Laplace Transformation Ex 11 2 Umer Asghar MethodDokument34 SeitenInverse Laplace Transformation Ex 11 2 Umer Asghar MethodSikandar Khan100% (1)

- 50-555circuits 2 PDFDokument102 Seiten50-555circuits 2 PDFAlfonso RamosNoch keine Bewertungen

- Reservoir Saturation ToolDokument19 SeitenReservoir Saturation ToolAli Jay JNoch keine Bewertungen

- 19Ma2Icmat Module 5 - Elementary Numerical MethodsDokument4 Seiten19Ma2Icmat Module 5 - Elementary Numerical Methods1DS19CH011 Jashwanth C RNoch keine Bewertungen

- Hydrogen in 1 ShotDokument86 SeitenHydrogen in 1 ShotSaloum Muhammed Islam0% (1)

- Materi Welding Defect IIDokument64 SeitenMateri Welding Defect IIsmartz inspectionNoch keine Bewertungen

- Grade 6 MathDokument12 SeitenGrade 6 Mathapi-264682510Noch keine Bewertungen

- Huawei E5885ls 93a Mobile Wifi DatasheetDokument22 SeitenHuawei E5885ls 93a Mobile Wifi DatasheetMohammed ShakilNoch keine Bewertungen

- DactylosDokument150 SeitenDactylosJay-r Pabualan DacoNoch keine Bewertungen

- Hkts 210 Sub/Hkts 200 Sub: SubwooferDokument6 SeitenHkts 210 Sub/Hkts 200 Sub: SubwooferDan PopNoch keine Bewertungen

- GGGDokument3 SeitenGGGAnkitNoch keine Bewertungen

- Timetable Saturday 31 Dec 2022Dokument1 SeiteTimetable Saturday 31 Dec 2022Khan AadiNoch keine Bewertungen

- G4pc50ud-Fd IgbtDokument10 SeitenG4pc50ud-Fd IgbtMiguel DuranNoch keine Bewertungen

- KUKA Sim 30 Installation enDokument49 SeitenKUKA Sim 30 Installation enRégis Naydo0% (1)

- Hassāniyya Arabic DialectDokument15 SeitenHassāniyya Arabic DialectTiddukla Tadelsant Imedyazen100% (1)

- Monitor AOC 24P3CW EnglishDokument32 SeitenMonitor AOC 24P3CW Englishflorinf_uNoch keine Bewertungen