Beruflich Dokumente

Kultur Dokumente

COLUMN BASE PLATE DESIGN FORCE CALCULATIONS

Hochgeladen von

toliveira80Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

COLUMN BASE PLATE DESIGN FORCE CALCULATIONS

Hochgeladen von

toliveira80Copyright:

Verfügbare Formate

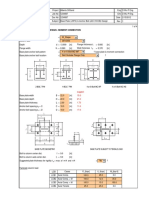

COLUMN BASE PLATE DESIGN (BS5950-1:2000)

Base plate reference; Design forces and moments Axial force; Bending moment; Shear force; Column details Column section; Depth; Breadth; Flange thickness; Web thickness; Design strength; Column flange to base plate weld; Column web to base plate weld; Baseplate details Steel grade; Depth; Breadth; Thickness; Design strength; Holding down bolt and anchor plate details Total number of bolts; Bolt spacing; Edge distance; Anchor plate steel grade;

B1;

Fc = ;1265.2; kN (Compression) M = 50.7 kNm; Fv = 20.5 kN

HE 360 A (Grade S355) D = 350.0 mm B = 300.0 mm T = 17.5 mm t = 10.0 mm pyc = 345 N/mm 10 mm FW; 8 mm FW;

2

S355 Dp = 550 mm Bp = 400 mm tp = 20 mm pyp = 345 N/mm

2

4 No. M20 Grade 8.8 sbolt = ;150; mm e1 = 50 mm S355

Anchor plate dimension (square); Anchor plate thickness; Design strength; Embeddment to top of anchor plate; Characteristic strength of concrete;

bap = 120 mm tap = 25 mm pyap = 345 N/mm E = 450 mm fcu = 30 N/mm

2 2

Concrete compression force and bolt tension force Plate overhang beyond face of flange; Effective width of plate; Distance from bolts to compression edge; From static equilibrium; Rearranging the quadratic equation; Factor a; Factor b; Constant c; Depth of compression block; Compression force in concrete; Tension force in bolts; Actual compression force in concrete; Actual force in bolts; Eccentricity of compression force; Depth of compression block; Stress in concrete; L1 = (Dp - D)/2) = ;100.0; mm Bpc = min(Bp, B + 2L1) = ;400.0; mm h = Dp - e1 = 500 mm M = 0.6fcuBpcx(h-x/2) - Fc(h-Dp/2) 0.3fcuBpcx - 0.6fcuBpchx + Fc(h-Dp/2) + M = 0 a = 0.3 fcu Bpc = 3600.0 N/mm b = -0.6 fcu Bpc h = -3600000.0 N c = Fc (h-Dp/2) + M = 335320000.0 Nmm x = [-1.0b - (b - 4ac)]/(2a) = 104.0 mm

2 2

Assuming a rectangular compression block of width bpc, length x and intensity 0.6fcu then:-

Cf = 0.6 fcu Bpc x = 748.4 kN Tf = Cf - Fc = -516.8 kN Cf = Fc = 1265 kN Tf = 0 kN e = M/Fc = 40.0 mm x = 2 (Dp/2 - e) = 469.9 mm fc = Fc / (Bpc x) = 6.7 N/mm

2

Therefore the bolts are not in tension - Recalculate depth of compression block

The depth of the compression block exceeds Dp - D + T Therefore the compression block will be T shaped Let; and let; (Note x is length of stem of T); Quadratic equation; Factor a; Factor b; Constant c; Length of stem of T; Now additionally let; is depth of flange of I); Quadratic equation; M/Fc))x+Bpcm /2+nl(m+l/2)-(Bpcm+nl)(Dp/2-M/Fc)

2

m = 2L1 + T = 217.5 mm n = min(2L1 + t, Bpc) = 210.0 mm

Then equating eccentricity of applied loading to centroid of compression T and rearranging the equation 0 = nx /2 + n(m-(Dp/2-M/Fc))x+ Bpcm(m-(Dp-2M/Fc))/2 a = n/2 = 105.0 mm b = n(m-(Dp/2-M/Fc)) = -3668 mm

2 2 3 2

c = Bpcm(m-(Dp-2M/Fc))/2 = -10980862 mm x = [-1.0b + (b - 4ac)]/(2a) = 341.3 mm l = D - 2(L1+T) = 115.0 mm

Length of stem of 'T' exceeds D-2(L1+T) - Recalculate with 'I' shaped compression block; Equating eccentricity of applied loading to centroid of compression I and rearranging the equation (Note x 0 = Bpcx /2 + Bpc((m+l)-(Dp/2a = Bpc/2 = 200.0 mm b = Bpc((m+l)-(Dp/2-M/Fc)) = 39013 mm

2 3 2 2

Factor a; Factor b; Constant c; 10014060 mm Depth of flange of I;

c = Bpcm /2+nl(m+l/2)-(Bpcm+nl)(Dp/2-M/Fc) = x = [-1.0b + (b - 4ac)]/(2a) = 146.6 mm

2

Area of compression 'I'; Stress in concrete; Compression side bending Moment in plate; Plate thickness required; Plate thickness Plate thickness required; Plate thickness provided;

Acomp = (Bpcm) + (ln) + (Bpcx) = ;169775; mm fc = Fc / Acomp = 7.5 N/mm

2 2

mc = fc (L1 - 0.8swf) /2) = ;31538 Nmm/mm; tpc = (4 mc/pyp) = 19.1 mm

tp_req = tpc = ;19.1 mm; tp = 20 mm PASS - Plate thickness provided is adequate (0.956)

Flange weld Tension capacity of flange; Force in tension flange; Flange weld design force; Weld force per mm; Transverse capacity of 10 mm fillet weld; Ptf = B T pyc = ;1811.3; kN Ftf = M/(D - T) - Fc (BT)/A = ;-313.0; kN Ff = min(Ptf, max(Ftf, 0 kN)) = 0.0 kN fwf = Ff/(2B - t) = ;0.000; kN/mm pwf = 2.188 kN/mm; (Cl. 6.8.7.3) PASS - Flange weld capacity is adequate (0.000) Longitudinal capacity of web weld Weld force per mm; Longitudinal capacity of 8 mm fillet weld; fwwl = Fv/(2(D - 2T)) = ;0.033; kN/mm pwwl = 1.400 kN/mm; (Cl. 6.8.7.3) PASS - Longitudinal capacity of web weld is adequate (0.023) Shear transfer to concrete Assumed coefficient of friction; Available shear resistance; = 0.30 Pv = Cf = ;380; kN PASS - Frictional shear capacity is adequate (0.054)

Das könnte Ihnen auch gefallen

- Pile Horizontal CheckDokument8 SeitenPile Horizontal CheckDINESHNoch keine Bewertungen

- Anchor ForceDokument14 SeitenAnchor ForceAdi Mulyadi100% (1)

- Conceptual Design of Plem Structure Labuhan DeliDokument4 SeitenConceptual Design of Plem Structure Labuhan DeliFandy SipataNoch keine Bewertungen

- Jis g3456 Grade STPT 410 Pipes PDFDokument1 SeiteJis g3456 Grade STPT 410 Pipes PDFMitul MehtaNoch keine Bewertungen

- Weight Calculation For 200 NB, 150, 100nb PipeDokument2 SeitenWeight Calculation For 200 NB, 150, 100nb PipeAnujGargNoch keine Bewertungen

- C I F D: Ommercial and Ndustrial Looring EsignDokument22 SeitenC I F D: Ommercial and Ndustrial Looring EsignJibbs OyawoyeNoch keine Bewertungen

- Super Clamps-General Clamp Industries IncDokument19 SeitenSuper Clamps-General Clamp Industries IncTagor SianiparNoch keine Bewertungen

- Abs Buckling and Ultimate Strength 126-Bus-CommentaryDokument151 SeitenAbs Buckling and Ultimate Strength 126-Bus-CommentaryAnonymous zxFhXenNoch keine Bewertungen

- SEO Optimized Title for Retirement Home Exhaust Stack Structural Calculations SpreadsheetDokument4 SeitenSEO Optimized Title for Retirement Home Exhaust Stack Structural Calculations SpreadsheetMario Sajulga Dela CuadraNoch keine Bewertungen

- Imp Design GuideDokument32 SeitenImp Design GuideRahulNoch keine Bewertungen

- FPS Riser Design Challenges in Deep WatersDokument6 SeitenFPS Riser Design Challenges in Deep WatersRajeuv GovindanNoch keine Bewertungen

- FKT NiehII Statik GRP StressDokument98 SeitenFKT NiehII Statik GRP StressSakshi AgrawalNoch keine Bewertungen

- Cooling Tower PDFDokument7 SeitenCooling Tower PDFSimoncarter LawNoch keine Bewertungen

- Moment of InertiaDokument3 SeitenMoment of InertiaFreed CreedNoch keine Bewertungen

- Bethlehem Structural Shapes Catalogue 1911Dokument122 SeitenBethlehem Structural Shapes Catalogue 1911Alberto ChazarretaNoch keine Bewertungen

- Crimp PLTDokument5 SeitenCrimp PLTSai SushankNoch keine Bewertungen

- Analysis of The Steel Joint With Four Bolts in The RowDokument8 SeitenAnalysis of The Steel Joint With Four Bolts in The RowMahmoud El-KatebNoch keine Bewertungen

- Broadway Hilti Handrail Base PDFDokument4 SeitenBroadway Hilti Handrail Base PDFjijinjohnNoch keine Bewertungen

- Structural Steel Fabrication Tolerances GuideDokument6 SeitenStructural Steel Fabrication Tolerances GuideRene Alfonso BeltranNoch keine Bewertungen

- 3Dokument6 Seiten3Petrus Jese Patarmatua PardedeNoch keine Bewertungen

- Step by Step Procedure For Concrete RepairDokument4 SeitenStep by Step Procedure For Concrete RepairMdShahbazAhmedNoch keine Bewertungen

- 18m Mast TowerDokument1 Seite18m Mast Towerunikmyquestar100% (1)

- BASEPLT9.xls Program Version 3.7 Steel Column Base Plate AnalysisDokument1 SeiteBASEPLT9.xls Program Version 3.7 Steel Column Base Plate AnalysisNagender Kumar0% (1)

- Atmatec - Fibreglass Products For Drainage Systems PDFDokument44 SeitenAtmatec - Fibreglass Products For Drainage Systems PDFHafiz KamalNoch keine Bewertungen

- Fiche Tech Ancrage 1X15 en V05Dokument2 SeitenFiche Tech Ancrage 1X15 en V05florin_iacob2001Noch keine Bewertungen

- DNV OS-C502 (2004) Offshore Concrete StructuresDokument100 SeitenDNV OS-C502 (2004) Offshore Concrete StructuresnimitNoch keine Bewertungen

- Wind Turbine API RP2 SeriesDokument8 SeitenWind Turbine API RP2 SeriesBona_VentureNoch keine Bewertungen

- Lichtgitter GRP ManualDokument68 SeitenLichtgitter GRP ManualGeorgi KalchevNoch keine Bewertungen

- InsulationDokument13 SeitenInsulationBaDa Lee100% (1)

- #160 Lifting Fixture 38tons 020807Dokument14 Seiten#160 Lifting Fixture 38tons 020807halder_kalyan9216Noch keine Bewertungen

- Blog Mechguru Com Machine Design Example of Concrete Anchor Bolt Design Calculation Part 6 Determining Concrete Breakout Strength of Anchor in ShearDokument7 SeitenBlog Mechguru Com Machine Design Example of Concrete Anchor Bolt Design Calculation Part 6 Determining Concrete Breakout Strength of Anchor in ShearJoel TanNoch keine Bewertungen

- Butterfly ValvesDokument27 SeitenButterfly ValvesИгорьNoch keine Bewertungen

- IIT Hyderabad Faculty Housing Design CalculationsDokument33 SeitenIIT Hyderabad Faculty Housing Design CalculationssmijusNoch keine Bewertungen

- 5 - Cantilever or Continuous Beam-Column ConnectionDokument1 Seite5 - Cantilever or Continuous Beam-Column ConnectionRohan ReddyNoch keine Bewertungen

- Master SpecificationsDokument395 SeitenMaster SpecificationsHaymanot BaynesagnNoch keine Bewertungen

- Anything Design of Roof Purlins and Roof TrussDokument7 SeitenAnything Design of Roof Purlins and Roof TrussAlex MachariaNoch keine Bewertungen

- HE-A Steel BeamsDokument2 SeitenHE-A Steel BeamsAbdul BasitNoch keine Bewertungen

- Raccordi A Inserto Forgiato PDFDokument3 SeitenRaccordi A Inserto Forgiato PDFpeppino di capriNoch keine Bewertungen

- MTO - Cathodic Protection - Temporary Systems and Below Ground Items - GreeceDokument5 SeitenMTO - Cathodic Protection - Temporary Systems and Below Ground Items - GreeceyamegNoch keine Bewertungen

- FOUNDATION ANALYSISDokument14 SeitenFOUNDATION ANALYSISJuli NirwantoNoch keine Bewertungen

- CS-150-2c3 - Pulled Bend Min THKDokument1 SeiteCS-150-2c3 - Pulled Bend Min THKJoanna NewtonNoch keine Bewertungen

- Facilities On Offshore Installations: Guide For Building and ClassingDokument209 SeitenFacilities On Offshore Installations: Guide For Building and ClassingKarthick VenkatswamyNoch keine Bewertungen

- Buckling of Free Pipe Under External PressureDokument38 SeitenBuckling of Free Pipe Under External Pressurevictortownshend100% (1)

- Clevis HangerDokument60 SeitenClevis HangerFernando RuizNoch keine Bewertungen

- 134004-SEP-MEC-DAT-0004 Rev.B2 PDFDokument11 Seiten134004-SEP-MEC-DAT-0004 Rev.B2 PDFDhakshina KNoch keine Bewertungen

- CYPECAD - User's Manual PDFDokument141 SeitenCYPECAD - User's Manual PDFBelak1Noch keine Bewertungen

- Design ReportDokument22 SeitenDesign Reportamit_saxena_10Noch keine Bewertungen

- Knife Gate Valves PDFDokument2 SeitenKnife Gate Valves PDFashish_pradhan75Noch keine Bewertungen

- Civil DesignDokument2 SeitenCivil Designarunasagar_2011Noch keine Bewertungen

- DNV 2.22 - 2008Dokument92 SeitenDNV 2.22 - 2008Thanhdong DoNoch keine Bewertungen

- 1 Beam Fails Ub305x165x54Dokument4 Seiten1 Beam Fails Ub305x165x54Elencheliyan PandeeyanNoch keine Bewertungen

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part4-Blow Out Strength in TensionDokument3 SeitenConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part4-Blow Out Strength in TensionVenu GopalNoch keine Bewertungen

- Oil-Water Design Installation & OperationDokument21 SeitenOil-Water Design Installation & OperationdsahmedNoch keine Bewertungen

- Corrosion Failure Analysis of Galvanized Steel Pipes in A Water Irrigation SystemDokument6 SeitenCorrosion Failure Analysis of Galvanized Steel Pipes in A Water Irrigation SystemC_rovere100% (1)

- Offshore & Structural Plate SizeDokument4 SeitenOffshore & Structural Plate Sizelaleye_olumideNoch keine Bewertungen

- Column Base Plate DesignDokument4 SeitenColumn Base Plate Design_jessecaNoch keine Bewertungen

- Column Base Plate Design (Bs5950-1:2000) : Project Job RefDokument4 SeitenColumn Base Plate Design (Bs5950-1:2000) : Project Job RefronyNoch keine Bewertungen

- Column Base Plate DesignDokument5 SeitenColumn Base Plate Design_jessecaNoch keine Bewertungen

- Column Base Plate Design CalculationDokument3 SeitenColumn Base Plate Design CalculationPilippenge Asanka Iraj LaknathaNoch keine Bewertungen

- Ruukki Hot Rolled Steels Standard Steel Grades Comparison Designation and Codes1Dokument6 SeitenRuukki Hot Rolled Steels Standard Steel Grades Comparison Designation and Codes1Cad AutocadNoch keine Bewertungen

- Structural Analysis HandoutDokument2 SeitenStructural Analysis HandouthgorNoch keine Bewertungen

- Maximum Width-To-Thickness Ratios For Compression PDFDokument3 SeitenMaximum Width-To-Thickness Ratios For Compression PDFtoliveira80Noch keine Bewertungen

- European Recommendations For The Design of Simple Joints in Steel Structures - 1st Draft 2003 - JaspartDokument152 SeitenEuropean Recommendations For The Design of Simple Joints in Steel Structures - 1st Draft 2003 - JaspartZelzozo Zel Zozo100% (3)

- !multi Storey Steel BuildingDokument111 Seiten!multi Storey Steel BuildingWexkat KulNoch keine Bewertungen

- Ec3 HandoutDokument1 SeiteEc3 HandoutflasnicugNoch keine Bewertungen

- Tata Steel - Blue Book - Advance - Section - Properties - For - Students PDFDokument20 SeitenTata Steel - Blue Book - Advance - Section - Properties - For - Students PDFshugd31085100% (1)

- 1 Historical Development and Characteristics of Structural SteelsDokument30 Seiten1 Historical Development and Characteristics of Structural Steelsron_dany100% (1)

- 10 Combined Axial Compression and Bending Handout PDFDokument6 Seiten10 Combined Axial Compression and Bending Handout PDFtoliveira80Noch keine Bewertungen

- The Design Manual For Moment and Stiff of Column PlatesDokument135 SeitenThe Design Manual For Moment and Stiff of Column PlatesjdkelleyNoch keine Bewertungen

- Commentary and Worked Examples en 1993-1-5 PDFDokument242 SeitenCommentary and Worked Examples en 1993-1-5 PDFtoliveira80Noch keine Bewertungen

- Limit State DesignDokument12 SeitenLimit State DesignEzhil KumarNoch keine Bewertungen

- 10 Combined Axial Compression and Bending Handout PDFDokument6 Seiten10 Combined Axial Compression and Bending Handout PDFtoliveira80Noch keine Bewertungen

- Chapter3 PDFDokument25 SeitenChapter3 PDFtoliveira80Noch keine Bewertungen

- Eurocode 3 steel joint design guideDokument2 SeitenEurocode 3 steel joint design guideneverreturnNoch keine Bewertungen

- Templates and Reports 170 EnuDokument33 SeitenTemplates and Reports 170 EnuAndres Hugo GalloNoch keine Bewertungen

- Steel Column Design Eurocode 3Dokument2 SeitenSteel Column Design Eurocode 3Jonp4ul_MiddletonNoch keine Bewertungen

- Limit State DesignDokument12 SeitenLimit State DesignEzhil KumarNoch keine Bewertungen

- Composite Deck DesignDokument16 SeitenComposite Deck Designvejanidb100% (1)

- Paper - High Strength Steel Can Reduce Weight ThicknessDokument24 SeitenPaper - High Strength Steel Can Reduce Weight ThicknessaunyaneeNoch keine Bewertungen

- Comp Constr PDFDokument2 SeitenComp Constr PDFtoliveira80Noch keine Bewertungen

- ECCS Examples To Eurocode 3Dokument124 SeitenECCS Examples To Eurocode 3toliveira80100% (6)

- Composite Deck DesignDokument16 SeitenComposite Deck Designvejanidb100% (1)

- EuroCode 4Dokument420 SeitenEuroCode 4Mohamed Tahar Allagui100% (3)

- EC4 DesignOfCompositeColumns PDFDokument27 SeitenEC4 DesignOfCompositeColumns PDFtoliveira80100% (1)

- Composite ConstructionDokument524 SeitenComposite ConstructionHarold Abubo Haber67% (3)

- Composite Section - Tutorials - (CSI Wiki)Dokument4 SeitenComposite Section - Tutorials - (CSI Wiki)Wilson100% (1)

- Scott & Whittle 2005 Moment Redistribution Effects in BeamsDokument13 SeitenScott & Whittle 2005 Moment Redistribution Effects in BeamsRm1262Noch keine Bewertungen

- HND Structural Analysis and Design Assignment 2017.11.19 - EsoftDokument11 SeitenHND Structural Analysis and Design Assignment 2017.11.19 - EsoftSasitha SooriyabandaraNoch keine Bewertungen

- 1984 JN Reddy A Refined Nonlinear Theory of Plates With Transverse Shear Deformation IJSS 20Dokument16 Seiten1984 JN Reddy A Refined Nonlinear Theory of Plates With Transverse Shear Deformation IJSS 20fritz2000Noch keine Bewertungen

- SLE123 - Sample Quiz 03 QuestionsDokument14 SeitenSLE123 - Sample Quiz 03 QuestionsNinaNoch keine Bewertungen

- The Modular Compact Rheometer SeriesDokument20 SeitenThe Modular Compact Rheometer SeriesSupriyo PNoch keine Bewertungen

- 3 Thermodynamics TDEEDokument129 Seiten3 Thermodynamics TDEENikhilNoch keine Bewertungen

- Design of Torsion ReviseDokument6 SeitenDesign of Torsion ReviseAnton_Young_1962Noch keine Bewertungen

- Fracture ToughnessDokument31 SeitenFracture ToughnessX800XLNoch keine Bewertungen

- Freely Falling Bodies GuideDokument10 SeitenFreely Falling Bodies GuidePrecious Grace F. PeregrinoNoch keine Bewertungen

- Introduction To CFX: Domains and Boundary ConditionsDokument39 SeitenIntroduction To CFX: Domains and Boundary ConditionsJoonhong KimNoch keine Bewertungen

- Calculating The Cavitation NumberDokument2 SeitenCalculating The Cavitation NumberSunil Kumar P GNoch keine Bewertungen

- CH 01Dokument49 SeitenCH 01fatface3000100% (1)

- Lab ReportDokument3 SeitenLab ReportTom DonohueNoch keine Bewertungen

- Composite BeamsDokument16 SeitenComposite BeamsNoureddine SemaraNoch keine Bewertungen

- Lateral Stability of Prestressed Precast Concrete Girders During Lifting: Study CaseDokument9 SeitenLateral Stability of Prestressed Precast Concrete Girders During Lifting: Study Caseel000011Noch keine Bewertungen

- Compression of Granular Materials: Gholamreza Mesri and Barames VardhanabhutiDokument24 SeitenCompression of Granular Materials: Gholamreza Mesri and Barames VardhanabhutiRat Jaga CivilNoch keine Bewertungen

- Modeling &analysis of Aluminum Alloy Crankshaft For Optimization of Weight Using FeaDokument7 SeitenModeling &analysis of Aluminum Alloy Crankshaft For Optimization of Weight Using FeadarkruseNoch keine Bewertungen

- Belt DrivesDokument35 SeitenBelt Drives222Gaurav AherNoch keine Bewertungen

- Gyrocompass Manual All TypeDokument473 SeitenGyrocompass Manual All TypeZemia LubaslikaNoch keine Bewertungen

- Proposed Macro-Model For The Analysis of Infilled Frame StructuresDokument12 SeitenProposed Macro-Model For The Analysis of Infilled Frame StructuresAngga AriefNoch keine Bewertungen

- Lecture - 10 - Mech PropDokument4 SeitenLecture - 10 - Mech PropRajib BaruaNoch keine Bewertungen

- AERO3261 Turbojet: Ass. Prof Dries VerstraeteDokument25 SeitenAERO3261 Turbojet: Ass. Prof Dries VerstraeteTuan HoangNoch keine Bewertungen

- Revolusi Instrumentasi AlatDokument8 SeitenRevolusi Instrumentasi AlatMuchlis fauzi100% (1)

- Physics ECET by AANM VVRSR GVLDokument128 SeitenPhysics ECET by AANM VVRSR GVLnandaNoch keine Bewertungen

- Convective Mass Transfer PDFDokument14 SeitenConvective Mass Transfer PDFAnonymous 4XZYsImTW5100% (1)

- Tabla Periódica de VibracionesDokument1 SeiteTabla Periódica de VibracionesCristian CerqueraNoch keine Bewertungen

- Dynamic Balancing Machines Measure and Correct UnbalanceDokument9 SeitenDynamic Balancing Machines Measure and Correct UnbalanceAmmar Al-Aghbari100% (1)

- KZN Jit MechanicsDokument48 SeitenKZN Jit Mechanicsrowan chibiNoch keine Bewertungen

- Calculation of metallic pillar stabilityDokument2 SeitenCalculation of metallic pillar stabilityVirginia Elena IordacheNoch keine Bewertungen

- Nifft B.tech MME Syllabus.Dokument36 SeitenNifft B.tech MME Syllabus.Rajesh0% (1)