Beruflich Dokumente

Kultur Dokumente

BMW E23 24 28 Odogear

Hochgeladen von

porkfaceOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

BMW E23 24 28 Odogear

Hochgeladen von

porkfaceCopyright:

Verfügbare Formate

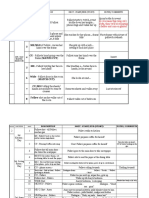

Instrument Cluster Light Upgrade and Odometer Gear Replacement

Cost: $25 (plus shipping) each gear, $3.00 for the bulbs Pros: Fairly easy repair, Working odometer, Easier to see instruments Cons: Delicate job, Working odometer (for areas where insurance cost is based in part on mileage) Time: ~3 hours A very common problem in the BMW 635CSi is the breaking of the plastic gears in the instrument cluster. The most likely culprit of this would be gears made of a material not able to hold up to the temperature changes the poorly- insulated instrument pod might be subjected. After 15 plus years, the gears can become brittle. A trip meter and the odometer which has ceased recording mileage is a symptom of broken odometer gears. Most owners report their odometer fails after they reset the trip meter - particularly if the car is moving. Both of these actions - and in particular the latter - put a greater amount of stress on the gears than any other time, thus causing the brittle gears to break. After determining which gear I needed, I ordered the replacement gear from http://members.ispwest.com/jkcaplan/gearwebpage/gear.html (please tell them Z3Bimmer.com sent you). They have reproduced gears made from a stronger, more heat tolerant resin material. The gears are produced using molds cast from OEM gears. I only ordered the one smaller gear (called E1). One of these days I may buy and replace the other 2 gears just so I won't have to worry about them breaking. These procedures are based on my 1985 635CSiA with an ///M style steering wheel and no airbag. I don't have enough experience with other years and variations of the 635 to determine how many variances you might experience applying these procedures to your car. If you have the original dim 3w instrument cluster light bulbs, replacing them with a set of 5w bulb will make the instruments much easier to read at night. I used a pair of Sylvania 2825 European Lamps. I understand the Sylvania 168 will also work.

Some say it isn't necessary to remove the steering wheel. I did it simply because without an airbag, it is very easy to do and gets it out of your way. If you decide not to remove the steering wheel, simply skip this and the next step. Using a bladed screwdriver, remove the center cap from the steering wheel.

Using a 22mm socket with a 3 inch or more extension, remove the steering wheel nut. Before removing the steering wheel, note the V shaped mark etched on the spindle, and the line etched on the steering wheel adjacent to the hole. These are the reference points for properly installing the steering wheel. Remove the nut and the steering wheel from the spindle.

Remove 4 screws to remo ve the knee panel.

Remove the connectors and vacuum hose from the knee panel mounted equipment. Note where they came from...or take pictures before hand :^)

Loosen the steering column lever to gain access to and remove 3 screws holding the bottom steering column cover.

Using a thin bladed screw driver, carefully pry the bottom of the check panel cover out. The check panel cover is held in place with 2 tabs at the top. Do not try to pry the cover off from the top.

Remove 3 screws holding the check panel module in place.

Carefully pull the module out so that the connector to the cable bundle at the back of the check panel module is accessible. Carefully disconnect the wire bundle connector and set the check panel module aside in a safe place.

Use a 13mm socket wrench to remove 2 bolts on either side of the steering column. These hold the steering column in place. When removing the second bolt, support the steering column and gently lower it until it rests in place.

Using a thin bladed screw driver, carefully pry loose the molding to the right of the instrument cluster.

Remove the 2 right side instrument cluster mounting screws.

Remove the 2 left side instrument cluster mounting screws.

Place a thick towel or other padded covering over the top of the steering column. Gently pull the instrument cluster out to lay face down on the top of the steering column.

Remove the fog light switch light bulb by pulling the bulb straight out of the yellow holder.

Remove the head light switch light bulb by pulling the bulb straight out of the yellow holder (green arrow). While spreading the 2 locking tabs, disconnect the headlight wire bundle connector (blue arrow). Be careful to pull the connector straight out and to not break the connector. Disconnect the speedometer wire bundle (red arrow). Be careful to pull the connector straight out and to not break the connector.

Disconnect the odometer wires (red arrows), the main SI board bundle connector (blue arrow), and the Gas/Temp gauge bundle connectors (green arrow). Connectors should be disconnected in the direction of the arrows. Be careful to pull the connector straight out and to not break the connector.

Disconnect the fog light switch wires (red arrows) and the Anti-Lock instrument bulb (green arrow) Be careful to pull the connector straight out and to not break the connector. After these connectors are disconnected, the instrument cluster will be freed.

Lay the instrument cluster face down on a soft, wellpadded surface. A throw pillow works nicely. If you are changing the instrument cluster light bulbs, this is the time to do it. Remove the two bulb sockets by turning the socket left 90 degrees to unlock it. You can use a 5/6 open end wrench to turn the socket. Simply slide the old bulb out of the socket and replace with the new one. Lock the bulb and socket back in place. I also took this opportunity to remove the other bulbs (along the bottom of the cluster) and clean them. Over the years, they had accumulated a layer of dirt. After

cleaning the bulbs, they too were noticeably brighter.

If you will be removing the tachometer for some reason, you will need to: Remove the real- time mileage gauge wire (red arrow) Press the tachometer locking tabs in the direction of the blue arrows, and remove the locking key by pulling in the direction of the green arrow.

Remove the 8 instrument cluster screws. Gently pull the instrument cluster electronics straight up and out of the body. Set the body and the pillow aside.

Lay the cluster assembly face up on a sturdy surface. The speedometer is attached to the circuit board by a pin connector on the circuit board. At the points indicated, gently rock, lift and disconnect the speedometer from the circuit board. Be especially careful not to touch and damage the instrument needles. They are easily bent. Set the remainder of the instrument assembly aside where it cannot get damaged.

Inspect the gears on the right side of the speedometer. Determine which gear(s) need(s) replacing. Remove the gear cover as necessary to get to the larger gears. Remove any old gear fragments from the spindles. Gently shake out any gear fragments that may be loose in the speedometer gear case.

Press the new gear(s) fully in place on the appropriate spindle(s). Make sure each interlocks with the other gears. You can gently rotate the gears to ensure they drive each other.

Reassemble and reinstall the instrument cluster in reverse order of disassembly. One of the reasons for the breaking of the odometer gears is in part because of the material of the gears, but also because the dash under which the instrument cluster is mounted is not isolated at all. Exposure to sun and cold contributes to making the gears brittle. Before remounting my cluster, I lined the underneath of the dash with insulation material to help protect the instrument cluster from the Sandy Eggo heat.

Copyright 2003 Z3Bimmer.com All Rights Reserved

Das könnte Ihnen auch gefallen

- Testing The AFM's Air Temperature SensorDokument1 SeiteTesting The AFM's Air Temperature SensorporkfaceNoch keine Bewertungen

- W211 SBC Brakes Bleeding MainDokument4 SeitenW211 SBC Brakes Bleeding MainnikNoch keine Bewertungen

- Service Booklet: Passenger CarsDokument0 SeitenService Booklet: Passenger CarsEngine Tuning Up100% (1)

- F12 M6 CIC To NBT EVO RetrofitDokument6 SeitenF12 M6 CIC To NBT EVO RetrofitErmin CisicNoch keine Bewertungen

- Sportautomatic DIY: Upgrading Cars From non-SATDokument16 SeitenSportautomatic DIY: Upgrading Cars From non-SATArik YeganyanNoch keine Bewertungen

- Service Manual: LC-32A33T LC-37A33TDokument38 SeitenService Manual: LC-32A33T LC-37A33TSetiawan Abdul RochimNoch keine Bewertungen

- BMW E60 Park Light ReplaceDokument10 SeitenBMW E60 Park Light ReplaceJeromeNoch keine Bewertungen

- BMW E46 330i Cooling System Water HosesDokument1 SeiteBMW E46 330i Cooling System Water Hosesdr_pardeeNoch keine Bewertungen

- DIY Heated Seats RetrofitDokument27 SeitenDIY Heated Seats RetrofitvalymadNoch keine Bewertungen

- Timing Cover 190EDokument8 SeitenTiming Cover 190ESergio Belmar CrisostoNoch keine Bewertungen

- Front Axle BMW E60 Sedan 47750Dokument2 SeitenFront Axle BMW E60 Sedan 47750Kifah ZaidanNoch keine Bewertungen

- E83 Car and Key Memory SettingsDokument4 SeitenE83 Car and Key Memory SettingspolidorosNoch keine Bewertungen

- BMW 528i Sunroof RepairDokument30 SeitenBMW 528i Sunroof RepairNerijus BartusevičiusNoch keine Bewertungen

- Body - GeneralDokument21 SeitenBody - GeneralEmre EmlekNoch keine Bewertungen

- Chrysler IIIH Engine Assembly Pentastar 3.6 SYNCHRONIZATIONDokument22 SeitenChrysler IIIH Engine Assembly Pentastar 3.6 SYNCHRONIZATIONScribdTranslationsNoch keine Bewertungen

- BMW Paddle Instalação e AtivaçãoDokument32 SeitenBMW Paddle Instalação e AtivaçãoNicolas MNoch keine Bewertungen

- E46 AirbagDokument6 SeitenE46 AirbagTutzu99Noch keine Bewertungen

- BMW E32 EDC SuspensionDokument7 SeitenBMW E32 EDC SuspensionXaockaNoch keine Bewertungen

- Airbag System (SRS)Dokument6 SeitenAirbag System (SRS)خليل مقبوعNoch keine Bewertungen

- HID Retrofit For Halogen HeadlightsDokument32 SeitenHID Retrofit For Halogen Headlightsanon9114095Noch keine Bewertungen

- Oem Rear Fog Light DiyDokument18 SeitenOem Rear Fog Light DiyJosé ShermanNoch keine Bewertungen

- G35 & 350Z Rev2 Clutch Bracket InstructionsDokument33 SeitenG35 & 350Z Rev2 Clutch Bracket InstructionsChelsey VezinaNoch keine Bewertungen

- Fitting A MK2.5 Spoiler PDFDokument7 SeitenFitting A MK2.5 Spoiler PDFAlexandru-Mihai NitaNoch keine Bewertungen

- Haltech Support CenterDokument15 SeitenHaltech Support Centerkorovnikovdenis8Noch keine Bewertungen

- SBT Electrical Distribution Centre - E87, E90, E91, E92Dokument2 SeitenSBT Electrical Distribution Centre - E87, E90, E91, E92Engsolution LdaNoch keine Bewertungen

- SI Repair Instructions For Seat Belt Tensioner Ignition CircuitDokument15 SeitenSI Repair Instructions For Seat Belt Tensioner Ignition CircuitNadszyszkownik KumoternikNoch keine Bewertungen

- VW Passat B5 1.8T Timing Belt Replacement DIYDokument26 SeitenVW Passat B5 1.8T Timing Belt Replacement DIYaweed100% (1)

- A540 ToyotaDokument7 SeitenA540 ToyotaporkfaceNoch keine Bewertungen

- Switches Senders and Sensors TAS 2018Dokument89 SeitenSwitches Senders and Sensors TAS 2018Sean OsborneNoch keine Bewertungen

- FaultMemoryList VIN7-B914278 PDFDokument2 SeitenFaultMemoryList VIN7-B914278 PDFZakaria ElNoch keine Bewertungen

- WAPU Overhaul BZBDokument8 SeitenWAPU Overhaul BZBNedim ErkocevicNoch keine Bewertungen

- BMW E46 2 Driver Information Internet-1Dokument37 SeitenBMW E46 2 Driver Information Internet-1Salisbur100% (1)

- Abs/A ASC T Pum MP Block R Refurbish: Part 1: D Disassemb LyDokument10 SeitenAbs/A ASC T Pum MP Block R Refurbish: Part 1: D Disassemb LyEd MoralesNoch keine Bewertungen

- BMW Cruise Control E23 E28Dokument14 SeitenBMW Cruise Control E23 E28onukvedat72190% (1)

- 12 ZF 6HP26 TeardownDokument32 Seiten12 ZF 6HP26 TeardownSanda NeumanNoch keine Bewertungen

- E60 - Navi RetrofitDokument19 SeitenE60 - Navi RetrofitaizullinNoch keine Bewertungen

- Front Impact Severity Sensor Removal and InstallationDokument2 SeitenFront Impact Severity Sensor Removal and InstallationMichael HernandezNoch keine Bewertungen

- BMW 5 Series E34 Service ManualDokument67 SeitenBMW 5 Series E34 Service ManualRoland SzaboNoch keine Bewertungen

- 2008 Mazda MPV - Brake - Conventional Brake SystemDokument28 Seiten2008 Mazda MPV - Brake - Conventional Brake Systemlo mio es mio100% (1)

- Chapter Pressure SensorsDokument24 SeitenChapter Pressure SensorsPiotr ProkulskiNoch keine Bewertungen

- Manual Transmàssion 6 Speed PDFDokument55 SeitenManual Transmàssion 6 Speed PDFIvan Alex Escobar100% (1)

- MST Removing and Installing Both Front Brake DisksDokument4 SeitenMST Removing and Installing Both Front Brake DisksNeeDog20Noch keine Bewertungen

- Traction Control Systems (TCS) Does Your Shop Need A Dvom?: - The Opposite of ABSDokument11 SeitenTraction Control Systems (TCS) Does Your Shop Need A Dvom?: - The Opposite of ABSPutu Budi DharmaNoch keine Bewertungen

- 219 Ho KG (GC, RP) 08-16-02Dokument41 Seiten219 Ho KG (GC, RP) 08-16-02arkhom1100% (1)

- Sensotronic Brake ControlDokument22 SeitenSensotronic Brake ControlMahesh Shrishail HulkundNoch keine Bewertungen

- Removing and Installing Mechatronic Unit For Dual Clutch Gearbox - J743Dokument93 SeitenRemoving and Installing Mechatronic Unit For Dual Clutch Gearbox - J743Sandro CozaciucNoch keine Bewertungen

- Getrag Special Tools 6DCT250 (DPS6, DC4) : L K Basic Tool KitDokument4 SeitenGetrag Special Tools 6DCT250 (DPS6, DC4) : L K Basic Tool KitHumberto Cadori Filho100% (1)

- E46 Door Handles and Locks AdjustmentDokument2 SeitenE46 Door Handles and Locks Adjustmentpatr01Noch keine Bewertungen

- Mini Cooper ATF Change PDFDokument21 SeitenMini Cooper ATF Change PDFLUKSmadrizNoch keine Bewertungen

- Master Tugger Hyd Tube PullerDokument5 SeitenMaster Tugger Hyd Tube Pullerjromero_rpg0% (1)

- Charging 2001-04 PDFDokument19 SeitenCharging 2001-04 PDFoz23Noch keine Bewertungen

- Schimbare Baterie E90Dokument3 SeitenSchimbare Baterie E90Andrei PavelNoch keine Bewertungen

- Audi 80Dokument5 SeitenAudi 80dattilom100% (1)

- 16.heating, Ventilation, Air ConditioningDokument112 Seiten16.heating, Ventilation, Air Conditioningrobin machadoNoch keine Bewertungen

- Maintenance and Care: Form No.8CC7-EA-11HDokument52 SeitenMaintenance and Care: Form No.8CC7-EA-11HChaiyakorn Aaron100% (1)

- 2009-12-10 025739 Mercedes 722 5 Trans PDFDokument5 Seiten2009-12-10 025739 Mercedes 722 5 Trans PDFjuanNoch keine Bewertungen

- Intermittent Transmission Clutch Shudder Dps6 Automatic Transmission And/Or Transmission Fluid Leak TSB 14-0047Dokument6 SeitenIntermittent Transmission Clutch Shudder Dps6 Automatic Transmission And/Or Transmission Fluid Leak TSB 14-0047peter064Noch keine Bewertungen

- A540 ToyotaDokument7 SeitenA540 ToyotaporkfaceNoch keine Bewertungen

- 319 Mod 6-2 SAS Leak Detection (WH MG) 7-17-02Dokument4 Seiten319 Mod 6-2 SAS Leak Detection (WH MG) 7-17-02porkfaceNoch keine Bewertungen

- Accord 94 95Dokument219 SeitenAccord 94 95porkfaceNoch keine Bewertungen

- Installation Instructions: H-2003-0152 31-Mar-05Dokument1 SeiteInstallation Instructions: H-2003-0152 31-Mar-05porkfaceNoch keine Bewertungen

- Regina BookDokument38 SeitenRegina Bookporkface100% (1)

- CF-48 Reference Manual: Personal ComputerDokument64 SeitenCF-48 Reference Manual: Personal ComputerporkfaceNoch keine Bewertungen

- BMW Tools Catalog 2012Dokument95 SeitenBMW Tools Catalog 2012Arvydas Raščikas67% (6)

- The Battery: SubjectDokument36 SeitenThe Battery: SubjectporkfaceNoch keine Bewertungen

- Bosch Oxygen SensorsDokument31 SeitenBosch Oxygen SensorsmihajlovichenkelNoch keine Bewertungen

- Service Time Schedule 308Dokument101 SeitenService Time Schedule 308porkfaceNoch keine Bewertungen

- BMW Dmes, EtcDokument1 SeiteBMW Dmes, EtcporkfaceNoch keine Bewertungen

- Manual EnglishDokument31 SeitenManual EnglishporkfaceNoch keine Bewertungen

- s38 Base SettingDokument3 Seitens38 Base SettingporkfaceNoch keine Bewertungen

- Scopes and TransducersDokument72 SeitenScopes and TransducersporkfaceNoch keine Bewertungen

- Automatic Transmisson Aw55-50 SN - Volvo XC 90 Opel VectraDokument16 SeitenAutomatic Transmisson Aw55-50 SN - Volvo XC 90 Opel VectraNovacovici Dorel100% (1)

- 02 - Engine Electronics IPOsDokument44 Seiten02 - Engine Electronics IPOsporkface82% (11)

- Mr. West: Emma Mr. West: Emma Mr. West: Emma Mr. West: Emma Mr. West: Emma Mr. WestDokument2 SeitenMr. West: Emma Mr. West: Emma Mr. West: Emma Mr. West: Emma Mr. West: Emma Mr. WestNgân GiangNoch keine Bewertungen

- Chicago/Turabian 17 Edition Format and Documentation: Formatting Your PaperDokument4 SeitenChicago/Turabian 17 Edition Format and Documentation: Formatting Your Paperpure soulNoch keine Bewertungen

- TongDokument3 SeitenTongTangaka bobo0% (2)

- Complete Infinitynest Starter GuideDokument9 SeitenComplete Infinitynest Starter GuideSeptian Citra KusumaNoch keine Bewertungen

- MCQ Type QuestionsDokument2 SeitenMCQ Type QuestionsAnonymous rn5Te9MwkNoch keine Bewertungen

- The Hunter 2012 Unlock All Animals PDFDokument3 SeitenThe Hunter 2012 Unlock All Animals PDFCorneliusNoch keine Bewertungen

- UB9 Bertoglio PDFDokument26 SeitenUB9 Bertoglio PDFaarrNoch keine Bewertungen

- Yoga Therapy & Integrative Medicine: Where Ancient Science Meets Modern MedicineDokument11 SeitenYoga Therapy & Integrative Medicine: Where Ancient Science Meets Modern MedicineAshu ToshNoch keine Bewertungen

- Transformation of The Videogame IndustryDokument2 SeitenTransformation of The Videogame IndustrydigitalbridgemediaNoch keine Bewertungen

- Semi ColonDokument21 SeitenSemi ColonJopax CanedaNoch keine Bewertungen

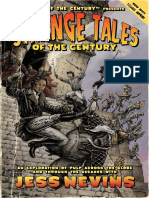

- StrangeTalesOTC PDFDokument522 SeitenStrangeTalesOTC PDFRichard Loveday100% (6)

- Selection Process For Candidates 3d Character Animator 2018 1Dokument3 SeitenSelection Process For Candidates 3d Character Animator 2018 1Samuel DuarteNoch keine Bewertungen

- Steinberger R Trem Maintenance Web PDFDokument1 SeiteSteinberger R Trem Maintenance Web PDFOscar Antonio HumanoNoch keine Bewertungen

- EXTRACT - The Truth About The Harry Quebert AffairDokument23 SeitenEXTRACT - The Truth About The Harry Quebert AffairKristy at Books in Print, Malvern0% (1)

- Egyptian Gods & Mythology - Hollywood SubliminalsDokument10 SeitenEgyptian Gods & Mythology - Hollywood SubliminalsVen GeanciaNoch keine Bewertungen

- Hyperdesmo Polyurea 2K HCDokument3 SeitenHyperdesmo Polyurea 2K HCmeena nachiyarNoch keine Bewertungen

- The Pilgrim's Progress by John Bunyan (PDFDrive)Dokument96 SeitenThe Pilgrim's Progress by John Bunyan (PDFDrive)Adeniyi Adedolapo OLanrewajuNoch keine Bewertungen

- WP 5020Dokument2 SeitenWP 5020Mark CheneyNoch keine Bewertungen

- Reading Worksheet: Soccer Balls of The Future - What Will They Be Like?Dokument2 SeitenReading Worksheet: Soccer Balls of The Future - What Will They Be Like?Leonardo MORENO RAMIREZNoch keine Bewertungen

- BG 15.15 - Krsna Is Source of Knowledge Remembrance & ForgetfulnessDokument1 SeiteBG 15.15 - Krsna Is Source of Knowledge Remembrance & ForgetfulnessSiddharth Hosangadi - Sridamasakha dasNoch keine Bewertungen

- 14 PatolliDokument8 Seiten14 PatolliCaroline Martins Nacari100% (1)

- Musical Instruments of IndonesiaDokument3 SeitenMusical Instruments of IndonesiaAimee HernandezNoch keine Bewertungen

- JCR Vol. 08 No. 02: Symposium On The AtonementDokument245 SeitenJCR Vol. 08 No. 02: Symposium On The AtonementChalcedon Foundation100% (2)

- Ramazani's A Transnational PoeticsDokument3 SeitenRamazani's A Transnational PoeticsPatrícia AnziniNoch keine Bewertungen

- Gre Analogies: A Racket Is Used To Play TennisDokument9 SeitenGre Analogies: A Racket Is Used To Play TennisaslamzohaibNoch keine Bewertungen

- Digital Watermarking Using Matlab: B.Uma Surya SaiDokument4 SeitenDigital Watermarking Using Matlab: B.Uma Surya SaiparamkusamNoch keine Bewertungen

- 3rd Generation Intel® Core™ I5 ProcessorsDokument2 Seiten3rd Generation Intel® Core™ I5 Processors8336121Noch keine Bewertungen

- Medieval Concept of GodDokument13 SeitenMedieval Concept of GodEJ JoseNoch keine Bewertungen

- Ceating Abundance Ram SutrasDokument1 SeiteCeating Abundance Ram SutrasAbhijeet DeshmukkhNoch keine Bewertungen

- Bethel Academy-Senior High School Department: Division of CaviteDokument3 SeitenBethel Academy-Senior High School Department: Division of CaviteVIRGILIO JR FABI100% (1)