Beruflich Dokumente

Kultur Dokumente

SPIE 6422-32 Risley Prisms Torales

Hochgeladen von

norbdudeCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SPIE 6422-32 Risley Prisms Torales

Hochgeladen von

norbdudeCopyright:

Verfügbare Formate

High precision prism scanning system

G. Garca-Torales

*

, J. L. Flores, Roberto X. Muoz.

Dpto. of Electronic, Univ. of Guadalajara/CUCEI, Av. Revolucin 1500,

Guadalajara Jal., MX CP 44840;

ABSTRACT

Risley prisms are commonly used in continuous scanning manner. Each prism is capable of rotating separately about a

common axis at different speeds. Scanning patterns are determined by the ratios of the wedge angles, the speed and

direction of rotation of both prisms. The use of this system is conceptually simple. However, mechanical action in most

applications becomes a challenge often solved by the design of complex control algorithms. We propose an electronic

servomotor system that controls incremental and continuous rotations of the prisms wedges by means of an auto-tuning

PID control using a Adaline Neural Network Algorithm, NNA.

Keywords: Risley prism, scnning system, Adaline, automatic control

1. INTRODUCTION

The Risley prism scanning system consists in a pair of sequential wedge prisms, which have wedge angles used to

deviate a light beam has been used in several applications. Each prism of the system is capable of rotating about the

optical scan axis at angular speeds. A focussed laser beam propagated through the prisms, along the optical scan axis is

deviated in a direction according to the relative orientation of the prisms with respect to each other.

When the individual prisms are rotated clockwise or counterclockwise, the combined deviation angle and the orientation

phase change with time, such that the image spot traces out a vector pattern

1

. These set of wedge prisms has been used in

many scanning and laser applications where accurate wave front positioning is required. Such is the case also in many

interferometric systems, like the shearing types, where the shear of the wavefront under test has to be known.

Advantages and limitations of the Risley prism system in specific applications have been presented and solved for many

authors

2-7

.

Figure 1 shows the propagation of a ray, incident in the object space along the optical axis, as it passes through the

Risley prisms to the detection plane. Consider that both prisms have the same refraction index, a fixed refracting angle

and rotates at a fixed selectable angular speed e1 and e2, respectively. A set of linear and circular scan patterns can be

generated regarding two cases: when the two wedge prisms rotate in the same direction with selected angular velocities,

and when the two wedge prisms rotate in opposite directions, always whit the possibility of selecting the initial relative

orientation of the prisms.

Due to the wide use of Risley prisms, special-purpose mathematical ray-trace models have been developed. In scanning

techniques, for example, the ratio of velocity, the deviation angles and the relative angle between prisms rotations is of

interest. However, in the alignment and positioning applications we are interested solely in the image or pupil. We

develop a simple ray trace formulation to demonstrate the performance of the laser pointer director, by the use of

generalized matrix equations.

*garcia.torales@cucei.udg.mx; phone (052)33 394-259-20; fax (052)33 394-259-20 ext. 7744

Sixth Symposium Optics in Industry, edited by Julio C. Gutirrez-Vega, Josu Dvila-Rodrguez, Carlos Lpez-Mariscal,

Proc. of SPIE Vol. 6422, 64220X, (2007) 0277-786X/07/$18 doi: 10.1117/12.742275

Proc. of SPIE Vol. 6422 64220X-1

(a) (b)

Fig. 1 Risley system: The relative angle between prisms determines the deviation angle and also the position of the ray on

the plane. (a) View of a circular pattern generated when one is prism is rotated 360 respect to stationary prism. (b)

Lateral view of the prism system.

2. RAY TRACE EQUATIONS

We use the vector ray-trace methodology, incorporating the vector transfer and the refraction equations at the prism

surfaces.We developed a simple ray-trace program to model the ray propagation through the Risley prisms. With Pi is

the point at the corresponding surface U

i

the direction of propagation of each point. We can find the refraction R

i

and

translation T

i

equations for the hole system that can be written as:

(

=

I

P I N F I

R

i

T

i i

i

0

(1)

and

(

(

(

+

|

|

.

|

\

|

=

+

I U AI

dn

t

I

T T

i

i i

1 *

'

0

, 1

. (2)

Here the term

i

dn

t

'

is constant and depending on the physical parameter of the prisms and their relative position, and A

is the unit vector along the optical axis, F

i

is defined as the deviation power of the prisms given by

( ) ( ) |

i i i i i

n n F | cos cos

1 1

=

+ +

. (3)

Then for a six surfaces system we can apply iteratively equations 1 and 2 in order to obtain the position and direction for

any ray that was propagated through the wedge prisms by

Proc. of SPIE Vol. 6422 64220X-2

( ) ( )

(

=

(

0

0 0

1 1 1 , 2 2 2 , 3 3 2 3 , 4 4 4 , 5 5

5

5 5

' ' ' '

P

U n

R T R T R T R T R

P

U n

e e . (4)

According with eq.4, it is necessary to know the initial conditions; the starting point coordinates and its direction, the

prisms parameters; refraction index, wedge angle and the relative position between prisms, besides, the system

parameters; distances between prism and the detection plane. All these parameters feed the data requirements of servo

controller which drives the servomotor in order to achieve the desire position of the laser beam. Next, we show some

general characteristic of servo controller system.

3. OPTO-MECHANICAL DESING

In practice, accuracy in the determination of laser point displacement is limited by the error in the deflection angle that

depends on three essential parameters: (a) the apex angle c , which depends on the fabrication process, (b) the index of

refraction n that depends on the quality of the glass, and (c) the relative angle between prisms c which depends on the

accuracy of the rotary holders. All surfaces of the wedges must be of high quality, e. g. figure error less than /20, and

pex angles with tolerances on the order of arc seconds. Nowadays, transparent materials with high degree of

homogeneity are commercially available, e.g., ultra pure synthetic fused silica.

Therefore, the deciding parameter over the net deviation is the relative angle. Hence, a precise optomechanical design

for mutual orientation and rotation of the wedges is necessary. The precision and accuracy of the mechanical system

determine the degree of control upon the wedge rotation. Commercial rotary holders perform rotations in the order of

minutes or even seconds of arc, however, most of them do not permit change parameters freely. Next, we show our

proposed to control the wedges by servo motors controlled with Adaline Neural Network

8

.

Figure 2 shows a schematic drawing of the servo motion system that controls the angular position of the prisms. Each

prism is mounted in a plastic base attached to the tension pulley that is driven by the servo motor. Speed motion and

position are controlled by the servo motor is controlled by a servo amplifier. Some of the main specifications of the

servo motor used are its size down to 40 mm square, fast response with rapid acceleration and mechanical time constants

down to 2 msecs, maintenance-free 3 phase brushless construction, peak torque ratings up to 7.2 Nm, ratings up to 250

Nm. Encoder commutation facilitates sinewave drive technology to provide smooth operation and high resolution up to

131,072 counts/rev.

Servo motor 1

Encoder 1

Prism system

Tension pulley

Servo motor 2

(a) (b)

Fig. 2 Opto-mechanical device for the prism system. (a) View of the hole system, (b) Cross-section showing the prisms

position.

Proc. of SPIE Vol. 6422 64220X-3

4. PID CONTROLLER

Servomotors are extensively used to perform highly precise positioning systems. Servo control in general can be divided

into two fundamental classes of problems. The first class deals with command tracking. It addresses the question of how

well does the actual motion follow what is being commanded. The typical commands in rotary motion control are

position, velocity, acceleration and torque. A second problem deals with the disturbance rejection characteristics of the

system. Disturbances can be anything from torque disturbances on the motor shaft to incorrect motor parameter

estimations used in the feed-forward control. Here, P.I .D. (Proportional Integral and Derivative position loop) control

is used to combat these types of problems. In contrast to feed-forward control, which predicts the needed internal

commands for zero following error, disturbance rejection control reacts to unknown disturbances and modelling errors.

Complete servo control systems combine both these types of servo control to provide the best overall performance. Even

though the fundamental concepts of servo motion control have not changed significantly in the last years, new

technologies using servo systems have improved the accuracy on control positioning. Improve transient response times,

reduce the steady state errors and reduce the sensitivity to load parameters

9

.

Controllers are designed to eliminate the need for continuous operator attention. Controllers are used to automatically

adjust some variable to hold the measurement (or process variable) at the set-point. The set-point is where you would

like the measurement to be. Error is defined as the difference between set-point and measurement. The variable being

adjusted is called the manipulated variable which usually is equal to the output of the controller. The output of PID

controllers will change in response to a change in measurement or set-point . Manufacturers of PID controllers use

different names to identify the three modes. Depending on the manufacturer, integral or reset action is set in either

time/repeat or repeat/time. One is just the reciprocal of the other. Note that manufacturers are not consistent and often

use reset in units of time/repeat or integral in units of repeats/time. Derivative and rate are the same.

Figure 3 shows, using Laplace notation, the basic components of a servo motor system. The servo drive, modeled as

G(s), receive a voltage command. It can be approximated as the unity for the relatively lower motion frequencies. The

servomotor is modelled as a lump inertia, J, a viscous damping term, b, and a torque constant, Kt. The lump inertia term

is comprised of both the servomotor and load inertia. I t is also assumed that the load is rigidly coupled such that the

torsional rigidity moves the natural mechanical resonance point well out beyond the servo controllers bandwidth. This

assumption allows us to model the total system inertia as the sum of the motor and load inertia for the frequencies we

can control. Somewhat more complicated models are needed if coupler dynamics are incorporated.

The output of the P.I .D. controller is a torque signal. I ts mathematical expression in the time domain is

given in eq. (5).

)

+ + =

dt

t error d

K dt t error Ki r error K t D I P

d p

)) ( (

) ( )) ( ( ) .( . . (5)

p

K

s

i

K

s K

d

t

K

1

( ) s G

Servo

Drive

t

K

Js

1

s

1

b

E E

d

T

Risley

Prism

System

P.I.D. Control

Speed

and

Position

E

Servo

Motor

Fig. 3. Basic P.I.D. servo control configuration

Proc. of SPIE Vol. 6422 64220X-4

5. TUNING THE P.I.D.

One of the problems in servo control is to accomplish the tuning of controllers PID. There are logic programmable

controls on the market that permit the use of mathematical tools using digital controls for servo-drivers. A PID tuning

controller with a linear adaptive element is compounded by a servo-driver of type multi-axle programmed on its own

programming language, it makes use of learning algorithms with NNA, it learns to make the tuning simpler and

automatic in its function, no only of constants. Nets with a RNAs process discreet signals, in order to use adaptive

filters, the analog signal converts by analogical to digital to digital values, and processed by a microprocessor.

Tuning methods are divided in open loop and feedback loop methods, where the Ziegler and Nichol method (feedback

loop) is widely used. Theoretical PID control structures become very useful since Minorsky publications in 1922. In

spite of the plenty of work published about PID control systems are still used practically in most of the industry

controlling more than the 95 % of the feedback control process.

Tuning a PID controller involves adjustment of three parameters: the proportionality constant K

I

, the integral time

constant T

I

and the anticipative time constant T

d

. First to all, the dynamic parameters of the process must be identified in

order to obtain a reliable and robust performance of those parameters of the system for. The variables of in loop control

are the reference value wish r(t), the output c(t) from a transmitter that generates the wish value, the feedback signal y(t)

the output of the controller that modifies the final control element, ands the error x

W

(t) defined as the difference between

the real value and the expected value.

The dynamics of the process is often identifying analytically and experimentally. The analytical method must solve the

mathematical expression that describes the system as a function of time. This method is very complex in most of the real

systems applications. In most cases mathematical functions are included o digital controllers and the distributed control

due to their calculus power.

The experimental method, the static and dynamical features are obtained from direct measurements, where the Ziegler

and Nichols is commonly used in two ways limit gain and the reaction curve

10

. Ziegler and Nichols technique is one of

the first tuning methods applied to the feedback loop systems. The tuning process can be achieved following a two step

procedure.

Step 1: Set K

i

and K

d

to zero. Excite the system with a step command. Slowly increase K

P

until the shaft position begins

to oscillate. At this point, record the value of K

p

and set K

o

equal to this value. Record the oscillation frequency, fo.

Step 2: Set the parameters of the PID controller according with the table 1.

Table 1. Parameter of the controller: using the limit gain method.

Action of control K

p

K

i

K

d

Proportional-Integral-Derivative 0.6 K

O

2 f

O

K

p

/8K

d

6. NEURAL NETWORK ADALINE

The first meaning for Adaline was ADAptive LInear NEuron but its meaning change to o Adaptive LInear Element and

only has one neural element; it has been used to solve linearly separable systems

6

. This one element adds the product of

the input vectors and its weights applying an output function in order to obtain one value response. Using a NNA, it is

possible to establish a proceeding to modify the weight function and get a correct value to a given input. Signal to be

proceeded by a NNA must be digitalized with sample times and the variables are the set point the reference signal w(t), a

feedback signal x(t) (the output of system) then is possible to asses the error e(t), that correspond to the input G

C

(s). The

PID controller generates an output g

C

(k), where Kp is the proportional gain, Ti is the integration time, and Td is the

derivative time, where the discrete representation of the output of the PID controller in the time domain is given by

Proc. of SPIE Vol. 6422 64220X-5

( )

|

|

.

|

\

|

+ + =

=

_

Ts

e e

K Ts e K k e K k g

n n

n

j

D j I p C

1

1

) ( (8)

The tuning process for discrete signals using the Ziegler-Nichols method is similar to those before explained and as a

result only preserve the error and proportional constant K

P

as is shown next.

( ) | | ( ) ) ( ) ( ) ( k w k x K k x K k g

P W p C

= = (9)

At the output of the ADALINE controller we obtain the signal that is represented by vector u(k) that becomes in the

sequential input u(k-1), generating the knowledge matrix W(Kp). This matrix information is useful to calculate the new

Adaline control outputs. Then, the constant for the conventional system are obtained applying the limit gain method

regarding the transfer function of he servo-driver. The learning rule of Adaline needs aprori information about the input

parameters. Once the NNA have learned, the error is reduced by an o factor, at the same time, the weights of the system

change according with the input values. The weights are renewed every time until the system converges.

( )

( ) ( ) ( )

) (

) (

2

k e

k p

k p k p k e

k e

T

o o = = A (10)

The best selection of o, helps to manage the training process stability and velocity of convergence. Stability condition in

achieve if 0.1 > o < 2. The selection of o does not depends on the input magnitude, every weight actualized is collinear

respect the inputs parameters and its magnitude is inversely proportional to ( )

2

k p . Figure

p

K

s

i

K

ff

K

s K

d

Transfer

Function

of

Servo

System

E E E

Adaline auto-tuning

Speed

and

Position

( )

( )

d d

i i

p

T K

T K

K

Control

Signal

P.I.D. Control

Encoder

position

Fig. 4. Basic P.I.D. with Adaline servo control configuration

Proc. of SPIE Vol. 6422 64220X-6

'

I

d

I

l

I

O

I

O

A

k

p

p

.

I

j

C

l

A

f lm .

I

7. RESULTS

In order to implement the rotary holder control, it was regarded a security factor ranging from 40% to 100% in some

cases, e.g. load effects. We used two servomotors with resolution 131,072 pulses per revolution without considering the

reducer factor of 100 due to use a pulley system.

Typically, servo systems are first tuned with a step input in order to get a feel for the system response. Once this is done,

the user now is often interested in how their actual motion will behave. At this point, the user must decide on the nature

of the velocity profile. By far the most common velocity profile is the trapezoid. This is due to the relative ease of

calculating all the state variables needed for motion: position, velocity and acceleration. As the need for smoother

accelerations and decelerations becomes greater, either "S" profiles or cubic splines are often employed. For the

purposes of our investigation, we will focus on the use of a simple trapezoidal velocity profile. The matrix of weight is

formed applying the conditions before exposed tuning with the Adaline. Figure 5 shows the response to the step function

applying the auto tuner ADALINE. Note that the velocity does not change, but the position is corrected smoothly.

Figure 6 shows two pictures of the rotary system. At left, show the lateral view and a perspective view on the right.

Fig. 5. Response to the step function applying the auto tuner Adaline.

Fig. 6. Pictures of the rotary prism system.

Proc. of SPIE Vol. 6422 64220X-7

8. CONCLUSIONS

Risley prism system has been designed, assembled and tested using a P.I.D. control with an Adaline neural network.

P.D.I. tuning process was implemented in a rotary holder servo-controller using the neural network Adaline. Algorithms

were programmed in Motion Arquitect Program (c) in order to facilitate the introduction of constants. PID tuning can be

used in SISO process automatically. The rotary holder can be programmed using exact ray trace equations until find the

proper position of the prism system in order of perform scanning applications.

REFERENCES

1. G. F. Marshall, Risley prism scan patterns, Optical Scanning: Design and Application, Proc. SPIE 3787, 74-

86 (1999).

2. M. Ostaszewski, et. al, Risley prism beam pointer, Free-Space laser communications VI, edited by Arun K.

Majumar, Chritopher C. Davis, Proc. Of SPIE Vol. 6304, 630406, (2066).

3. D. C. Weber, J. D. Trolinger, R. G. Nichols, A.K. Lal, Diffractively corrected Risley prism for infrared

imaging, Acquisition, Tracking, and Pointing XIV, Proc. SPIE 4025, 79-86 (2000).

4. J. Lacoursiere, et. al., Large-deviation achromatic Risley prisms pointing systems, Optical Scanning 2002,

Proc. SPIE 4773, 123-131 (2002).

5. Michael Snchez, David Gutow, Control laws for a 3-element Risley prism optical beam pointer Free-Space

laser communications VI, edited by Arun K. Majumar, Chritopher C. Davis, Proc. Of SPIE Vol. 6304, 630403,

(2066).

6. B. D. Duncan, P. J. Bos, V. Sergan, Wide-angle achromatic prism beam steering for infrared countermeasure

applications, Opt. Eng 42(4), 1038-1047 (2003).

7. G. Garcia-Torales, M. Stronjnik, G. Paez, Risley prisms to control wave-front tilt and displacement in a

vectorial shearing interferometer, Applied Optics 41(7), 1380-1384 (2002).

8. James, A. Freeman-David M. Skapura, Artifcial Neural Networks, Addison Wesley, (1991).

9. K.J. strm and T. Hgglund, PID Controllers: Theory, Design, and Tuning.Research Triangle Park, NC:

Instrum. Soc. Amer. (1995).

10. Ziegler, J.G., and Nichols, N.B., Optimum Settings for Automatic Controllers, Transactions of the American

Society of Mechanical Engineers (ASME). v. 64, 1942, pgs. 759-768.

Proc. of SPIE Vol. 6422 64220X-8

Das könnte Ihnen auch gefallen

- EF5A HDT Infra Bijali Paani PCB7 1669801048119Dokument43 SeitenEF5A HDT Infra Bijali Paani PCB7 1669801048119Zala DivyarajsinhNoch keine Bewertungen

- The Discrete Wavelet Transform Based Iris Recognition For Eyes With Non-Cosmetic Contact LensDokument10 SeitenThe Discrete Wavelet Transform Based Iris Recognition For Eyes With Non-Cosmetic Contact LensIAES IJAINoch keine Bewertungen

- Curriculam Vitae Ms. Mercy Theresa SagayarajDokument4 SeitenCurriculam Vitae Ms. Mercy Theresa SagayarajAaron RodriguesNoch keine Bewertungen

- IoB for Improving Customer ServicesDokument4 SeitenIoB for Improving Customer ServicesHannan GharadeNoch keine Bewertungen

- Jeevan Pramaan Face App 3.6Dokument5 SeitenJeevan Pramaan Face App 3.6Akash Reddy K0% (1)

- Project WKM Copy12111Dokument67 SeitenProject WKM Copy12111Leo SaimNoch keine Bewertungen

- XG-X Series: Communications Control ManualDokument918 SeitenXG-X Series: Communications Control ManualJesus R. Bernal SalazarNoch keine Bewertungen

- Financial Competency Assessment Model 2167 0234 1000317Dokument7 SeitenFinancial Competency Assessment Model 2167 0234 1000317sabetaliNoch keine Bewertungen

- Impact of Branding On Consumer Buying Behavior20191106 47784 Omm6sc With Cover Page v2Dokument13 SeitenImpact of Branding On Consumer Buying Behavior20191106 47784 Omm6sc With Cover Page v2Việt PhạmNoch keine Bewertungen

- Ai Presentation Ceps Webinar L. Sioli 23.4.21Dokument21 SeitenAi Presentation Ceps Webinar L. Sioli 23.4.21Miguel Angel LarrinagaNoch keine Bewertungen

- Merck IndianDokument752 SeitenMerck IndianAnurag KyalNoch keine Bewertungen

- Saraswati Science College: A Project Report OnDokument6 SeitenSaraswati Science College: A Project Report Ondeepak_143Noch keine Bewertungen

- NOTES - Quality ReviewDokument4 SeitenNOTES - Quality ReviewRahul KumarNoch keine Bewertungen

- BC AssignmentDokument22 SeitenBC AssignmentAnnapurna PurohitNoch keine Bewertungen

- Deep Learning for Efficient Sign Language RecognitionDokument48 SeitenDeep Learning for Efficient Sign Language Recognitionatul pontedNoch keine Bewertungen

- Bharart Ko JanoDokument183 SeitenBharart Ko JanoAGRIM UPADHYAYNoch keine Bewertungen

- D'Iberville SidewalkPedStudy ClientReview2Dokument66 SeitenD'Iberville SidewalkPedStudy ClientReview2leslie3mitchell3robeNoch keine Bewertungen

- Compliance With: Saudi NCA-ECC Based On ISO/IEC 27001Dokument8 SeitenCompliance With: Saudi NCA-ECC Based On ISO/IEC 27001Pratik BhaleraoNoch keine Bewertungen

- CYW20721 Bluetooth Audio SolutionDokument35 SeitenCYW20721 Bluetooth Audio SolutionNguyễn Bá DũngNoch keine Bewertungen

- Fusionex ADA (Day1) v3.1 2022Dokument106 SeitenFusionex ADA (Day1) v3.1 2022izzudinrozNoch keine Bewertungen

- A.D. Pearle - Surgical Technique and Anatomic Study of Latissimus Dorsi and Teres Major Transfers (2006)Dokument9 SeitenA.D. Pearle - Surgical Technique and Anatomic Study of Latissimus Dorsi and Teres Major Transfers (2006)João Pedro ZenattoNoch keine Bewertungen

- Receipt for Reservation Fee PaymentDokument1 SeiteReceipt for Reservation Fee PaymentSk NurhasanNoch keine Bewertungen

- Madurai Kamaraj University: Capital Market Efficiency and Development of Capital Market in IndiaDokument11 SeitenMadurai Kamaraj University: Capital Market Efficiency and Development of Capital Market in Indiachanus92Noch keine Bewertungen

- Functional Organization of Motoneuron Pool and Its InputsDokument85 SeitenFunctional Organization of Motoneuron Pool and Its InputsPabloNoch keine Bewertungen

- There's No Way This Isn't Racist - Daniels2018Dokument19 SeitenThere's No Way This Isn't Racist - Daniels2018elisaNoch keine Bewertungen

- A Socio-Ecological Study of Population, Migration, Urbanization, and Socio-Climate Variation in Andhra Pradesh and Telangana, IndiaDokument33 SeitenA Socio-Ecological Study of Population, Migration, Urbanization, and Socio-Climate Variation in Andhra Pradesh and Telangana, IndiaKousik D. MalakarNoch keine Bewertungen

- 2020 Ccaf Legal Regulatory Considerations ReportDokument50 Seiten2020 Ccaf Legal Regulatory Considerations ReportKarem MahmoudNoch keine Bewertungen

- Transparency and Algorithmic Governance PDFDokument57 SeitenTransparency and Algorithmic Governance PDFannas fahlevieNoch keine Bewertungen

- S W ?F Fe W 3 3 TS:, ',V Illii'Dokument290 SeitenS W ?F Fe W 3 3 TS:, ',V Illii'Crazy JattNoch keine Bewertungen

- Draft Report on Socio-Economic Development and Tourism Potential of LigligkotDokument34 SeitenDraft Report on Socio-Economic Development and Tourism Potential of Ligligkotroman poudyalNoch keine Bewertungen

- BankDokument32 SeitenBankBaby Prasanna Lakshmi KNoch keine Bewertungen

- Analysis On Customer Service Department Activities Of: HBL, Itahari BranchDokument50 SeitenAnalysis On Customer Service Department Activities Of: HBL, Itahari BranchSujan BajracharyaNoch keine Bewertungen

- Question BankDokument5 SeitenQuestion Bankmanisha mudgalNoch keine Bewertungen

- Business License Revocation Letter. Naomi I. Halter.1Dokument3 SeitenBusiness License Revocation Letter. Naomi I. Halter.1T RNoch keine Bewertungen

- Domain Engineering2Dokument507 SeitenDomain Engineering2darkHorseNoch keine Bewertungen

- Opm632 ErpDokument16 SeitenOpm632 ErpFARISYA HARMANNoch keine Bewertungen

- Managing Team Centricity in Modern Organizations-Information Age Publishing (2022)Dokument337 SeitenManaging Team Centricity in Modern Organizations-Information Age Publishing (2022)sappi13Noch keine Bewertungen

- Tata Motors Financial Analysis Case StudyDokument6 SeitenTata Motors Financial Analysis Case StudySoumendra RoyNoch keine Bewertungen

- Congenital Talipes (Clubfoot)Dokument222 SeitenCongenital Talipes (Clubfoot)Sampath MarasingheNoch keine Bewertungen

- Efficacy of Nano-Hydroxyapatite Coating On Osseointegration of Early Loaded Dental ImplantsDokument12 SeitenEfficacy of Nano-Hydroxyapatite Coating On Osseointegration of Early Loaded Dental ImplantsIJAR JOURNALNoch keine Bewertungen

- CRM Project-1: CRM Practices in FlipkartDokument14 SeitenCRM Project-1: CRM Practices in FlipkartKumar UtkarshNoch keine Bewertungen

- Statistics For MGMT I & IIDokument161 SeitenStatistics For MGMT I & IIewnetuNoch keine Bewertungen

- Report of Khushhali BankDokument20 SeitenReport of Khushhali BankZIA UL REHMANNoch keine Bewertungen

- Form 601-Partial Withdrawal Under NPSDokument3 SeitenForm 601-Partial Withdrawal Under NPSRanga Nayak PaltyaNoch keine Bewertungen

- Students' Council Involvement in Decision Making and Students' Discipline in Secondary Schools in Tongaren Sub County, KenyaDokument6 SeitenStudents' Council Involvement in Decision Making and Students' Discipline in Secondary Schools in Tongaren Sub County, KenyaEditor IJTSRDNoch keine Bewertungen

- SGS NT TRAINING MATERIAL - 1st EditionDokument48 SeitenSGS NT TRAINING MATERIAL - 1st EditionChigozie-umeh OgechukwuNoch keine Bewertungen

- Smart Irrigation System: Enhancing Agricultural SustainabilityDokument4 SeitenSmart Irrigation System: Enhancing Agricultural SustainabilityInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Design and Evaluation of A Smart-Glasses-based Service Support SystemDokument15 SeitenDesign and Evaluation of A Smart-Glasses-based Service Support SystemAl-Mahmudur RahmanNoch keine Bewertungen

- Book Shop System ManagementDokument18 SeitenBook Shop System ManagementFitim IbraimiNoch keine Bewertungen

- A Comparative Analysis On Customer Satisfaction Towards Reliance Jio and Airtel With Reference To AnantapurDokument12 SeitenA Comparative Analysis On Customer Satisfaction Towards Reliance Jio and Airtel With Reference To AnantapurEditor IJTSRDNoch keine Bewertungen

- Relevance of Laboratory On Teaching of Int - ScienceDokument83 SeitenRelevance of Laboratory On Teaching of Int - ScienceAdemolaNoch keine Bewertungen

- Scoring Package 3rd Eng 2021-22-1Dokument48 SeitenScoring Package 3rd Eng 2021-22-1Tayab TayabNoch keine Bewertungen

- JeebookDokument391 SeitenJeebookch100% (1)

- Application of Data ScienceDokument8 SeitenApplication of Data SciencepallaB ghoshNoch keine Bewertungen

- Resume With ExpDokument7 SeitenResume With ExprambabuNoch keine Bewertungen

- Bibliometric Analysis of The Research On Hydrogen Economy: An Analysis of Current Findings and Roadmap AheadDokument22 SeitenBibliometric Analysis of The Research On Hydrogen Economy: An Analysis of Current Findings and Roadmap AheadJoana SalgadoNoch keine Bewertungen

- NIU Transaction HandlingDokument20 SeitenNIU Transaction HandlingKriti Jain100% (2)

- Extent Managers Applied Inventory Control Approaches For Improving Operations of Small and Medium Scale Enterprises in South-East NigeriaDokument9 SeitenExtent Managers Applied Inventory Control Approaches For Improving Operations of Small and Medium Scale Enterprises in South-East NigeriaInternational Journal of Recent Innovations in Academic ResearchNoch keine Bewertungen

- Low-Cost Accelerometers For Robotic Manipulator PerceptionDokument7 SeitenLow-Cost Accelerometers For Robotic Manipulator PerceptionAbbé BusoniNoch keine Bewertungen

- On Sensorless Induction Motor Drives: Sliding Mode Observer and Output Feedback ControllerDokument8 SeitenOn Sensorless Induction Motor Drives: Sliding Mode Observer and Output Feedback ControllerRaja ReddyNoch keine Bewertungen

- Proc SPIE - Optra PaperDokument9 SeitenProc SPIE - Optra PapernorbdudeNoch keine Bewertungen

- Proc SPIE - 6304Dokument10 SeitenProc SPIE - 6304norbdudeNoch keine Bewertungen

- 2011 AO Li Y Risley Prisms Thick 2 Inverse ProblemXXDokument8 Seiten2011 AO Li Y Risley Prisms Thick 2 Inverse ProblemXXnorbdudeNoch keine Bewertungen

- 2010 - AO - 3D Scan - Telecentric Scanner and Double WedgesDokument21 Seiten2010 - AO - 3D Scan - Telecentric Scanner and Double WedgesnorbdudeNoch keine Bewertungen

- 2008 Appl Opt - Prism Interferometer - Small Angle DeviationDokument7 Seiten2008 Appl Opt - Prism Interferometer - Small Angle DeviationnorbdudeNoch keine Bewertungen

- 2009 Jbo Rat With SsoctDokument3 Seiten2009 Jbo Rat With SsoctnorbdudeNoch keine Bewertungen

- 2009 AO ND Filters With Risley PrismsDokument8 Seiten2009 AO ND Filters With Risley PrismsnorbdudeNoch keine Bewertungen

- 2011 AO Li Y Risley Prisms Thick XXDokument8 Seiten2011 AO Li Y Risley Prisms Thick XXnorbdudeNoch keine Bewertungen

- 2011 AO Li Y Risley Prisms Thick XXDokument8 Seiten2011 AO Li Y Risley Prisms Thick XXnorbdudeNoch keine Bewertungen

- 2008 OPEX Microprisms ArrayDokument11 Seiten2008 OPEX Microprisms ArraynorbdudeNoch keine Bewertungen

- 2009 SpringerOpt Review - OCT PT Carii DentareDokument6 Seiten2009 SpringerOpt Review - OCT PT Carii DentarenorbdudeNoch keine Bewertungen

- 2007 OPEX Baumann - FD OCT - No Phase ShiftersDokument13 Seiten2007 OPEX Baumann - FD OCT - No Phase ShiftersnorbdudeNoch keine Bewertungen

- Beat The Micros in 2012Dokument43 SeitenBeat The Micros in 2012norbdudeNoch keine Bewertungen

- 2010 AO - Lee - Rolland - Dual Detection FD OCTDokument3 Seiten2010 AO - Lee - Rolland - Dual Detection FD OCTnorbdudeNoch keine Bewertungen

- 7 Deadly Sins of Style Edition 2 PDFDokument47 Seiten7 Deadly Sins of Style Edition 2 PDFBagus ZakiNoch keine Bewertungen

- 2007 JBO Jenkins 4D Scan Avian Heart XDokument3 Seiten2007 JBO Jenkins 4D Scan Avian Heart XnorbdudeNoch keine Bewertungen

- 2005 Ao Lee Rolland FD OctDokument14 Seiten2005 Ao Lee Rolland FD OctnorbdudeNoch keine Bewertungen

- 2006 OPEX Miyazaki - Volumetric Display - 3D ScanningDokument10 Seiten2006 OPEX Miyazaki - Volumetric Display - 3D ScanningnorbdudeNoch keine Bewertungen

- 2003 - Taylor & Francis Chap - Montagu - GS and Resonant ScannersDokument53 Seiten2003 - Taylor & Francis Chap - Montagu - GS and Resonant ScannersnorbdudeNoch keine Bewertungen

- 2011 PRER Elsevier - Podoleanu - Retina OCTDokument36 Seiten2011 PRER Elsevier - Podoleanu - Retina OCTnorbdudeNoch keine Bewertungen

- Booklet Global Marketing - 2013Dokument12 SeitenBooklet Global Marketing - 2013norbdudeNoch keine Bewertungen

- Cross-Validation of Component Models: A Critical Look at Current MethodsDokument12 SeitenCross-Validation of Component Models: A Critical Look at Current MethodsDũng PhạmNoch keine Bewertungen

- OMAE2018 ProgramDokument124 SeitenOMAE2018 ProgramTahsin TezdoganNoch keine Bewertungen

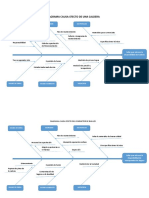

- Caldera causa-efecto diagrama mantenimiento fallasDokument2 SeitenCaldera causa-efecto diagrama mantenimiento fallasDaniel Will Morales GuerreroNoch keine Bewertungen

- Relevance of Research in Social WorkDokument15 SeitenRelevance of Research in Social WorkangelgijoNoch keine Bewertungen

- Hatch Cover Analysis of Capesize Bulk CarriersDokument6 SeitenHatch Cover Analysis of Capesize Bulk CarriersBasem TamNoch keine Bewertungen

- UV Visible SpectrosDokument8 SeitenUV Visible Spectrosbarani_autNoch keine Bewertungen

- AS (GCE) Instant Revision of ChemistryDokument130 SeitenAS (GCE) Instant Revision of ChemistryOlivia Panterka Vainilla100% (4)

- TR-4/2011 Hdb/Hds/Sdb/Pdb/Mrs Listed Materials PPI Listing ofDokument69 SeitenTR-4/2011 Hdb/Hds/Sdb/Pdb/Mrs Listed Materials PPI Listing ofDAVID GREGORIO FRANCO ANDRADENoch keine Bewertungen

- The Key To Extra Terrestrial Disclosure May Be The Lake Erie UFO's!Dokument34 SeitenThe Key To Extra Terrestrial Disclosure May Be The Lake Erie UFO's!Michael Lee Hill100% (1)

- United Institute of Technology: B-Tech (En Vii SEM-2014-15) Lecture PlanDokument2 SeitenUnited Institute of Technology: B-Tech (En Vii SEM-2014-15) Lecture PlanRudra Kumar MishraNoch keine Bewertungen

- Mass Transfer PartDokument54 SeitenMass Transfer Partoctoviancletus100% (3)

- 6 Materials Summary 2014Dokument31 Seiten6 Materials Summary 2014api-248740887Noch keine Bewertungen

- Airy FunctionDokument10 SeitenAiry Functionalokesh1982Noch keine Bewertungen

- Diffusivity Equation: 13 February 2008Dokument17 SeitenDiffusivity Equation: 13 February 2008Yaser RashedNoch keine Bewertungen

- Theory of Time MachineDokument127 SeitenTheory of Time MachineUday HiwaraleNoch keine Bewertungen

- Copia de GranulometriaDokument1 SeiteCopia de GranulometriaSantiago GiraldoNoch keine Bewertungen

- Precast Bridge DeckDokument4 SeitenPrecast Bridge DeckPaul_delgadoNoch keine Bewertungen

- TEC Novatop Terminal GBDokument79 SeitenTEC Novatop Terminal GBahmedNoch keine Bewertungen

- Hecke's L-FunctionsDokument102 SeitenHecke's L-FunctionsluisufspaiandreNoch keine Bewertungen

- Magnetic Field and Magnetic Effects of Current: Assignment 2Dokument2 SeitenMagnetic Field and Magnetic Effects of Current: Assignment 2HaRryNoch keine Bewertungen

- Geotechnical Aspects of Building Design (EN 1997) : Eurocode 2Dokument55 SeitenGeotechnical Aspects of Building Design (EN 1997) : Eurocode 2margitorsiNoch keine Bewertungen

- CAESAR II MAX Combination LoadCaseDokument2 SeitenCAESAR II MAX Combination LoadCasePrashant ChauhanNoch keine Bewertungen

- The Four Ethers: Contributions to Rudolf Steiner's Science of the EthersDokument33 SeitenThe Four Ethers: Contributions to Rudolf Steiner's Science of the EthersSolomanTrismosin100% (2)

- Buttwelding ProcedureDokument5 SeitenButtwelding ProcedurePrageeth Nalaka ArambegedaraNoch keine Bewertungen

- Engineering Design Guideline - Measurement Rev02webDokument16 SeitenEngineering Design Guideline - Measurement Rev02weblutfi awn0% (1)

- Friction PDFDokument32 SeitenFriction PDFKudzai MushunjeNoch keine Bewertungen

- Ordinary Level Heat NotesDokument44 SeitenOrdinary Level Heat Notespatrick omonyNoch keine Bewertungen

- V Notch PracticalDokument13 SeitenV Notch PracticalAnushaBheenuck0% (2)

- Soil Bearing CapacityDokument33 SeitenSoil Bearing CapacityAce JokerNoch keine Bewertungen

- Determination of The Surface Tension of Liquid Stainless SteelDokument5 SeitenDetermination of The Surface Tension of Liquid Stainless SteelĐào ThườngNoch keine Bewertungen