Beruflich Dokumente

Kultur Dokumente

Ball Bearing Damage Analysis

Hochgeladen von

ho-faCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ball Bearing Damage Analysis

Hochgeladen von

ho-faCopyright:

Verfügbare Formate

Automotive

T echTips

Volume 7 Issue 2 Part 2 of a 2-Part Series

Maximizing bearing performance and life remains an objective throughout The Timken Company, from design teams and manufacturing associates to our field sales team and distributors. TechTips help you install and maintain Timken bearings, seals and components to maximize their life and performance and the systems in which they operate. For more information regarding Timken automotive products and services, visit www.timken.com or contact your local Timken distributor.

Ball Bearing Damage Analysis

The most common types of bearing damage that may result in a reduction of bearing or application life are often caused by:

insufficient maintenance

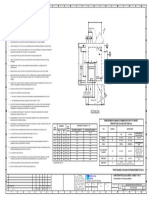

Fretting Corrosion

practices

mishandling improper installation and fitting

practices

inadequate lubrication excessive application loads contamination

The following offers a quick reference to the common types/causes of bearing damage. Fretting on inner ring due to out-ofround shaft. Fretting on the outer ring due to out-ofround housing bore.

Foreign Material / Contamination

Fatigue Spalling

Grease Etching

Fine particle abrasive wear on the inner race, commonly known as frosting.

Inclusion origin: spalling from oxides or other hard inclusions in bearing steel.

Chemical reaction of grease and moisture in a prolonged static condition resulting in pitting and corrosion. A witness mark is generated at each ball location on the inner race.

True Brinelling

Gross contamination resulting from harsh operating conditions and/or seal failure.

Geometric stress concentration (GSC): spalling from misalignment, system deflections or heavy loading.

Damage from shock or excessive loads.

False Brinelling

Lubrication characteristics of the grease are compromised by water ingress.

Point surface origin (PSO): spalling from contamination in the ball path or raised metal exceeding the lubricant film thickness.

Wear caused by vibration or axial movement between the balls and races in a static condition.

WARNING Failure to observe the following warnings

could create a risk of serious injury.

Proper maintenance and handling procedures are critical. Always follow installation instructions and maintain proper lubrication.

www.timken.com

Timken is a registered trademark of The Timken Company

TechTips is not intended to substitute for the specific recommendations of your equipment suppliers. Every reasonable effort has been made to ensure the accuracy of the information contained in this writing, but no liability is accepted for errors, omissions or for any other reason.

2009 The Timken Company Printed in U.S.A. 119M 08-09-29 Order No. 10313

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Building Services Planning Manual-2007Dokument122 SeitenBuilding Services Planning Manual-2007razanmrm90% (10)

- Chhay Chihour - SS402 Mid-Term 2020 - E4.2Dokument8 SeitenChhay Chihour - SS402 Mid-Term 2020 - E4.2Chi Hour100% (1)

- Girth Gear WearDokument6 SeitenGirth Gear Wearho-fa100% (2)

- NotesOnFluidFilmJournalBearing OverviewDokument71 SeitenNotesOnFluidFilmJournalBearing OverviewbatporaNoch keine Bewertungen

- Machinery Lubrication Brochure EDokument2 SeitenMachinery Lubrication Brochure Eho-faNoch keine Bewertungen

- Creating Survey Periods and Printing The Survey Period ReportDokument6 SeitenCreating Survey Periods and Printing The Survey Period Reportho-faNoch keine Bewertungen

- ST101 in A PDM ProgramDokument4 SeitenST101 in A PDM Programho-faNoch keine Bewertungen

- Filling The GapDokument3 SeitenFilling The Gapho-faNoch keine Bewertungen

- DCA31 QuickGuideDokument23 SeitenDCA31 QuickGuideho-fa100% (1)

- Mobility... A New Approach To Measuring Actual Forces in MachineryDokument4 SeitenMobility... A New Approach To Measuring Actual Forces in Machineryho-faNoch keine Bewertungen

- Fabreeka Am EprintDokument4 SeitenFabreeka Am Eprintho-faNoch keine Bewertungen

- Vibration ANALYSIS StandardsDokument24 SeitenVibration ANALYSIS Standardsho-faNoch keine Bewertungen

- Lowfreq Preceng PDFDokument4 SeitenLowfreq Preceng PDFho-faNoch keine Bewertungen

- Man As God Created Him, ThemDokument3 SeitenMan As God Created Him, ThemBOEN YATORNoch keine Bewertungen

- CV & Surat Lamaran KerjaDokument2 SeitenCV & Surat Lamaran KerjaAci Hiko RickoNoch keine Bewertungen

- Quiz 140322224412 Phpapp02Dokument26 SeitenQuiz 140322224412 Phpapp02Muhammad Mubeen Iqbal PuriNoch keine Bewertungen

- Activity On Noli Me TangereDokument5 SeitenActivity On Noli Me TangereKKKNoch keine Bewertungen

- Friction: Ultiple Hoice UestionsDokument5 SeitenFriction: Ultiple Hoice Uestionspk2varmaNoch keine Bewertungen

- Anemia in PregnancyDokument5 SeitenAnemia in PregnancycfgrtwifhNoch keine Bewertungen

- SOL LogicDokument21 SeitenSOL LogicJa RiveraNoch keine Bewertungen

- Genetics Icar1Dokument18 SeitenGenetics Icar1elanthamizhmaranNoch keine Bewertungen

- Rajiv Gandhi University of Health Sciences, Bengaluru, KarnatakaDokument9 SeitenRajiv Gandhi University of Health Sciences, Bengaluru, KarnatakaNavin ChandarNoch keine Bewertungen

- Canoe Matlab 001Dokument58 SeitenCanoe Matlab 001Coolboy RoadsterNoch keine Bewertungen

- Cloud Comp PPT 1Dokument12 SeitenCloud Comp PPT 1Kanishk MehtaNoch keine Bewertungen

- Module 2 MANA ECON PDFDokument5 SeitenModule 2 MANA ECON PDFMeian De JesusNoch keine Bewertungen

- QuexBook TutorialDokument14 SeitenQuexBook TutorialJeffrey FarillasNoch keine Bewertungen

- UltimateBeginnerHandbookPigeonRacing PDFDokument21 SeitenUltimateBeginnerHandbookPigeonRacing PDFMartinPalmNoch keine Bewertungen

- Mosfet Irfz44Dokument8 SeitenMosfet Irfz44huynhsang1979Noch keine Bewertungen

- Peer PressureDokument13 SeitenPeer PressuremightymarcNoch keine Bewertungen

- Sveba Dahlen - SRP240Dokument16 SeitenSveba Dahlen - SRP240Paola MendozaNoch keine Bewertungen

- Week 4 - Theoretical Framework - LectureDokument13 SeitenWeek 4 - Theoretical Framework - LectureRayan Al-ShibliNoch keine Bewertungen

- Cisco BGP ASPATH FilterDokument115 SeitenCisco BGP ASPATH FilterHalison SantosNoch keine Bewertungen

- National Anthems of Selected Countries: Country: United States of America Country: CanadaDokument6 SeitenNational Anthems of Selected Countries: Country: United States of America Country: CanadaHappyNoch keine Bewertungen

- Desktop 9 QA Prep Guide PDFDokument15 SeitenDesktop 9 QA Prep Guide PDFPikine LebelgeNoch keine Bewertungen

- Activity Title: Learning Targets: Reference (S)Dokument5 SeitenActivity Title: Learning Targets: Reference (S)Jhev LeopandoNoch keine Bewertungen

- World Insurance Report 2017Dokument36 SeitenWorld Insurance Report 2017deolah06Noch keine Bewertungen

- Acute Appendicitis in Children - Diagnostic Imaging - UpToDateDokument28 SeitenAcute Appendicitis in Children - Diagnostic Imaging - UpToDateHafiz Hari NugrahaNoch keine Bewertungen

- CHAPTER 1 SBL NotesDokument13 SeitenCHAPTER 1 SBL NotesPrieiya WilliamNoch keine Bewertungen

- Lesson 6 - Vibration ControlDokument62 SeitenLesson 6 - Vibration ControlIzzat IkramNoch keine Bewertungen

- Notes:: Reinforcement in Manhole Chamber With Depth To Obvert Greater Than 3.5M and Less Than 6.0MDokument1 SeiteNotes:: Reinforcement in Manhole Chamber With Depth To Obvert Greater Than 3.5M and Less Than 6.0Mسجى وليدNoch keine Bewertungen

- Teaching Profession - Educational PhilosophyDokument23 SeitenTeaching Profession - Educational PhilosophyRon louise PereyraNoch keine Bewertungen