Beruflich Dokumente

Kultur Dokumente

Victaulic PDF

Hochgeladen von

Lim PaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Victaulic PDF

Hochgeladen von

Lim PaCopyright:

Verfügbare Formate

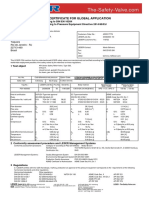

Pipe Fittings

IPS CARBON STEEL PIPE GROOVED FITTINGS

Victaulic offers a broad line of fittings in sizes through 24 (610.0 mm) in a variety of straight and reducing styles. Most standard fittings are cast of durable ductile iron to precise tolerances. Victaulic standard fittings pressure ratings conform to the ratings of Victaulic Style 77 couplings. Stainless SteelGrooved end fittings are available in Schedule 10 Type 316 stainless steel (Schedule 5, 40 and Type 304 optionally available) in various sizes. Fitting center-to-end dimensions will vary depending upon type and schedule. AluminumGrooved end fittings are available in aluminum alloy 356 T6, in sizes from 1 - 8 (33.7 219.1 mm.)

FittingsDuctile Iron (except as noted)

C to E

C to E

C to E

E to E

C to E

C to E

C to E

C to E

C to E

SIZE Nominal Inches 3/4 1 1-1/4 1-1/2 2 2-1/2 76, 1 mm 3 3-1/2 4 108.0 mm 4-1/2 5 133,0 mm 139,7 mm 6 159,0 mm 165,1 mm 8 10 12 14 16 18 20 24

No. 10 90 Elbow Aprx. C to E Wgt. Ea. Inches Lbs. 2.25 0.5 2.25 0.6 2.75 1.0 2.75 1.2 3.25 1.8 3.75 3.2 3.75 3.7 4.25 4.5 4.50 5.6 5.00 7.1 5.00 11.0 5.25 sw 10.0 5.50 11.7 5.50 11.7 5.50 11.7 6.50 17.2 6.50 18.6 6.50 15.5 7.75 29.9 9.00 63.3 10.00 74.0 # # # # # # # # # #

No. 11 45 Elbow Aprx. C to E Wgt. Ea. Inches Lbs. 1.50 0.5 1.75 0.6 1.75 0.9 1.75 0.9 2.00 1.3 2.25 2.2 2.25 sw 3.4 2.50 3.1 2.75 4.3 3.00 5.6 3.00 5.6 3.13 sw 6.0 3.25 8.3 3.25 8.3 3.25 8.3 3.50 10.8 3.50 10.8 3.50 9.8 4.25 20.4 4.75 37.5 5.25 66.7 # # # # # # # # # #

No. 12 22-1/2 Elbow Aprx. C to E Wgt. Ea. Inches Lbs. 1.63 sw 3.25 @ 0.6 1.75 0.8 1.75 0.8 3.75 @ 1.4 4.00 @ 2.3 4.50 @ 3.1 2.50 sw 4.0 2.88 5.6 3.50 6.6 2.88 sw 7.8 6.25@ 12.2 3.13 11.4 7.75 @ 20.0 4.38 sw 30.0 4.88 sw 40.0 5.00 sw 46.0 5.00 sw 58.0 5.00 sw 58.0 6.00 sw 78.6 7.00 sw 140.0

No. 13 11-1/4 Elbow Aprx. C to E Wgt. Ea. Inches Lbs. 1.38 sw 1.38 sw 0.3 1.38 sw 0.5 1.38 sw 0.5 1.38 1.0 1.50 1.1 1.50 2.1 1.75 sw 2.7 1.75 3.6 1.88 sw 4.2 2.00 sw 5.0 2.00 7.0 2.00 7.4 2.00 10.1 2.13 sw 11.8 2.25 sw 29.3 3.50 sw 32.0 4.00 sw 42.0 4.50 sw 53.2 5.00 sw 65.0 6.00 sw 60.0

No. 20 Tee Aprx. C to E Wgt. Ea. Inches Lbs. 2.25 0.6 2.25 1.0 2.75 1.5 2.75 2.0 3.25 3.0 3.75 4.3 3.75 5.2 4.25 6.8 4.50 7.9 5.00 11.9 5.00 15.5 5.25 sw 15.0 5.50 17.8 5.50 17.8 5.50 17.8 6.50 25.7 6.50 27.1 6.50 22.0 7.75 47.6 9.00 99.0 10.00 133.0 11.00 sw* 151.0 12.00 sw* 188.0 15.50 sw* 263.0 17.25 sw* 339.0 20.00 sw* 473.0

No. 35 Cross (sw) Aprx. C to E Wgt. Ea. Inches Lbs. 2.25 0.9 2.25 1.3 2.75 2.1 2.75 2.5 3.25 3.8 3.75 6.1 4.25 10.5 4.50 11.5 5.00 15.8 5.25 18.5 5.50 20.0 6.50 28.0 6.50 28.0 7.75 48.0 9.00 121.5 10.00 110.0 11.00 198.0 12.00 250.0 15.50 350.0 17.25 452.0 20.00 795.0

#14, 16, 18, 20, 24 (355.6) elbows (90, 45) are 1-1/2D long radius forged steel elbows No. 100 and No. 110. For 2842 fittings. For 1D radius elbows contact Victaulic. Long radius 3D, 5D and 6D are available, request 07.02 (s) Steel (sw) Segmentally welded steel @ Gooseneck design, end-to-end dimension * Cast ductile iron fittings available, contact Victaulic for details.

265

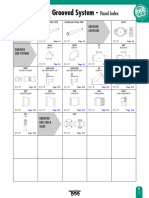

Pipe Fittings

IPS CARBON STEEL PIPE GROOVED FITTINGS

No. 33 True Wye

Segmentally Welded Steel

C to LE

No. 29M Tee with Thd. Branch

Ductile Iron

C to GE

No. 100 & No. 110 90 and 45 Long Radius Elbows 1-1/2 D

Ductile Iron

C to E

No. 48 Hose Nipple (U.S.)

Steel

E to E

C to E C to TE C to SE

3D Cast Elbows For Abrasive Services

C to E

Long Radius Elbows Steel

No. 41 ANSI 125 No. 45 ANSI 150 No. 46 ANSI 300 Flanged Adapter Nipples

No. 80 Female Threaded Adapter

Ductile Iron

C to E

90 Elbow3D

45 Elbow3D

No. 10

No. 30 45 Lateral

Segmentally Welded Steel

No. R-10 Reducing Base Support Elbows

Ductile Iron

Fabricated Fittings Steel

No. 60, 40, 42, 43 Cap and Nipples

Victaulic offers a broad line of segmentally welded fittings in sizes through 24" (610.0 mm) in a variety of straight and reducing styles. Fittings are fabricated of ASTM A-53 carbon steel, or other materials by special order. Victaulic segmentally welded fittings pressure ratings conform to the ratings of Victaulic Style 77 couplings. All fittings are grooved to permit fast installation without field preparation. The grooved design permits flexibility for easy alignment. Cap Ductile Iron Nipples Steel

266

Pipe Fittings

IPS CARBON STEEL PIPE GROOVED FITTINGS

No. 52 Reducer Threaded Small End No. 53,54,55 Swaged Nipples* Steel No. 50 & No. 51 Concentric/Eccentric Reducers

Steel

*Also available in threaded small end No. 54 or threaded large end No. 55.

No. 25 & No. 29 Reducing Tees

Segmentally Welded Steel

No. 18 & No. 19 Adapter Elbows

Ductile Iron

No. 61 Bull Plug

Steel

No. 21 Bullhead Tee

Ductile Iron

No. 27 Sandpipe Tee

Ductile Iron

No. 32 Tee Wye

Segmentally Welded Steel

No. 30-R Reducing Lateral

Segmentally Welded Steel

No. 32-R Reducing Tee Wye

Segmentally Welded Steel

267

Pipe Fittings

IPS CARBON STEEL PIPE GROOVED COUPLINGS

Style 07 Zero-Flex Rigid Coupling

The unique angle-pad design of Zero-Flex Style 07 adjusts to standard pipe and roll or cut groove tolerances, positively clamping the pipe to resist flexural and torsional loads. Wider key section fills more of the groove area.

Style 77 Standard Flexible Coupling

Style 77 couplings are designed with cross-ribbed construction to provide a strong component for pressure piping systems. Sizes 3/4-12" (26.9 - 323.9 mm) are two-piece housings. Sizes 14 - 22" (355.6 - 559.0 mm) are cast in four identical segments, with larger sizes cast in six segments.

Style 770 Standard Coupling for Roll Grooved Pipe

Style 770 couplings are designed for joining large diameter piping systems. Ranging in size from 28" (711.0 mm) to 42" (1067.0 mm), Style 770 is ideal for roll grooved IPS black or galvanized steel and stainless steel systems.

Style 75 Flexible Coupling

Style 75 is available where moderate pressures are expected or weight considerations are a factor. Up to 50% lighter in weight than the Style 77, the Style 75 coupling is recommended for service up to 500 PSI (3450 kPa) depending on size.

Style 741 Vic-Flange Adapter

ANSI Class 125 & 150 Flange Sizes 2 - 12 (60.3 - 323.9 mm)

Style 741 Vic-Flange adapter is designed for directly incorporating flanged components with ANSI CL 125 or CL 150 bolt hole patterns into a grooved pipe system. Sizes 2 - 12 (60.3 - 323.9 mm) are hinged for easy handling with integral end tabs to facilitate assembly.

Style 743 Vic-Flange Adapter

Grooved pipe adapter to ANSI Class 300 flanges

Vic-Flange Style 743 flange-to-groove adapter permits direct connection of ANSI Class 300 raised face flanged components. It can be used with flat-face flanges by removing the raised projections on the outside face of the flange.

Style 741 Vic-Flange Adapter

ANSI Class 125 & 150 Flange Sizes 14 - 24 (355.6 - 610.0 mm)

Style 741 Vic-Flange adapter is designed for directly incorporating flanged components with ANSI CL. 125 or CL. 150 bolt hole patterns into a grooved pipe system. Sizes 14 - 24 (355.6 - 610.0 mm) are cast in four (4) identical segments which interconnect as assembly is completed.

Style HP-70 Rigid Coupling

Style HP-70 is designed to clamp the pipe, thus providing an essentially rigid joint. To achieve rigidity it is necessary to torque the bolts on sizes 2 - 4 (60.3 - 114.3 mm) to 60 - 80 ft. lbs. (80 110 Nm); 14 - 16 (355.6 - 406.4 mm) to 600 and 700 ft. lbs. (800 and 950 Nm), respectively. The nuts on the 14 & 16 (355.6 & 406.4 mm) sizes are torqued to 600 & 700 ft. lbs. (810 & 950 Nm), respectively. All other sizes must be bolted securely metal-to-metal.

Style HP-70ES Coupling with Fire-R Gasket

The Victaulic HP-70ES EndSeal coupling has an oil-resistant nitrile gasket with a high modulus for resistance to extrusion. The Fire-R gasket features a stainless steel inner leg that provides a secondary closure. Style HP-70ES with Fire-R gasket is fire tested to API 607 standards.

268

Pipe Fittings

IPS CARBON STEEL PIPE GROOVED VALVES

Vic-300 Butterfly Valves Series 712 & 713 Swinger Check Valve Series 779 Venturi-Check Valves

Series 712 Lever Lock Gear Operator

Series 713

Tamper Resistant

Series 712 Swinger swing check valves have large closure access bonnet for internal coating. A 316 stainless steel clapper features a bonded bumper for coating protection. Series 712 swing check valves are rated to 300 PSI (2065 kPa) service. A 2" (60.3 mm) size stainless steel model is also available. Series 713 is available in 2" (60.3 mm) size rated to 1000 PSI (6900 kPa).

Vic-300 butterfly valves are designed for services from vacuum to 300 PSI (2065 kPa). Vic300 butterfly valves feature a narrow profile disc design with a smooth, coated inner body which combine for superior flow characteristics. This combination results in extremely low break-away torque, reducing gear operator and actuator sizing and costs. Standard polyphenylene sulfide blend (PPS) coating accommodates a wide variety of severe services (epoxy coating or full stainless body are available for severe services). The dual-seal disc provides bubbletight sealing up to 300 PSI (2065 kPa) in both directions without added valve modifications or cost.

The Victaulic Series 779 Venturi-Check valves provide a versatility of service unlike any flow measuring device. The CAD-designed hydrodynamic inlet profile provides a natural venturi as part of the valve. The inlet is drilled, tapped and plugged, ready to receive the flow kit (included). The venturi-like taps provide much greater measurement accuracy than taps placed across the valve seat. Valve turbulence and interference across the valve seat need not be a consideration. Twin taps on both sides of the valve provide positioning of measurement outlets for convenient meter connection. Every valve is factory tested and rated to 300 PSI (2065 kPa) working pressure. All sizes can be installed in horizontal or vertical position and provide leak-free sealing under conditions as low as five feet (1.5 m) of head pressure.

Series 716 Vic-Check Valves

Series 700 Butterfly Valves Series 377 Vic-Plug Balancing Valve

Typical 2-1/2 & 3" Sizes

Typical 4 - 14" Sizes

Victaulic Series 700 butterfly valves are designed for bubble-tight shut-off to 200 PSI (1400 kPa). Two-piece stem permits narrow disc design for low pressure drop performance and is self-centering for positive shut-off. Valves are available with EPDM for water service to +230F (+110C) or nitrile for oil services to +150F (+66C) liners. Refer to Liner/Disc Selection for general service recommendations.

The Series 716 check valve is available in sizes 2-1/214" (73.0355.6 mm). It is a spring assisted single disc design that achieves a leakfree seal with as little as 5 ft. (1.5 m) of head and can be installed in both horizontal and vertical positions. Every valve is factory tested to its working pressure of 300 PSI (2065 kPa). Drains are optional both upstream and downstream of the disc.

Series 377 Vic-Plug balancing valve is the first eccentric grooved end plug valve for throttling services. Victaulic Style 307 Transition couplings are available (312"/88.9323.9 mm) to directly connect Vic-Plug valves to grooved end steel and other IPS pipe.

269

Pipe Fittings

CIRCUIT BALANCING VALVES

The TA Hydronics* balancing valves offer a reliable, simple and cost effective way to measure and balance all flow rates. Full throttling range is achieved by 4, 8, 12 or 16 full turns of the hand wheel, enabling a more precise setting. Actual pressure drops are difficult to establish by calculation. Water flows are frequently incorrect. They can be corrected easily by regulating the desired water flow with TA Hydronics Globe Style Balancing Valves. By measuring the pressure drop across measuring ports at a particular hand wheel setting, the water flow for the valve size can be read easily from the appropriate pressure drop graph. Series 785, 786 and 787 have full Ametal* copper alloy bodies which obviate dielectric connections. Series 788 and 789 have ductile iron bodies and Ametal trim. All valves are rated to +250F (+120C) and 22F (-30C), but service will be governed by the connecting coupling gasket ratings.

*Registered trademark of TA Hydronics.

Series 785 TBV-S

Sweated End Mini (125 PSI)

A

Series 786 STAS

Solder End (300 PSI)

Dim.In./mm SIZE Nom. In.

B

Series 787 STAD

NPT (Fem.) End (300 PSI)

Dim.In./mm Dim.In./mm

A

Actual mm

1/2

21.3

A 2.63

67.0

Aprx. Hgt. Wgt. Ea. B Lbs./kg 2.88 1.0

73.0 0.5

SIZE Nom. In.

Actual mm

1/2

21.3

B Drain Kit (Optional)

A 3.50

89.0

Aprx. Hgt. Wgt. Ea. B Lbs./kg 4.00 1.4

102.0 0.6

SIZE Nom. In.

Actual mm

1/2

21.3

B Drain Kit (Optional)

A 3.50

89.0

Aprx. Hgt. Wgt. Ea. B Lbs./kg 4.00 1.5

102.0 0.7

3/4

26.9

3.16

80.2

2.56

65.0

1.0

0.5

3/4

26.9

3.81

97.0

4.00

102.0

1.4

0.6

3/4

26.9

3.81

97.0

4.00

102.0

1.6

0.7

Overall height with valve fully opened.

1

33.7

4.31

110.0

4.50

114.0

1.9

0.9

1

33.7

4.31

110.0

4.50

114.0

2.0

0.9

1-1/4

42.4

4.88

124.0

4.31

110.0

2.4

1.1

1-1/4

42.4

4.88

124.0

4.31

110.0

2.6

1.2

1-1/2

48.3

5.13

130.0

4.75

121.0

3.1

1.4

1-1/2

48.3

5.13

130.0

4.75

121.0

3.3

1.5

2

60.3

6.13

156.0

4.75

121.0

4.5

2.0

2

60.3

6.13

156.0

4.75

121.0

5.0

2.3

Overall height with valve fully opened.

Overall height with valve fully opened.

Series 787-U

A

Series 788 STAF

Dim.In./mm SIZE Nom. In.

Actual mm

B

Series 789 STAG

Grooved End (300 PSI)

Dim.In./mm Dim.In./mm

A

1/2

21.3

A 4.81

122

Aprx. Hgt. Wgt. Ea. B Lbs./kg 4.00 1.7

102 0.8

Flanged End (250 PSI)

SIZE Nom. In.

Actual mm

3/4

26.9

5.13

130

4.00

102

1.8

0.8

2-1/2

D

Aprx. Hgt. Wgt. Ea. A B Lbs./kg 11.38 7.88 29.0

289.0 311.0 350.0 400.0 480.0 600.0 730.0 851.0 200.0 216.0 229.0 267.0 286.0 451.0 470.0 521.0 13.2

SIZE Nom. In.

Actual mm

2-1/2

73.0

Aprx. Hgt. Wgt. Ea. A B Lbs./kg 11.38 7.88 14.0

289.0 311.0 350.0 400.0 480.0 600.0 730.0 851.0 200.0 216.0 229.0 267.0 286.0 451.0 470.0 521.0 6.4

1

33.7

6.00

152

4.50

114

2.2

1.0

73.0

3

B

12.25 8.50 13.75 9.00 15.75 10.50 18.88 11.25 23.63 17.75 28.75 18.50 33.50 20.50

38.0

17.2

B

3

88.9

12.25 8.50 13.75 9.00 15.75 10.50 18.88 11.25 23.63 17.75 28.75 18.50 33.50 20.50

20.0

9.1

Overall height with valve fully opened.

88.9

4

114.3

50.0

22.7

4

114.3

31.0

14.1

5

141.3

74.0

33.6

5

141.3

50.0

22.7

6

168.3

101.0

45.8

6

168.3

69.0

31.3

8

219.1

243.0

110.2

8

219.1

175.0

78.8

10

273.0

324.0

147.0

10

273.0

240.0

108.0

12

323.9

463.0

208.4

12

323.9

360.0

162.0

Overall height with valve fully opened.

Overall height with valve fully opened.

270

Pipe Fittings

IPS CARBON STEEL PIPE GROOVED END ACCESSORIES

Style 731 Suction Diffuser

Victaulic Style 731 Suction-Diffuser provides optimum flow conditions at the inlet side of the pump. Each suction diffuser is provided with a removable strainer and a fine mesh sleeve which acts as a start-up strainer. A 1-1/4" (42.4 mm) pipe support boss is provided for support and side taps for pressure measurement. A plug is also provided to allow for easy draining of the system. Victaulic Style 731 is rated at 300 PSI (2065 kPa) working pressure.

Style 730 Vic-Strainer Tee Type

Style 732 Vic-Strainer Wye Type

Style 150 Mover Expansion Joint

Style 155 Expansion Joint

Style 47 Dielectric Waterway Fittings

Clearflow* Dielectric Waterway fittings create a dielectric waterway by insulating the inside of the metal casing, thus inhibiting the internal formation of galvanic local cell corrosion between the dissimilar metals in the presence of water. Clearflow fittings use materials which meet the requirements of ASTM F492-77. Clearflow fittings are designed for continuous use at temperatures up to 230F (110C) and pressures up to 300 PSI (2065 kPa).

IPS Carbon Steel Pipe Hole Cut Products

Styles 920 & 920N Mechanical-T Bolted Branch Outlet

1. Inert, non-corrosive thermoplastic lining (NSF/FDA listed) 2. Patented ring-groove locks the steel casting to the thermoplastic lining, or molded liner with identifying roll marking on casing. 3. Zinc electroplated casing, threaded in accordance with American National Pipe Thread Tapered (ANSI A1.20.1)

Style 47-GG Grooved End Steel (IPS) to Grooved Copper (CTS) Transition Fitting

Style 47-GT and 47-TT

Styles 920 and 920N w/Grooved Outlet Style 47-GT Grooved X Threaded Grooved X Threaded

2 - 3" Sizes

4 - 8" Sizes

Style 47-GG Grooved X Grooved

*Clearflow is a registered trademark of Perfection Corp.

Style 47-TT Threaded X Threaded

Threaded X Threaded Styles 920 and 920N w/Female Threaded Outlet

271

Pipe Fittings

IPS CARBON STEEL PIPE HOLE CUT PRODUCTS

Style 923 Vic-Let Strapless Outlet

The Victaulic Style 923 Vic-Let outlet has integral lugs which insert into a hole cut in the pipe, gripping against the pipes inside wall, while a nut threaded on the main body is tightened. Style 923 Vic-Let outlets are rated at 300 PSI (2065 kPa) working pressure for standard weight steel pipe.

4 - 8" Sizes 10" and larger

Style 924 Vic-O-Well Strapless Thermometer Outlet

The Victaulic Style 924 Vic-O-Well outlet main body casting has integral lugs which insert into a hole, gripping against the I.D. wall, while a nut threaded on the main body. The Vic-O-Well outlet main body is machined internally to standard thread well dimensions. Both sizes are rated at 300 PSI (2065 kPa) working pressure on steel pipe.

4 - 8" IPS

10" and larger

IPS Carbon Steel Pipe Pressfit System

The Pressfit System offers economy, speed and reliability for joining small diameter pipe for fire protection, heating/air conditioning and many other services. Pressfit products for carbon steel pipe are externally zinc electroplated. Pressfit carbon steel is not intended for use in open loop water systems. The system incorporates Schedule 5 steel pipe from 3/42" (26.960.3mm), with a system of Pressfit couplings, elows, tees, reducers and adapters. This system allows pipe assembly in seconds. A portable, hand-held electric or hydraulic tool assembles the fitting on the pipe with a permanent mechanical attachment. The Pressfit System for carbon steel is BOCA listed HVAC (Cat. 23) and Fire Protection (Cat. 15). It is Listed by SBCCI PST and ESI in Report No. 9535. Pressfit System products are rugged and reliable. They are UL/ULC Listed and FM Approved for 175 PSI (1200 kPa) fire protection service and rated to 300 PSI (2065 kPa) for heating water and other general services. Pressfit System also available in stainless.

O-ringPrecisely molded compresses against pipe O.D. HousingPrecision formed externally zinc electroplated carbon steel with integral pipe stop Pipe StopAssures uniform take-out dimension and positions pipe for proper assembly (not on Slip Coupling) O-ring PocketSized to contain the o-ring, the pocket is deformed during assembly Pressfit Tool IndentHousing is uniformly compressed with the Pressfit Tool into a permanent mechanical engagement onto the pipe.

NOTE: Designers of systems exposed to potentially corrosive situations (high humidity, marine or process environments, etc.) should always consider use of protective coatings on any carbon steel piping products.

Style 505 Standard Coupling

(P X P)

Style 510 90 Elbow

(P X P)

Style 511 45 Elbow

(P X P)

Style 509 Short Tangent 90 Elbow

(P X P)

Style 509 Short Radius 90 Elbow Reducing

(P X F)

Style 506 Slip Coupling

(P X P)

272

Pipe Fittings

IPS CARBON STEEL PIPE PRESSFIT SYSTEM

Style 520 Tee

(P X P X P)

Style 520 Tee Reducing Branch

(P X P X F)

Style 520 End-of-Line Tee

With Threaded Reducing Branch (P X C X F)

With Pressfit Reducing Branch (P X D X P)

Style 550 Reducer Insert Style 522 Brass Body Ball Valve with Carbon Steel Pressfit Ends

(P X P)

Style 535 Cross

(P X P)

(T X P)

Style 580 Adapter Female Threaded

(P X F)

Style 580 Adapter Male Threaded

(P X M)

Approved Pipe Products in the Pressfit carbon steel system are easily installed on approved Schedule 5 carbon steel pipe using the Pressfit tool. The Pressfit System requires no special preparation of the pipe ends before assembly. Pipe should be square cut (0.030") and deburred, if

required, to prevent damage to the o-ring during assembly. Pressfit System carbon steel products are designed for use only on approved Schedule 5 carbon steel pipe having a maximum yield strength of 45,000 PSI (310000 kPa) and maximum hardness of Rb70.

273

Pipe Fittings

IPS CARBON STEEL PIPE PLAIN END SYSTEM

Style 99 Roust-A-Bout Coupling Plain End Fittings

The Style 99 Roust-A-Bout coupling consists of a durable ductile iron housing. Its curved, case-hardened steel jaws grip into the pipe when nuts are tightened to full torque specifications, and it requires no pipe end preparation.

Long Radius Elbows

Long Tangent Elbows

CTS Copper Tubing Grooved Piping System

TUBING TYPE K, L, M, DWV

The Victaulic copper connection system is for joining large diameter copper tubing (CTS) in 28" (54.0206.4 mm) sizes. Patented angled pad design adjusts to standard tubing tolerances and provides positive clamping on the tubing to resist flexural and torsional loads. The system uses a proven pressure-responsive synthetic rubber FlushSeal gasket to seal on the outside diameter of the tubing. This means no heat is required and no lead is used. The housing provides the gripping strength for pressure ratings up to 300 PSI (2065 kPa), depending on type and size of copper tubing.

Style 606 Coupling for Copper Tubing

No. 650 Reducer

No. 652 Reducer

Groove x Copper Sweat Groove x Groove

Style 641 Vic-Flange Adapter for Copper Tubing

The Style 641 VicFlange Adapter provides a direct connection from flanged components (Cl. 125 and Cl. 150 bolt hole pattern) to grooved copper tubing, with integral tabs to ease handling.

No. 610, No. 611 & No. 620 Elbows and Tee No. 660 Cap

Victaulic copper fittings are full-flow, standard radius fittings, supplied roll grooved.

274

Das könnte Ihnen auch gefallen

- Dimensions of Sockolets Pressure Class 3000 and 6000 Lbs - MSS-SP97Dokument3 SeitenDimensions of Sockolets Pressure Class 3000 and 6000 Lbs - MSS-SP97konazoi100% (1)

- Stub EndDokument4 SeitenStub EndFranciscoplazaNoch keine Bewertungen

- Nozzle CatalogueDokument53 SeitenNozzle CatalogueMike UpNoch keine Bewertungen

- SOCKOLETDokument1 SeiteSOCKOLETJOSE DIAZ HERNANDEZNoch keine Bewertungen

- Dimensions Weldolet® Size On Size STD MSS SP97Dokument2 SeitenDimensions Weldolet® Size On Size STD MSS SP97Musslih Yulianto100% (1)

- Air Handing Unit Alu Profile 2019 PDFDokument43 SeitenAir Handing Unit Alu Profile 2019 PDFWINNoch keine Bewertungen

- Argus FK 76M Ball Valve Material ListDokument2 SeitenArgus FK 76M Ball Valve Material ListFelipe Gamboa Gálvez100% (1)

- Tabla de Bridas y Esparragos PDFDokument1 SeiteTabla de Bridas y Esparragos PDFjairo ardila100% (1)

- Channel Astm A36Dokument2 SeitenChannel Astm A36alexmc000123Noch keine Bewertungen

- Wave Washer For BearingsDokument2 SeitenWave Washer For Bearingspradipbhosale81Noch keine Bewertungen

- Din 931 PDFDokument2 SeitenDin 931 PDFsorinenngNoch keine Bewertungen

- ERZG Blanking Plug Technical DatasheetDokument3 SeitenERZG Blanking Plug Technical DatasheetEvolution Oil ToolsNoch keine Bewertungen

- Weldolet CalculationDokument20 SeitenWeldolet Calculationanhdung_proNoch keine Bewertungen

- Dic Pps Weld StrengthDokument1 SeiteDic Pps Weld StrengthWoong KimNoch keine Bewertungen

- ASTM A36 Steel plate propertiesDokument1 SeiteASTM A36 Steel plate propertiesStan HonNoch keine Bewertungen

- CEPE02100A1 CAG Updated Jan23 14Dokument60 SeitenCEPE02100A1 CAG Updated Jan23 14rudi setiawanNoch keine Bewertungen

- Reliable SOLBERG Foam Chambers F 2011010 6NLDokument5 SeitenReliable SOLBERG Foam Chambers F 2011010 6NLjonejackrousseauNoch keine Bewertungen

- Not For Production Use (For Reference Only) : ASTM A778-01Dokument1 SeiteNot For Production Use (For Reference Only) : ASTM A778-01Abu Bakr AsharefNoch keine Bewertungen

- LCS310UR Diagrama2 PDFDokument13 SeitenLCS310UR Diagrama2 PDFKnspeis0% (1)

- LARGE DIAMETER FLANGES & FITTINGS GUIDEDokument38 SeitenLARGE DIAMETER FLANGES & FITTINGS GUIDEAshfaq Anwer100% (1)

- Torquing Specification Inch & Metric Fastener Chart: Socket Head Cap ScrewsDokument2 SeitenTorquing Specification Inch & Metric Fastener Chart: Socket Head Cap ScrewsgielNoch keine Bewertungen

- IMI Remosa ValvesDokument4 SeitenIMI Remosa ValvesDhananjay B KNoch keine Bewertungen

- Industrial belt tension tester guideDokument3 SeitenIndustrial belt tension tester guidedaniel castilloNoch keine Bewertungen

- Class Flanges Bolt Torque LoadsDokument2 SeitenClass Flanges Bolt Torque LoadsAulia RahmanNoch keine Bewertungen

- ASME B16.5 - 3 InchDokument1 SeiteASME B16.5 - 3 InchRanjan KumarNoch keine Bewertungen

- Gasket Installation: DurlonDokument3 SeitenGasket Installation: Durlonlorenzo100% (1)

- Acsr SPLN 41-7 PDFDokument2 SeitenAcsr SPLN 41-7 PDFDharta Wira100% (1)

- 800 1500lb ValvoletDokument1 Seite800 1500lb ValvoletAugusto Manuel Inga SánchezNoch keine Bewertungen

- QT 16Cr PDFDokument1 SeiteQT 16Cr PDFYaroslav RuizNoch keine Bewertungen

- CRANE-Ficha Tecnica-Valvula CompuertaDokument1 SeiteCRANE-Ficha Tecnica-Valvula CompuertaWillyam JiménezNoch keine Bewertungen

- Anvil Fig137 U-Bolt PDFDokument1 SeiteAnvil Fig137 U-Bolt PDFAin AzmiNoch keine Bewertungen

- Denso Protal 7200Dokument2 SeitenDenso Protal 7200min_one447065Noch keine Bewertungen

- SHORTSTOPP 300D Split Tees With Guide BarsDokument3 SeitenSHORTSTOPP 300D Split Tees With Guide BarsMartin AndradeNoch keine Bewertungen

- Paint Specification SheetDokument1 SeitePaint Specification Sheetheru firmansyahNoch keine Bewertungen

- 10.flange Bolts, STD TeesDokument7 Seiten10.flange Bolts, STD TeesNIRMAL SINGHNoch keine Bewertungen

- Zmitoiii: Nnovation Efficiency QualityDokument12 SeitenZmitoiii: Nnovation Efficiency QualityCristian Muñoz AlarcónNoch keine Bewertungen

- Ductile Iron Backup Rings for HDPE FlangesDokument1 SeiteDuctile Iron Backup Rings for HDPE FlangesnestorNoch keine Bewertungen

- Garlock Bolt Torque Values for Rubber Gaskets in B16.5 and ASTM A193 FlangesDokument1 SeiteGarlock Bolt Torque Values for Rubber Gaskets in B16.5 and ASTM A193 FlangesPedro Viru BernaolaNoch keine Bewertungen

- Tabla de Severidad Unidades SullairDokument1 SeiteTabla de Severidad Unidades Sullairlambjabibi100% (1)

- Bolt Depot - Bolt Grade Markings and Strength ChartDokument3 SeitenBolt Depot - Bolt Grade Markings and Strength ChartfrancisNoch keine Bewertungen

- Tubos Astm A53Dokument1 SeiteTubos Astm A53RAFAELNoch keine Bewertungen

- PSV 430066 PDFDokument41 SeitenPSV 430066 PDFErikikoNoch keine Bewertungen

- Pipe ScheduleDokument1 SeitePipe SchedulePraveenNoch keine Bewertungen

- Bolt Torque Chart: ASTM A307Dokument5 SeitenBolt Torque Chart: ASTM A307Leonardo Díaz Cerna100% (1)

- SN398 2008-04 eDokument4 SeitenSN398 2008-04 ewasim_akp9885Noch keine Bewertungen

- SEO-Optimized title for steel plate inspection certificateDokument1 SeiteSEO-Optimized title for steel plate inspection certificateJosé Miguel Otárola SandovalNoch keine Bewertungen

- Long Radius Steel Elbows - 3D, 5D and 6D: Product DescriptionDokument3 SeitenLong Radius Steel Elbows - 3D, 5D and 6D: Product Descriptionbadesharamk100% (2)

- Fire Test Certificate SummaryDokument1 SeiteFire Test Certificate SummaryjajakaNoch keine Bewertungen

- Butt Welded Fittings Dimensions ANSI B-16.9 16.28 MSS SP-43Dokument3 SeitenButt Welded Fittings Dimensions ANSI B-16.9 16.28 MSS SP-43Reginaldo Matias NunesNoch keine Bewertungen

- SAES Saudi Aramco Engineering Standard1Dokument14 SeitenSAES Saudi Aramco Engineering Standard1Ibraa IbraaNoch keine Bewertungen

- LE B-255 H4R: ClassificationDokument2 SeitenLE B-255 H4R: ClassificationVivien EmeraldoNoch keine Bewertungen

- Tee GuiadaDokument1 SeiteTee GuiadaDANIELCOLUNGANoch keine Bewertungen

- UNI EN 24014 DIN EN 24014 ISO 4014: Viti A Testa Esagonale Con Gambo Parzialmente FilettatoDokument2 SeitenUNI EN 24014 DIN EN 24014 ISO 4014: Viti A Testa Esagonale Con Gambo Parzialmente FilettatoEng. EmersonNoch keine Bewertungen

- Gruvlok Stainless SteelDokument16 SeitenGruvlok Stainless Steellink2u_007Noch keine Bewertungen

- Gaugeable SAF 2507™ Super Duplex Tube Fittings, (MS-01-174, R5)Dokument12 SeitenGaugeable SAF 2507™ Super Duplex Tube Fittings, (MS-01-174, R5)김윤식Noch keine Bewertungen

- Swagelok Gaugeable Tube Fittings SAF 2507 Super DuplexDokument12 SeitenSwagelok Gaugeable Tube Fittings SAF 2507 Super DuplextotcsabNoch keine Bewertungen

- Stainless Steel Pipe, Fittings & FlangesDokument24 SeitenStainless Steel Pipe, Fittings & Flangesgame firmanNoch keine Bewertungen

- ES B MarineDeckPenetrationsDokument2 SeitenES B MarineDeckPenetrationsBLUCHERNoch keine Bewertungen

- MasterSeries 850 Specification SheetDokument2 SeitenMasterSeries 850 Specification SheetFEBCONoch keine Bewertungen

- ASV 10 20 BrochureDokument8 SeitenASV 10 20 BrochureThomas Duane DavidsonNoch keine Bewertungen

- MPSA-SOP - 07 Cranes and Lifting EquipmentDokument14 SeitenMPSA-SOP - 07 Cranes and Lifting EquipmentLim PaNoch keine Bewertungen

- Tubemac Section e PDFDokument16 SeitenTubemac Section e PDFLim PaNoch keine Bewertungen

- Malleable Iron Threaded FittingsDokument16 SeitenMalleable Iron Threaded Fittingsenvitech72Noch keine Bewertungen

- Pipe SMLS VS Welded PDFDokument1 SeitePipe SMLS VS Welded PDFLim PaNoch keine Bewertungen

- NIH Design Requirements Manual (NIH, 2016 Rev 2019)Dokument1.219 SeitenNIH Design Requirements Manual (NIH, 2016 Rev 2019)Mic MostalesNoch keine Bewertungen

- Hl250M Parts Breakdown: Build Code CI-ACW-1Dokument13 SeitenHl250M Parts Breakdown: Build Code CI-ACW-1Amanda FitzgeraldNoch keine Bewertungen

- Rexx Part1Dokument17 SeitenRexx Part1CartecSyriaNoch keine Bewertungen

- AP EAMCET - 2018 Engineering Mock Counselling - AP EAMCET 2017 Last Ranks - SAKSHI Education, Expected Engineering CollegesDokument7 SeitenAP EAMCET - 2018 Engineering Mock Counselling - AP EAMCET 2017 Last Ranks - SAKSHI Education, Expected Engineering CollegesAnantha KrishnaNoch keine Bewertungen

- Ab Admin W EnuDokument952 SeitenAb Admin W Enus6i6x6Noch keine Bewertungen

- Service Manual: Personal Navigation SystemDokument62 SeitenService Manual: Personal Navigation Systemmarnel_16242Noch keine Bewertungen

- RS 485 25a ManDokument8 SeitenRS 485 25a MansitronixexNoch keine Bewertungen

- 210X3E Electrical 3Dokument1 Seite210X3E Electrical 3ArmandoCalderonNoch keine Bewertungen

- Blince OMR Hydraulic MotorDokument10 SeitenBlince OMR Hydraulic MotorJoaquin CarvajalNoch keine Bewertungen

- Engine Log Book ReadingsDokument59 SeitenEngine Log Book ReadingsjevguNoch keine Bewertungen

- 2015.1 ModelS LHD ReleaseDokument45 Seiten2015.1 ModelS LHD ReleaseBilly HaglerNoch keine Bewertungen

- OTC119101 OptiX OSN 9800 Hardware Description ISSUE1.11Dokument76 SeitenOTC119101 OptiX OSN 9800 Hardware Description ISSUE1.11EliValdiviaZúnigaNoch keine Bewertungen

- Energex Commercial and Industrial PMT App ADokument8 SeitenEnergex Commercial and Industrial PMT App AdseugenioNoch keine Bewertungen

- Soviet Weapon-System AcquisitionDokument92 SeitenSoviet Weapon-System AcquisitionJohn Greenewald100% (1)

- Hazid Loading 1Dokument5 SeitenHazid Loading 1poetoetNoch keine Bewertungen

- Selection Guide OboDokument40 SeitenSelection Guide ObovjtheeeNoch keine Bewertungen

- Rigid Pavement Thesis - 2Dokument12 SeitenRigid Pavement Thesis - 2san htet aung100% (1)

- 495HR2 US Ss 042710 LRDokument2 Seiten495HR2 US Ss 042710 LRAlonso FernandoNoch keine Bewertungen

- Joel MeyerowitzDokument5 SeitenJoel MeyerowitzRobertKienerNoch keine Bewertungen

- Electronic: Whole Brain Learning System Outcome-Based EducationDokument19 SeitenElectronic: Whole Brain Learning System Outcome-Based EducationTrinidad, Gwen StefaniNoch keine Bewertungen

- HRM NotesDokument2 SeitenHRM NotesPrakash MahatoNoch keine Bewertungen

- Radar Presentation 01Dokument30 SeitenRadar Presentation 01cozdim100% (5)

- Dragonfly Topology and RoutingDokument27 SeitenDragonfly Topology and RoutingVictor Dias AlmeidaNoch keine Bewertungen

- DocxDokument6 SeitenDocxkareNoch keine Bewertungen

- The Toyota Way - Chapters 1 - 3Dokument10 SeitenThe Toyota Way - Chapters 1 - 3Juan PabloNoch keine Bewertungen

- 16th International Conference on Quality in Research (QiRDokument1 Seite16th International Conference on Quality in Research (QiRArifo Gunawan CahyanegoroNoch keine Bewertungen

- SCP 30 Minute Demo - Installation and Execution: Create A Master Password: SCP 4.0Dokument37 SeitenSCP 30 Minute Demo - Installation and Execution: Create A Master Password: SCP 4.0septriNoch keine Bewertungen

- Solid Waste Pollution in Ho Chi Minh CityDokument33 SeitenSolid Waste Pollution in Ho Chi Minh CityLamTraMy13Noch keine Bewertungen

- Seepage Sump Pumps (Location at Undercroft Level) - Data - Sheet - 65 - DL - 515ADokument4 SeitenSeepage Sump Pumps (Location at Undercroft Level) - Data - Sheet - 65 - DL - 515AGokula Krishnan CNoch keine Bewertungen

- Unit 3 Slides PSK - QAMDokument87 SeitenUnit 3 Slides PSK - QAMSam JonesNoch keine Bewertungen