Beruflich Dokumente

Kultur Dokumente

Splice Joints

Hochgeladen von

Manoj ManoharanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Splice Joints

Hochgeladen von

Manoj ManoharanCopyright:

Verfügbare Formate

Aircraft structures - The aircraft splice joint/connection definition and description

The splice connection is present in all aircraft structure. The aircraft is made of several simple structural members and all this members are connected together by the called splice connection. Therefore this type of connection is the most commonly used in the aircraft. But what is a splice? How can I define a splice and where I will find this connection in the aircraft.

Splice connection is defined as a connection that performs the total load transfer between two structural elements. When we find a structural connection that makes the transfer of 100% of the total load applied, this is a splice connection. The splice connection is different of the doubler reinforcement. This two types of connections are quite different regarding the function and load transfer analysis, future post will define the difference. The aircraft structural splice is made for several reasons and very good reasons. They are:

Manufacturing limitations - the limitation that we have with the techniques and machines in the manufacturing process of structures, requires the application of the splice connection. For example: if we have a fuselage frame, skin or stringer that exceeds the dimensions of my manufacturing process machine. I must divide the structure in several parts that can be made in my manufacturing process machine and then connect the parts with splices. In my manufacturing shop we have a forming machine that produces a 100 inch by 100 inch part like a stringer. But my aircraft needs a 1000 inch stringer, then we must produce 10 simple stringers parts and connect them with splices to give the required 1000 inch stringer. We will have 10 splice connections in the aircraft stringer. The same applies to frames, skin panels, beams, etc...all aircraft structure as splices and need splices.

Fail Safe design philosophy - this structural design philosophy is defined as: the structural load must be transferred by two loading paths, if one of the loading paths fails the other must be capable to safely transfer all the load with no structural failure. If we design for fail safe the structure must be divided in several parts if one fails the others are capable to maintain the structural integrity. This type of design occurs in the stringers, we have several stringers in the fuselage, if one stringer fails the others are capable to transfer all applicable load. The splice connection is the structural option to separate the structures and maintain the structural integrity independent one of the other. As example the wing upper or lower panel can be made of a single panel, but to apply the Fail Safe design generally we separate this panel in 3 or 4 independent panels connected by splice joints. If failure occurs in panel 1, the failure (crack) will not propagate to panel 2 and 3. The total load will be redistributed only to panel 2 and 3 and this two panels must be capable to transfer the load by splice joints. In this case the splice joint is used to maintain the individual structural parts independent one of the others in order that, if cracks occurs in one of them the crack will not propagate to the others, Fail Safe design.

Geometry construction and assembly proposes - sometimes we need to use splice joints because we are required to construct a specific geometry with individual manufactured parts. The structural assembly of the individual parts, up to the main structural components, up to the aircraft itself requires that connection and attachments are needed all over the aircraft. This type of connection are defined as splice joints. As you know the aircraft structural main parts in a large aircraft manufacturing are made in several parts of the world, they are all put together in the final assembly line of the aircraft, all this parts are connected using splice joints. All over the aircraft you will find orbital splices, longitudinal splices, frames splices, stringer splices, wing panel splices, rib splices, spar splices, etc. As you see splice joints/connection are quite common, and very easy to find in the aircraft. For this reason you must understand well the definition, when to use them and the structural behavior of this type of joint. Future load analysis posts of a splice and doubler joint/connection will be available for better understanding the difference.

Das könnte Ihnen auch gefallen

- Tom Swift PaperDokument53 SeitenTom Swift Paperimran_chaudhryNoch keine Bewertungen

- Multi-Spring Representation of Fasteners For Msc/nastran ModelingDokument13 SeitenMulti-Spring Representation of Fasteners For Msc/nastran ModelingSteve MahoneyNoch keine Bewertungen

- Spars and Stringers - Function and Designing PDFDokument4 SeitenSpars and Stringers - Function and Designing PDFprabs20069178Noch keine Bewertungen

- Steel 17-4PH MmpdsDokument18 SeitenSteel 17-4PH MmpdsManoj ManoharanNoch keine Bewertungen

- 012-NetNumen U31 R22 Northbound Interface User Guide (SNMP Interface)Dokument61 Seiten012-NetNumen U31 R22 Northbound Interface User Guide (SNMP Interface)buts101100% (5)

- 4.torque Diagram of The WingDokument3 Seiten4.torque Diagram of The WingBalaji AeroNoch keine Bewertungen

- HCSR Chapter 8 - BucklingDokument62 SeitenHCSR Chapter 8 - Bucklingjitenisha1010Noch keine Bewertungen

- Spar LocationDokument4 SeitenSpar LocationParth ChopraNoch keine Bewertungen

- Design and Analysis of Aircraft WingDokument7 SeitenDesign and Analysis of Aircraft WingSai RahulNoch keine Bewertungen

- Lug AnalysisDokument4 SeitenLug AnalysisKuldeep BhattacharjeeNoch keine Bewertungen

- Airbus DTA AntennaDokument37 SeitenAirbus DTA AntennaTabatha BarnesNoch keine Bewertungen

- Multhopp Method PDFDokument18 SeitenMulthopp Method PDFsizzleNoch keine Bewertungen

- Structure Design A350 KAIDokument56 SeitenStructure Design A350 KAIManoj Manoharan91% (11)

- Bolted Joint CalculatorDokument12 SeitenBolted Joint Calculatorharoub_nasNoch keine Bewertungen

- Hi Lok FastenersDokument4 SeitenHi Lok FastenersManoj Manoharan75% (4)

- CP4P Week3 Course Preview ActivityDokument4 SeitenCP4P Week3 Course Preview ActivityPresiNoch keine Bewertungen

- Aircraft Structural DesignDokument30 SeitenAircraft Structural Designarun_justin_1Noch keine Bewertungen

- EASA Presentation Antennas GeneralDokument11 SeitenEASA Presentation Antennas Generalayhun100% (1)

- 4281 - 03 Stiffened Shear WebDokument26 Seiten4281 - 03 Stiffened Shear WebAndrew GilbrideNoch keine Bewertungen

- Aircraft Stress Analysis and Structural Design Full VersionDokument20 SeitenAircraft Stress Analysis and Structural Design Full VersionErhanNoch keine Bewertungen

- Design of Rivet JointDokument34 SeitenDesign of Rivet JointDarsHan MoHanNoch keine Bewertungen

- Virtual Testing of Aircraft StructuresDokument21 SeitenVirtual Testing of Aircraft StructuresChandresh ZinzuwadiaNoch keine Bewertungen

- Thesis Ilhan - 10122010 - Final VersionDokument180 SeitenThesis Ilhan - 10122010 - Final VersionRamesha Aswathanarayanappa100% (2)

- Supersonic PDFDokument10 SeitenSupersonic PDFVijay ChandarNoch keine Bewertungen

- Analysis of Different Designed Landing Gears For A Light AircraftDokument4 SeitenAnalysis of Different Designed Landing Gears For A Light AircraftarulmuruguNoch keine Bewertungen

- 5 Wing DesignDokument48 Seiten5 Wing DesignRidhima KaulNoch keine Bewertungen

- M96SC05 Oleo StrutDokument6 SeitenM96SC05 Oleo Strutchaumont12345Noch keine Bewertungen

- Landing Gear Shock Absorber ModelingDokument46 SeitenLanding Gear Shock Absorber ModelingkhaziNoch keine Bewertungen

- COMPOSITE WING OPTIMALIZATION USING FEM ANALYSES SYSTEMS by Miroslav Spišák - Peter MalatinDokument3 SeitenCOMPOSITE WING OPTIMALIZATION USING FEM ANALYSES SYSTEMS by Miroslav Spišák - Peter MalatinVesa RäisänenNoch keine Bewertungen

- Wing Rib Stress Analysis and Design OptimizationDokument5 SeitenWing Rib Stress Analysis and Design OptimizationNeeraja ManemNoch keine Bewertungen

- Wing Rib Analysis Shear Center For 3 Stringer Closed CellDokument33 SeitenWing Rib Analysis Shear Center For 3 Stringer Closed CellpramodssgNoch keine Bewertungen

- Aircraft Design With Maneuver and Gust Load AlleviationDokument15 SeitenAircraft Design With Maneuver and Gust Load AlleviationNeoNoch keine Bewertungen

- Linear Static Analysis of CFRP Aircraft WingDokument4 SeitenLinear Static Analysis of CFRP Aircraft WingduyphuocNoch keine Bewertungen

- Design and Static Structural Analysis of Aircraft Floor BeamDokument5 SeitenDesign and Static Structural Analysis of Aircraft Floor BeamGRD JournalsNoch keine Bewertungen

- Design and Linear Static Analysis of Transport Aircraft Vertical Tail For Different Rudder Deflection (Rotation)Dokument13 SeitenDesign and Linear Static Analysis of Transport Aircraft Vertical Tail For Different Rudder Deflection (Rotation)Alaek Nu'manNoch keine Bewertungen

- Design and Analysis of The Main Assembly Jig For A Multirole Civilian Aircraft's Main DoorDokument6 SeitenDesign and Analysis of The Main Assembly Jig For A Multirole Civilian Aircraft's Main DoorPrasanta Kumar SamalNoch keine Bewertungen

- 51 00 00 1Dokument21 Seiten51 00 00 1Alonso Herrera AguilarNoch keine Bewertungen

- Wing Spar CalculationDokument18 SeitenWing Spar CalculationJürgen StorlNoch keine Bewertungen

- Weight Estimation of Aircraft PDFDokument32 SeitenWeight Estimation of Aircraft PDFSanthosh PraveenNoch keine Bewertungen

- AF Structure ContDokument21 SeitenAF Structure ContlongmilkNoch keine Bewertungen

- 26-BucklindCrippling CompressionCripplingDokument34 Seiten26-BucklindCrippling CompressionCripplingvaler1989Noch keine Bewertungen

- Aircraft Design - University Old QuestionsDokument8 SeitenAircraft Design - University Old QuestionsJef LeNoch keine Bewertungen

- Fastener FlexibilityDokument3 SeitenFastener FlexibilitySonell ShroffNoch keine Bewertungen

- Sor 25 PDFDokument16 SeitenSor 25 PDFIan KellyNoch keine Bewertungen

- Prelim DesignDokument94 SeitenPrelim DesignccoyureNoch keine Bewertungen

- Aircraft Drag Reduction An OverviewDokument33 SeitenAircraft Drag Reduction An OverviewLuis GuillermoNoch keine Bewertungen

- App-D-Geometry of Lifting Surfaces PDFDokument23 SeitenApp-D-Geometry of Lifting Surfaces PDFmiguelNoch keine Bewertungen

- 2013-Materials Selection in Design of Aircrafts StructuresDokument9 Seiten2013-Materials Selection in Design of Aircrafts StructuresMario Mantilla SánchezNoch keine Bewertungen

- Finite Element Analysis of Aircraft Wing Using Composite StructureDokument7 SeitenFinite Element Analysis of Aircraft Wing Using Composite StructureMuHaZirNoch keine Bewertungen

- NASA-CR-1457 Manual For Structural Stability Analysis of Sandwich PanelsDokument385 SeitenNASA-CR-1457 Manual For Structural Stability Analysis of Sandwich Panelsmuhanned100% (1)

- ADA160718 - AGARD-R-723 - Aircraft Drag Prediction and ReductionDokument270 SeitenADA160718 - AGARD-R-723 - Aircraft Drag Prediction and ReductionopedroestebanNoch keine Bewertungen

- Airplane Stress Analysis NACA TR 82 1918Dokument72 SeitenAirplane Stress Analysis NACA TR 82 1918brkappaNoch keine Bewertungen

- Wing Layout Structure: To Carry The Distributed and Concentrated Loads Prescribed by The Airwortheness RequirementDokument29 SeitenWing Layout Structure: To Carry The Distributed and Concentrated Loads Prescribed by The Airwortheness Requirementappanna_Noch keine Bewertungen

- Damage Tolerance of Laminated Composites Containing An Open Hole and Subjected To Compressive Loadings - Part I - AnalysisDokument42 SeitenDamage Tolerance of Laminated Composites Containing An Open Hole and Subjected To Compressive Loadings - Part I - AnalysisEstebanNoch keine Bewertungen

- Solid Rivet InformationDokument6 SeitenSolid Rivet InformationKukyong LeeNoch keine Bewertungen

- Model Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionVon EverandModel Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNoch keine Bewertungen

- Aircraft Construction and MaterialsDokument4 SeitenAircraft Construction and Materialsgalaxy_hypeNoch keine Bewertungen

- ScriptDokument11 SeitenScriptMykhailo ShaidaNoch keine Bewertungen

- Aeroteaching - May 2012Dokument7 SeitenAeroteaching - May 2012jmgoodmanNoch keine Bewertungen

- Aircraft Construction and Materials1Dokument4 SeitenAircraft Construction and Materials1govindarajan017Noch keine Bewertungen

- Aircraft Basic Construction: Learning ObjectivesDokument26 SeitenAircraft Basic Construction: Learning ObjectivesdanishNoch keine Bewertungen

- 14014A ch4Dokument26 Seiten14014A ch4Sajjad ShamimNoch keine Bewertungen

- Chapter 4 FuselageDokument29 SeitenChapter 4 FuselageSaumay ErazoNoch keine Bewertungen

- A. Fuselage ConstructionDokument5 SeitenA. Fuselage ConstructionGezs AmarNoch keine Bewertungen

- Aircraft Wing & Fuselage Design and Control Surfaces, Engines Suitable For UAVDokument44 SeitenAircraft Wing & Fuselage Design and Control Surfaces, Engines Suitable For UAVjayaramjaya1996Noch keine Bewertungen

- MSC Composite TrainingDokument28 SeitenMSC Composite TrainingManoj ManoharanNoch keine Bewertungen

- Fatigue TemDokument2 SeitenFatigue TemManoj ManoharanNoch keine Bewertungen

- Trusses: Method of Joints: Introduction To StaticsDokument37 SeitenTrusses: Method of Joints: Introduction To StaticsManoj ManoharanNoch keine Bewertungen

- Chapter 2 Mechanics of Materials: Normal StressDokument18 SeitenChapter 2 Mechanics of Materials: Normal StressManoj ManoharanNoch keine Bewertungen

- STAR MethodDokument1 SeiteSTAR MethodManoj ManoharanNoch keine Bewertungen

- Truss-Beer & Johnston 9th EdDokument15 SeitenTruss-Beer & Johnston 9th EdManoj Manoharan100% (1)

- Manual Software Testing Interview Questions and AnswersDokument6 SeitenManual Software Testing Interview Questions and AnswersManoj ManoharanNoch keine Bewertungen

- Solid MechanicsDokument19 SeitenSolid MechanicsManoj ManoharanNoch keine Bewertungen

- Embedded System CourseDokument5 SeitenEmbedded System CourseChetan ByalihalNoch keine Bewertungen

- Truss ProblemsDokument16 SeitenTruss ProblemsManoj ManoharanNoch keine Bewertungen

- Method of Joints Method of JointsDokument5 SeitenMethod of Joints Method of JointsManoj ManoharanNoch keine Bewertungen

- Oops ConceptsDokument8 SeitenOops ConceptsManoj ManoharanNoch keine Bewertungen

- Chap8 RivetsDokument51 SeitenChap8 RivetsManoj ManoharanNoch keine Bewertungen

- Python-Howto CursesDokument8 SeitenPython-Howto CursesManoj ManoharanNoch keine Bewertungen

- Socket Programming HOWTO: Guido Van Rossum Fred L. Drake, JR., EditorDokument6 SeitenSocket Programming HOWTO: Guido Van Rossum Fred L. Drake, JR., EditorManoj ManoharanNoch keine Bewertungen

- Python How To RegexDokument19 SeitenPython How To RegexJohn KellyNoch keine Bewertungen

- Kier IFASD 2005 If 044Dokument13 SeitenKier IFASD 2005 If 044Manoj ManoharanNoch keine Bewertungen

- Porting Python 2 Code To Python 3: Guido Van Rossum Fred L. Drake, JR., EditorDokument12 SeitenPorting Python 2 Code To Python 3: Guido Van Rossum Fred L. Drake, JR., EditorManoj ManoharanNoch keine Bewertungen

- Structural Joint FailuresDokument4 SeitenStructural Joint FailuresManoj ManoharanNoch keine Bewertungen

- Solid Rivets ComparisonDokument3 SeitenSolid Rivets ComparisonManoj ManoharanNoch keine Bewertungen

- Aircraft Weight - Why Weight and Balance Are Important?Dokument3 SeitenAircraft Weight - Why Weight and Balance Are Important?Manoj Manoharan100% (1)

- Lenovo G460e Compal LA-7011P PAW10 Rev1.0A SchematicDokument41 SeitenLenovo G460e Compal LA-7011P PAW10 Rev1.0A Schematicserrano.flia.coNoch keine Bewertungen

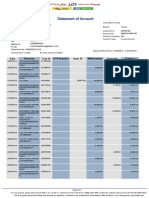

- Statement of Account: Date Tran Id Remarks UTR Number Instr. ID Withdrawals Deposits BalanceDokument8 SeitenStatement of Account: Date Tran Id Remarks UTR Number Instr. ID Withdrawals Deposits Balancedinesh namdeoNoch keine Bewertungen

- Guidely Age Set 1 PDFDokument5 SeitenGuidely Age Set 1 PDFPriya KumariNoch keine Bewertungen

- 11 SwitchingDokument20 Seiten11 SwitchingShalini Kumari GuptaNoch keine Bewertungen

- Es ZC424 Course HandoutDokument13 SeitenEs ZC424 Course HandoutJAYAKRISHNAN.K.RNoch keine Bewertungen

- Bus Pass Management SystemDokument71 SeitenBus Pass Management SystemAngamuthuNoch keine Bewertungen

- A320LEAP1A-B12-0008.5 Cont&Ind R1 220517Dokument78 SeitenA320LEAP1A-B12-0008.5 Cont&Ind R1 220517simsimsomNoch keine Bewertungen

- Kulubukedoguru Runotabixapika Farulepolo RejezaxogDokument2 SeitenKulubukedoguru Runotabixapika Farulepolo RejezaxogBISHOY magdyNoch keine Bewertungen

- SVCN CSE AI With IP InternshipDokument72 SeitenSVCN CSE AI With IP Internshipkvpravee28nNoch keine Bewertungen

- Cisco - Aci - White Paper c11 740861Dokument67 SeitenCisco - Aci - White Paper c11 740861PrasannaNoch keine Bewertungen

- Security Alarm SystemDokument32 SeitenSecurity Alarm SystemAnamika Yadav100% (2)

- FAA Safety Briefing Nov-Dec 2017 PDFDokument36 SeitenFAA Safety Briefing Nov-Dec 2017 PDFAllison JacobsonNoch keine Bewertungen

- A Guide To Noise Measurement TerminologyDokument24 SeitenA Guide To Noise Measurement TerminologyChhoan NhunNoch keine Bewertungen

- Econstruct Issue 2Dokument40 SeitenEconstruct Issue 2ArNushiMahfodzNoch keine Bewertungen

- Pharmaceutical Distribution Management System - ERDiagramDokument1 SeitePharmaceutical Distribution Management System - ERDiagram1000 ProjectsNoch keine Bewertungen

- CaFSET (Antigua) Office Workbook - Sixth Edition - Programming Concepts Sample PagesDokument4 SeitenCaFSET (Antigua) Office Workbook - Sixth Edition - Programming Concepts Sample PagescafsetNoch keine Bewertungen

- Hipaa Information and Consent FormDokument1 SeiteHipaa Information and Consent FormJake HennemanNoch keine Bewertungen

- Write About Global Catalog. How To View Replication Properties For AD PropertiesDokument19 SeitenWrite About Global Catalog. How To View Replication Properties For AD PropertiesChandan KumarNoch keine Bewertungen

- DirectionalEQManual PDFDokument2 SeitenDirectionalEQManual PDFdorutNoch keine Bewertungen

- Asml 20110808 Careers Brochure ASML NLDokument12 SeitenAsml 20110808 Careers Brochure ASML NLerkin1989Noch keine Bewertungen

- FortiOS v4.0 MR3 Patch Release 11 Release NotesDokument31 SeitenFortiOS v4.0 MR3 Patch Release 11 Release NotesmonsieurkozoNoch keine Bewertungen

- Feature Evaluation For Web Crawler Detection With Data Mining TechniquesDokument11 SeitenFeature Evaluation For Web Crawler Detection With Data Mining TechniquesSlava ShkolyarNoch keine Bewertungen

- DSLC™ Digital Synchronizer and Load Control: Installation and Operation ManualDokument114 SeitenDSLC™ Digital Synchronizer and Load Control: Installation and Operation ManualEdy TonelNoch keine Bewertungen

- Sony HCD-N555AV SchematicDokument78 SeitenSony HCD-N555AV SchematicAnonymous XVAl0834ykNoch keine Bewertungen

- Motorola Cp140Dokument104 SeitenMotorola Cp140Neil BotesNoch keine Bewertungen

- Bharat Heavy Elelctricals Limited: Operation & Maintenance Manual of Bhelscan Flame Scanner System (Bn10)Dokument25 SeitenBharat Heavy Elelctricals Limited: Operation & Maintenance Manual of Bhelscan Flame Scanner System (Bn10)MukeshKrNoch keine Bewertungen

- Poly Matla BBDokument2 SeitenPoly Matla BBdandiNoch keine Bewertungen

- Heat Dissipation (BTU - HR) For UPSs With 1500 KW I - O Cabinet - Galaxy VX Technical Manuals 480 VDokument3 SeitenHeat Dissipation (BTU - HR) For UPSs With 1500 KW I - O Cabinet - Galaxy VX Technical Manuals 480 VBryn rpNoch keine Bewertungen